The Reliable Automatic Sprinkler Co., Inc.

(800) 431-1588 Sales Offices

(800) 848-6051 Sales Fax

(914) 829-2042 Corporate Offices

www.reliablesprinkler.com Internet Address

Manufactured by

Recycled

Paper

Revision lines indicate updated or new data.

EG. Printed in U.S.A 05/12 P/N 9999970014

The equipment presented in this bulletin is to be installed in accordance with the latest published Standards of the National Fire Protection Association, Factory

Mutual Research Corporation, or other similar organizations and also with the provisions of governmental codes or ordinances whenever applicable.

Productsmanufactured and distributed by Reliable have been protecting life and property for over 90 years, and are installed and serviced by the most highly

qualified and reputable sprinkler contractors located throughout the United States, Canada and foreign countries.

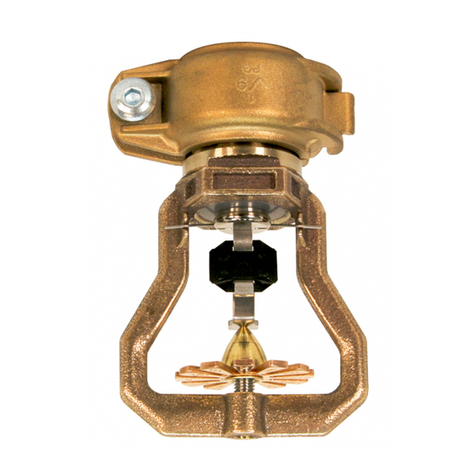

Installation

Do not install The Concealer®in ceilings which have posi-

tive pressure in the space in the space above.

After a 25/8inch diameter hole is cut in the ceiling, the sprin-

kler is to be installed with the Model G4 Wrench. The wrench

has drive tangs which insert into cup slots. When installing

a sprinkler the wrench is first positioned into the sprinkler/

cup assembly until the wrench tangs engage drive slots in

the top of the cup (there are two sets of mating drive slots in

the cup). The sprinkler is then tightened into the pipe fitting.

When inserting or removing the wrench from the sprinkler/

cup assembly care should be taken to prevent damage to

the sprinkler. DO NOT WRENCH ON ANY OTHER PART OF

THE SPRINKLER/CUP ASSEMBLY.

The adjustable inlet versions are similar to the standard

Model G4 except that an addition 1” (25mm) of adjustment is

provided by means of a telescoping inlet section that threads

in or out of a stationary coupling reducer (either 1 male or 1

female) as shown in Fig. 2 or Fig. 3. These sprinklers must be

installed before the ceiling is in place, by wrenching on only

the coupling reducer hex flats. After the ceiling has been in-

stalled with holes for the sprinkler, each telescoping inlet sec-

tion is to be adjusted with the G4 Wrench. Install the cover

plate assembly by hand turning it clockwise until it is tight

against the ceiling.

Maintenance

The Model G4 Concealer®should be inspected quarterly

and the sprinkler system maintained in accordance with

NFPA 25. Do not clean sprinklers with soap and water, am-

monia or any other cleaning fluids. Remove any sprinkler that

has been painted (other than factory applied) or damaged in

any way. A stock of spare sprinklers should be maintained

Temperature Ratings

Classification Sprinkler Cover Plate Max. Ambient

Temp.

Ordinary 135°F/57°C 135°F/57°C 100°F/38°C

Ordinary 165°F/74°C 135°F/57°C 100°F/38°C

Ordinary 165°F/74°C 165°F/74°C 150°F/66°C

Intermediate 212°F/100°C 165°F/74°C 150°F/66°C

Installation Data

Sprinkler

Inlet

Total

Adjustment

Nominal

Orifice

Nominal

K Factor Thread Approvals

Sprinkler

Identification

Number (SIN)

US Metric

Non–Adjustable ½” (13mm) ½” (15mm) 5.6 80 ½” NPT (R½) 1,2,3 R2115

Non–Adjustable ½” (13mm) 7

/

16”(11mm) 4.2 60 ½” NPT (R½) 1,2,3 R2113

Non–Adjustable ½” (13mm) 3

/

8” (10mm) 2.8 40 ½” NPT (R½) 1,2,3 R2111

Adjustable 1½” (38mm) ½” (15mm) 5.6 80 1” NPT Male or Female 1,2,3 R2118

Adjustable 1½” (38mm) 7

/

16” (11mm) 4.2 60 1” NPT Male or Female 1,2,3 R2113

Adjustable 1½” (38mm) 3

/

8” (10mm) 2.8 40 1” NPT Male or Female 1,2,3 R2112

Cover Plate Finishes(1)

Standard Finishes

Chrome

White Paint

Special Application

Finishes(2)

Bright Brass

Finished Bronze

Black Plating

Black Paint

Off White

Satin Chrome

(1) Other finishes and colors

are available on special

order. Consult factory for

details. Coverplate custom

paint is semi-gloss, unless

specified otherwise.

