8

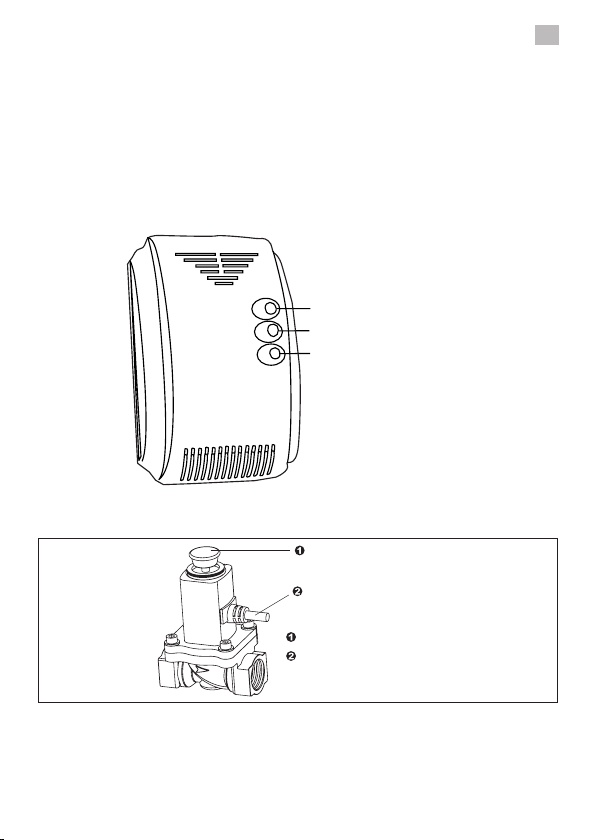

1. Electrovalva poate fi actionata pentru inchidere in doua moduri:

a) Un impuls electric de 1 secunda (9 - 12V c.c.)

b) Prin apasarea butonului rosu (mai intai trebuie sa indepartati capacul

protector din plastic).

Dupa aceasta operatiune, electrovalva ramane inchisa.

NOTA: Capacul protector trebuie sa ramana pus pe tot timpul folosirii

electrovalvei.

2. Atunci cand electrovalva este inchisa, trageti de butonul rosu vertical in

sus pentru a debloca electrovalva. Electrovalva va ramane deschisa.

3. Electrovalva se va inchide automat atunci cand primeste semnal de

intrare de la senzor. Daca acest lucru nu se intampla, contactati furnizorul

sau producatorul pentru reparatii.

4. Dupa inchiderea electrovalvei se va realiza o inspectie a instalatiei de

gaz. Umblati cu prudenta atunci cand electrovalva trebuie repornita.

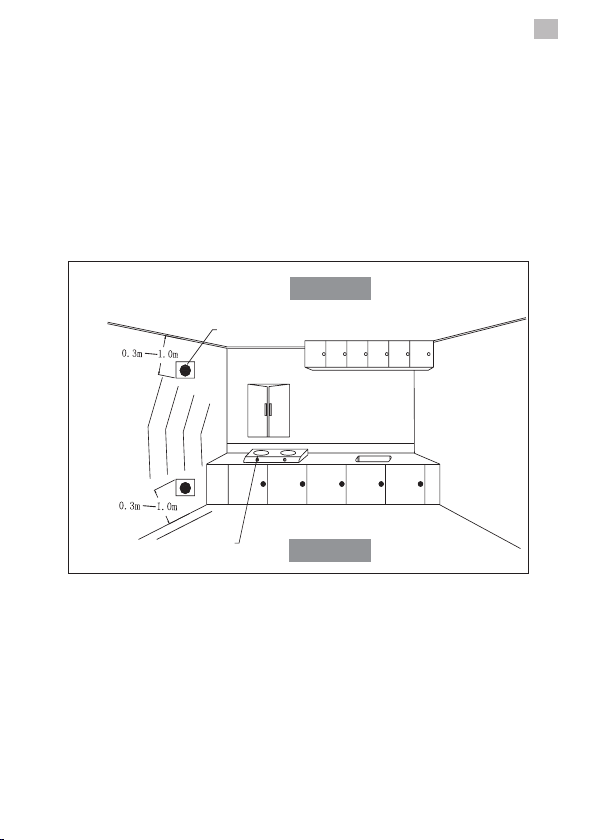

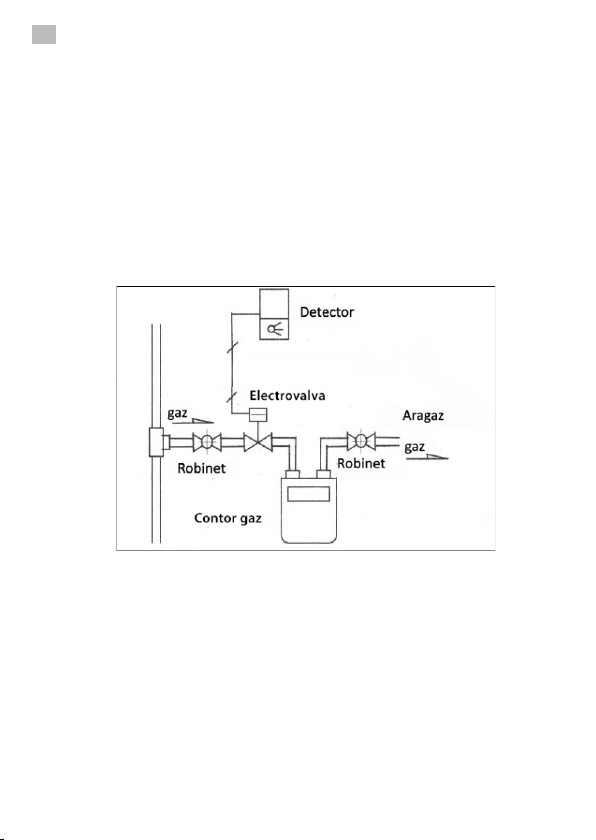

1. Electrovalva se va instala numai de catre personal calificat.

2. Electrovalva trebuie instalata dupa robinetul principal de gaz interior.

3. Electrovalva trebuie instalata in directia fluxului de gaz marcata pe

supapa electrovalvei. Bobina nu trebuie montata cu fata in jos. Electrovalva

poate fi instalata pe orizontala sau verticala.

4. Firele de control ale electrovalvei trebuie conectate corect. Firul alb este

pozitiv, iar negru este negativ. Realizarea unei conexiuni incorecte poate

duce la risc de scurtcuit.

5. In timpul lucrarilor de mentenanta la teava de gaz, cum ar fi curatarea tevii

cu presiune, electrovalva trebuie demontata pentru a evita defectiunile

acesteia.

6. In timpul testelor de presiune, electrovalva trebuie deschisa.

7. Butonul de deschidere al electrovalvei poate fi tras vertical in sus atunci

cand presiunile sunt egale (admisie si evacuare).

8. Polaritatea inversata si tensiunea gresita pot deteriora bobina

electromagnetica a electrovalvei.

Instructiuni de utilizareInstructiuni de utilizare

Recomandari pentru instalare

RO