7

en

The DIP switches (A) can be used for activating (ON) or deactivating (OFF) the

following functions:

• Manual mode (DIP switch 1)

• Maximum temperature limitation (DIP switch 2)

• Antifreeze function (DIP switch 3)

• Minimum temperature limitation (DIP switch 4)

With the potentiometre on the left-hand side (E), the switch-on temperature dif-

ference can be adjusted (in K).

With the potentiometre on the right-hand side (D), the minimum speed of the HE

pump can be adjusted, see chap. 3.8 on page 8.

With the lower potentiometre (C), the temperature for the maximum or minimum

temperature limitation can be adjusted (in °C).

With the jumper (B), the PWM profile of the output signal (solar or heating) can

be selected.

Note

Pump speed control is only possible if a HE pump with a PWM input is

used.

3.3 Switch-on temperature difference

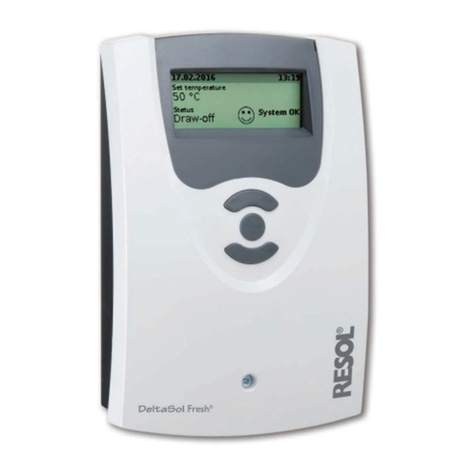

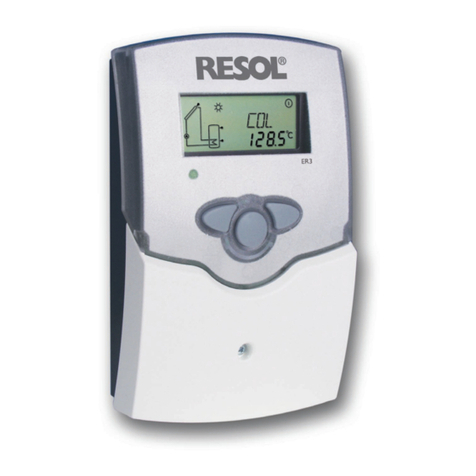

EThe controller calculates the temperature difference

between the temperature sensors S1 and S2. If the dif-

ference is larger than or identical to the switch-on val-

ue adjusted with the potentiometer E, the relay will be

switched on.The operating control LED flashes green.

If the temperature difference falls below the set value

by 1.6 K (non adjustable hysteresis), the controller de-

activates the relay.

For commissioning or maintenance work, the relay

can be permanently energised by means of the manual

mode.The manual mode can be activated or deactivated

respectively with DIP switch 1. If the manual mode is

active, the operating control lamp flashes red and green.

3.4 Manual mode

3.5 Maximum temperature limitation

With DIP switch 2, the temperature limitation can be

activated as a maximum temperature limitation. The

limit temperature can be adjusted by means of the po-

tentiometer C.The sensor connected to the terminals

S2 is used as the reference sensor. If the store tem-

perature reaches the adjusted maximum temperature,

the store will no longer be loaded in order to avoid

damage caused by overheating. If the store tempera-

ture exceeds the maximum value, the operating con-

trol lamp flashes red.

3.6 Antifreeze function

With DIP switch 3, the antifreeze function can be acti-

vated.The antifreeze function activates the loading cir-

cuit between the collector and the store when the col-

lector temperature falls below +4°C.This will protect

the fluid against freezing or coagulating. If the tempera-

ture at S1 reaches +5 °C, the pump will be switched off.

When the antifreeze function is active, the operating

control lamp flashes quickly.

Adjustment range: 2 … 16 K

Factory setting: 6 K

Activated by default

(DIP switch in ON position)

Adjustment range: 20 … 90 °C

Factory setting: 60 °C

Deactivated by default

(DIP switch in OFF position)

Note

Since this function uses the limited heat quantity of the store, the anti-

freeze function should be used in regions with few days of temperatures

around the freezing point.

Deactivated by default

(DIP switch in OFF position)

Controller in automatic mode

C

A

A

A