Page 8of 12 CP0526

R&G Racing

Unit 1, Shelley’s Lane, East Worldham, Alton, Hampshire, GU34 3AQ

Tel: +44 (0)1420 89007 Fax: +44 (0)1420 87301 www.rg-racing.com Email: info@rg-racing.com

NOTICE DE MONTAGE

Avant de retirer les boulons du moteur, assurez-vous que la moto soit bien droite et soutenue par un

support moteur ou un cric approprié placé sous le carter de la moto pour supporter le poids partiel du

moteur, cela empêchera le moteur de bouger pendant le montage. NE PAS ENLEVER PLUS D'UN

BOULON DE MOTEUR EN SIMULTANÉ.

PRÉPARATION:

•Placez un cric approprié sous le moteur dans une position centrale en utilisant un morceau de

bois ou de plastique entre le cric et le moteur.

•Appliquez une très légère pression sur le dessous du moteur pour soutenir le moteur pendant le

processus de montage.

•Assemblez les protections crash avant de retirer les boulons du moteur pour limiter la durée

pendant laquelle le moteur est partiellement non soutenu.

•Visser les écrous (ARTICLE 7) sur l'extrémité de la barre moteur (ARTICLE 5/6) avec 20mm de

filetage. Vous pouvez utiliser une clé de 10 mm pour maintenir la barre tout en fixant les

écrous.

•Insérez la barre du moteur et l'écrou, avec les rondelles dans la protection latérale (ARTICLE 1),

suivis des entretoises de protection (ARTICLE 3/4).

INSTALLATION:

