IF.PUG.001 R3

PRODUCT CONTENTS

Package includes the following:

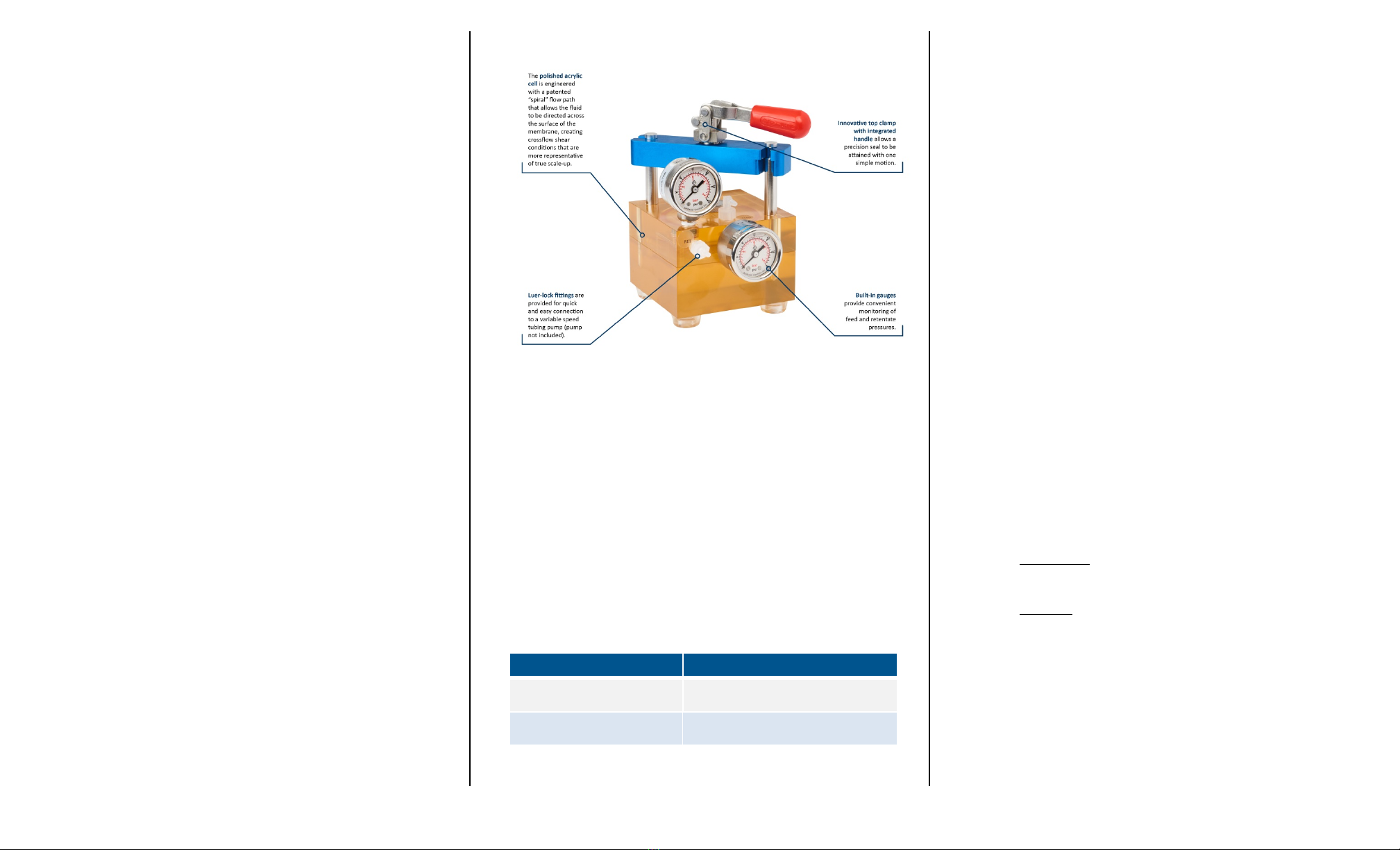

•Membrane holder (cell)

oPolished Acrylic (Cat # TX001)

oPolished Polysulfone (Cat # TX 068)

•Tie Rods: 316L stainless steel

•Integrated top clamp: 316L stainless steel

•Membrane support: polypropylene screen

HOLDER SPECIFICATIONS

Holder Dimensions:

Width: 4.1” (10.4 cm)

Depth: 6” (15.2 cm)

Height:

•With handle lowered: 5.4” (13.7 cm)

•With handle raised: 8” (20.3 cm)

•Shipping Weight: 5 lbs. ( kg)

Membrane Diameter: 76mm

Effective Membrane Area: 30cm2

Pump Requirements:

Variable speed tubing pump

RPM: 10-600

Flow rate: 50-200 mL/min

MEMBRANE INSTALLATION

1. Open the integrated stainless steel clamp by lifting the colored handle.

Remove the clamp yoke by twisting it counter-clockwise and sliding it off

the guide-pins.

