SM-A27751-A/3 CONTENTS

iv 2021-11-18

CONTENTS

PREFACE........................................................................................................................... i

SAFETY INFORMATION .................................................................................................. ii

Product precautions.......................................................................................................iii

Disposal precautions .....................................................................................................iii

CONTENTS...................................................................................................................... iv

1. PRODUCT OVERVIEW ............................................................................................. 1

1.1 System Overview ................................................................................................ 1

System Structure and Workflow (ECG-A Series)......................................... 1

System Structure and Workflow (ECG-B Series)......................................... 3

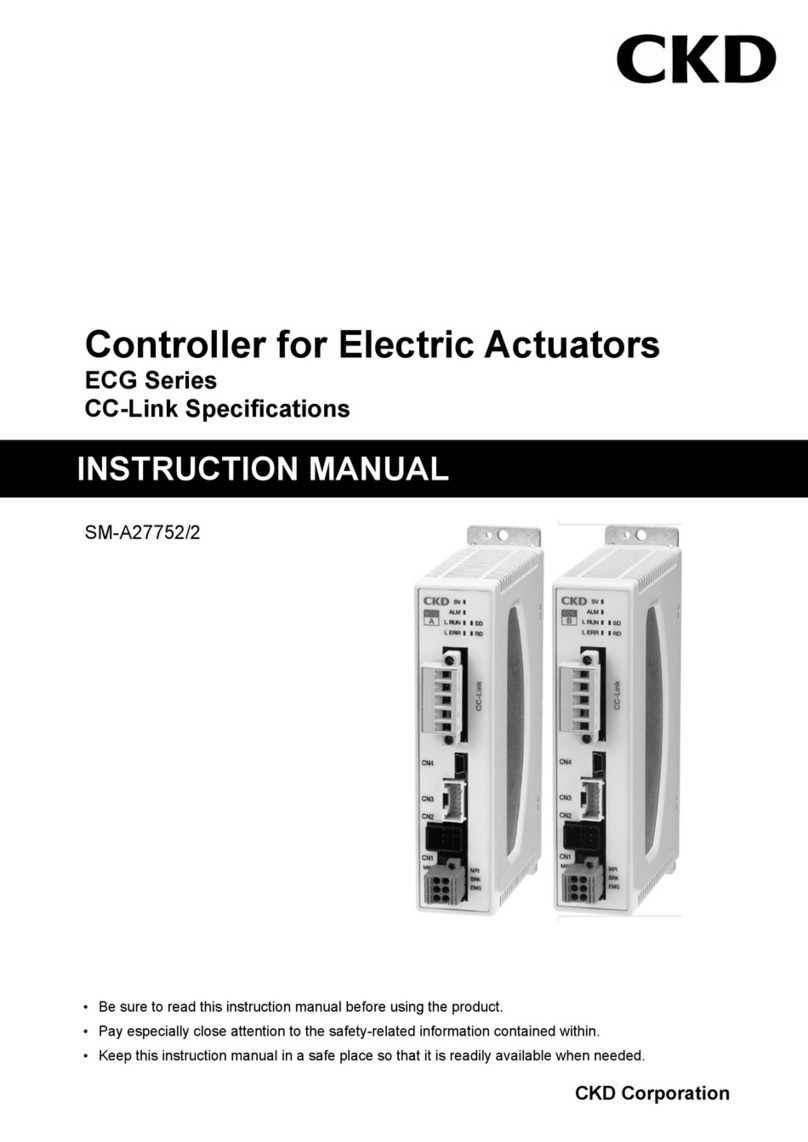

1.2 Instruction Manuals Related to This Product...................................................... 6

1.3 Names of Parts ...................................................................................................7

1.4 Model Number Indication....................................................................................8

1.5 Specifications......................................................................................................9

Basic specifications ...................................................................................... 9

1.6 Dimensions ........................................................................................................11

ECG-A (Parallel I/O specifications) .............................................................11

ECG-B (Parallel I/O specifications)............................................................ 12

2. INSTALLATION ....................................................................................................... 13

2.1 Installation precautions ..................................................................................... 16

2.2 Unpacking .........................................................................................................16

2.3 Connection........................................................................................................17

Power supply wiring ................................................................................... 18

Actuator wiring............................................................................................ 21

I/O cable wiring........................................................................................... 26

S Tools setting software wiring................................................................... 33

3. USAGE..................................................................................................................... 34

3.1 Setting actuator information..............................................................................35

3.2 PARAMETERS DATA CONFIGURATION ........................................................ 36

Parameters List .......................................................................................... 36

Soft limit...................................................................................................... 39

Zone output ................................................................................................ 40

Adjusting the gains ..................................................................................... 42

3.3 POINT DATA CONFIGURATION ...................................................................... 47

Positioning point ......................................................................................... 47

Point data list.............................................................................................. 48

Selecting the position specification method............................................... 49

Selecting the operation method ................................................................. 50

Setting the position..................................................................................... 51

Setting the positioning width ...................................................................... 52

Setting the speed ....................................................................................... 53

Setting the acceleration.............................................................................. 56

Setting the deceleration.............................................................................. 56

Selecting the acceleration/deceleration method ........................................ 57

Selecting the stop method.......................................................................... 57

Selecting the rotation direction................................................................... 58

Setting the gain magnification.................................................................... 59

Setting the point zone................................................................................. 59

Setting the pressing rate ............................................................................ 60

Setting the pressing speed......................................................................... 61

Setting the pressing distance ..................................................................... 61