Primes HP-MSM-HB User manual

Revision 00 EN - 01/2021

HighPower-MSM-HighBrilliance

HP-MSM-HB, HP-MSM-HB 20 kW

LaserDiagnosticsSoftware LDS 2.98

35,0(6

Original Instructions

3

Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

IMPORTANT!

READ CAREFULLY BEFORE USE.

KEEP FOR FUTURE USE.

4Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

Table of Contents

1 Basic safety instructions 9

2 Symbol explanations 11

3 About this operating manual 12

4 Device description 13

4.1 Device models and options .....................................................................................................13

4.2 Area of Application..................................................................................................................13

4.3 Device Assembly.....................................................................................................................13

4.4 Lever to adjust the magnification.............................................................................................14

4.5 Measuring principle .................................................................................................................15

4.6 Measurement Range of the HP-MSM-HB ...............................................................................16

4.6.1 Measurement Range of the HP-MSM-HB 10 kW ......................................................16

4.6.2 Measurement Range of the HP-MSM-HB 20 kW ......................................................17

4.7 Magnetic spring ......................................................................................................................17

5 Short overview installation 18

6 Transport 19

7 Installation 20

7.1 Conditions at the installation site .............................................................................................20

7.2 Preparation and mounting position..........................................................................................20

7.3 Manually aligning the HP-MSM-HB .........................................................................................21

7.3.1 Important conditions for the position of the focused laser beam................................21

7.3.2 Mounting the cyclone................................................................................................22

7.3.3 Positioning the pilot laser beam above the cyclone ...................................................23

7.4 Mounting the Fibre Bridge (option)...........................................................................................25

8 Cooling water and compressed air connections 27

8.1 Cooling Circuit System............................................................................................................27

8.1.1 Water quality.............................................................................................................28

8.1.2 Water pressure .........................................................................................................29

8.1.3 Humidity ...................................................................................................................29

8.1.4 Water connections and water flow rate .....................................................................30

8.2 Compressed Air .....................................................................................................................30

9 Electrical connection 31

9.1 Connections............................................................................................................................31

9.2 Pin assignment .......................................................................................................................32

9.2.1 Power supply............................................................................................................32

9.2.2 Inlet external trigger ..................................................................................................32

9.2.3 Outlet internal trigger.................................................................................................32

9.2.4 Outlet internal data-transfer signal.............................................................................32

9.2.5 External Safety Circuit (Interlock) ...............................................................................33

9.3 Connection to the PC and connect power supply ...................................................................33

10 Status LEDs 35

11 Installation and configuration of the LaserDiagnosticsSoftware LDS 36

11.1 System requirements ..............................................................................................................36

11.2 Installing the software..............................................................................................................36

11.3 Ethernet configuration .............................................................................................................37

5

Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

11.3.1 Enter IP address .......................................................................................................37

11.3.2 Establishing a connection to PC)...............................................................................38

11.3.3 Changing the standard IP address of the device .......................................................39

11.3.4 Retrieve IP address automatically with DHCP............................................................40

12 Description of the LaserDiagnosticsSoftware LDS 42

12.1 Graphical user interface...........................................................................................................42

12.1.1 The menu bar ...........................................................................................................44

12.1.2 The toolbar ...............................................................................................................45

12.1.3 Menu overview..........................................................................................................46

13 Measurement 49

13.1 Safety instructions...................................................................................................................49

13.2 HP-MSM-HB with 5-fold HP-objective and cyclone.................................................................49

13.3 HP-MSM-HB with Fiber Bridge ...............................................................................................50

13.4 Prepare measurement.............................................................................................................51

13.4.1 Check list measurement settings...............................................................................51

13.4.2 Check list measurement settings...............................................................................51

13.5 Flowchart of a measurement...................................................................................................52

13.5.1 Prepare measurement...............................................................................................52

13.5.2 Set caustic limits.......................................................................................................52

13.5.3 Perform caustic measurement ..................................................................................53

13.6 Perform measurement settings in the LaserDiagnosticsSoftware LDS .....................................54

13.6.1 Sensor parameters (menu Measurement > Sensor parameter)..............................54

13.6.2 Measuring environment (menu Measurement > Environment)................................55

13.6.3 Measurement settings (menu Measurement > Single).............................................56

13.6.4 Caustic settings (menu Measurement > Caustic) ....................................................57

13.6.5 CCD settings (menu Measurement > CCD Settings)..............................................58

13.6.6 Option (advanced user only) (menu Measurement > Option)...................................60

13.6.7 CCD info (menu Measurement > CCD Info)............................................................61

13.6.8 Single measurement (menu Measurement > Single)................................................62

13.6.9 Caustic measurement (menu Measurement > Caustic)...........................................64

14 Troubleshooting 67

14.1 Error during a measurement....................................................................................................67