2. Lift the upper manifold off the base by sliding it up and over the guide-

pins.

3. Rinse the polypropylene membrane support screen with deionized (DI)

water or water for injection (WFI). Place it flat against the bottom

manifold; ensure that the screen is sitting flat in the manifold.

4. Obtain a 76mm membrane disc. Rinse the membrane disc with DI water

or WFI. Place it flat against the bottom manifold; ensure that the

membrane is flat on the membrane support screen and manifold.

5. Replace the upper manifold on the base by sliding it down over the guide-

pins.

6. Replace the clamp yoke by twisting it clockwise and sliding it onto the

guide-pins. Close the integrated stainless steel clamp by depressing the

colored handle.

7. Attach a piece of #16 tubing, approximately 18’ in length, to the feed

barb located in the center of the top manifold.

8. Attach a piece of #16 tubing, approximately 10’ in length, to the retentate

barb located on the left front of the top manifold. Also place a small

tubing clamp in the middle of the tubing attached to the retentate.

9. Attach a piece of #16 tubing, approximately 10’ in length, to the filtrate

barb located in the center of the lower manifold.

10. Thread the tubing attached to the feed through the head of a peristaltic

pump.

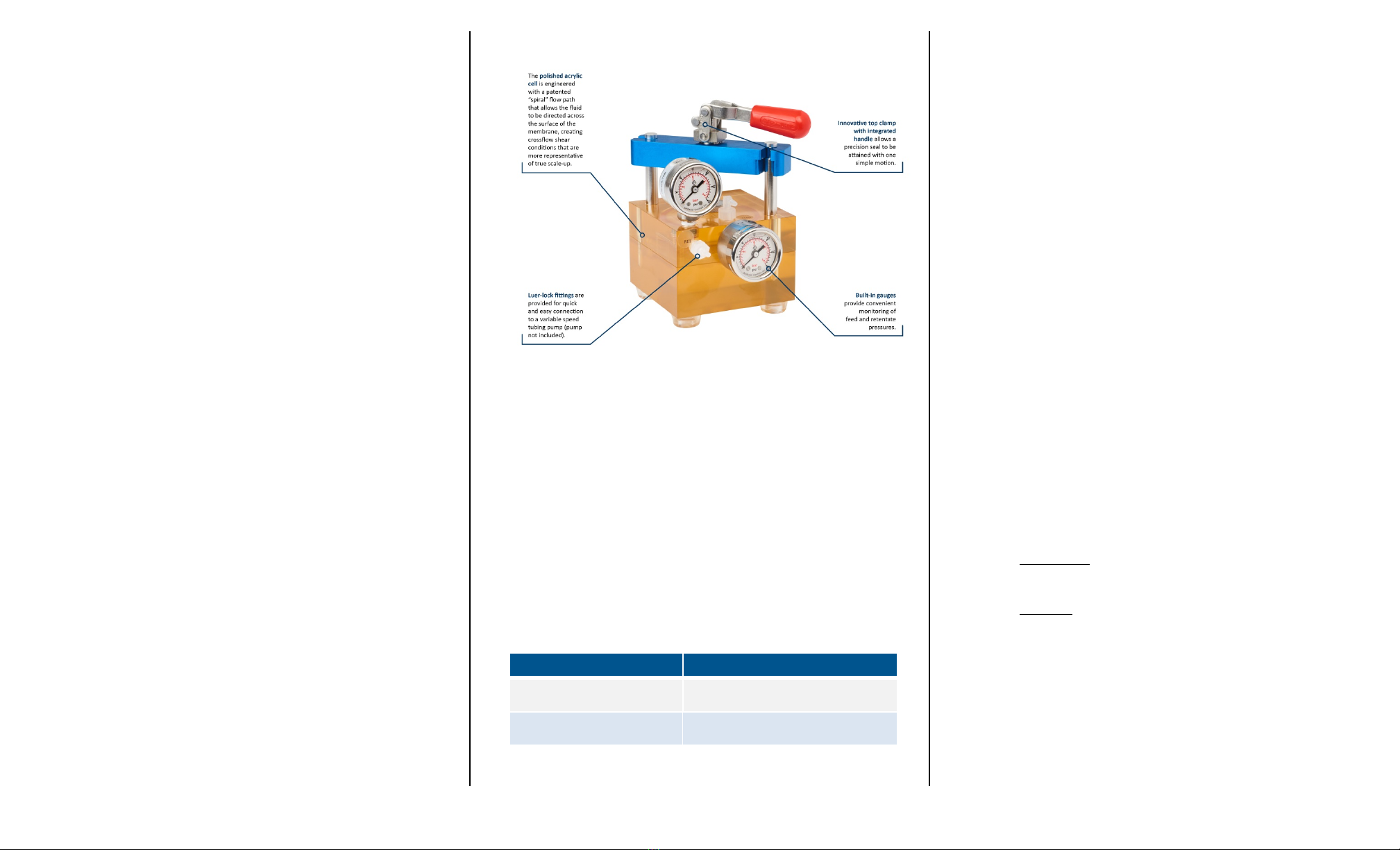

DEVICE DIAGRAM

FIRST TIME USE OF DEVICE

Once the membrane is installed, the device should be flushed with DI

water or WFI to ensure removal of the storage and preservative agents

from the membrane and to minimize any possible interaction with your

particular application. It is critical to use the highest quality water possible

to avoid fouling the membrane or introducing contaminants into the

system that could affect membrane performance and product recovery.

For some applications, further sanitization is required.

CLEANING OF DEVICE

The X-Flo76 device must be cleaned properly prior to reuse. To clean,

flush the device with a recommended cleaning solution from Table 2. Use