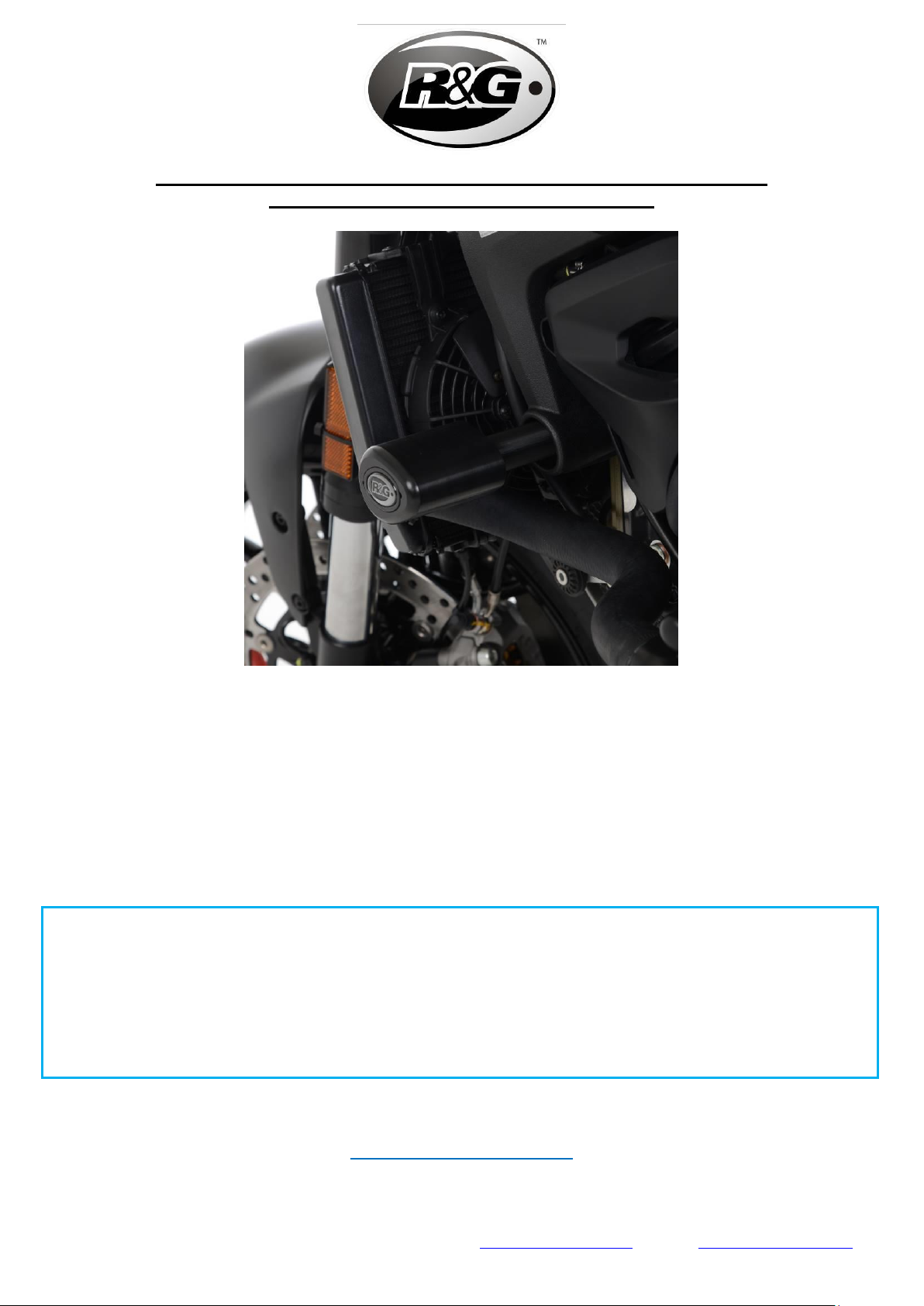

•Retirez le boulon de fixation du moteur d’origine illustré sur la photo 1.

•Installez l'ensemble protection et boulon préalablement préparé dans le support du moteur.

Vissez la barre de moteur M12 et l'écrou dans le filetage qui maintiendra l'ensemble en position.

REMARQUE : Pour éviter un filetage croisé, appliquez une pression vers l'avant sur le boulon et

tournez dans le sens inverse des aiguilles d'une montre jusqu'à ce qu'un clic se fasse entendre,

puis commencez à tourner dans le sens des aiguilles d'une montre et serrez.

•À l'aide d'une clé dynamométrique équipée d'une clé Douille 19mm, serrez la barre du moteur

et l'écrou à 45 Nm. Vous devrez peut-être maintenir la protection en position pour l'empêcher

de tourner pendant le serrage du boulon.