14.2 No measurement signal at the HP-MSM-HB ...........................................................................67

15 Maintenance and service 67

15.1 Demounting the Measuring Objective......................................................................................68

15.2 Changing the aperture at the Beam entrance ..........................................................................69

15.3 Exchanging the Protective Window in front of the Power Output Aperture...............................70

15.4 Exchanging beam splitter ........................................................................................................71

16 Accessories 72

17 Transport or Storage 73

17.1 Installing the transportation clamp...........................................................................................73

17.2 Draining the cooling circuit of the HP-MSM-HB.......................................................................74

17.3 Sealing the cooling circuit of the HP-MSM-HB ........................................................................74

17.4 Draining the cooling circuit of the PowerLossMonitor ..............................................................75

17.5 Sealing the aperture of the HB objective..................................................................................75

17.6 Packing the device..................................................................................................................76

18 Measures for the product disposal 76

19 Declaration of conformity 77

20 Technical data 78

6Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

21 Dimensions 79

21.1 Dimensions of the HP-MSM-HB..............................................................................................79

21.2 Dimensions of the HP-MSM-HB with fibre bridge....................................................................81

21.3 Dimensions of the HP-MSM-HB 20kW...................................................................................84

21.4 Dimensions of the HP-MSM-HB 20 kW with fibre bridge ........................................................86

22 Appendix A: 88

22.1 Power measurement with the PLM on the HP-MSM-HB .........................................................88

22.2 Measuring pulsed irradiation ...................................................................................................89

22.2.1 Measuring configuration selection .............................................................................91

22.2.2 Influence of the pulse parameters on the integration time control ..............................91

22.2.3 Examples for triggered measuring mode...................................................................95

22.2.4 Summary ..................................................................................................................96

23 Appendix B: Basis of laser beam diagnosis 97

23.1 Laser beam parameter............................................................................................................97

23.1.1 Rotationally symmetric beams...................................................................................98

23.1.2 Non rotationally symmetric beams ............................................................................99

23.2 Calculation of beam data ......................................................................................................100

23.2.1 Determination of the zero level ................................................................................100

23.2.2 Determination of the beam position.........................................................................101

23.2.3 Radius determination with the 2. moment method of the power density distribution101

23.2.4 Radius determination with the method of the 86% power inclusion .......................102

23.2.5 Further radius definitions (option).............................................................................103

23.3 Measurement errors ..............................................................................................................104

23.3.1 Error in determining zero level .................................................................................104

23.3.2 Saturating the signal ...............................................................................................104

23.3.3 Errors from incorrect measurement window size .....................................................105

24 Appendix: LaserDIagnosticSoftware LDS 106

24.1 File ........................................................................................................................................107

24.1.1 New (menu File > New)..........................................................................................107

24.1.2 Open (menu File > Open).......................................................................................107

24.1.3 Close/Close all (menu File > Close/Close all).........................................................107

24.1.4 Save (menu File > Save).........................................................................................107

24.1.5 Save as (menu File > Save As)...............................................................................107

24.1.6 Export (menu File > Export)...................................................................................107

24.1.7 Load measurement preferences (menu File > Load measurement preferences)..108

24.1.8 Save measurement preferences (menu File > Save measurement preferences)...108

24.1.9 Protocol (menu File > Protocol).............................................................................108

24.1.10 Print (menu File > Print).........................................................................................108

24.1.11 Print preview (menu File > Print preview)...............................................................108

24.1.12 Recently opened files (menu File > Recently opened Files)...................................108

24.1.13 Exit (menu File > Exit).............................................................................................108

24.2 Edit .......................................................................................................................................109

24.2.1 Copy (menu Edit > Copy).......................................................................................109

24.2.2 Clear plane (menu Edit > Clear plane)...................................................................109

24.2.3 Clear all planes (menu Edit > Clear all planes).......................................................109

24.2.4 Change user level (menu Edit > Change User Level).............................................109

24.3 Measurement........................................................................................................................109

24.3.1 Measuring environment (menu Measurement > Environment)..............................109

24.3.2 Sensor parameters (menu Measurement > Sensor parameter)............................111

24.3.3 Beam find settings (menu Measurement > BeamFind Settings: Beamfind .........111

24.3.4 CCD info (menu Measurement > CCD Info)..........................................................112

24.3.5 CCD settings (menu Measurement > CCD Settings)............................................113

24.3.6 LQM adjustment (menu Measurement > LQM Adjustment)..................................115

7

Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

24.3.7 Power measurement (menu Measurement > Power Measurement).....................115

24.3.8 Single (menu Measurement > Single)....................................................................115

24.3.9 Caustic measurement (menu Measurement > Caustic).........................................119

24.3.10 Start adjust mode (menu Measurement > Start Adjust mode)..............................120

24.3.11 Option (advanced user only) (menu Measurement > Option).................................121

24.4 Presentation..........................................................................................................................123