(2) For the perforated style

coverplate, consult factory

for availability on these

and other custom finishes.

Note: Paint or any other coat-

ings applied over the factory

finish will void all approvals

and warranties.

Installation Wrench

Model G4 Sprinkler Wrench

to allow quick replacement of

damaged or operated sprin-

klers. Prior to installation, sprin-

klers should be maintained in

the original cartons and pack-

aging to minimize the potential

for damage to sprinklers that

would cause improper opera-

tion or non-operation.

Ordering Information

1. Sprinkler Model

2. Temperature Rating

3. Nominal Orifice

4. Flat Cover Plate Finish

5. Inlet Type

Note: Unless otherwise specified,

the 165°F (74°C) sprinkler will

be provided with the 165°F

(74°C) cover.

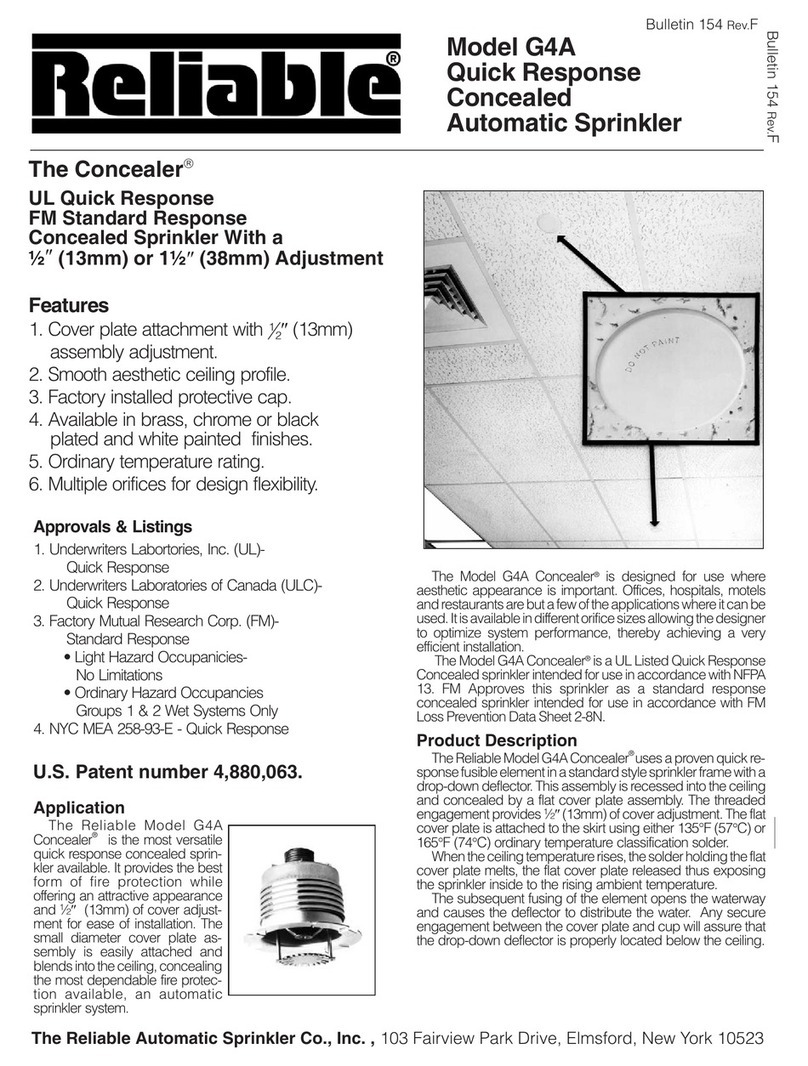

Fig. 1 - ½” NPT (R½) Non-Adjustable Inlet Fig. 2 - 1” NPT Male-Adjustable Inlet Fig. 3 - 1” NPT Female-Adjustable Inlet