3

Table OF CONTENTS

1. INTENDED USE..........................................................................................................................5

2. PRECAUTIONARY MEASURES................................................................................................5

3. WARRANTY CONDITIONS........................................................................................................6

4. UN ACKING AND MOUNTING .................................................................................................6P

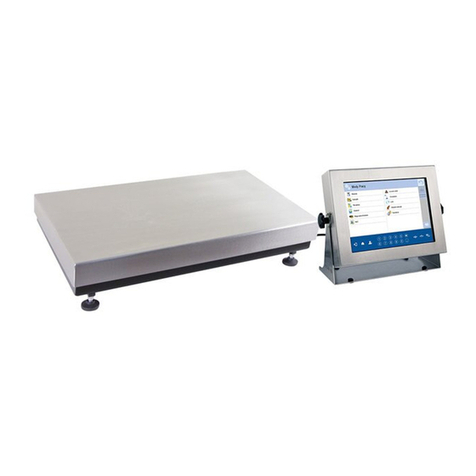

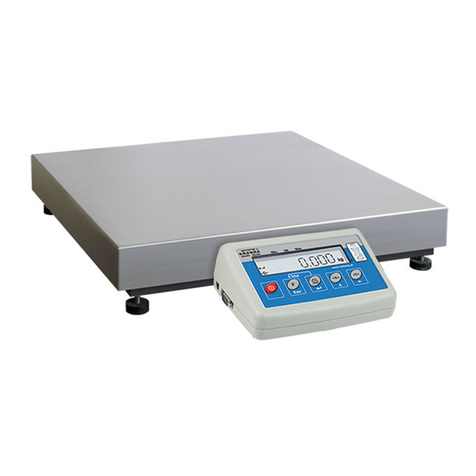

4.1. PY/KTPS/C1 scales...........................................................................................................6W

4.2.WPY/KTPS/D2 scales...........................................................................................................7

