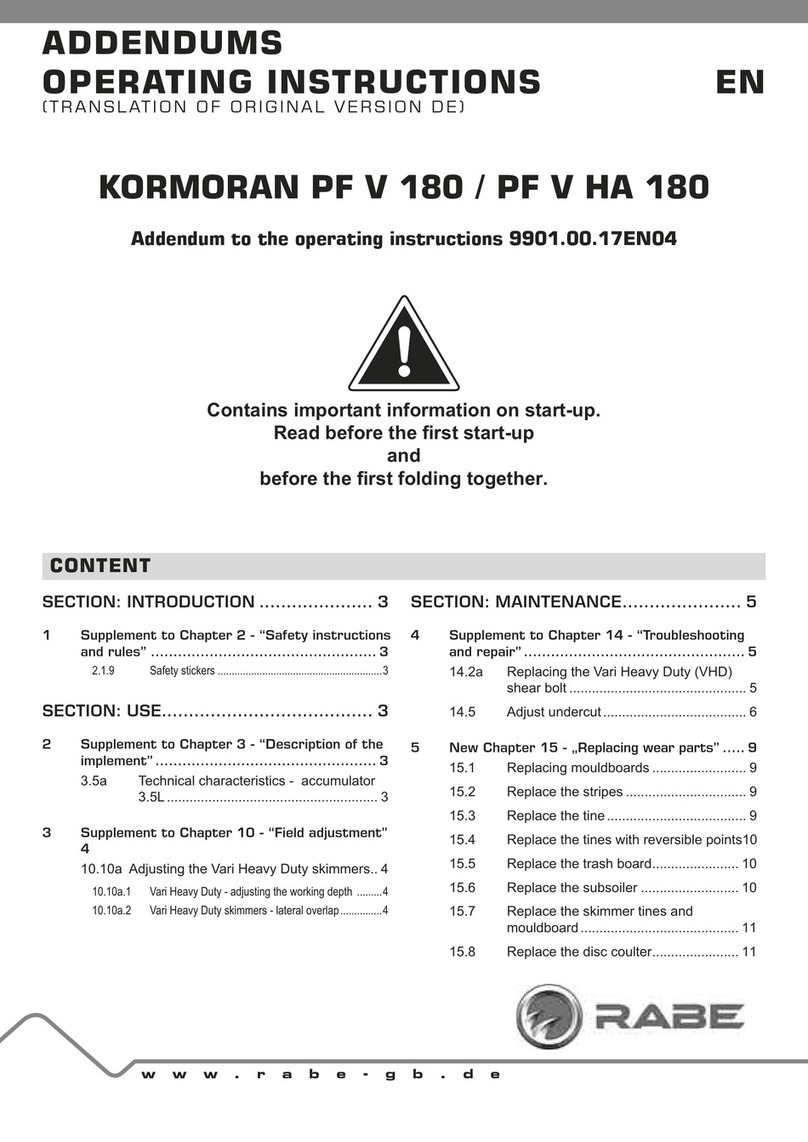

5

05.2013

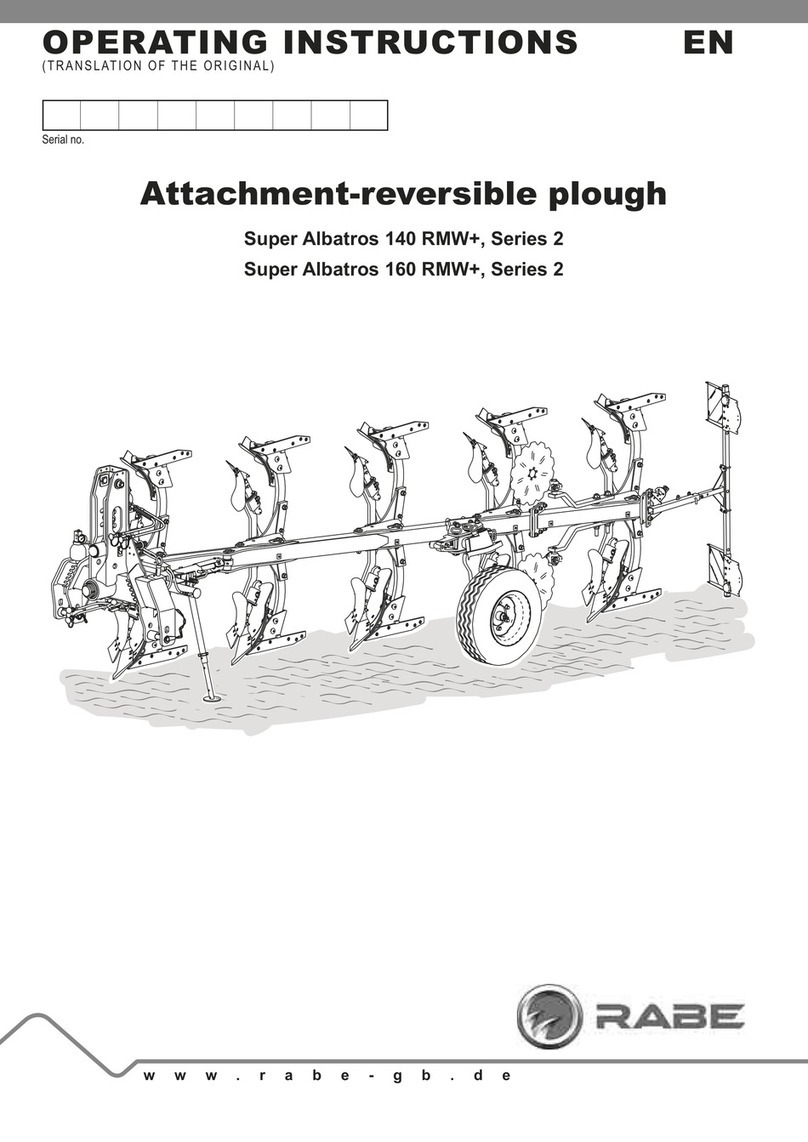

Albatros / Super-Albatros

Subject to technical modications

Table of contents

Locations of the warn signs at the implement .............................................................................6

Locations of the warn signs at the implement .............................................................................7

Description of the warn signs ......................................................................................................8

For your safety ..........................................................................................................................10

General information ......................................................................................................10

General notes on safety................................................................................................10

1. Intended use ............................................................................................................10

2. General notes on safety and accident prevention rules ........................................... 11

2.1 Mounted implements .............................................................................................. 11

2.3 Hydraulic system ....................................................................................................12

2.4 Maintenance ..........................................................................................................12

Machine data.............................................................................................................................13