24.4.1 False colors (menu Presentation > False colors)...................................................124

24.4.2 False colors (filtered) (menu Presentation > False colors (filtered)).......................125

24.4.3 Isometry (menu Presentation > Isometry).............................................................125

24.4.4 Isometry 3D (menu Presentation > Isometry 3D) .................................................126

24.4.5 Review 86% or 2. moment (menu Presentation > Review (86%)/(2. moment)) ..127

24.4.6 Caustic (menu Presentation > Caustic) ................................................................128

24.4.7 Raw beam (menu Presentation > Raw-beam) .....................................................132

24.4.8 Symmetry check (menu Presentation > SymmetryCheck)....................................132

24.4.9 Fixed contour lines (menu Presentation > Fixed Contour Lines)...........................134

24.4.10 Variable contour lines (menu Presentation > Variable Contour Lines)...................134

24.4.11 Graphical review (menu Presentation > Graphical Review)...................................137

24.4.12 Systemstate (menu Presentation > Systemstate).................................................137

24.4.13 Evaluation parameter view (menu Presentation > Evaluation Parameter View)....138

24.4.14 Evaluate document (menu Presentation > Evaluate doc)......................................139

24.4.15 Color tables (menu Presentation > Color Tables)..................................................141

24.4.16 Toolbar (Menu Presentation > Toolbar).................................................................141

24.4.17 Position (menu Presentation > Position)...............................................................142

24.4.18 Evaluation (option) (menu Presentation > Evaluation)............................................142

24.5 Communication.....................................................................................................................144

24.5.1 Rescan bus (menu Communication > Rescan bus)..............................................144

24.5.2 Free communication (menu Communication > Free Communication).................144

24.5.3 Scan device list (menu Communication > Scan device list) .................................145

24.6 Script (menu Script) .............................................................................................................146

24.6.1 Editor (menu Script > Editor) ................................................................................146

24.6.2 List (menu Script > List) ........................................................................................146

24.6.3 Python (menu Script > Python) .............................................................................146

25 Appendix D: File formats 147

25.1 File “laserds.ini” – an Example ...............................................................................................147

25.2 Description of the MDF file format .........................................................................................148

8Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

PRIMES - The Company

PRIMES manufactures measuring devices used to analyze laser beams. These devices are employed for

the diagnostics of high-power lasers ranging from CO2lasers and solid-state lasers to diode lasers. A wave-

length range from infrared through to near UV is covered, offering a wide variety of measuring devices to

determine the following beam parameters:

• Laser power

• Beam dimensions and position of an unfocused beam

• Beam dimensions and position of a focused beam

• Beam quality factor M²

Development, production and calibration of the measuring devices is performed at PRIMES. This guarantees

optimum quality, excellent service, and a short reaction time, providing the basis for us to meet all of our

customers’ requirements quickly and reliably.

PRIMES GmbH

Max-Planck-Str. 2

64319 Pfungstadt

Germany

Tel +49 6157 9878-0

www.primes.de

9

Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

1 Basic safety instructions

Intended Use

The HighPower-MSM-HighBrilliance has been designed exclusively for measurements in the beam of high-

power lasers.

Use for any other purpose is considered as not intended and is strictly prohibited. Furthermore, intended use

requires that you observe all information, instructions, safety notes and warning messages in this operating

manual. The specifications given in chapter x, „Technical Data“, on page y apply. Any given limit values must

be complied with.

If not used as intended, the device or the system in which the device is installed can be damaged or de-

stroyed. In addition, there is an increased risk to health and life. Only use the device in such a way that there

is no risk of injury.

If you still have questions after reading this operating manual, please contact PRIMES or your supplier for

your own safety.

Observing applicable safety regulations

Observe the safety-relevant laws, guidelines, standards and regulations in the current editions published by

the state, standardization organizations, professional associations, etc. In particular, observe the regulations

on laser safety and comply with their requirements.

Necessary safety measures

The device measures direct laser radiation, but does not emit any radiation itself. However, during the mea-

surement the laser beam is directed at the device. This produces scattered or directed reflection of the laser

beam (laser class 4). The reflected beam is usually not visible.

Protect yourself from direct and reflected laser radiation while working with the device by taking the following

measures:

• If the device is moved from its aligned position, increased scattered or directed reflection of the laser

beam occurs during measuring operation. Fix the device in such a way that it cannot be moved by unin-

tentional bumping or pulling on the cables.

• Connect the laser control’s safety interlock to the device. Check that the safety interlock will switch off

the laser properly in case of error.

