GENERAL SAFETY RULES 212 / 212Z

15.

Do not overreach. Keep proper footing and balance at all times.

16.

Always keep the machine in good working order. To do this, keep the cutting faces sharp and clean for

optimum performance. Follow the operating instructions for cleaning, lubricating and changing accessory

equipment.

17.

Always disconnect the machine from the mains before carrying out any maintenance work or changing

machine parts such as saw blade, cutting tools, etc.

18.

Only use the recommended accessories. Follow the instructions in the User Manual. The use of

unsuitable accessories may cause accidents.

19.

Prevent any accidental starting. Before connecting the equipment to the mains, always check that the operating

switch is in OFF position (“0”).

20.

Never stand on the machine. Serious injuries may occur if the machine tips over or comes in contact with

the cutting tool.

21.

Check for damaged parts. Damaged guards or other parts should be properly repaired or replaced

before further operation.

22.

Never leave a running machine unattended. Always switch off the mains supply. Do not leave the machine

unattended until it has come to a complete standstill.

23.

Never operate the machine if you are under the influence of alcohol, medication or drugs.

24.

Make sure that the machine is disconnected from the mains supply before carrying out works on the electrical

system, drive motor, etc.

NOTES ON SAFETY AT WORK

Transporting the machine

1. The machine weighs up to 50kg.

2. Use suitable means of transport.

3. The machine head is very heavy, there is thus a risk of tipping over during transport!

Work station

1. The work area must be well-lit and well-ventilated.

2. Lighting must be 300 LUXto work safely.

Noise level

According to Point 1.7.4.2u of the Machinery Directive 2006/42/EC

4 measurements were made when the machine was running in no-load mode:

- The microphone was placed on the operator’s head at a medium height.

- The continuous noise level was below 70 dB (A).

- The maximum noise level C was always measured below 130 dB.

Wear always safety googles!

NOTE: during machine operation, the noise intensity varies depending on the type of materials being

processed. The operator must therefore assess the intensity and equip machine users with suitable hearing

protection equipment.

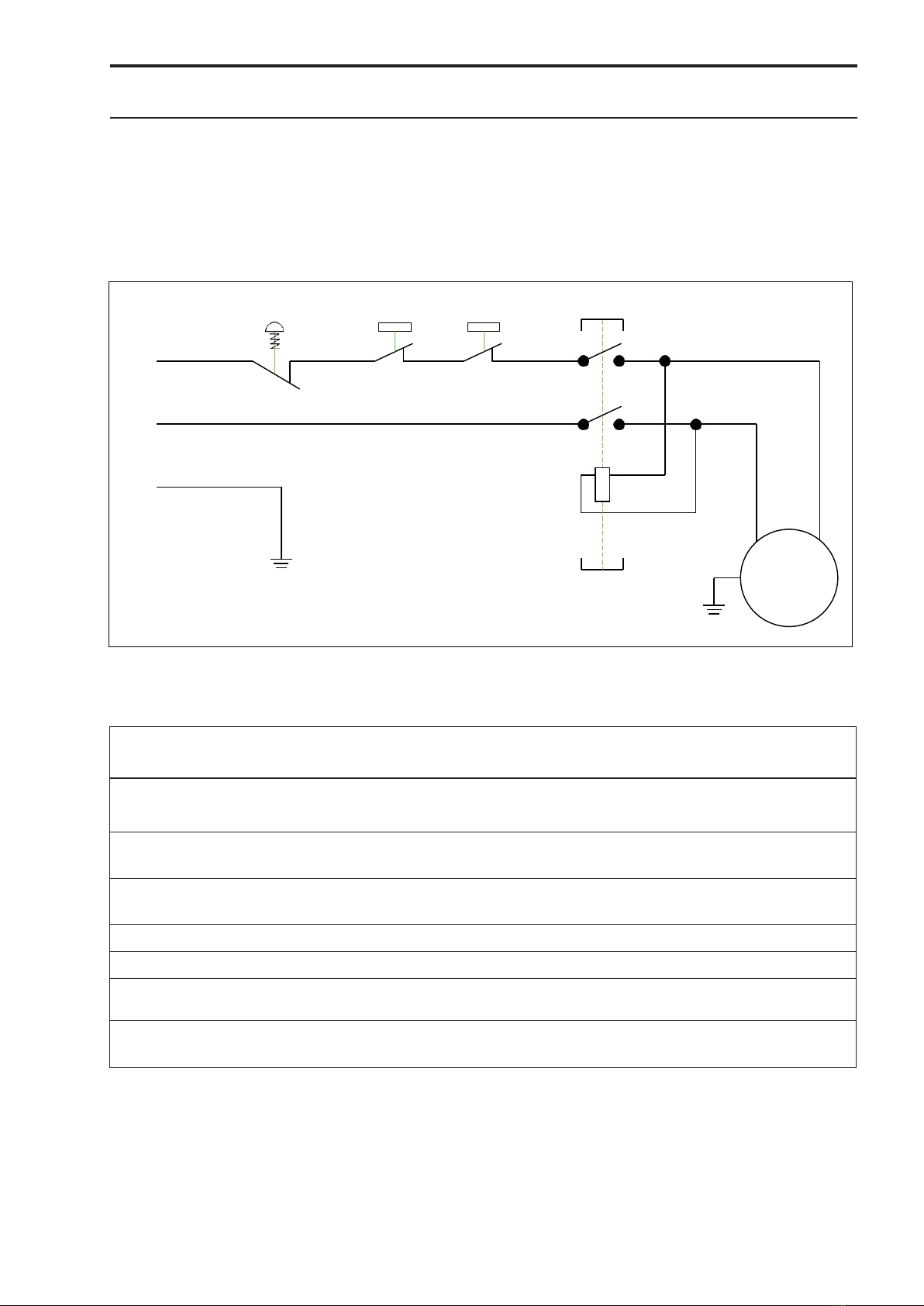

Electrical mains connection

1. The machines model 212 and 212Z are supplied with a mains cable with plug, 230V,50Hz.

Connections as well as changes of the mains connection must be carried out by a qualified technician, in accordance with

standard EN60204-1, Point 5.3.

2. The fuse protection must be at least 10.3A.

3. The exact electrical data can be found on the identification plate of the machine and in the wiring diagram,

enclosed with this Manual.

4. CAUTION: For all maintenance or conversion works as well as repairs, the machine must be disconnected

from the electrical mains (unplug the machine).

5. The yellow/green ground cable is important for electrical safety. Therefore, proceed with care to install it

correctly. 4