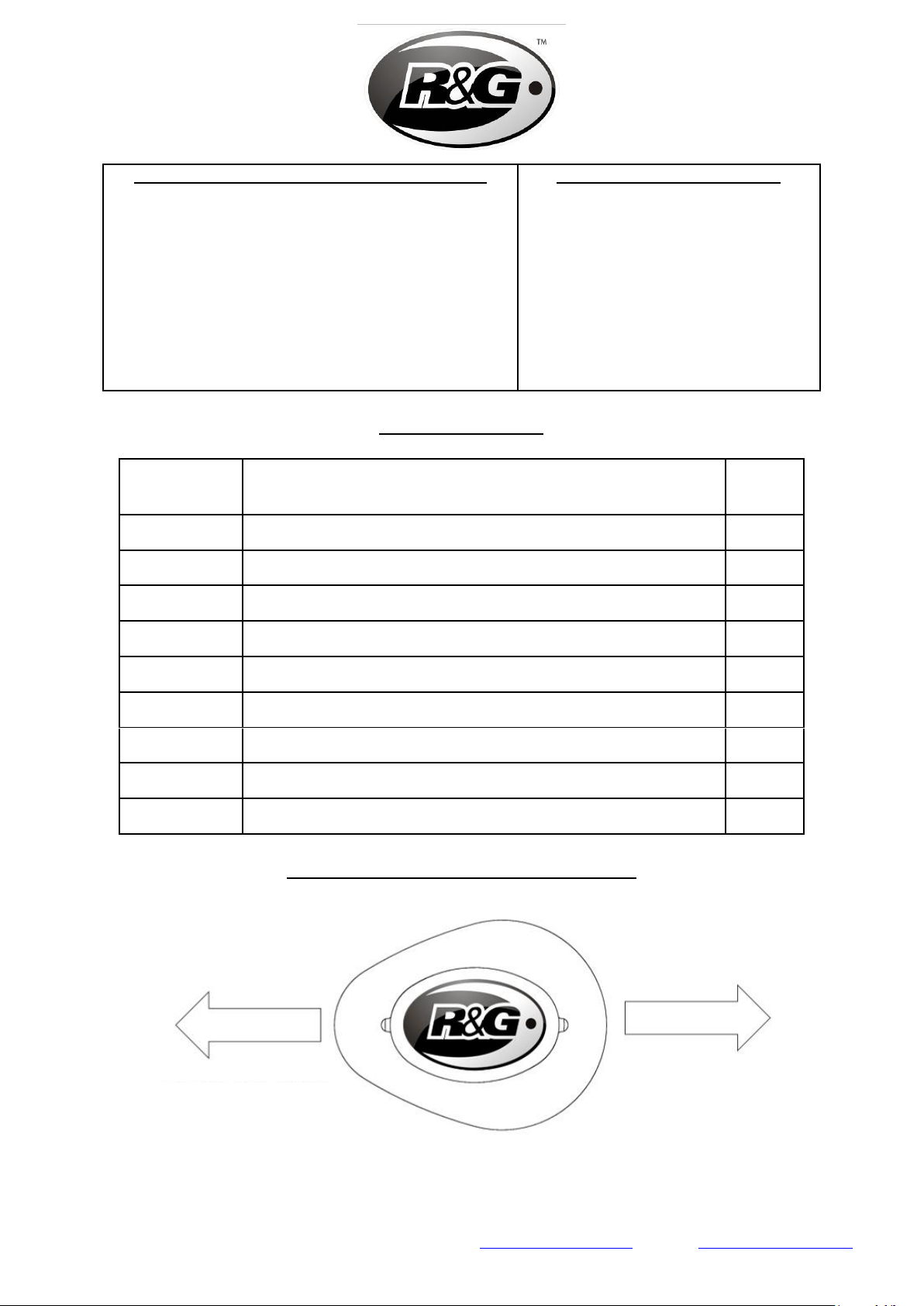

•Répétez le même processus de l'autre côté, en vous assurant que la protection soit orientée

dans le bon sens. Notez que le côté gauche est plus long que le côté droit afin que les bobines

soient positionnées de manière égale sur la moto.

•Une fois terminé, vérifiez les réglages de couple et la position/orientation des protections, puis

poussez les capuchons de protection (ARTICLE2) en place, puis retirez le cric.

ISSUE 1 - 09/09/2021 (WW)

ISSUE 2 –17/09/2021 –8MM ALLEN TOOL CHANGED TO 19MM SOCKET –(WW)

ISSUE 3 –28/09/2021 –NYLOC ERROR CORRECTED –(WW)

CONSUMER NOTICE

The catalogue description and any exhibition of samples are only broad indications of the Products and R&G may make design changes which do

not diminish their performance or visual appeal and supplying them in such state shall conform to the order. The Buyer acknowledges no

representation or warranty (other than as to title) has been given or will apply to the Products other than those in R&G’s order or confirmation and

the Buyer confirms it has chosen the Products as being of merchantable quality and suitable for its particular purposes. Where R&G fits the

Products or undertakes other services it shall exercise reasonable skill and care and rectify any fault free of charge unless the workmanship has

been disturbed. The Buyer is responsible for ensuring that the warranty on the motorcycle is not affected by the fitting of the Products. On return

of any defective Products R&G shall at its option either supply a replacement or refund the purchase money but shall not be liable if the Products

have been modified or used or maintained otherwise than in accordance with R&G’s or manufacturer’s instructions and good engineering practice or

if the defect arises from accident or neglect. Other than identified above and subject to R&G not limiting its liability for causing death and personal

injury, it shall not be liable for indirect or consequential loss and otherwise its liability shall be limited to the amounts paid by the Buyer for the

Products or the fitting or service concerned. These terms do not affect the Buyer’s statutory rights.

R&G RACING RETURNS POLICY (NON-FAULTY GOODS)

Returns must be pre-authorised (if not pre-authorised the return will be rejected). Goods may only be returned direct to us if they were purchased

direct from us (customer must prove if necessary). Otherwise to be returned to original vendor. Goods must be in re-sellable condition, in the

opinion of R&G Racing. All returns are subject to a 25% restocking and handling fee (25% of the gross value exc. P&P –at the prevailing price at

time of purchase). The customer must pay any and all carriage charges. No returns of discontinued products, unless within 14 days of purchase.

This policy does not affect your statutory rights and does not refer to faulty goods.