The Reliable Automatic Sprinkler Co., Inc., 103 Fairview Park Drive, Elmsford, New York 10523

Bulletin 018 Rev. E

Bulletin 018 Rev. E

Model JL-14 (SIN RA1812)

Early Suppression

Fast Response Sprinkler

Product Description

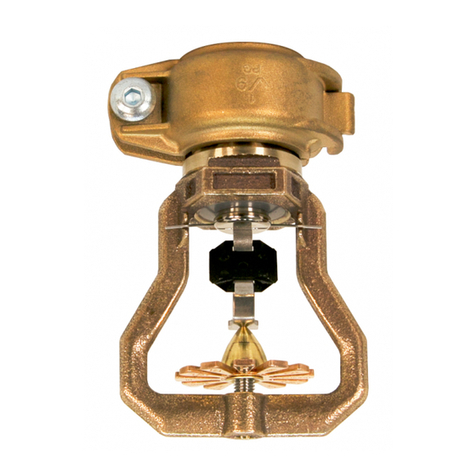

The Reliable Model JL-14 Early Suppression Fast

Response (ESFR) Sprinkler is intended for use against

severe fire challenges. This sprinkler is designed to re-

spond quickly to growing fires and will deliver a heavy

water discharge to “suppress” rather than “control”

fires.

Note: The Model JL-14 ESFR sprinkler utilizes a le-

vered fusible alloy solder link in either a 165°F (74°C)

or a 212°F (100°C) rating. FM Global considers this

a “Quick Response” storage sprinkler for use in Data

Sheet 8-9.

The sprinkler has a Nominal K Factor of 14.0 (metric

202) and will deliver approximately 100 gpm (378 L/min)

of water at 50 psi (3,5 bar).

The deflector and frame provide a broad, very sym-

metrical, hemispherical pattern capable of suppressing

fires between sprinklers in high storage height areas

and at the same time retaining a high momentum cen-

tral core to penetrate and suppress fires occurring di-

rectly beneath the sprinkler in low storage height areas.

Application and Installation

The Model JL-14 ESFR sprinkler is intended for instal-

lation in accordance with NFPA 13 and FM Loss Pre-

vention Data Sheets 2-0 and 8-9 as well as the Authority

Having Jurisdiction.

This sprinkler is intended for protection of palletized

and solid piled and open frame single row, double row,

multiple row and portable rack storage of most com-

mon materials including unexpanded and cartoned ex-

panded plastics.

The JL-14 ESFR sprinkler was designed to be short-

er, and more compact than other ESFR sprinklers. The

shorter sprinkler allows piping to be installed further

from the ceiling and obstructions. The JL-14 ESFR

sprinkler is also less susceptible to damage due to

smaller deflector and frame design. The lighter JL-14

ESFR passed rough use and abuse test in the labs with-

out plastic protectors.

The Model JL-14 ESFR Sprinkler is FM approved

[165°F (74°C) and 212°F (100°C) temperature ratings

only] when installed in accordance with Factory Mutual

Loss Prevention Data Sheet 8-9 and Data Sheet 2-0 and

other FM Installation Standards.

The Model JL-14 ESFR Sprinkler is UL Listed and Cer-

tified for Canada (all ratings) for installation in accor-

dance with NFPA 13 Standards.

Model JL-14 ESFR Sprinkler

Design Criteria

General guidelines:

Sprinkler Position: Pendent, align frame arms with

the pipe. Deflectors should be parallel with the ceiling

or roof.

System Type: Wet Pipe Systems Only

Maximum area of coverage: 100 ft2(9,3m2), greater

coverage area are allowable in some cases.

Minimum area of coverage: 64 ft2(5,8m2)

Maximum slope ceiling: 2/12 pitch (9.5°)

Maximum spacing: 12 ft (3,7m) for building heights up

to 30 ft (9,1m) and 10 feet (3,1m) for building heights

greater than 30 ft (9,1m)

Minimum spacing: 8 feet (2,4m)

Deflector distance from walls: At least 4 inches

(102mm) from walls, and no more than one-half the al-

lowable distance permitted between sprinklers.

Deflector to Top of Storage: at least 36in (914mm).

Deflector to ceiling Distance: 6-14 in (152-356mm)

per NFPA 13. 5-14 in (121-35mm) per FM 2-2.

Center Line of Thermal Sensing

Element To Ceiling Distance: 4-13 in (102-330mm)

per FM

Listings and Approvals

1. Listed by Underwriters Laboratories Inc. and UL cer-

tified for Canada (cULus)

2. FM Approved as a storage sprinkler

3. VdS Schadenverhütung GmbH (VdS)

4. Loss Prevention Certification Board (LPCB)