• The numerical aperture of the laser beam must be smaller than 0.11. Otherwise, in the lower measur-

ing positions Laser radiation from the edge of the measuring lens can be reflected into the room in an

uncontrolled manner.

• Please wear safety goggles adapted to the power, power density, laser wave length and operating

mode of the laser beam source in use.

• Depending on the laser source, it may be necessary to wear suitable protective clothing or protective

gloves.

• Protect yourself from direct laser radiation, scattered radiation, and beams generated from laser radiation

(by using appropriate shielding walls, for example, or by weakening the radiation to a harmless level).

• Use beam guidance or beam absorber elements that do not emit any hazardous substances when they

come in to contact with laser radiation and that can withstand the beam sufficiently.

• Install safety switches and/or emergency safety mechanisms that enable immediate closure of the laser

shutter.

10 Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

Necessary safety measures due to magnetic spring with strong permanent magnet

The device contains a magnetic spring made of neodymium magnets (NdFeB magnets) with a very strong

permanent magnet.

DANGER

Danger to life for persons with pacemaker or implanted defibrillator

Magnetic spring rotors consist mainly of neodymium magnets (NdFeB magnets). These can

impair the correct functioning of pacemakers.

X

If you have a cardiac pacemaker or implanted defibrillator, keep a minimum distance of 1m

from the device.

• Do not bring magnetic parts near the measuring device. Careless handling can lead to serious injuries

(bruises, broken fingers, etc.).

• Please note that magnetic springs can act like tensioned springs. The sliders spring back to their original

position as soon as they are let loose, even if he machine is disconnected from the power supply.

• Keep a safe distance to the magnetic spring with objects that can be damaged by magnetism. These

include, for example, televisions and monitors, credit cards, computers, data carriers, video tapes, me-

chanical watches, hearing aids and loudspeakers.

Employing qualified personnel

The device may only be operated by qualified personnel. The qualified personnel must have been instructed

in the installation and operation of the device and must have a basic understanding of working with high-

power lasers, beam guiding systems and focusing units.

Conversions and modifications

The device may not be modified in terms of design or safety without the express consent of the manufactur-

er. The same applies to unauthorized opening, dismantling and repair. The removal of covers is only permit-

ted within the scope of the intended use.

Liability disclaimer

Manufacturer and distributor exclude any liability for damages and injuries which are direct or indirect con-

sequences of using the device not as intended or modifying the device or the associated software without

authorization.

11

Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

2 Symbol explanations

Warning messages

The following symbols and signal words indicate possible residual risks:

DANGER

Means that death or serious physical injuries will occur if necessary safety precautions are not

taken.

WARNING

Means that death or serious physical injuries may occur if necessary safety precautions are not

taken.

CAUTION

Means that minor physical injury may occur if necessary safety precautions are not taken.

NOTICE

Means that property damage may occur if necessary safety precautions are not taken.

Product Safety Labels

The following symbols indicating requirements and possible dangers are used on the device:

No access for people with pacemakers or implanted defibrillators

General warning sign

Hand injuries warning

Magnetic field warning

Read and observe the operating instructions and safety guidelines before startup!

12 Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

Further symbols in this manual:

Here you can find useful information and helpful tips.

With the CE designation, the manufacturer guarantees that its product meets the requirements of

the relevant EC guidelines.

X

Call for action

3 About this operating manual

This manual describes how to work with the HP-MSM-HB and operate it with the LaserDiagnosticsSoftware

LDS 2.98 (referred to as “LDS” in the following).

The measuring device is operated via PC or via the system control.

The description of the software focuses on configuration and communication settings as well as measure-

ment operation.

This operating manual describes the software version valid at the time of printing.

Since the user software is continuously being developed further, the supplied data medium may

have a different version number. Correct functioning of the device is, however, still guaranteed with

the software.

If you have any questions, please let us know the software version you are using. The software version can

be found under the following menu item: Help > About LaserDiagnosticsSoftware.

Fig. 3.1: Information regarding the current LDS software version

13

Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

4 Device description

4.1 Device models and options

There are two models of HighPower-MSM-HighBrilliance:

• HP-MSM-HB and

• HP-MSM-HB 20 kW

The HP-MSM-HB is designed for a maximum beam power of 10 kW, the HP-MSM-HB 20 kW for a maxi-

mum of 20 kW.

The maximum travel distance zmax is 120 mm for the 10 kW model and 40 mm for the 20 kW model.

For the measurement of fiber lasers, the HP-MSM-HB can optionally be equipped with a measuring bridge

with fiber adapter.

Another option is to measure the laser power with a PowerLossMonitor PLM (additional device).

4.2 Area of Application

The HP-MSM-HB is intended for the analysis of the focused beam in the diameter range between 20µm

up to 1000µm. In the measuring range the power density distribution can be measured individually in up to

50measuring planes. The beam caustic is then made up of these measuring planes.

