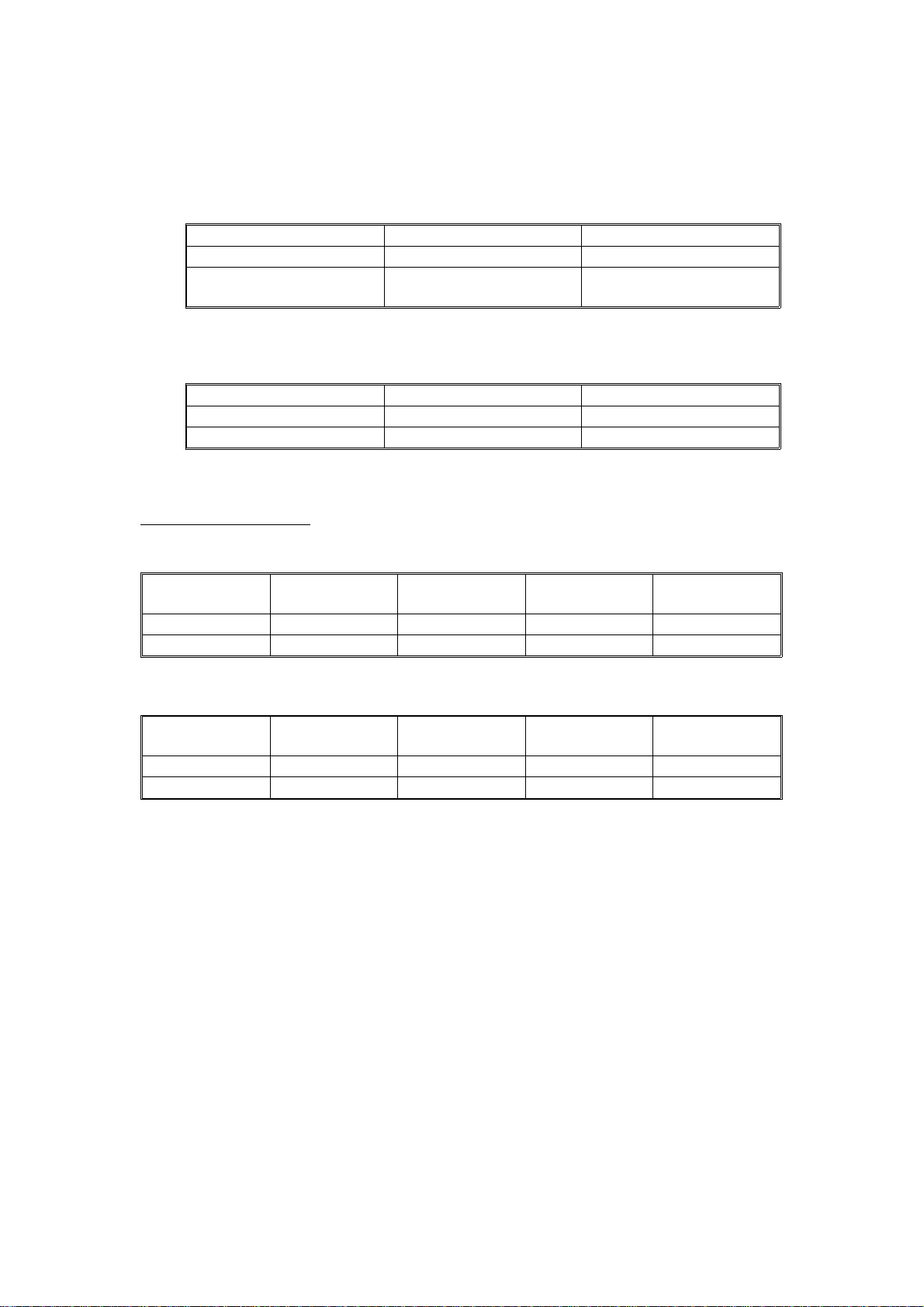

1. DRUM CHARGE

In the dark, the charge corona unit gives a uniform positive charge to the selenium drum.

The charge remains on the surface of the drum because the photo conductive selenium

has electrical resistance in the dark.

2. EXPOSURE

An image of the original is reflected to the selenium drum surface via the optics assembly.

The charge on the drum surface is dissipated in direct proportion to the intensity of the

reflected light, thus producing an electrical latent image on the drum surface.

3. ERASE

The erase lamp illuminates the areas of the charged drum surface that will not be used

for the copy image. The resistance of the drum in the illuminated areas drops and the

charge on those areas dissipates.

4. DRUM POTENTIAL SENSOR

The drum potential sensor detects the electric lines of force from the electric potential on

the drum to compensate image processing elements.

5. DEVELOPMENT

Negatively charged toner is attracted to the positively charged areas of the drum, thus

developing the latent image. (The negative triboelectric charge is caused by friction

between the carrier and toner particles.)

6. PRE-TRANSFER

The pre-transfer corona (PTC) applies a negative dc charge and an ac charge to the

drum. The dc charge increases the negative potential of the toner to improve toner

transfer to paper. The ac charge decreases positive charge on the drum and makes

paper separation easier. The pre-transfer lamp (PTL) also makes paper separation easier

by illuminating the drum and decreasing the positive charge on the drum.

7. IMAGE TRANSFER

Paper is fed to the drum surface at the proper time so as to align the copy paper and the

developed image on the drum surface. Then, a strong positive charge is applied to the

back side of the copy paper, providing an electrical force which causes the copy paper to

be attracted to the drum’s surface. At the same time, the toner particles are pulled to the

copy paper from the drum’s surface.

8. PAPER SEPARATION

A strong ac corona discharge is applied to the back side of the copy paper, reducing the

positive charge on the copy paper and breaking the electrical attraction between the

paper and the drum. Then, the stiffness of the copy paper causes it to separate from the

drum surface. The pick-off pawls help to separate paper which has low stiffness.

9. CLEANING

The cleaning brush first removes remaining toner on the drum surface. Then, the cleaning

blade which is angled against drum rotation (counter blade system) removes the rest of

the toner. The flick roller mechanically removes the toner on the cleaning brush.

10. QUENCHING

Light from the quenching lamp electrically neutralizes the drum surface.

31 July 1995 COPY PROCESSES AROUND THE DRUM

1-7