2.

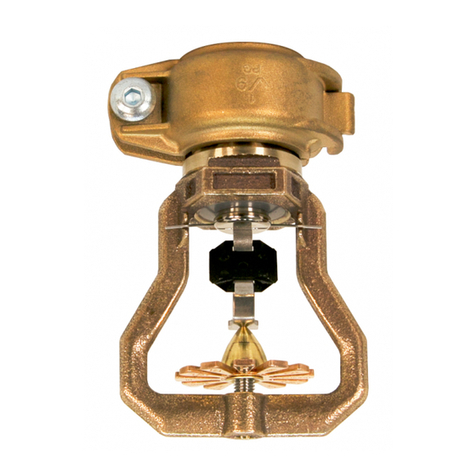

Operation

The Reliable Model N252 Extended Coverage Pendent

Control Mode Specific Application Storage Sprinklers

utilize a levered fusible alloy solder link. When the rated

temperature is reached, the solder melts and the two link

halves separate allowing sprinkler to operate and water

to flow.

FM Approved for the following:

1. Application: These FM Approved extended cover-

age CMSA automatic sprinklers may be used to pro-

tect Class 1 through 4, cartoned unexpanded plastic

commodities under ceilings up to and including 35

ft (10.7 m) high. They may be used to protect any

storage arrangement outlined in Data Sheet 8-9,

however portable racks must meet the guidelines re-

quired to be considered open-frame racks. Maintain

a minimum clearance of 3 ft (0.9 m) between the top

of storage and the sprinkler deflector.

Temperature Rating - The Reliable Model N252 EC

sprinkler is available in nominal temperature ratings

of either 165 °F (70 °C) or 212°F (100°C). Use the

nominally rated 165°F (70°C) sprinkler for all accept-

able applications unless the ambient temperature of

the protected occupancy requires the temperature

rating to be 212°F (100°C).

2. Hydraulic Design: Base the design for these auto-

matic sprinklers as follows:

Solid-Piled, Palletized, Shelf or Bin-Box and Open-

Frame Racks: See table 1

Storage Racks Equipped With Solid Shelves: Base

the design of the ceiling sprinkler system as outlined

above for open-frame racks, however base the need

for, as well as the design of, in-rack sprinkler protec-

tion the same as what is required for K16.8 (K240)

CMSA sprinklers.

Shape of Operating Area: Base the shape of the op-

erating area on a 1.2 shape factor for ceiling slopes

up to 5° or a 1.4 shape factor for ceilings having a

higher slope (up to 10° maximum).

3. System Type: Wet-pipe sprinkler systems or pre-

action sprinkler systems, whose sprinkler protection

design can be based on the equivalent of a wet-pipe

system, are acceptable.

4. Sprinkler Spacing: The minimum and maximum lin-

ear distances between sprinklers. are 10 ft (3.1 m)

and 14 ft (4.2 m), respectively for ceiling heights up

to and including 30 ft (9.0 m); for ceiling heights over

30 ft (9.0 m) and up to 35 ft (10.7 m) the maximum

linear spacing of the sprinkler is reduced to 12 ft (3.6

m), The minimum and maximum area of coverage

per sprinkler is 100 ft2(9 m2) and 196 ft2(18 m2), re-

spectively for ceiling heights up to and including 30

ft (9.0 m); for ceiling heights over 30 ft (9.0 m) and

up to 35 ft (10.7 m) the maximum area spacing of the

sprinkler is reduced to 144 ft2(13.5 m2).

5. Sprinkler Location from Walls: Locate the automat-

ic sprinklers with respect to walls, measured perpen-

dicular to the wall, as follows:

Minimum Horizontal Distance: 4 in. (100 mm)

Maximum Horizontal Distance unless indicated oth-

erwise in either the occupancy-specific data sheet or

the Approval Guide:

a. Wall Angle Greater Than 90°: 7 ft (2.1 m) for

ceilings up to 30 ft (9.0 m) high or 6 ft (1.8 m)

for ceilings over 30 ft (9.0 m) and up to 35 ft

(10.7 m) high.

b. Wall Angle Equal to or Less Than 90°: 10 ft

(3.0 m) for ceilings up to 30 ft (9.0 m) high or

8 ft (2.4 m) for ceilings over 30 ft (9.0 m) and

up to 35 ft (10.7 m) high.

6. Sprinkler Location from Ceilings: Locate the au-

tomatic sprinklers with respect to ceilings in accor-

dance with Data Sheet 2-0. However, the minimum

vertical distance below a ceiling can be reduced to

2 in. (50 mm) for smooth ceilings or 4 in. (100mm) for

non-smooth ceilings.

7. Obstructions: Use the obstruction guidelines out-

lined in D.S. 2-0 for extended coverage automatic

sprinklers in regards to the umbrella pattern. In ad-

dition, use the obstruction guidelines outlined in D.S.

2-0 for pendent automatic sprinklers in regards to

obstructions located below the automatic sprinkler,

except that an individual object up to a maximum

width of 1.25 in; (31 mm) can be tolerated less than

12 in. (300 mm) horizontally away from the sprinkler

as long as the object is located at least16 in. (400

mm) vertically below the sprinkler.

All other design details should be in accordance with

Data Sheet 8-9. All other installation details should be

in accordance with Data Sheet 2-0.

8. FM Global considers this a “Quick Response” Ex-

tended Coverage Sprinkler for use in Data Sheet 8-9.

9. For installations governed by NFPA #13 (2013), the

N252EC fire sprinkler meets the definition of Control

Mode Specific Application (CMSA) Sprinklers and is

approved for installation under chapter 21. Section

3.6.4.1. Section 8.11.1.1 states that CMSA sprinklers

shall be installed in accordance with Section 8.5 and

the manufacturer’s installation instructions.