- 3 -

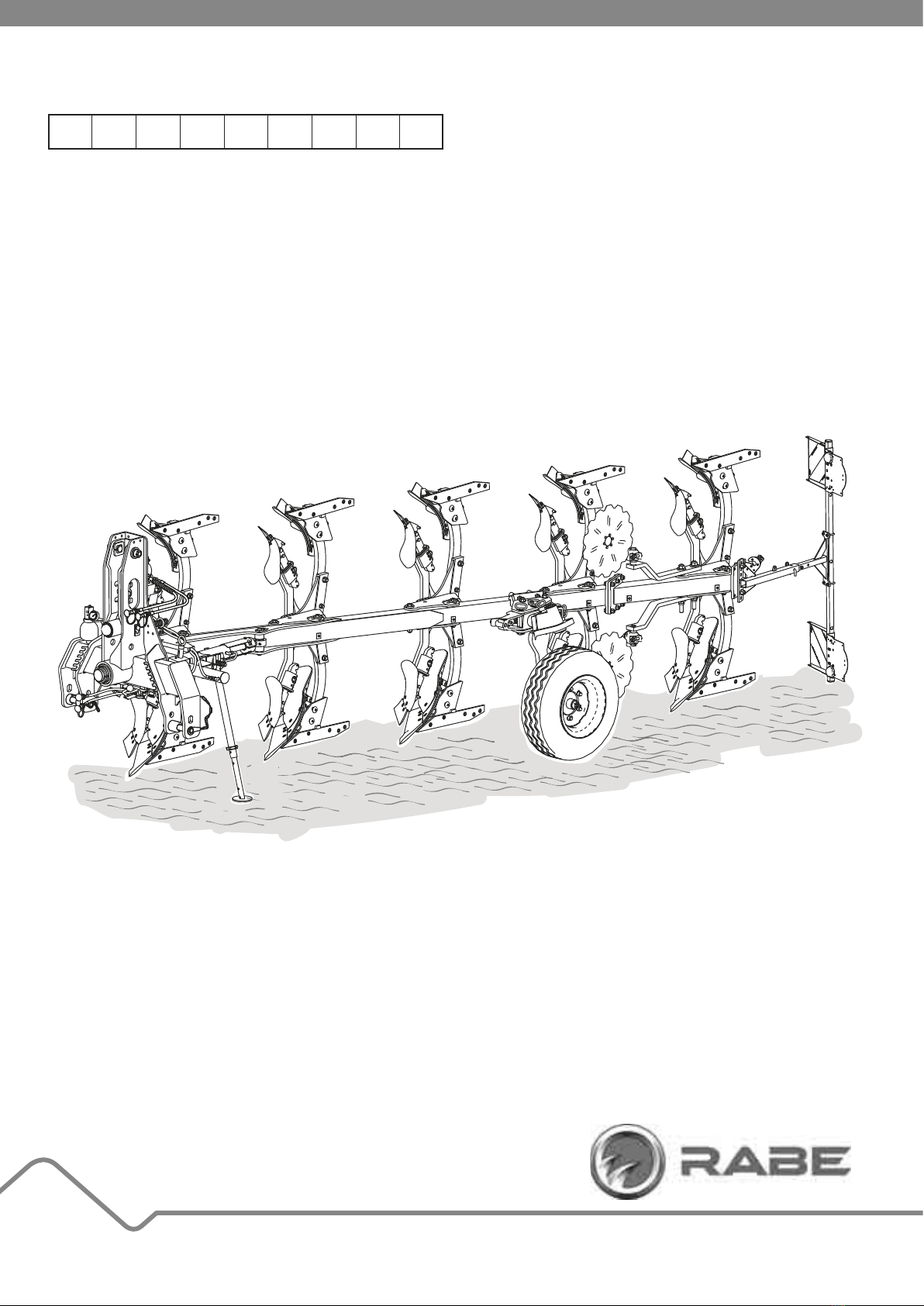

BRIEF INSTRUCTIONS SUPER ALBATROS 140 MW; SERIES 2

9901.00.34DE00; 02.2017 6XEMHFWWRWHFKQLFDOPRGL¿FDWLRQV

Quick guide for experienced operators, always observe the detailed operating

instructions as well.

