CONTENTS

1. INTENDED USE .................................................................................................................................................5

2. WARRANTY CONDITIONS ...............................................................................................................................5

3. MAINTENANCE .................................................................................................................................................5

4. SERVICE AND REPAIR.....................................................................................................................................6

5. RECYCLING.......................................................................................................................................................6

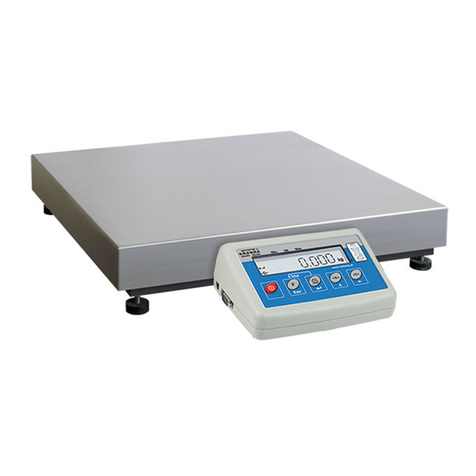

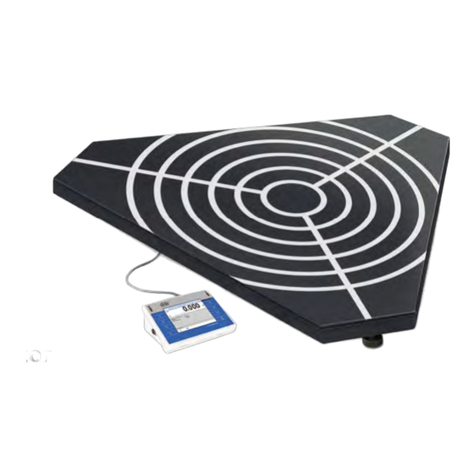

6. MECHANICAL DESIGN.....................................................................................................................................6

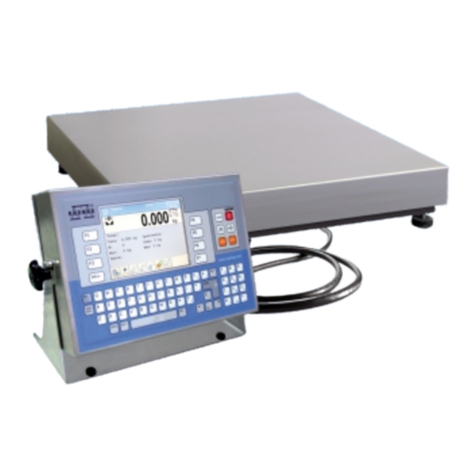

6.1.General View................................................................................................................................................7

6.2.Dimensions...................................................................................................................................................7

6.3.Connectors...................................................................................................................................................7

6.4.RS232 Connector.........................................................................................................................................8

6.5.Inputs/Outputs..............................................................................................................................................8

6.5.1.Technical Specifications......................................................................................................................9

6.6.Main Board Sockets.....................................................................................................................................9

6.7.Technical Specifications.............................................................................................................................10

6.8.Models........................................................................................................................................................11

7. INSTALLATION................................................................................................................................................11

7.1.Unpacking and Installation.........................................................................................................................11

7.2.START-UP..................................................................................................................................................11

8. INSTALLER INSTRUCTION............................................................................................................................11

8.1.6-Wire Load Cell Connection.....................................................................................................................11

8.2.4-Wire Load Cell Connection.....................................................................................................................12

8.3.Connecting Load Cell’s Cable Shield.........................................................................................................13

9. FACTORY PARAMETERS ..............................................................................................................................14

9.1.Factory Parameter Access.........................................................................................................................14

9.2.Factory Parameters....................................................................................................................................15

9.3.Parameter Value Modification....................................................................................................................16

9.4.Factory Adjustment ....................................................................................................................................17

9.4.1.Start Mass Determination..................................................................................................................17

9.4.2.Adjustment Factor Determination......................................................................................................17

9.5.Linearity Correction ....................................................................................................................................18

9.6.Gcor............................................................................................................................................................19

10. OPTIONAL EXTENSION MODULES ............................................................................................................19

10.1. Exclusions Regarding Installation of Additional Modules........................................................................19

10.2. RS485 Module .........................................................................................................................................20

10.2.1. RS485 Pins .....................................................................................................................................20

10.3. ETHERNET Module.................................................................................................................................20

10.4. ETHERNET IP Module ............................................................................................................................21

10.5. Analog Output Module .............................................................................................................................22

10.5.1. Wiring Diagrams of the Current Loop Module ................................................................................23

10.5.2. Technical Specifications..................................................................................................................23

10.6. PROFIBUS Module..................................................................................................................................24

10.6.1. PROFIBUS Pin Arrangement..........................................................................................................24

10.7. PROFINET Module..................................................................................................................................24

11. ACCESSORIES..............................................................................................................................................25