Reliable Automatic Sprinkler Co., Inc., 103 Fairview Park Drive, Elmsford, New York 10523

Bulletin 136 December 2020

Bulletin 136 December 2020

Model F1FR LO

K8.0 (115 metric)

Quick Response

Sprinklers

Model F1FR LO Sprinkler Types

Standard Spray Upright

Standard Spray Pendent

Conventional

Model F1FR LO Recessed Sprinkler Types

Recessed Standard Spray Pendent

For Model F1FR ½” K 5.6 (80), 4.2 (60) & 2.8 (40) Sprinkler

Types refer to Bulletin 014 for technical specications and

approvals.

Listings & Approvals

1. Listed by Underwriters Laboratories, Inc. (UL)

2. Listed by Underwriters’ Laboratories of Canada (ULC)

3. Factory Mutual Approvals (FM)

4. Loss Prevention Council (LPCB, UK)

5. Verband der Schadenversicherer Gmbh

6. EC Certicate: 1438-CPR-0049 (R3612)

1438-CPR-0048 (R3622)

1438-CPR-0047 (R3672)

UL Listing Category

Sprinklers, Automatic & Open

Quick Response Sprinkler

ULGuide Number

VNIV

Product Description

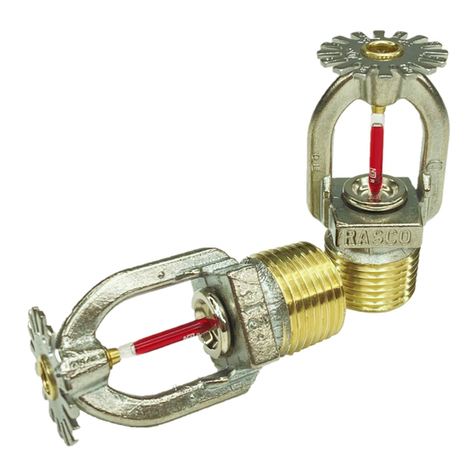

Reliable Models F1FR LO and F1FR LO Recessed Sprinklers

are quick response sprinklers which combine the durability of a

standard sprinkler with the attractive low prole of a decorative

sprinkler.

The Models F1FR LO and F1FR LO Recessed automatic

sprinklers utilize a 3.0 mm frangible glass bulb. These sprinklers

have demonstrated response times in laboratory tests which

are ve to ten times faster than standard response sprinklers.

This quick response enables the Model F1FR LO and F1FR LO

Recessed sprinklers to apply water to a re much faster than

standard sprinklers of the same temperature rating.

The glass bulb consists of an accurately controlled amount

of special fluid hermetically sealed inside a precisely manufac-

tured glass capsule. This glass bulb is specially constructed to

provide fast thermal response. The balance of parts are made

of brass, copper and beryllium nickel.

At normal temperatures, the glass bulb contains the fluid in

both the liquid and vapor phases. The vapor phase can be seen

as a small bubble. As heat is applied, the liquid expands, forcing

Upright

the bubble smaller and smaller as the liquid pressure increases.

Continued heating forces the liquid to push out against the bulb,

causing the glass to shatter, opening the waterway and allowing

the deflector to distribute the discharging water.

The temperature rating of the sprinkler is identied by the

color of the glass bulb.

Application

Quick response sprinklers are used in xed re protection

systems: Wet, Dry, Deluge or Preaction. Care must be exer-

cised that the orice size, temperature rating, deflector style

and sprinkler type are in accordance with the latest published

standards of the National Fire Protection Association or the ap-

proving Authority Having Jurisdiction. Quick response sprin-

klers are intended for installation as specied in NFPA 13, FM

Global Loss Prevention Data Sheet 2-0 or other applicable

standards. Quick response sprinklers and standard response

sprinklers should not be intermixed.

Installation

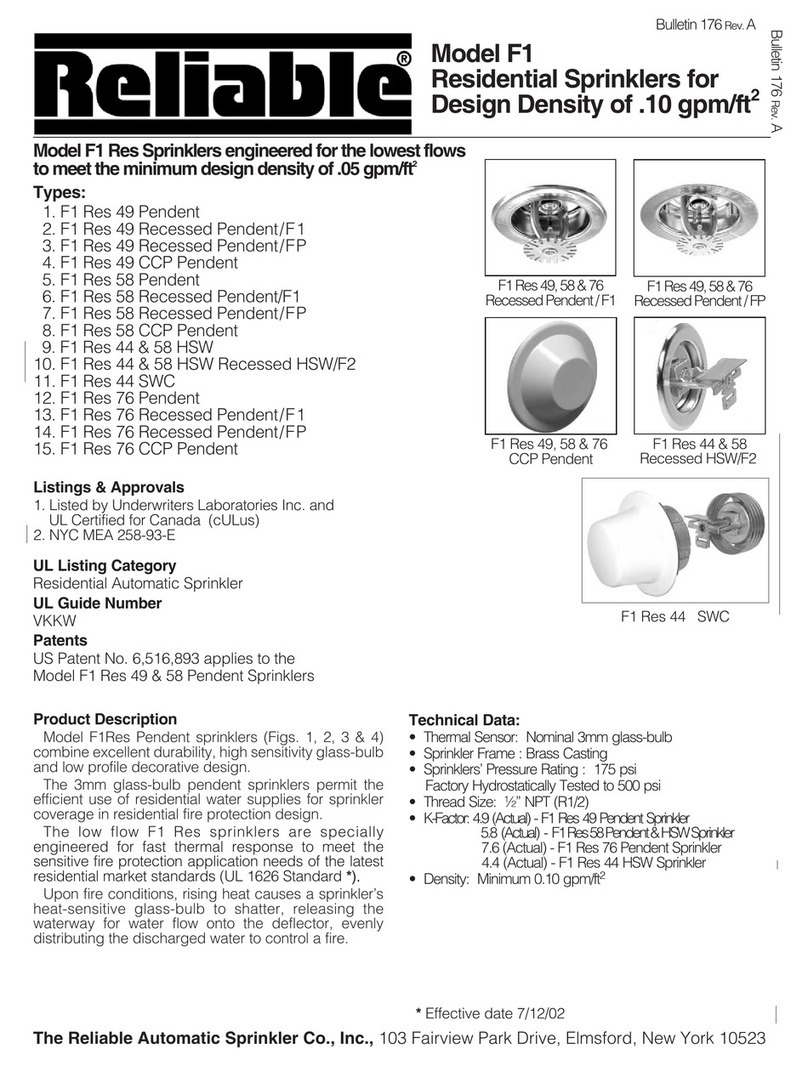

The Model F1FR LO Recessed Quick Response Sprinklers

are to be installed as shown. The Model F1 or F2 Escutcheons

illustrated are the only recessed escutcheons to be used with

the Model F1FR LO Sprinklers. The use of any other recessed

escutcheon will void all approvals and negate all warranties.

When installing Model F1FR LO Sprinklers, use the Model D

Sprinkler Wrench or Model W2 Sprinkler Wrench. When install-

ing Model F1FR LO Recessed Pendent or Sidewall Sprinklers,

use the Model GFR2 Sprinkler Wrench. Any other type of

wrench may damage these sprinklers.

Pendent

Conventional Recessed Pendent

(Model FP Shown)