BRIEF INSTRUCTIONS

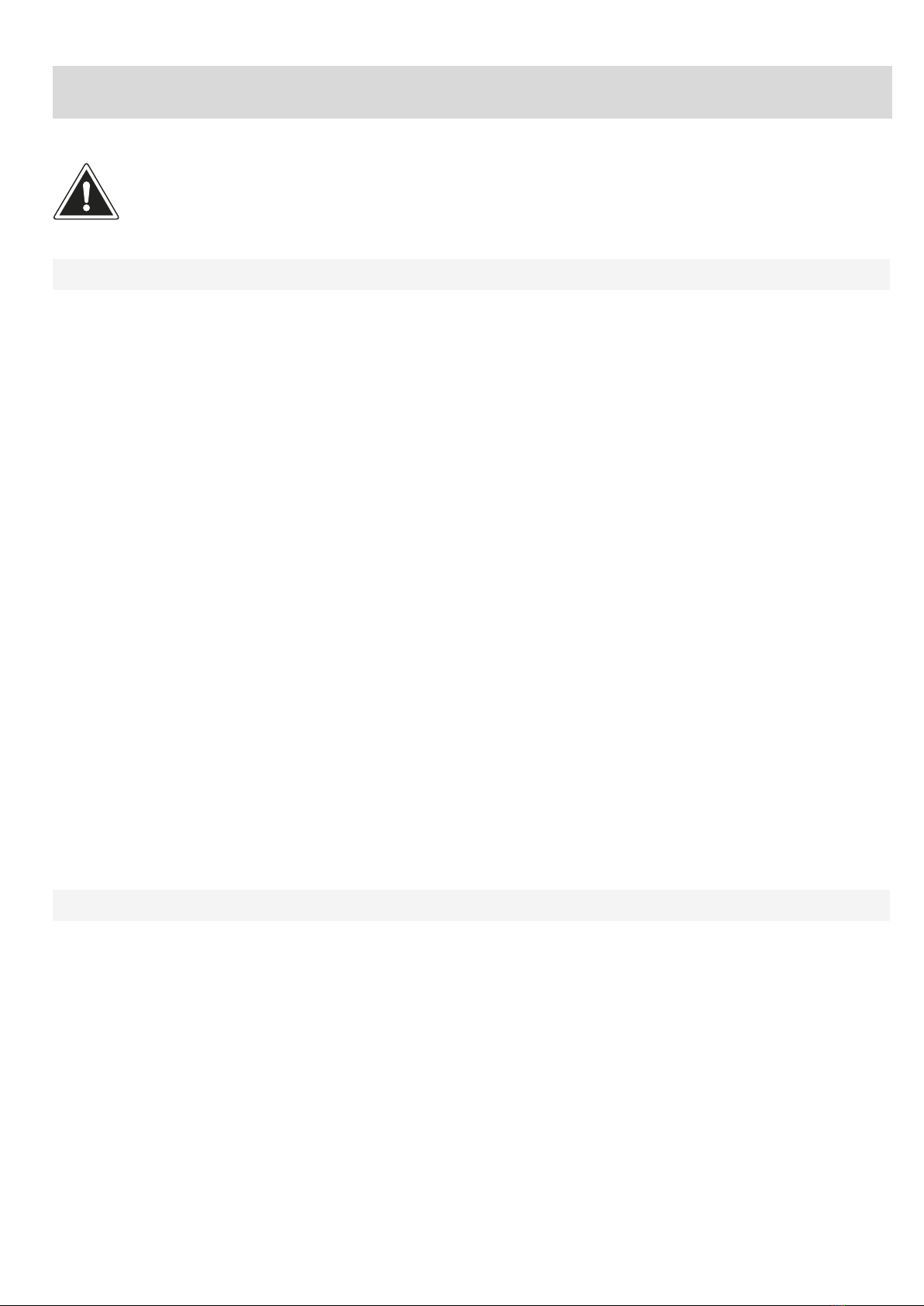

1 PREPARING THE TRACTOR

ŹCalculate required ballast for the tractor, then

attach ballast.

ŹCheck that the air pressure in the tractor's tyres

is correct and equal.

ŹCheck the output and lifting capacity of the rear

power lift on the tractor in relation to the plough

version.

ŹCheck the permissible axle load for the tractor.

ŹCheck that tractor’s and implement’s

connection categories are the same.

ŹSet the bottom links to the same height.

ŹLimit the bottom links to a low lateral ...

... tolerance with the side locks when raised

and adjust them so that they ...

... move freely when lowered.

ŹSet the tractor hydraulics to traction control.

ŹCheck the bottom link’s lifting height.