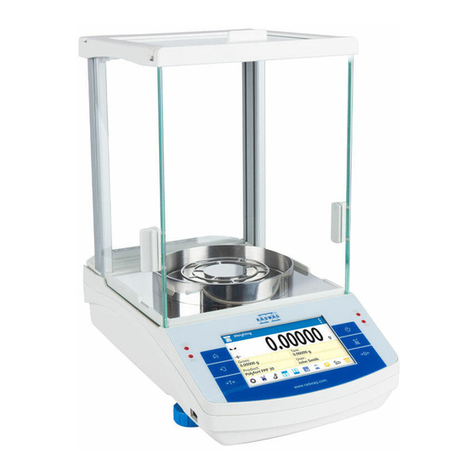

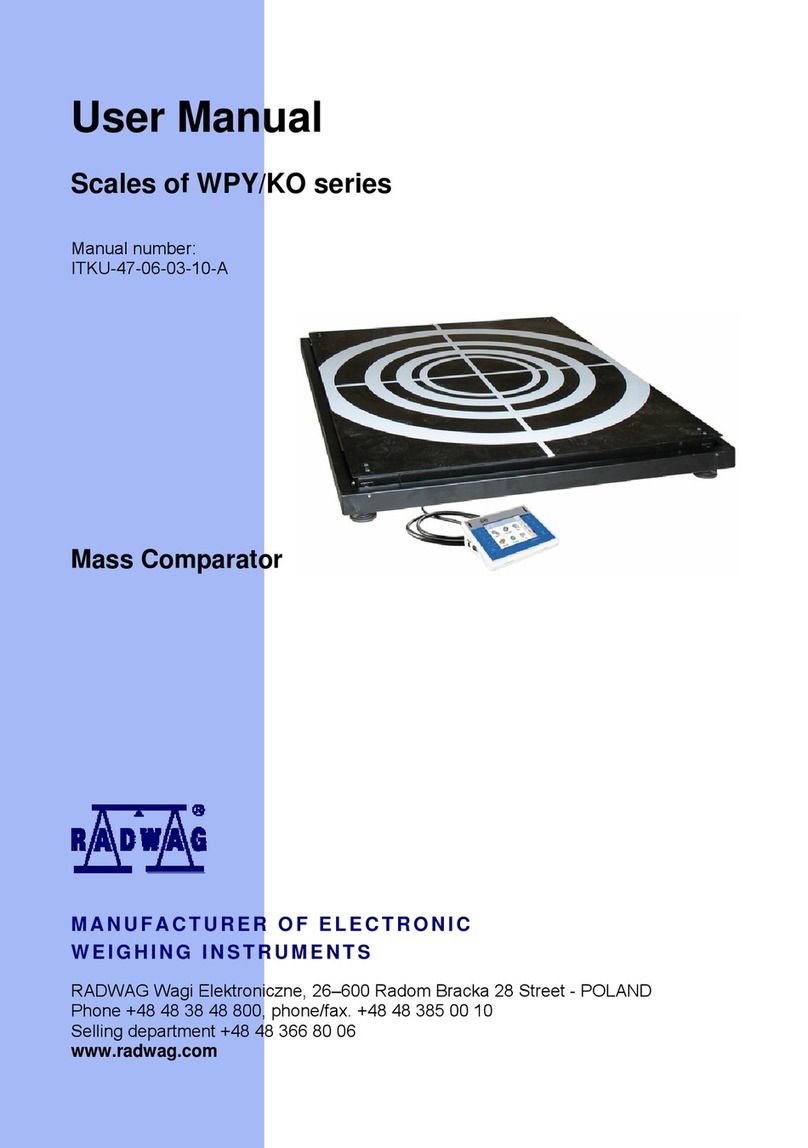

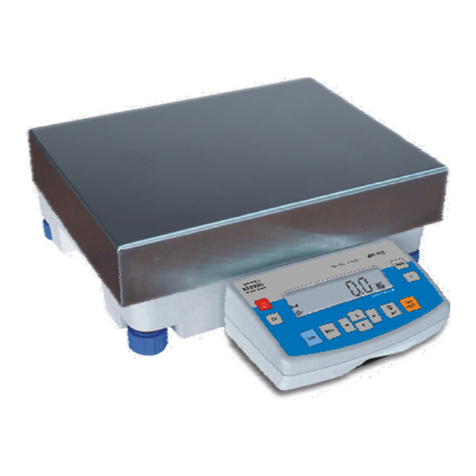

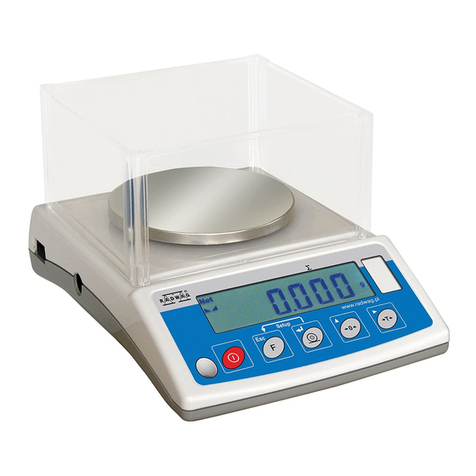

5. SCALE CONSTRUCTION ..........................................................................................................8

5.1.Main dimensions....................................................................................................................8

5.1.1. Y/KTPS/C1 scales ................................................................................................8WP

WPY/KTPS/D2 scales ................................................................................................85.1.2.

5.2.Description of connectors......................................................................................................9

5.2.1. ...............................................................................9Connectors’ description in PUE 7

5.2.2. .............................................................................9Connectors’ description in PUE 7P

5.2.3. ..................................................................................10Description of glands PUE 7P

5.2.4. Connector with RS232 and I/O.................................................................................10

6. GETTING STARTED ................................................................................................................11

7. KEYPAD OVERLAY.................................................................................................................11

8. FUNCTIONS OF KEYS.............................................................................................................12

8.1. eys on the overlay.............................................................................................................12K

8.2.Screen function buttons.......................................................................................................12

9. INDICATING WINDOW.............................................................................................................13

10. PROGRAM STRUCTURE ......................................................................................................14

10.1. Inventory of parameters....................................................................................................15

10.1.1. Scale parameters - weighing..................................................................................15

10.1.2. Communication......................................................................................................15

10.1.3. Devices ..................................................................................................................16

10.1.4. Display ...................................................................................................................17

10.1.5. Others ....................................................................................................................17

10.1.6. User Calibration .....................................................................................................18

10.2. Navigating within the menu...............................................................................................18

10.2.1. Buttons...................................................................................................................18

10.2.2. Return to weighing .................................................................................................19

11. WEIGHING..............................................................................................................................20

11.1. erational use ...........................................................................................20Conditions of op

11.2. ng..............................................................................................................................21Zeroi

11.3. ng...............................................................................................................................21Tarri

11.4. Weighing for dual range scales.........................................................................................22

12. SCALE PARAMETERS..........................................................................................................22

12.1. .......................................................................................................................23Median filter

12.2. ilter..................................................................................................................................23F

12.3. ............................................................................................................................24Autozero

12.4. Minimum weight for different functions (LO) .....................................................................24

13. COMMUNICATION.................................................................................................................25

13.1. .................................................................................................................25RS 232 settings

13.2. T setting...........................................................................................................25ETHERNE

13.3. TCP protocol setting .........................................................................................................26

14. DEVICES.................................................................................................................................26

14.1. Computer ..........................................................................................................................26

14.1.1. Computer port ........................................................................................................27