- 7 -

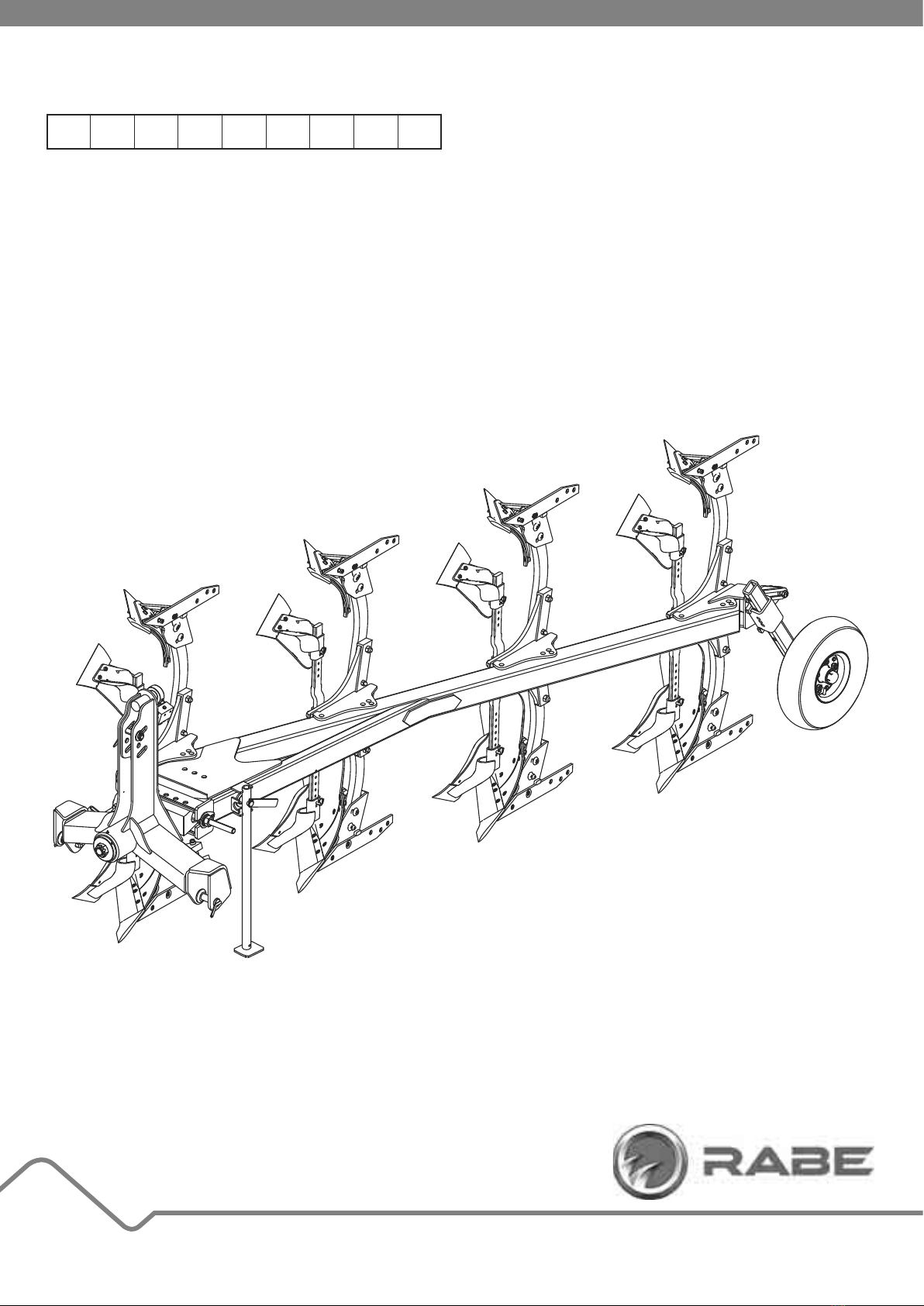

OPERATOR´SMANUAL FITIS 120 M

9901.00.20EN00 - 05/2015

2 SAFETY INSTRUCTIONS AND

RULES

2.1 Safety instructions

2.1.1 General instructions

CAUTION:

The risks of accidents during use, maintenance or

repair of the implement can be reduced if you follow

the safety instructions and preventative measures

described in this manual.