Minimum lifting height = 85 cm

BRIEF INSTRUCTIONS

TABLE OF CONTENTS FOR THE BRIEF INSTRUCTIONS

1 Preparing the tractor ......................................................... 3

2 Coupling the implement.................................................... 4

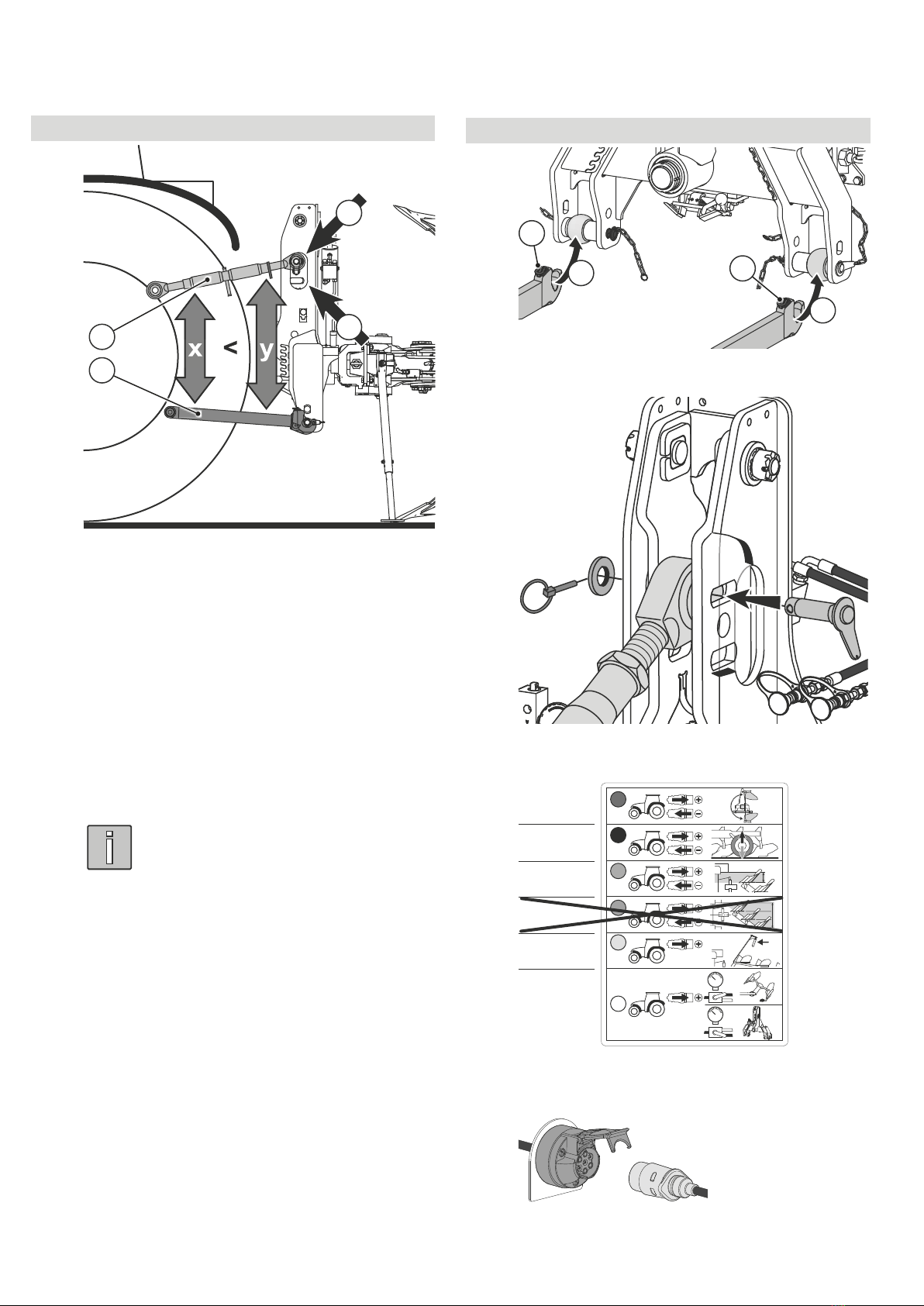

3 Folding up the parking support........................................ 5