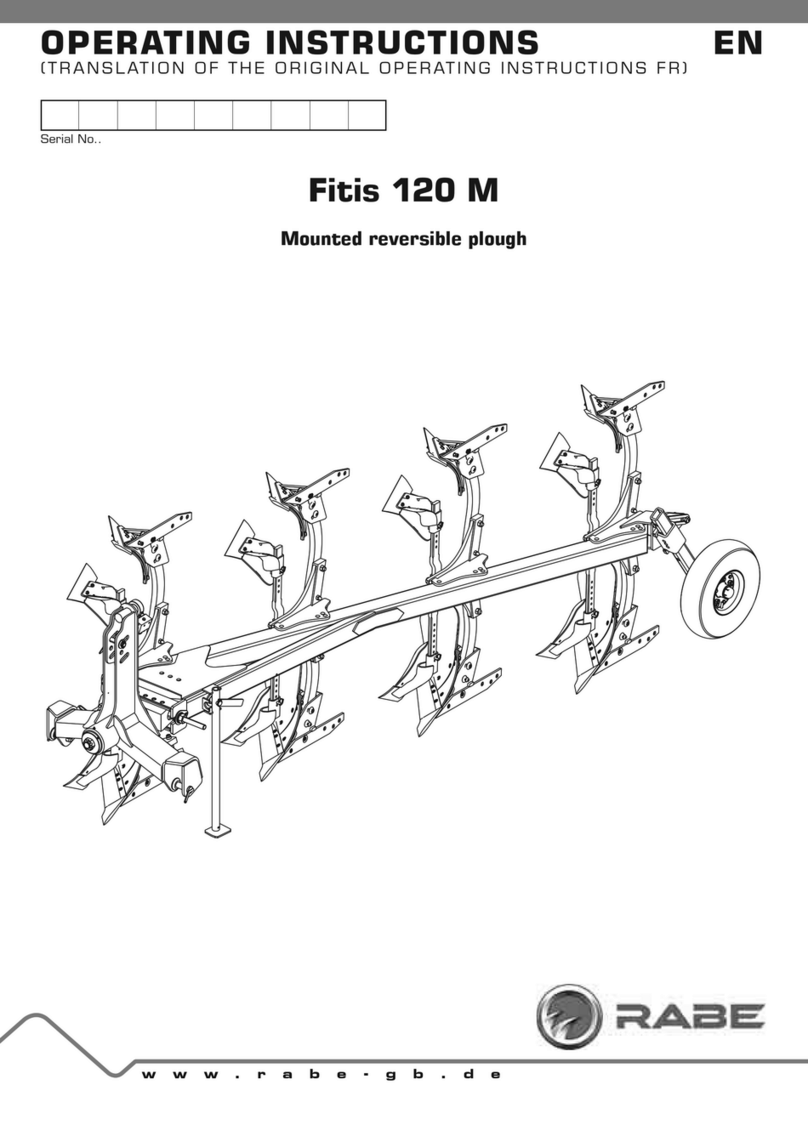

Mounting ...................................................................................................................................15

Coupling hydraulic hoses (Colour protecting cap) ....................................................................17

Turning test ...............................................................................................................................17

Presetting .................................................................................................................................18

Traction point.............................................................................................................................18

First furrow working width .........................................................................................................19

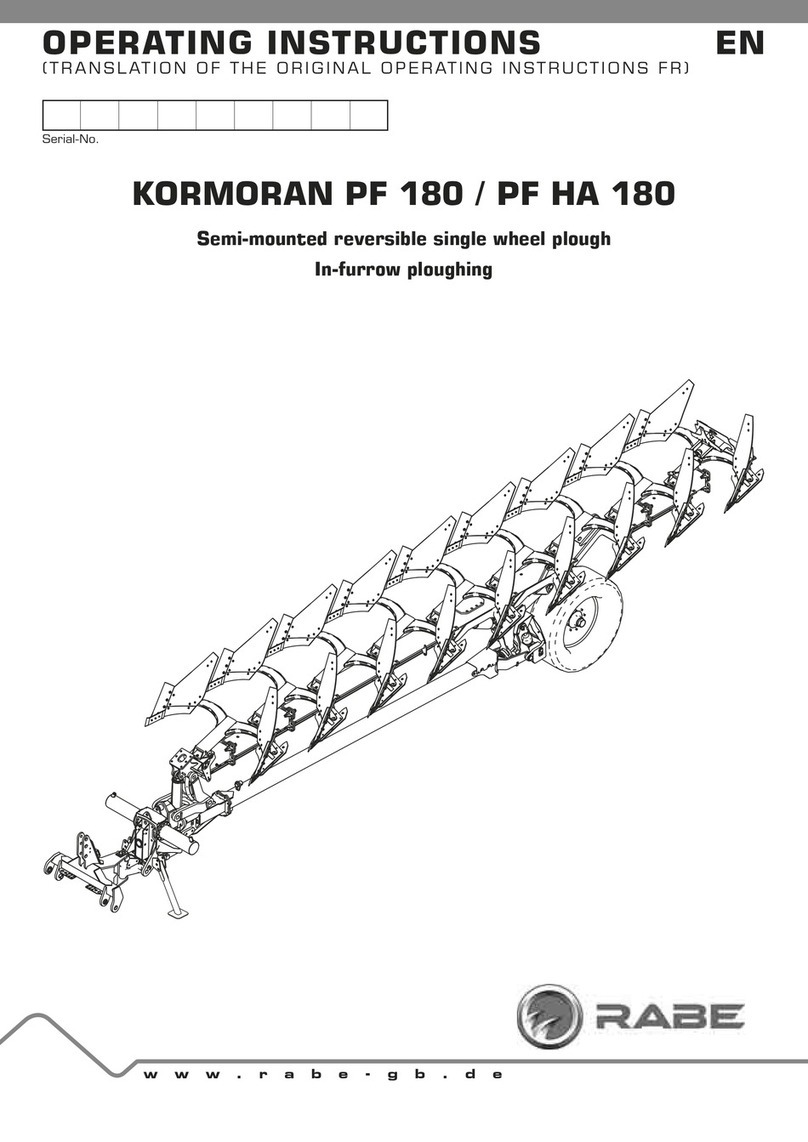

Field work..................................................................................................................................20

