PLANEPRINT SHARD Programming manual

Other PLANEPRINT Toy manuals

PLANEPRINT

PLANEPRINT SEAGULL GLIDER VERSION User manual

PLANEPRINT

PLANEPRINT NOTOS User manual

PLANEPRINT

PLANEPRINT Funbus User manual

PLANEPRINT

PLANEPRINT ZIGGY Programming manual

PLANEPRINT

PLANEPRINT paper plane User manual

PLANEPRINT

PLANEPRINT FOUGA MAGISTER Programming manual

PLANEPRINT

PLANEPRINT Swift S1 Programming manual

PLANEPRINT

PLANEPRINT AERON Programming manual

PLANEPRINT

PLANEPRINT Foka 4 Instructions for use

PLANEPRINT

PLANEPRINT JETWING User manual

PLANEPRINT

PLANEPRINT FEARLESS Programming manual

PLANEPRINT

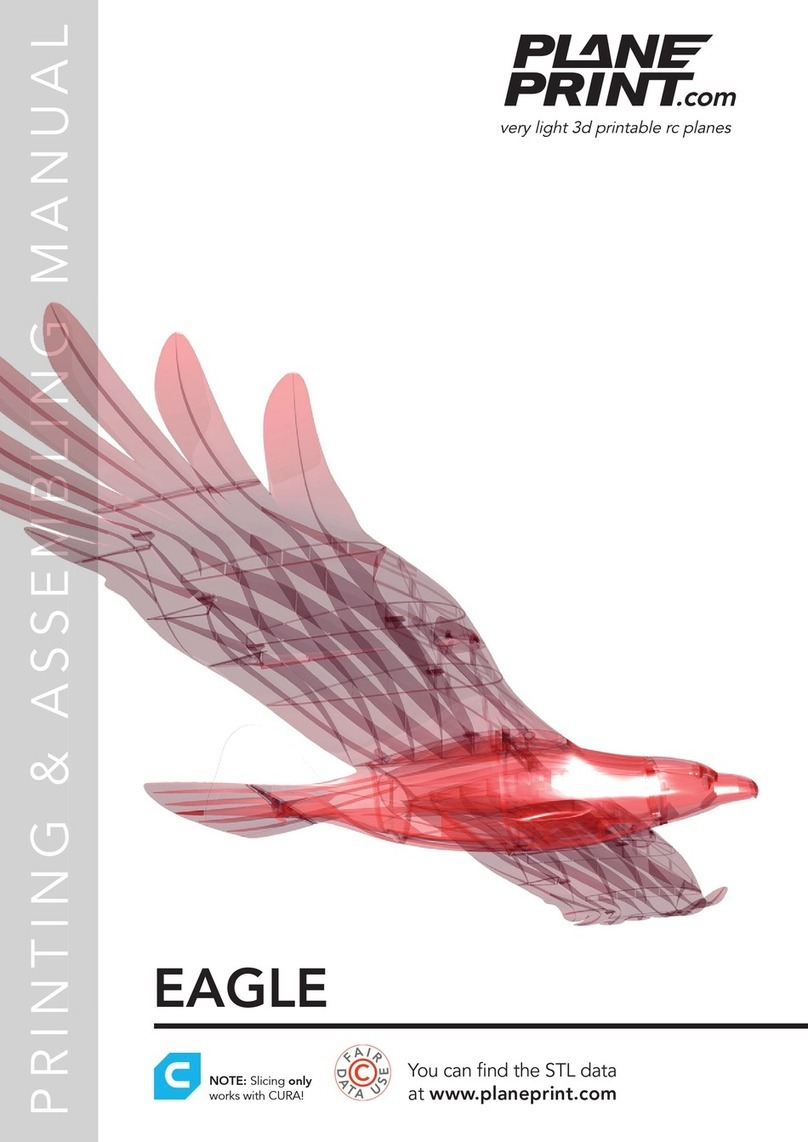

PLANEPRINT EAGLE User manual

PLANEPRINT

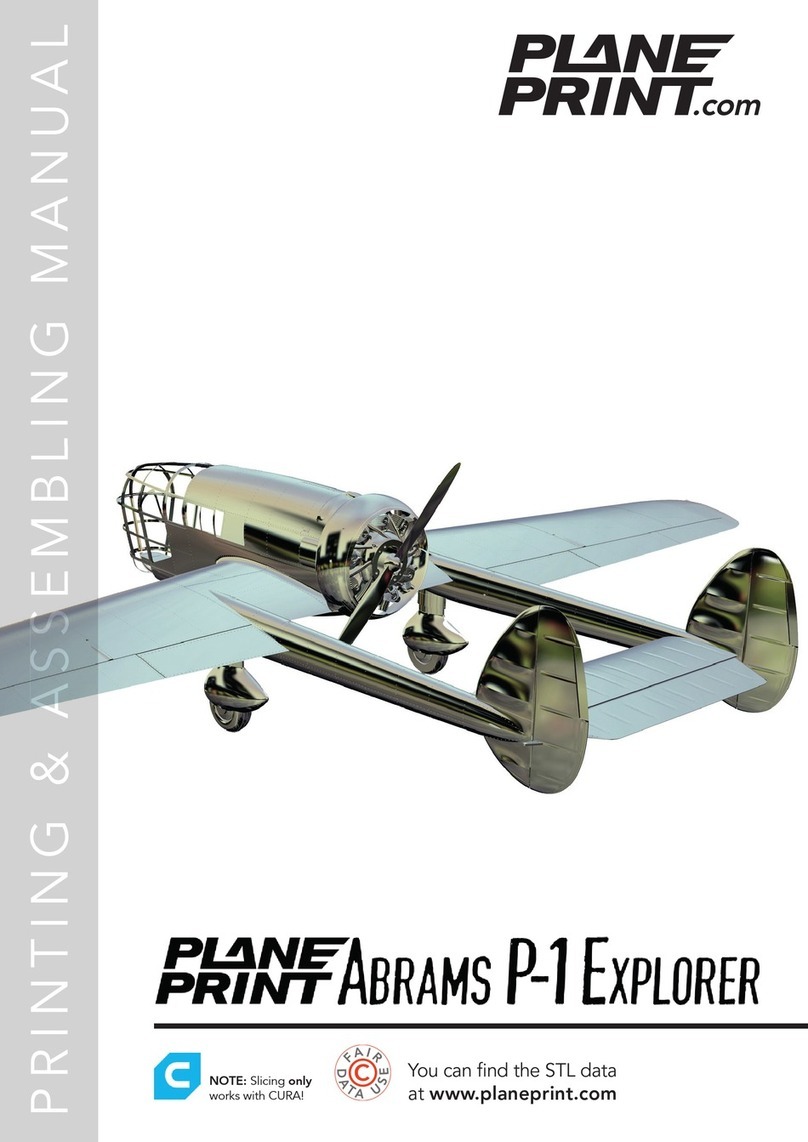

PLANEPRINT Abrams P-1 Explorer User manual

PLANEPRINT

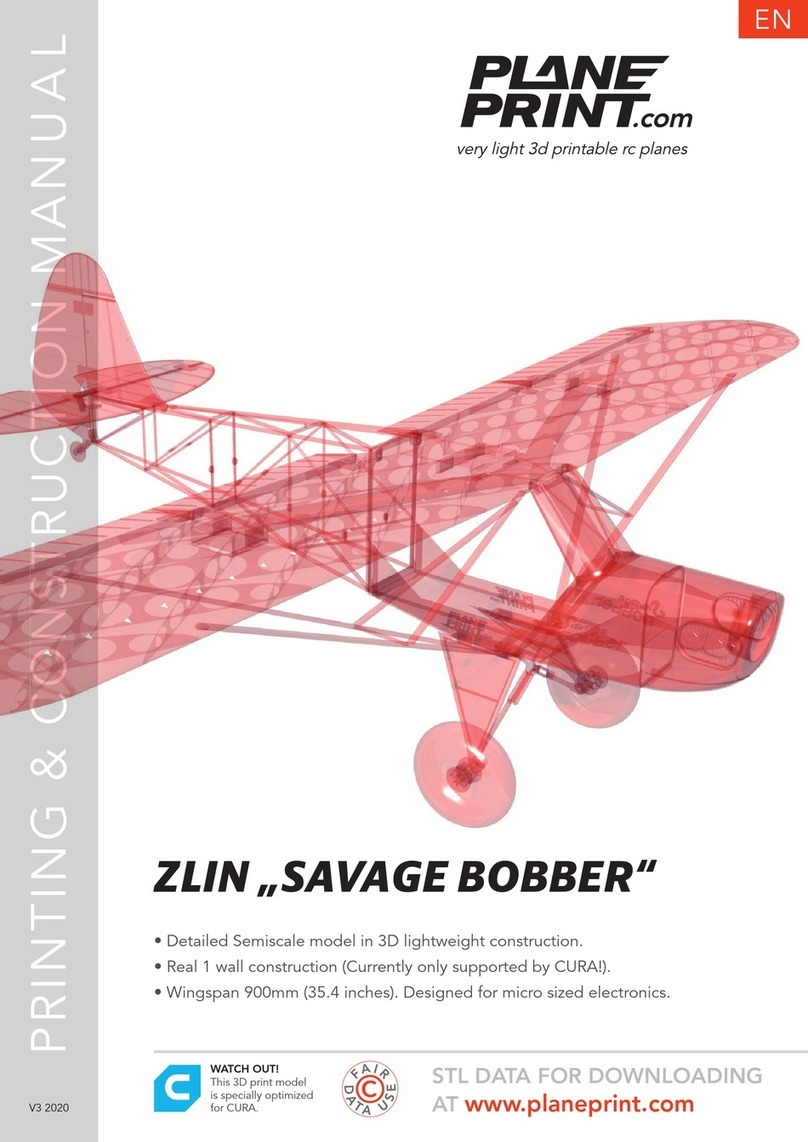

PLANEPRINT ZLIN SAVAGE BOBBER User manual