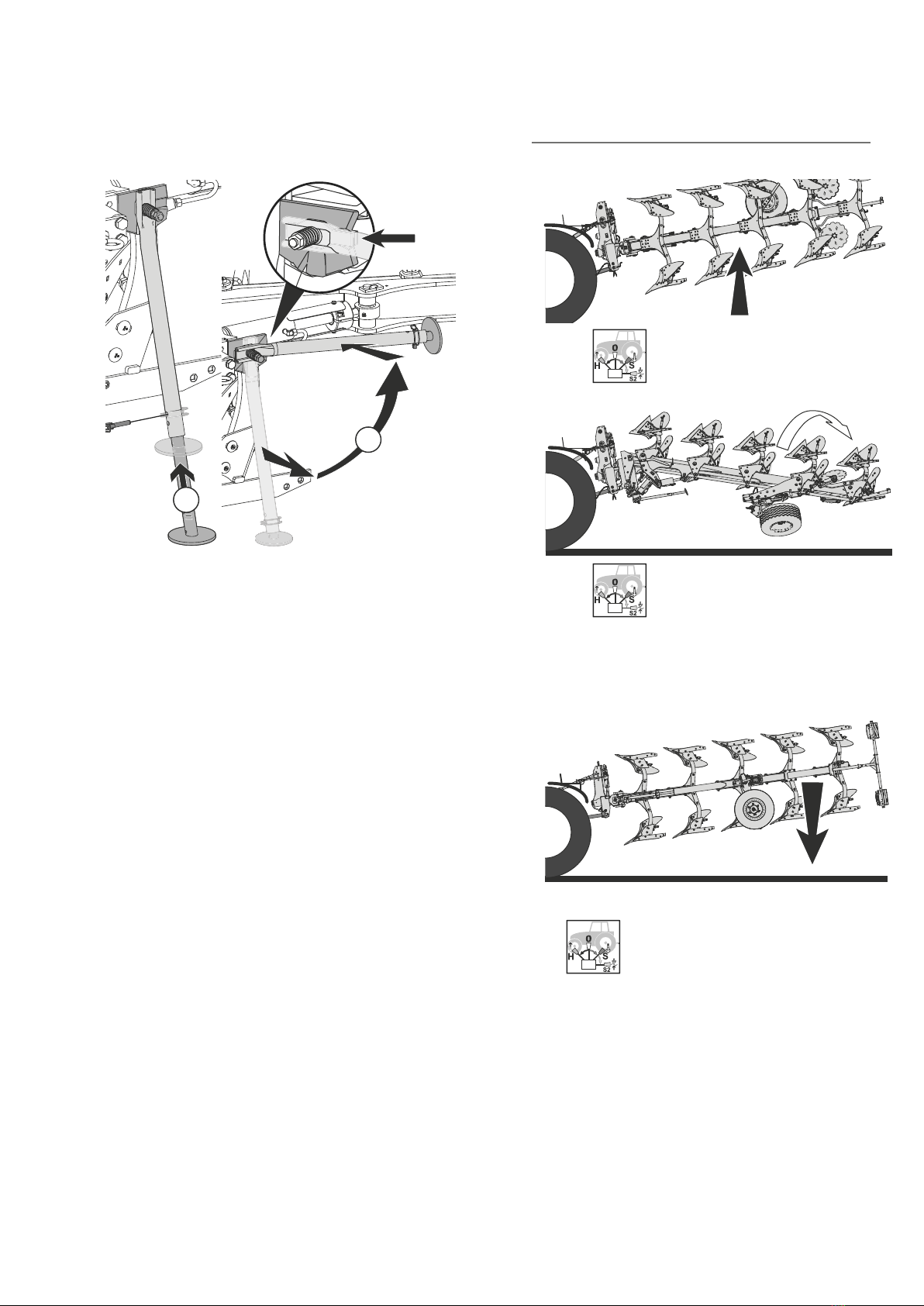

4 Moving the plough into the transport position............... 5

4.1 Turning the plough onto the right-hand side.............. 5

4.2 Turning the combination wheel into the transport

position ...................................................................... 6

