Rice Lake 1280 Enterprise Series User manual

Other Rice Lake Accessories manuals

Rice Lake

Rice Lake iDimension Plus Manual instruction

Rice Lake

Rice Lake 880 Performance Series User manual

Rice Lake

Rice Lake iDimension 100XL User manual

Rice Lake

Rice Lake RL1800 Series User manual

Rice Lake

Rice Lake 590 AG User manual

Rice Lake

Rice Lake IQ plus 390-DC User manual

Rice Lake

Rice Lake IQ plus 210 User manual

Rice Lake

Rice Lake MSI-8000HD User manual

Rice Lake

Rice Lake IQ plus 710 User manual

Rice Lake

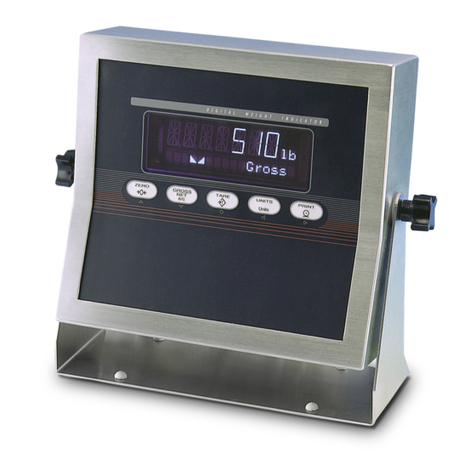

Rice Lake IQ plus 510 Guide

Rice Lake

Rice Lake IQ plus 590-DC Parts list manual

Rice Lake

Rice Lake 882D User manual

Rice Lake

Rice Lake 820i User manual

Rice Lake

Rice Lake iRite 920i User manual

Rice Lake

Rice Lake iRite 920i User manual

Rice Lake

Rice Lake MSI-3460 Challenger 3 User manual

Rice Lake

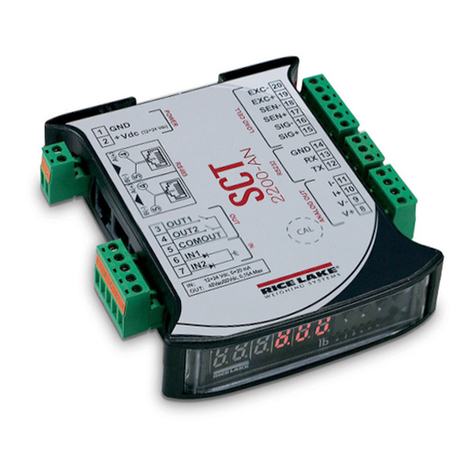

Rice Lake SCT-2200 User manual

Rice Lake

Rice Lake CLS420 User manual

Rice Lake

Rice Lake 880 Performance Series User manual

Rice Lake

Rice Lake 1280 Enterprise Series Operating and maintenance instructions