Reliable Automatic Sprinkler Co., Inc., 103 Fairview Park Drive, Elmsford, New York 10523

Model F3QR56 Dry

K5.6 (80 metric)

Quick-Response,

Standard Spray Sprinklers

Bulletin 157 Rev. M

Bulletin 157 Rev. M

Features

1. Available in the following configurations:

• Pendent with standard escutcheon

• Pendent with Model HB extended escutcheon

• Pendent with Model FP recessed escutcheon

• Pendent with Model F1 recessed escutcheon

• Concealed Pendent with Model CCP cover plate

• Horizontal Sidewall with Standard escutcheon

• Horizontal Sidewall with Model HB extended es-

cutcheon

• Horizontal Sidewall with Model FP recessed es-

cutcheon (FM Standard Response)

• Horizontal Sidewall with Model F1 recessed es-

cutcheon (FM Standard Response)

2. Available with 1” NPT, ISO7-1R1, 3/4” NPT, or ISO7-

1R3/4 inlet fitting.

3. 3/4” NPT inlet fittings permit replacement of older 3/4”

inlet dry sprinklers without changing to a larger sprin-

kler fitting.

4. Sprinklers, escutcheons, and cover plates are avail-

able in a wide variety of standard and special appli-

cation finishes.

5. White polyester, black polyester, and Electroless

Nickel PTFE (ENT) finish sprinklers are cULus Listed

as Corrosion Resistant.

6. Available with cULus Listed 250 psi (17.2 bar) pres-

sure rating for Dry Pendent and select HSW configu-

rations. FM Approved for 175 psi (12 bar).

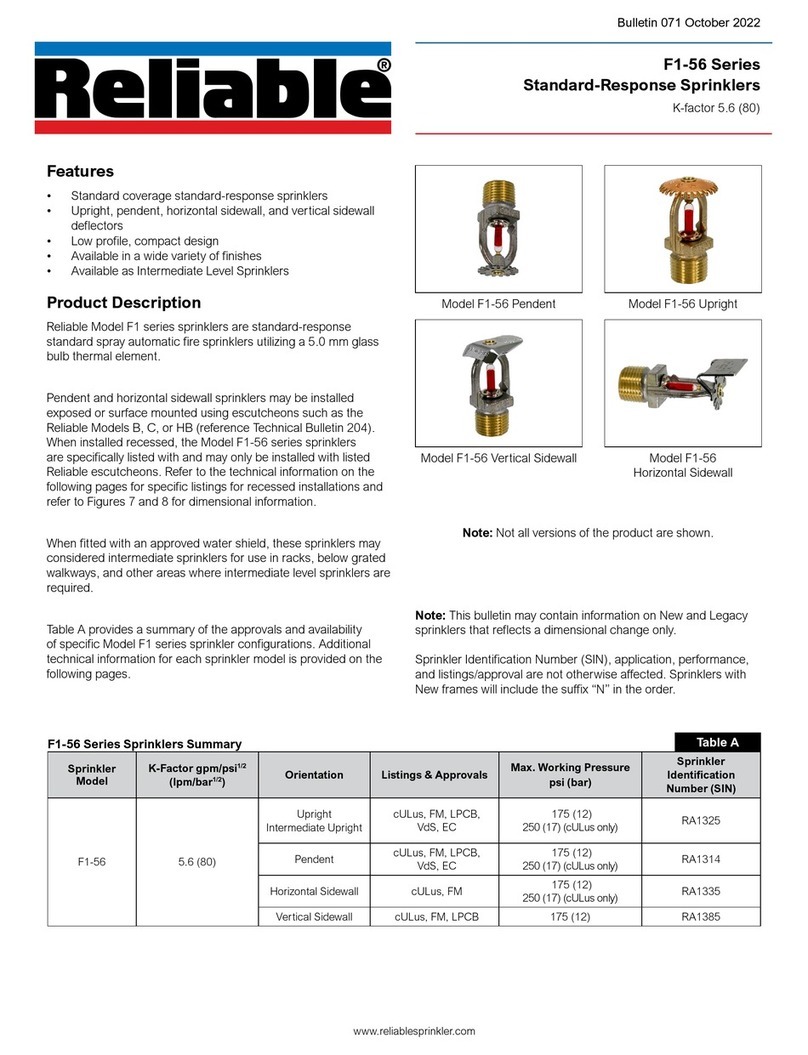

Product Description

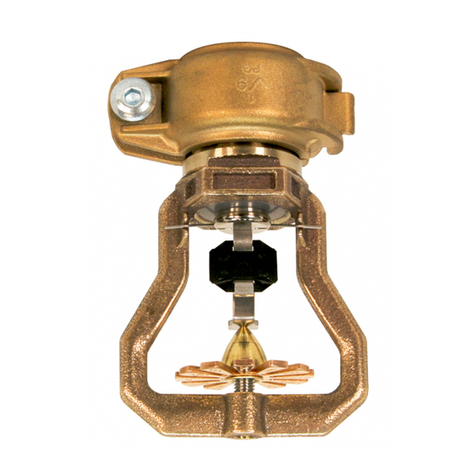

Model F3QR56 Dry sprinklers are quick-response, stan-

dard coverage sprinklers with a nominal K-Factor of 5.6 (80

metric). Available in Dry Pendent or Dry Horizontal Sidewall

configurations, Model F3QR56 Dry sprinklers all use a 3 mm

glass bulb operating element. See the Temperature Rat-

ings table in this Bulletin for available temperature ratings.