4.3 Lifting the ploughs with depth guide wheel into the

transport position....................................................... 7

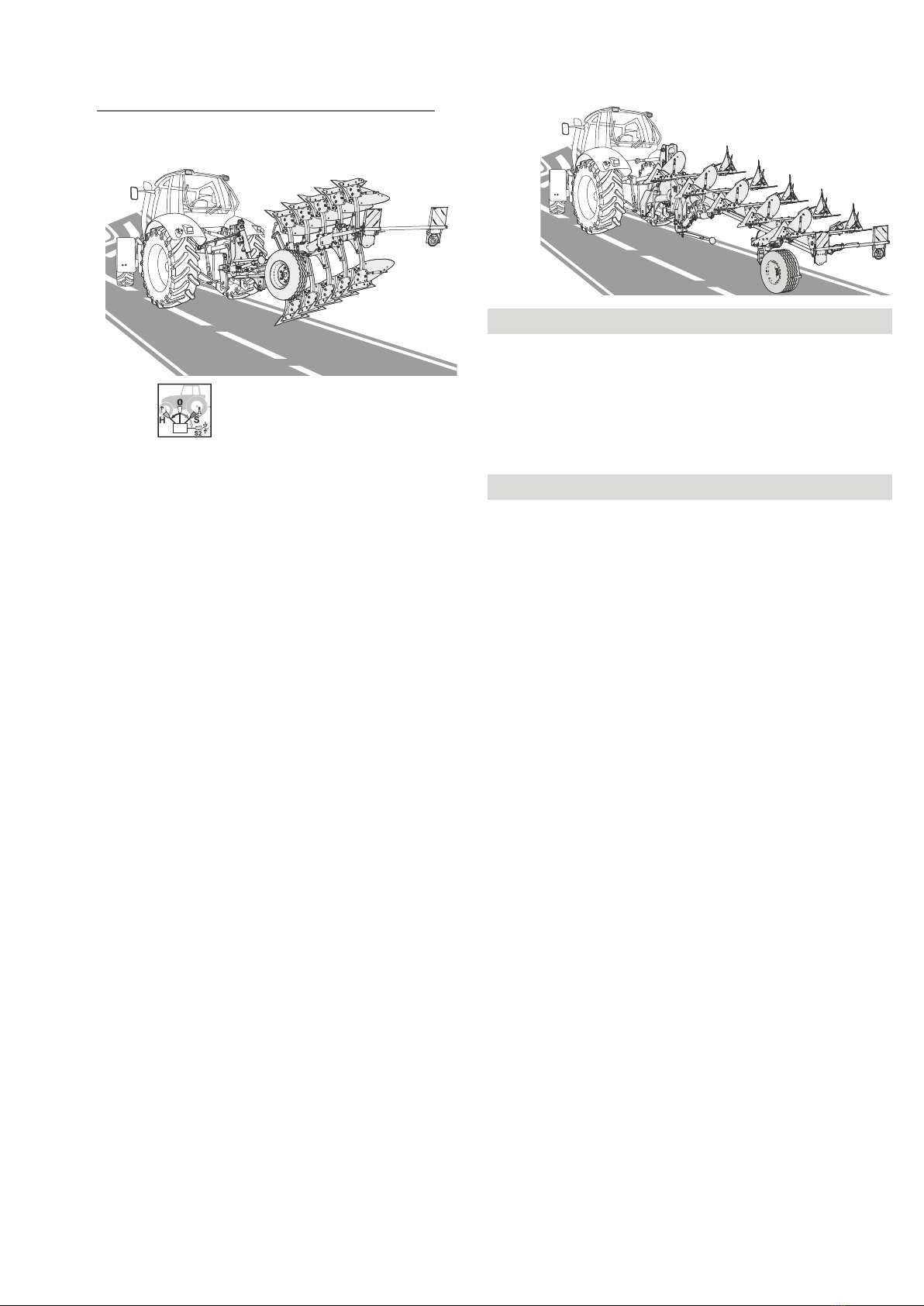

5 Travelling by road.............................................................. 7

6 Moving the plough with combination wheel into the

working position................................................................ 8

7 Moving the plough with depth control wheel into the

working position................................................................ 9

8 Removing the lighting....................................................... 9

9 Working values: Working speed / working depth........... 9

10 Adjusting the traction point............................................ 10

10.1 Plough with turnbuckle ............................................ 10

10.2 Plough with hydraulic frame slewing ....................... 10

11 $GMXVWLQJWKH¿UVWERG\ZRUNLQJZLGWK......................... 11

11.1 Plough with adjusting spindle .................................. 11

11.2 Ploughs with hydraulic cylinder ............................... 11

12 Adjusting the working depth .......................................... 12

12.1 Preparation.............................................................. 12

12.2 Depth adjustment, depth control wheel PS 5 .......... 12

12.3 Depth adjustment, depth control wheel PS 30

and combination wheel D 30 ................................... 12

12.4 Depth adjustment, RJR wheel................................. 13

13 Aligning the plough parallel to the ground ................... 13

14 Adjusting the incline ....................................................... 14

15 Installing the lighting...................................................... 14

16 Adjusting the working width........................................... 15

17 Adjusting the track of the contact or combination

wheel................................................................................. 15