The beam geometries (beam position, beam radius and semiaxes – lengths as well as the dumping of the

semiaxes to the device axes) are determined for each plane according to the procedures described in the

standard ISO 11146 (2. moment and 86 % power inclusion). By means of these beam geometries the beam

propagation parameters (focus position, focus radius, Rayleigh length, divergence, M², K and beam param-

eter product) are determined. By means of the measuring data for the semiaxes of the beam, the ellipticity of

the focus and the astigmatic difference are determined according to ISO 11146.

4.3 Device Assembly

Z-Axis-Drive

High Brilliance

Measuring Objektive

Beam Entrance

HighPower

Beam Absorber

Z-Axis-Drive

Fig. 4.1: Komponents of the HP-MSM-HB

14 Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

4.4 Lever to adjust the magnification

There are two levers on the side of the device for adjusting the magnification. With the help of these two

levers, either a magnification objective or an adjustment lens can be inserted into the beam path.

The magnification objective can be inserted into the beam path on the image side, directly behind a filter

wheel, by moving both levers to the upper position.

The alignment objective simplifies the beam search, since it reduces the size of the image and the required

positioning accuracy of the HP-MSM-HB is reduced by the reduction.

The alignment objective can also be inserted into the beam path on the image side by moving both levers to

the lower position.

Lever to adjust the

magnification

Magnification Objective (High)

Alignment Objective (Low)

Standard

Fig. 4.2: Levers to adjust the magnification

15

Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

4.5 Measuring principle

There are several beam splitters integrated in the measuring objective so that 99.9% of the laser power is

guided to appropriately dimensioned absorbers via the beam splitter. The laser beam is attenuated by further

optical elements in the device until it can be guided to a CCD sensor.

Measuring Plane

Upper Limit

Mirrows

Trigger diode

Filter Wheel

Lower Limit

Measuring Objective

Magnification Objective (MO)

Absorber

Laser Beam

Absorber

Alignment Objectiv (JO)