ʈOnly the operations and manoeuvres described in this manual

may be performed. The manufacturer is not able to predict

all possible situations involving risks. As a result, the safety

instructions described in the manual and on the implement are

QRWH[KDXVWLYH

ʈAs a user, you must make reasonable allowance for possible

ʈ

risks to yourself, others and implement while you are using it.

CAUTION:

Non-observance of safety and usage instructions,

repair or maintenance instructions for your

implement can result in serious, even fatal

accidents.

2.1.2 2SHUDWRUTXDOL¿FDWLRQ

ʈThe implement may only be used, serviced or repaired by

SHUVRQVZKRDUHIDPLOLDUZLWKLWVVSHFL¿FFKDUDFWHULVWLFVDQG

with the corresponding operational safety modes.

ʈBefore using your implement, familiarise yourself with all the

controls and with its proper operation.

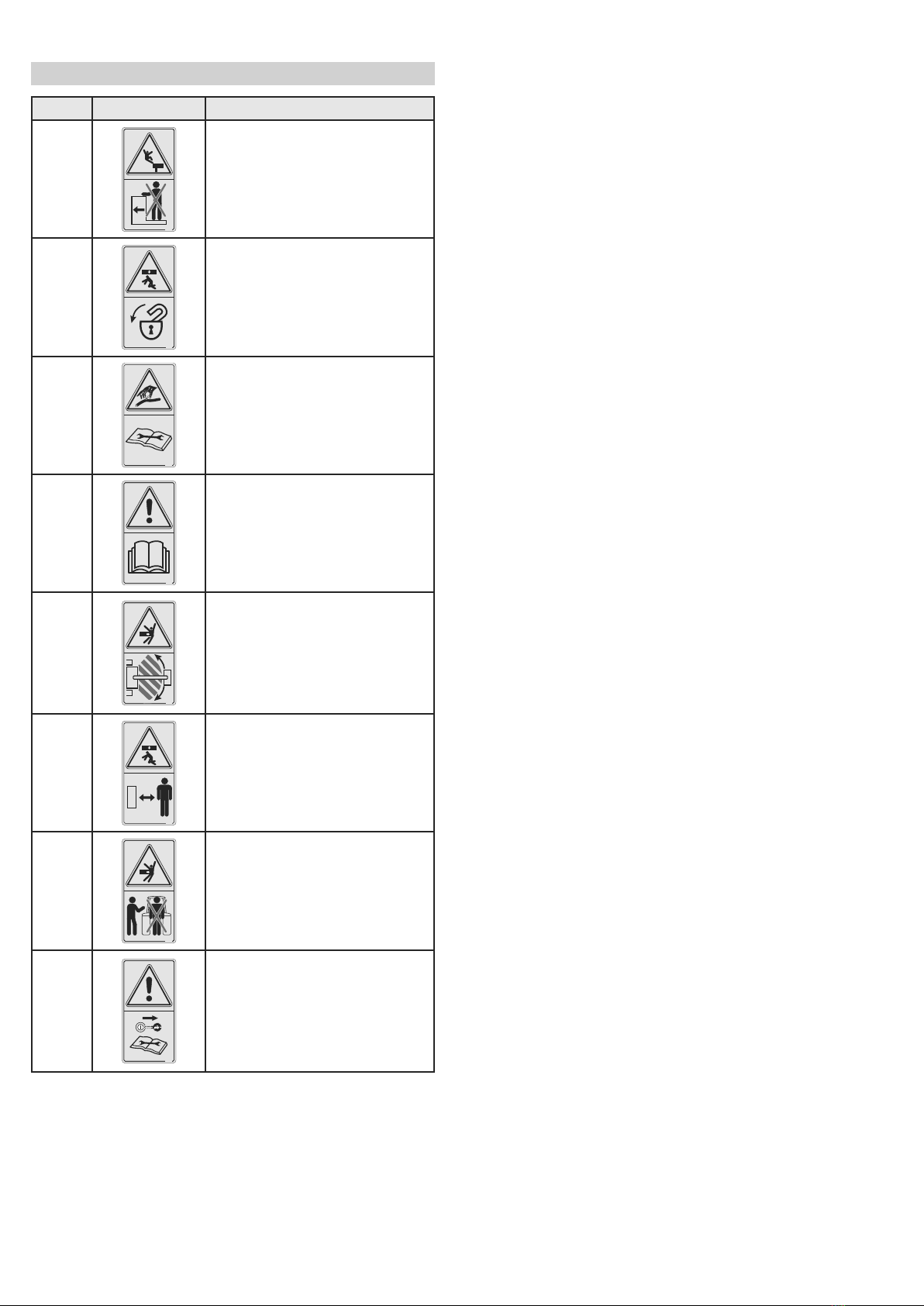

2.1.3 Hitching and unhitching the implement

ʈIf there is only one operator, then the driver himself is

responsible for hitching and unhitching the implement. Use the

H[WHUQDOOLIWFRQWUROV

ʈMake sure that no-one can get between the tractor and the

implement or come close to the implement during the hitching

and unhitching operations.

ʈBefore getting out of the cab to hitch or unhitch the implement,

apply the parking brake, stop the engine and take out the

tractor ignition key.

ʈBefore hitching your implement, make sure that there are no

signs of wear, incipient cracks or any incompatibility with your

tractor on the hitching pins, draw bar hitches or the ball joints.

ʈDepressurise the hydraulic circuit before connecting or

disconnecting the hydraulic couplings.

ʈConnect or disconnect the electrical connections.

ʈCompletely lower the implement to the ground, position the

VXSSRUWOHJVRIWKHLPSOHPHQWEHIRUHXQKLWFKLQJLW0DNHVXUH

WKDWWKHVXUIDFHLVOHYHODQGVXI¿FLHQWO\¿UPWRHQVXUHWKDWWKH

implement is perfectly stable during storage.

ʈIf your implement is parked, make sure that it is stable to avoid

the possibility of physical injury or material damage.