PLANEPRINT

PLANEPRINT Slingsby T31 Cadet Programming manual

PLANEPRINT

PLANEPRINT Aermacchi MB-339 User manual

PLANEPRINT

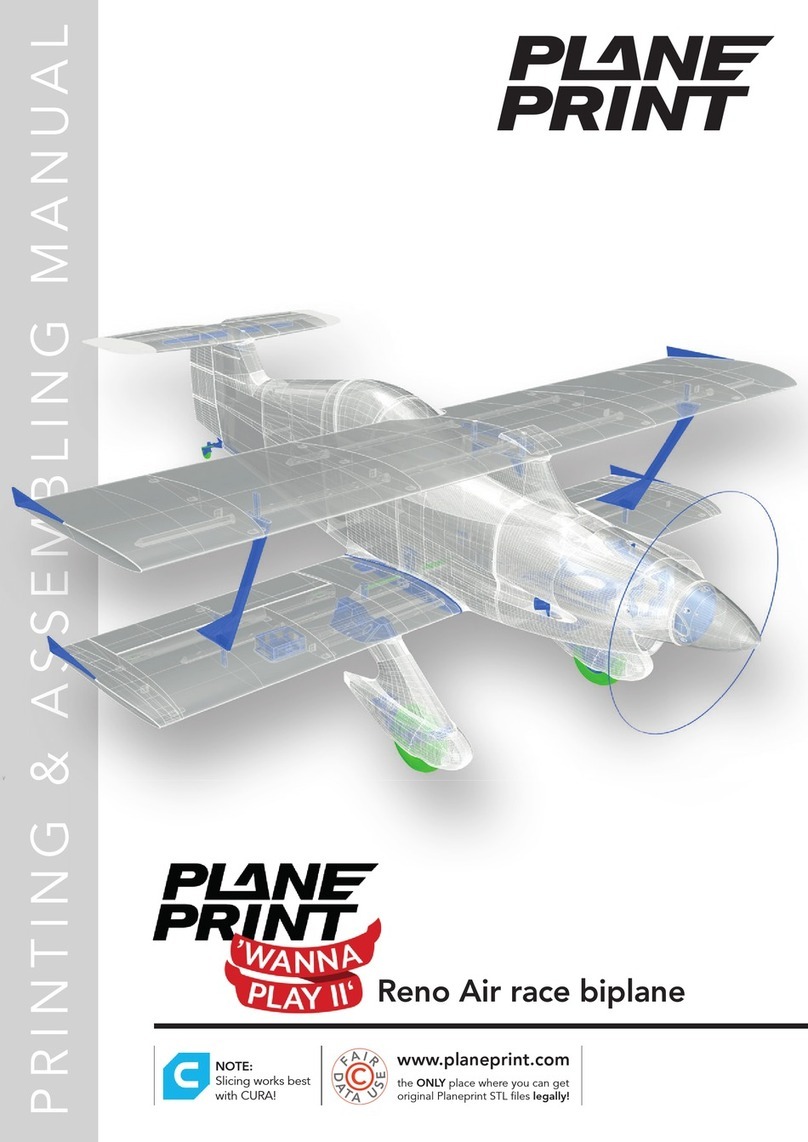

PLANEPRINT WANNA PLAY II Programming manual

PLANEPRINT

PLANEPRINT BIG BOBBER User manual

PLANEPRINT

PLANEPRINT V-TURN User manual

PLANEPRINT

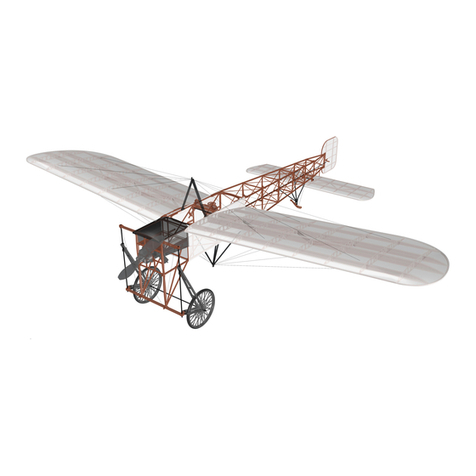

PLANEPRINT BLERIOT XI Programming manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions