1. INTENDED USE

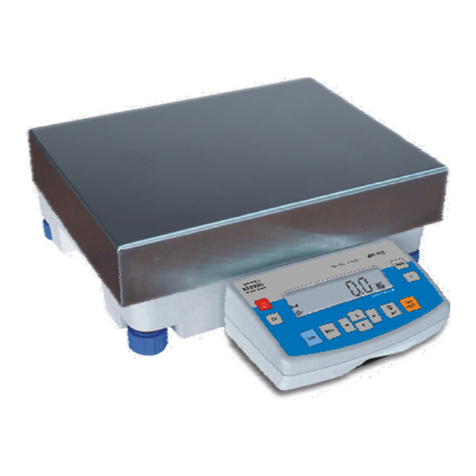

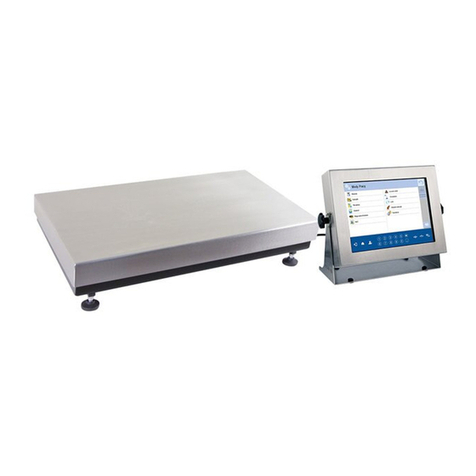

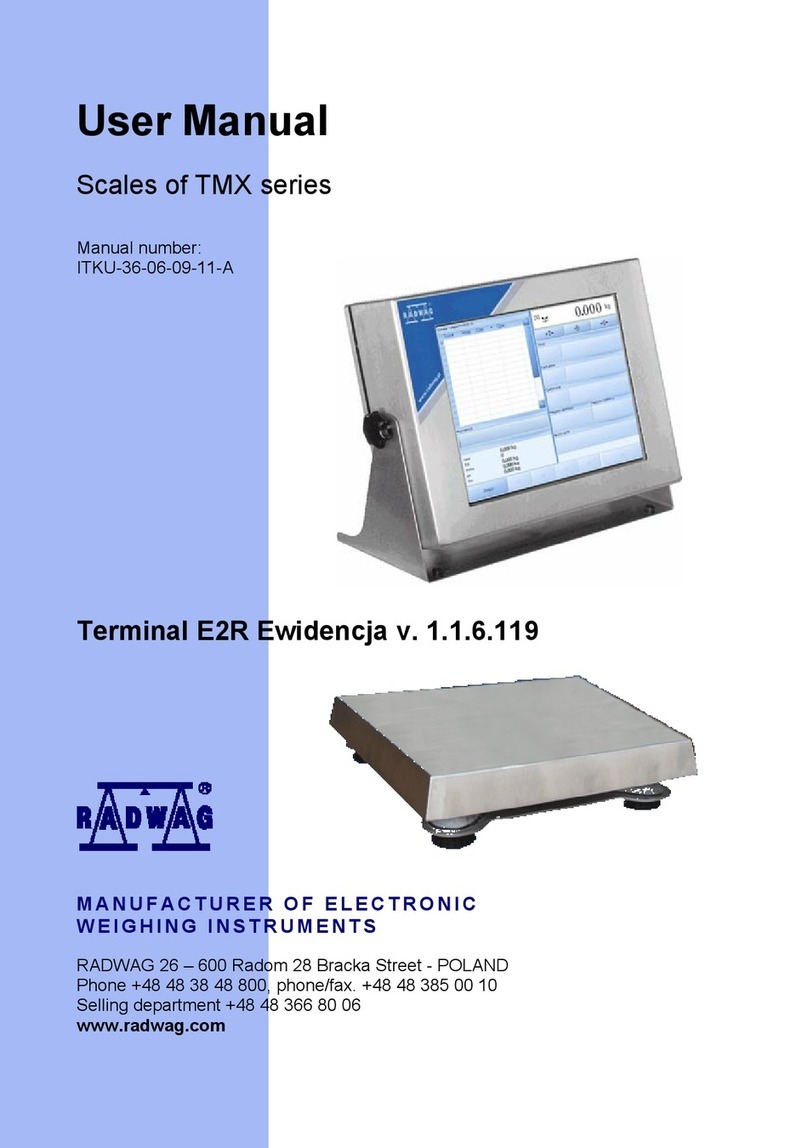

Scales are the response to growing expectations of the market regarding

simple use and maximum automation of the weighing process. The scales are

intended to quickly and precisely specify mass in laboratory and industrial

conditions. The scale is equipped with an ABS and aluminum housing as well

as a 10” high-resolution color display.

In the standard variant, the scale is supplied with 2 USB type-A connectors,

a USB type-C connector, Ethernet, wireless connection, Hotspot, 2 proximity

sensors, RFID sensor, HDMI port, loudspeakers, camera and microphone.

The device cooperates with receipt and label printers, barcode scanners

and PC equipment (mouse, keyboard, USB flash memory).

2. GUARANTEE TERMS

A. RADWAG undertakes to repair or replace the elements that prove

defective in terms of manufacture or structure.

B. It is allowed to specify defects of unclear origin and establish methods

of eliminating them only in cooperation with representatives of the

manufacturer and user.

C. RADWAG shall not be held responsible for defects or losses deriving from

unauthorized or improper production or servicing.

D. The guarantee does not cover the following:

mechanical damage arising from wrong use of the scale, and thermal,

chemical damage, or damage caused by atmospheric discharge,

overvoltage in the power system or other random event,

maintenance works (cleaning).

E. The guarantee cover becomes invalid when:

the repair is conducted out of the authorized service center,

the service technician detects unauthorized intervention in the

mechanical or electronic structure of the scale,

other version of the operating system is installed,

the scale does not hold any company protective marks.

F. The rights on accounts of the guarantee for storage batteries supplied with

devices cover a period of 12 months.

G. Detailed terms of the guarantee can be found in the service log.

H. The contact phone number for the authorized service center:

+48 (48) 386 63 30.

3. CLEANING

To clean the device safely, unplug it in the first place. Next disassemble

the weighing pan and other moving elements of the scale.