CCD-Sensor

Fixed Filter

Prisms

Fig. 4.3: Principle illustration of the optomechanical design

16 Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

4.6 Measurement Range of the HP-MSM-HB

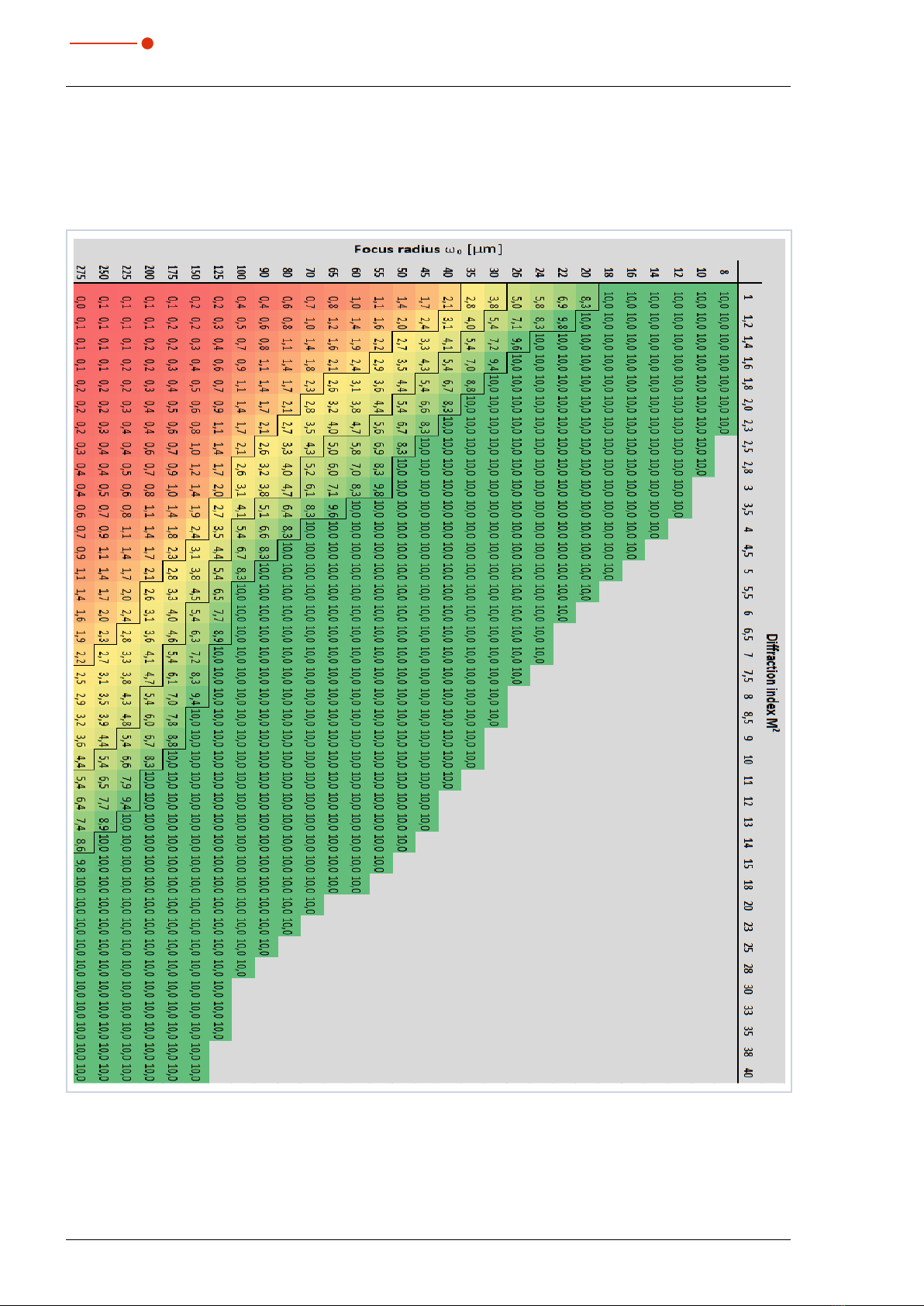

4.6.1 Measurement Range of the HP-MSM-HB 10 kW

Tab. 13.2 shows the correlation between power, diffraction index M² and the focus radius.

Tab. 4.1: Power in kW as a function of the diffraction index M² and the focus radius