a minimum of 0.2 liters of cleaning solution. Upon completion of the

cleaning cycle, flush the device with buffer, WFI, or DI water prior to

storing.

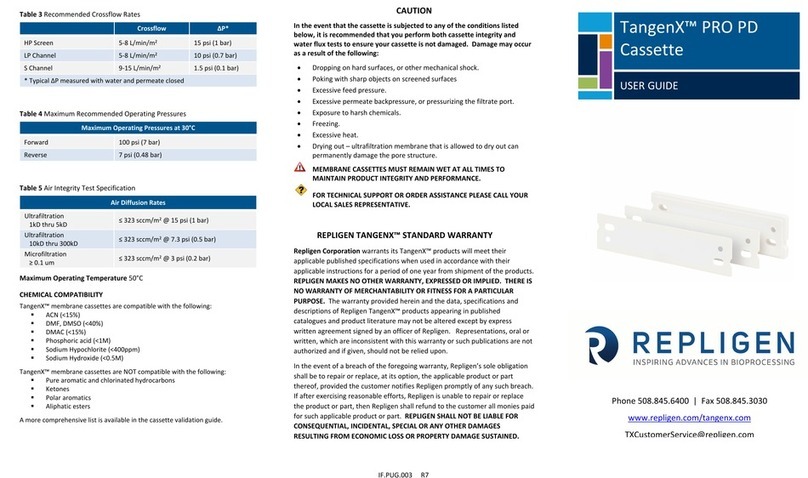

Recommended Cleaning Solutions

Cleaning Agent Cleaning Conditions

0.1N to 0.5N Sodium

Hydroxide

Contact Time = 30 – 60 minutes

Temperature = 35°C (95°F)

1.5% Alconox® Detergent

Contact Time = 30 – 60 minutes

Temperature = 40°C (104°F)

MEMBRANE DISC STORAGE

A membrane disc must be stored wet to maintain its performance

characteristics and integrity and prevent microbial growth. Below are

critical factors to remember when storing a membrane disc in the

X-Flo76TM device:

•To store a membrane disc greater than 2-4 weeks, remove disc from

the device and store separately in an appropriate storage agent.

•A membrane disc stored in the device should be flushed with fresh

storage agent approximately every 2 weeks. Contact the membrane

manufacturer for a list of appropriate storage agents.

•Recommended PH ranges:

o2 - 13, long-term (storage)

o1 - 14, short-term (cleaning)

•Recommended storage temperature:

o4°C - 15°C (optimal)

o25°C (maximum)

oDo not freeze device

MEMBRANE OPERATING CHARACTERISTICS

Take care to use the membrane at the lowest pressure possible while still

producing consistent permeate flow. Although higher operating pressures

initially improve flow rate, it also promotes increased concentration

polarization and membrane compaction, which ultimately limit flow. With

very low nominal molecular weight limit (NMWL) membranes, lower

operating pressure may also reduce the retention of salts and very low

molecular weight species.

•Recommended cross flow rates for processing are given below for

the device.

Flow rate: 50-200 mL/min

•Typical recommended operating pressures are given below for

normal use and cleaning conditions.

NORMAL USE

NMWL < 100 kDa 1.7 – 2.8 bar (25 – 40 psi)

NMWL ≥ 100 kDa - 0.6um 1.4 bar (20 psi)

CLEANING

NMWL < 100 kDa < 0.5 bar (7 psi)

NMWL ≥ 100 kDa - 0.6um < 0.5 bar (7 psi)

•Operating Temperature Limit

50°C