2.1.4 Hydraulic circuit and couplings

CAUTION:

The hydraulic circuit is subject to high pressures.

ʈ,IK\GUDXOLFÀXLGVKRXOGHVFDSHDYRLGDQ\GLUHFWFRQWDFWZLWK

WKHK\GUDXOLFÀXLG7KHSUHVVXULVHGRLOFDQSHQHWUDWHWKHVNLQ

and cause fatal injuries. Immediately consult a doctor in the

event of injury.

ʈObserve the order of assembly of the hydraulic couplings.

Ensure that the tractor couplings are properly positioned

horizontally or vertically.

ʈBefore connecting the hydraulic circuit, clean the couplings on

the tractor and implement, and check that the pressure is zero

both on the tractor and implement side.

ʈReplace damaged or used hydraulic lines, observing the

GLPHQVLRQDOVSHFL¿FDWLRQV

ʈPrior to carrying out any work on the hydraulic system, set the

implement down on the ground, depressurise the hydraulic

circuit, stop the tractor engine and actuate the hydraulic

valves.

2.1.5 Use of the implement

ʈ7KLVLPSOHPHQWLVH[FOXVLYHO\GHVLJQHGIRUVWDQGDUG

agricultural work. Any other use is considered to be contrary to

the implement's normal use and is thus prohibited.

ʈDo not attempt to adjust an implement when this is in motion.

ʈDo not enter the pivoting range of bolted, hydraulic or

mechanical locking elements.

ʈWear clothing and personal protection equipment suited to

the work to be performed (thick leather gloves, safety boots,

SURWHFWLYHJODVVHV«

ʈCreate a safety perimeter for other persons.

ʈ'RQRWSHUIRUPDQ\DGMXVWPHQWZRUNZLWKRXW¿UVWKDYLQJ

perfectly understood the required procedure.

ʈUse suitable tools or equipment for the work to be performed.

ʈCorrectly use the implement and its controls, do not let

untrained persons attempt to operate it.

ʈ'RQRWH[WHQGWKHPHFKDQLFDODGMXVWLQJURGVWRDYRLGWKHULVN

of threads being torn or spontaneous unscrewing.

ʈWhen working alone, the operator must be in his cab and

may never leave his seat. No-one may ride or stand on the

implement when it is in operation.

ʈStop the implement if you notice unusual noises or vibrations.

Identify and eliminate the cause before resuming work.