17

Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

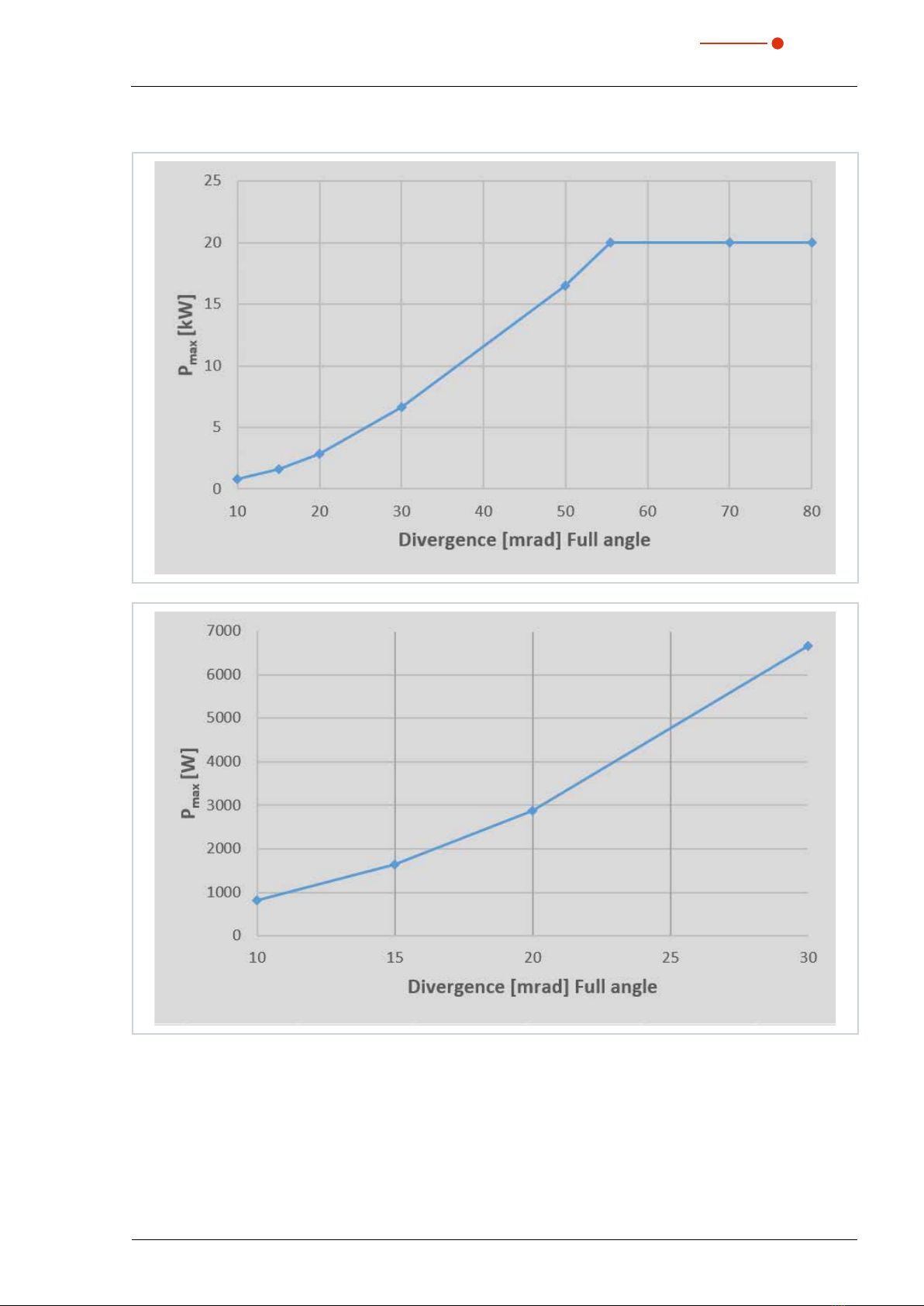

4.6.2 Measurement Range of the HP-MSM-HB 20 kW

Fig. 4.4: Maximum power as a function of the laser divergence angle

4.7 Magnetic spring

With the HighBrilliance measuring objective, a magnetic spring is mounted, which counteracts to the weight

of the measuring objective and thus relieves the traversing motors of the z-axis. Please note the warnings in

this instructions when handling the magnetic spring.

18 Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

5 Short overview installation

This short overview informs you in advance about necessary protective measures, media necessary for opera-

tion and required connecting elements.

1. Taking safety precautions Chapter 1 on page 9

DANGER

Danger to life for persons with pacemaker or implanted defibrillator

Magnetic spring rotors consist mainly of neodymium magnets (NdFeB magnets). These

can impair the correct functioning of pacemakers..

X

If you have a cardiac pacemaker or implanted defibrillator, keep a minimum distance of

1m from the device.

2. Disassemble the transport lock Chapter 6 on page 19

3. Alignment to the laser beam and stable mounting

• An alignment tool is included in the scope of delivery

• You need 6 screws M8x1 and 2 screws for the mounting holes Ø 6.6 mm

Chapter 7 on page 20

4. Installing the water-cooling

• Connection diameter 12 mm (16 mm for 20 kW-model)

• Flow rate 7l/min - 8l/min (14 l/mi - 16 l/min for 20 kW-model)

Chapter 8.1 on page 27

5. Connecting the compressed air

• Compressed air according to ISO 8573-1: 2010: 6:4:4.

• 0,5 bar - 1 bar

• Connection diameter 6 mm

Chapter 8.2 on page 30

6. Electrical connection

• Establish voltage supply

• External safety switch (interlock)

Chapter 9 on page 31

7. Connection with the PC

• Connection via Ethernet

Chapter 11.3.2 on page 38

8. Installing the LaserDiagnosticsSoftware LDS on the PC

• Software is part of the scope of delivery

Chapter 11 on page 36

19

Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

6 Transport

WARNING

Risk of injury when lifting or dropping the device

Lifting and positioning heavy devices can, for example, stress intervertebral disks and cause

chronic changes to the lumbar or cervical spine. The device may fall.

X

Use a lifting device to lift and position the device.

X

Without a lifting device, several people must lift and position the device.

NOTICE

Damaging/destroying the device

Optical components may be damaged if the device is subjected to hard shocks or is allowed

to fall.

X

Handle the measuring device carefully when transporting or installing it.

X

To avoid contamination, close the measuring objective with the cover provided.

X

Only transport the device in the original PRIMES transport box (option).

NOTICE

Damaging/destroying the device

The device must only be transported with a mounted lock..

X

Keep the transport lock in a safe place for future reuse.