Model F3QR56 Dry sprinklers are intended for installation

on wet-pipe, dry-pipe, or preaction sprinkler systems in ac-

cordance with NFPA 13, FM Property Loss Prevention Data

Sheets, and other applicable installation standards.

Model F3QR56 Dry sprinklers are available with a vari-

ety of escutcheon options as illustrated in Figs. 1 through

3 and Figs. 5 through 9. In addition, Model F3QR56 Dry

Pendent sprinklers are also available with the Model CCP

conical concealed cover plate as illustrated in Fig. 4. Avail-

able sprinkler, escutcheon, and cover plate finishes are

identified in the Finishes table in this Bulletin. The Model F1

escutcheon, Model FP escutcheon, and Model CCP cover

plate are the only recessed escutcheons and cover plate

listed for use with Model F3QR56 Dry sprinklers; the use of

any other recessed escutcheon or cover plate with Model

F3QR56 Dry sprinklers will void all guarantees, warranties,

listings and approvals.

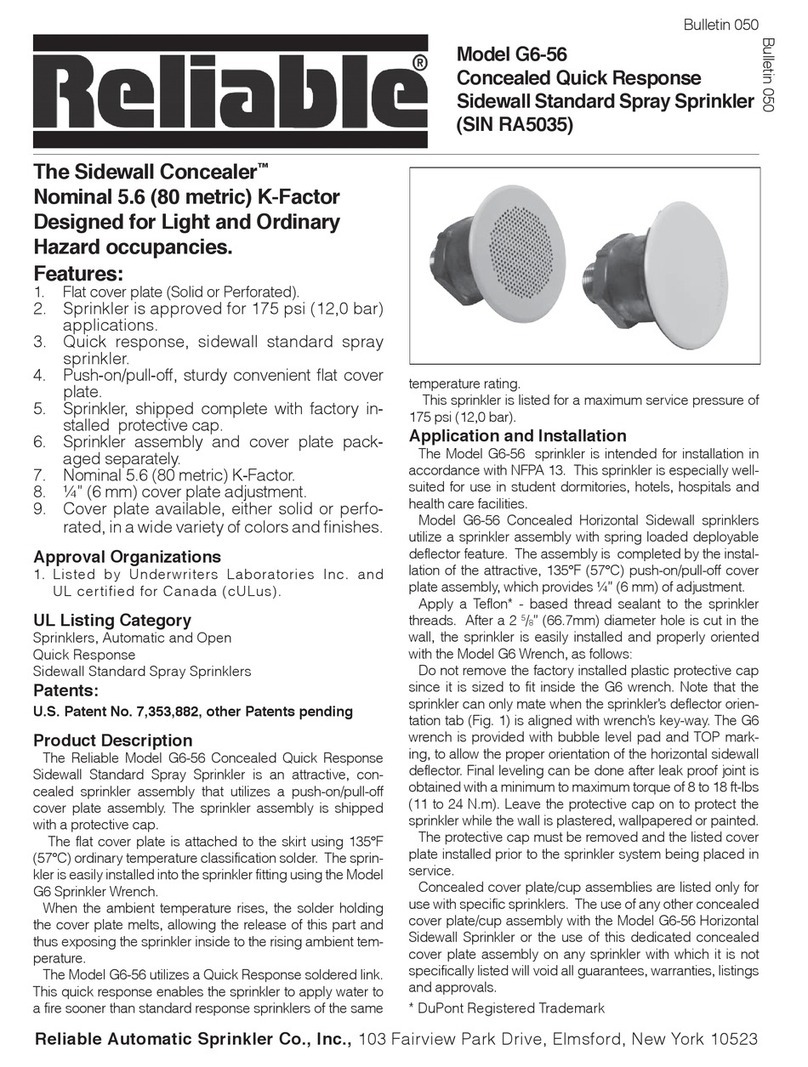

Concealed

(See Fig. 4)

Recessed FP Pendent

(See Fig. 3)

Recessed F1

Horizontal Sidewall

(See Fig. 9)

Horizontal Sidewall

(See Fig. 6)

Pendent

(See Fig. 1)

Recessed F1 Pendent

(See Fig. 5)

Recessed FP

Horizontal Sidewall

(See Fig. 8)

Pendent / HB

(See Fig. 2)

Horizontal Sidewall / HB

(See Fig. 7)