ADDENDUMS

OPERATING INSTRUCTIONS EN

(TRANSLATION OF ORIGINAL VERSION DE)

www.rabe-gb.de

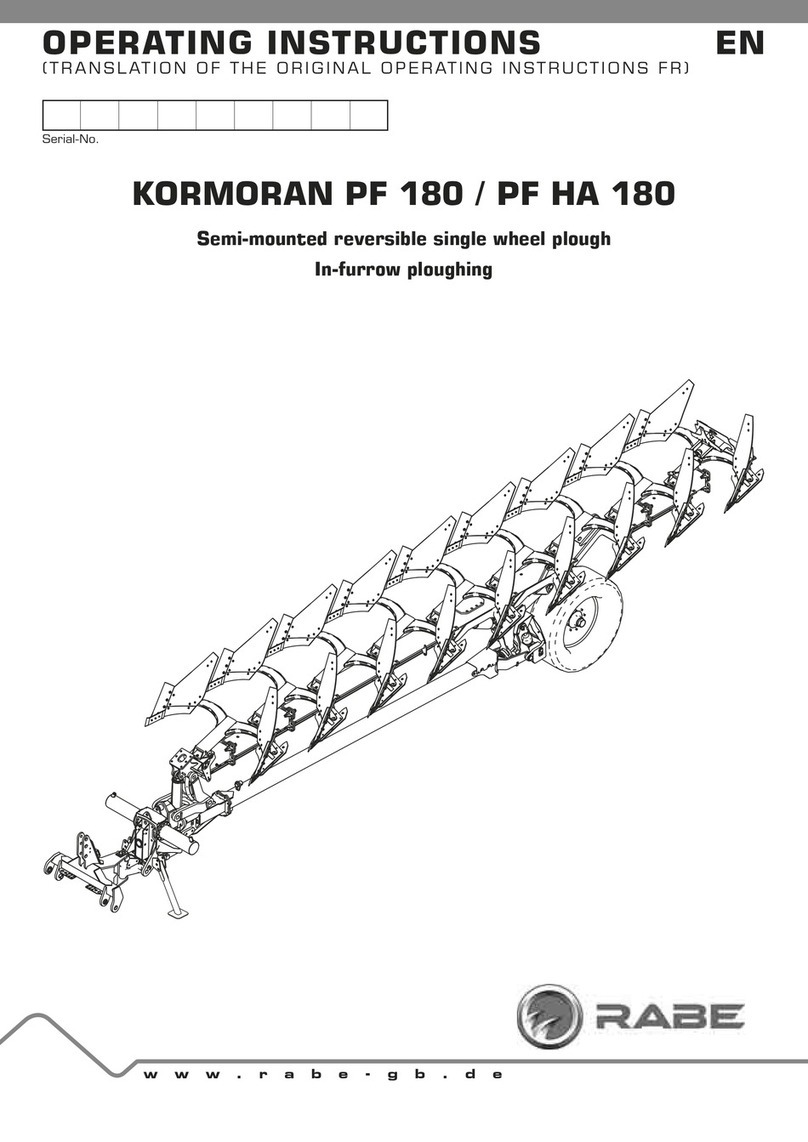

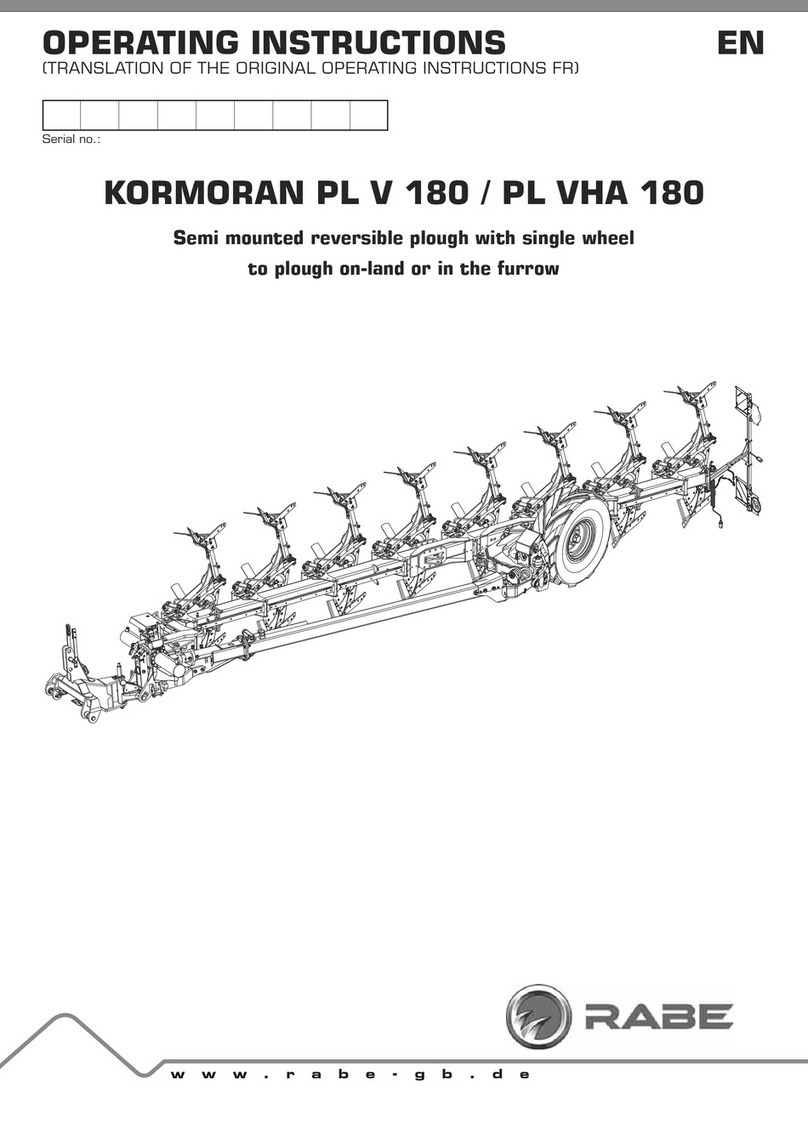

KORMORAN PF V 180 / PF V HA 180

Contains important information on start-up.

5HDGEHIRUHWKH¿UVWVWDUWXS

and

EHIRUHWKH¿UVWIROGLQJWRJHWKHU

CONTENT

Addendum to the operating instructions 9901.00.17EN04

SECTION: INTRODUCTION ..................... 3

1 Supplement to Chapter 2 - “Safety instructions

and rules” .................................................. 3

2.1.9 Safety stickers ...........................................................3

SECTION: USE....................................... 3

2 Supplement to Chapter 3 - “Description of the

implement” ................................................. 3

3.5a Technical characteristics - accumulator

3.5L ........................................................ 3

3 Supplement to Chapter 10 - “Field adjustment”

4

10.10a Adjusting the Vari Heavy Duty skimmers.. 4

10.10a.1 Vari Heavy Duty - adjusting the working depth .........4

10.10a.2 Vari Heavy Duty skimmers - lateral overlap...............4

SECTION: MAINTENANCE...................... 5

4 Supplement to Chapter 14 - “Troubleshooting

and repair” ................................................. 5

14.2a Replacing the Vari Heavy Duty (VHD)

shear bolt ............................................... 5

14.5 Adjust undercut ...................................... 6

5 New Chapter 15 - „Replacing wear parts” ..... 9

15.1 Replacing mouldboards ......................... 9

15.2 Replace the stripes ................................ 9

15.3 Replace the tine ..................................... 9

15.4 Replace the tines with reversible points10

15.5 Replace the trash board....................... 10

15.6 Replace the subsoiler .......................... 10

15.7 Replace the skimmer tines and

mouldboard .......................................... 11

15.8 Replace the disc coulter....................... 11