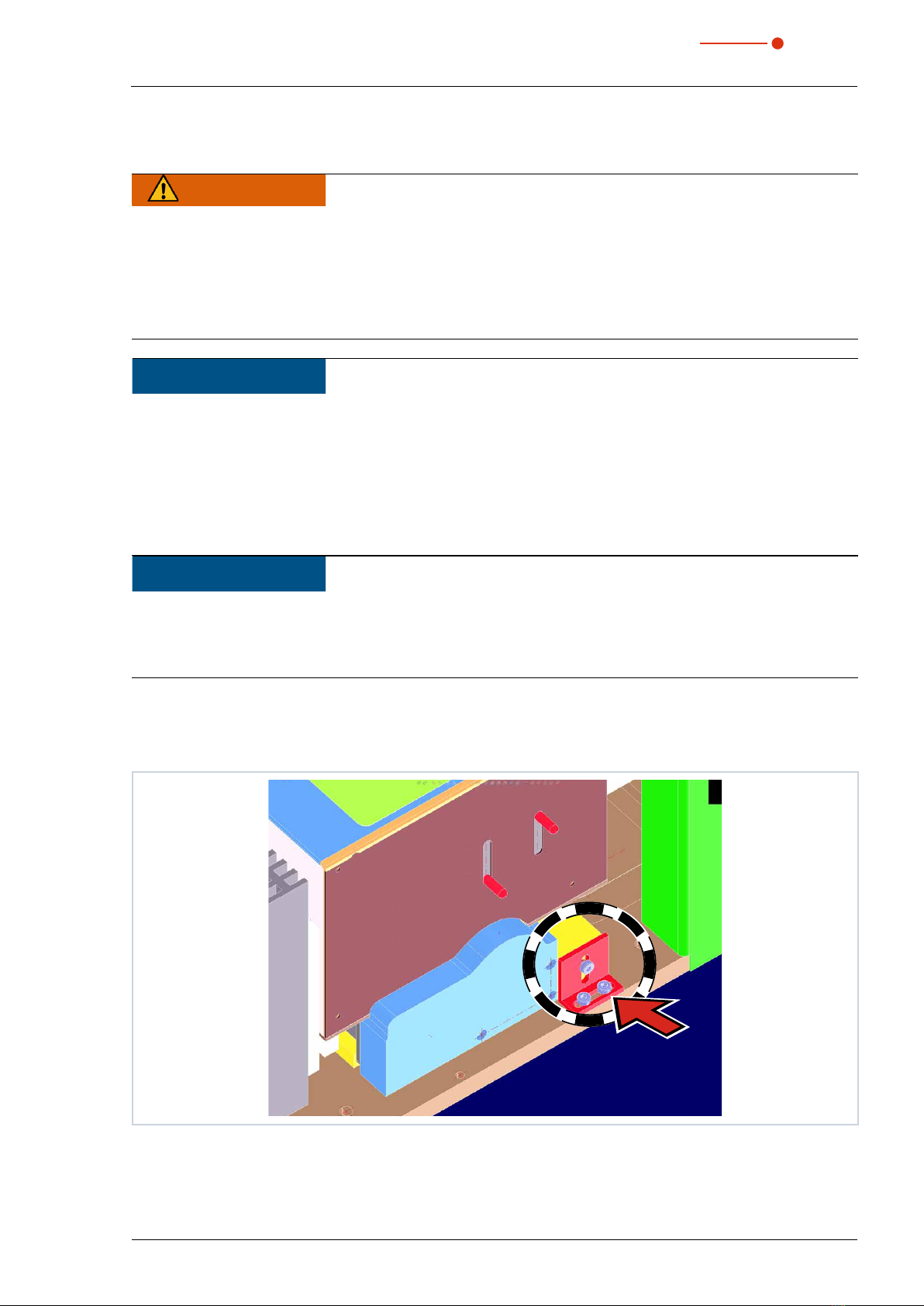

After unpacking the device, the transport lock has to be removed first. The transport lock secures the linear

actuator of the z-axis. It is located on the bottom plate and is fastened by means of 3 screws (see Fig. 6.1 on

page 19).

Fig. 6.1: Position of the transport lock

Keep this transport lock in a safe place, as it should be reassembled before each transport of the device.

20 Revision 00 EN - 01/2021

HP-MSM-HB

35,0(6

7 Installation

7.1 Conditions at the installation site

• The device must not be operated in a condensing atmosphere.

• The ambient air must be free of organic gases.

• Protect the device from splashes of water and dust.

• Operate the device in closed rooms only.

7.2 Preparation and mounting position

DANGER

Danger to life for persons with pacemaker or implanted defibrillator

Magnetic spring rotors consist mainly of neodymium magnets (NdFeB magnets). These can

impair the correct functioning of pacemakers..

X

DO NOT install the device if you have a cardiac pacemaker or implanted defibrillator. Keep a

minimum distance of 1m from the device.

DANGER

Serious eye or skin injury due to scattered radiation

The numerical aperture (NA) of the laser beam has to be smaller than 0.11 in order to ensure

that no scattered radiation occurs on the corner of the objective..

X

Wear safety goggles which are adapted to the used laser wavelength.

X

When mounting the device, please ensure that it cannot be moved by unintentional pushes

or pulling the cables or hoses..

X

Shield the device from scattered radiation.

WARNING

Danger of injuries due to a strong magnetic attraction

The magnet spring sliders can exert considerable forces as soon as they are close enough

to other sliders or iron. If they are not handled with the utmost care, this can lead to serious

injuries (contusions, broken fingers, etc.).

X

The magnet spring must only be mounted or demounted by trained personnel. Handle the

magnet spring with the utmost care when modifying the objective.

NOTICE

Danger of damage due to a strong magnetic field.

Magnet spring sliders mainly consist of very strong magnets.

X

Keep a safety distance to all devices and parts which could be damaged by magnetism, e.g.

TVs and screens, credit cards, computers, data mediums, video tapes, mechanical clocks,

hearing aids and loud speakers.

Table of contents

Other Primes Diagnostic Equipment manuals