8

7-1. Make sure the power voltage is for the machine. Before connecting the

plug to socket, it is necessary to check the power spec. to avoid any

damage occurring.

7-2. If the machine is not used for a long time, the plug should be

disconnected.

7-3. Never put the power cable near the fire or water environment, to break or press the power cable is not

allowed.

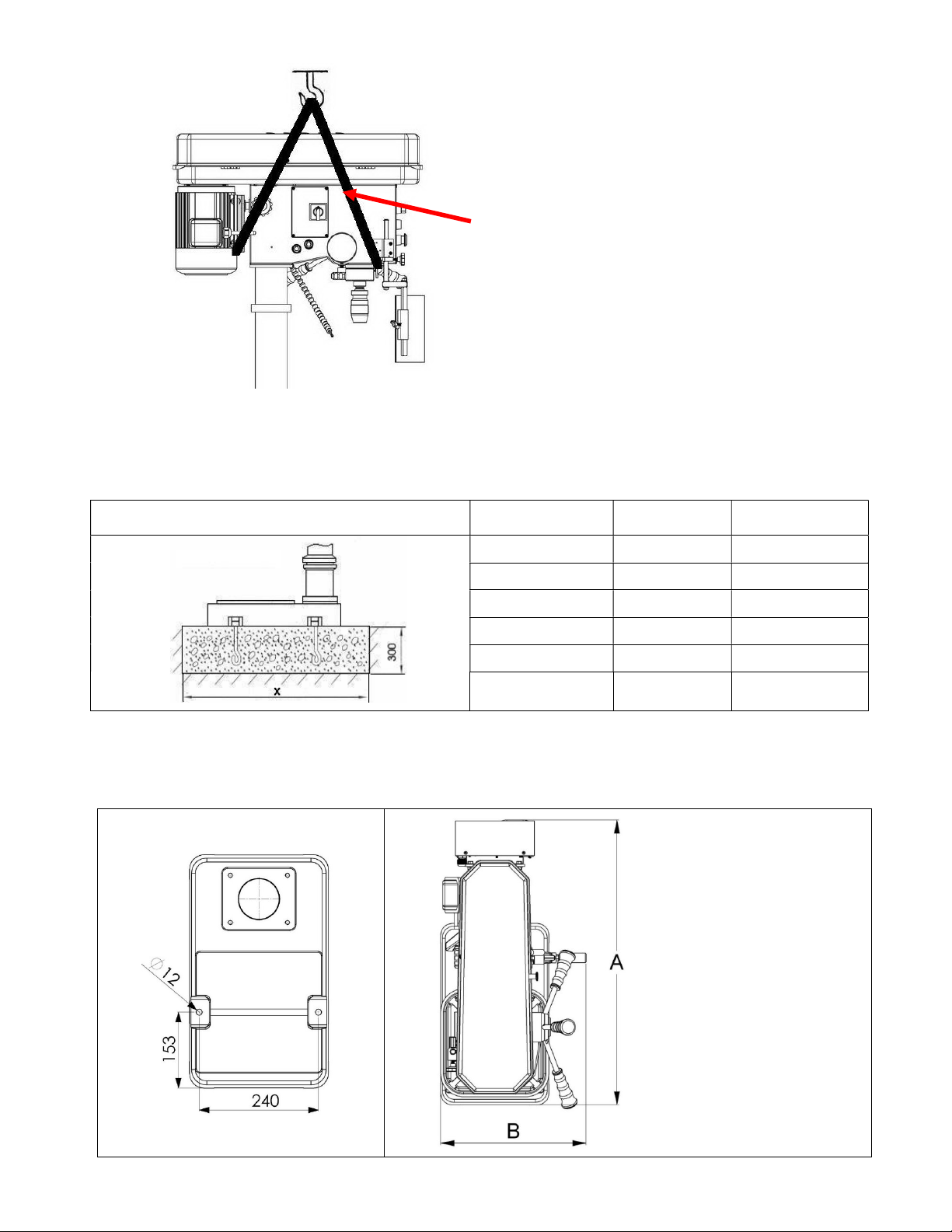

7-4. It shall be stable and securely fixed in machine installation procedure for the machine to be used safely.

7-5. The working piece must be tightly fixed on table by vise or clamp.

7-6. Use recommended cutting liquid; consult the owner’s manual for recommendation.

7-7. Feed speed should be executed under safety scope, please refer to manual 3-3.

7-8. Wear proper apparel, no loose clothing, gloves, neckties, ring, and bracelet during operation. Always

wear safety glasses, cap and specific clothes.

7-9. Check all parts are in place and securely locked before transportation. Bump and crash are prohibited.

7-10. Regular maintenance and repaired should be executed in accordance with the rules of manual.

7-11. Use the industrial suction to clean the chip is recommended.

7-12. Use carrier to move the working piece which the weight is more than 10 kg is recommended.

7-13. Wear safety gloves when install the drilling bit or tooling to avoid hurting your hand is recommended.

7-14. This machine only be used following material brass, cast iron, steel, iron, aluminum.

7-15. It is prohibited to open the pulley cover during operation.

7-16. It is prohibited to use damaged or cracked parts.

7-17. It is prohibited to remove the guard cover away during operation.

7-18. It is prohibited to move the table when machine is during operation.

7-19. It is prohibited to operate this machine beyond the limit of its capacity.

7-20. Refer to this instruction for details.

7-21. It is prohibited to insert one's hand or finger into the hole of working piece during operation.

7-22. It is prohibited all visitors and children should stand near work area while the machine during operation.

7-23. It is prohibited to wear gloves, neckties, ring, bracelet and loose clothing during operation.

7-24. It is prohibited to use plastic and wooden working.

7-25. Check again before switch on power:

A- Make sure the power voltage is for the machine.

B- Make sure the machine is completely assembled and installed

C- Make sure chuck, working table, working piece are completely secured or tightly fixed.

D- Make sure the chuck key is removed from chuck.

E- Make sure drill bit or tooling need to be fixed in the chuck.

7-26. Switch off power at once:

A- When fix or remove working piece.