Working depth ...........................................................................................................................20

Inclination / Tilt ..........................................................................................................................20

Traction point and first furrow working width .............................................................................21

Working width adjustment ........................................................................................................22

Levelling bars ...........................................................................................................................22

Pick-up arm for plough follower.................................................................................................23

Standard skimmers / Skimmers ................................................................................................24

Trash boards .............................................................................................................................24

Disc coulter ..............................................................................................................................25

Subsoil decompactor ................................................................................................................25

Plough leg overload protection .................................................................................................26

Automatic stone protection “HydroAvant”..................................................................................27

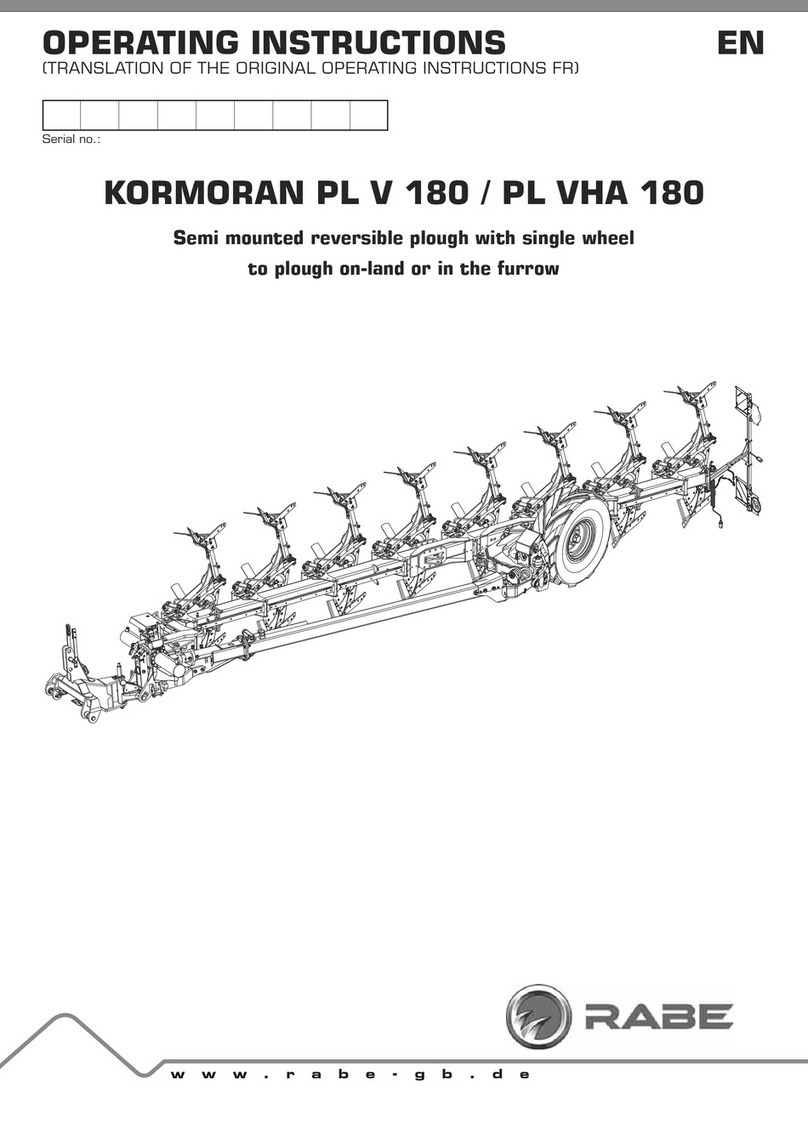

Transport - Ploughs without combination wheel........................................................................28

Transport - Ploughs with combination wheel.............................................................................28

Switching to working position ....................................................................................................28

Setting down the plough............................................................................................................29

Maintenance..............................................................................................................................30

Residual dangers ......................................................................................................................32

Caution / Transport ...................................................................................................................33