Operation Panel...........................................................................................................................................29

Rear Cover...................................................................................................................................................30

Upper Cover................................................................................................................................................30

By-pass Tray.................................................................................................................................................30

Left Cover......................................................................................................................................................32

Front Door.....................................................................................................................................................32

Right Cover ..................................................................................................................................................33

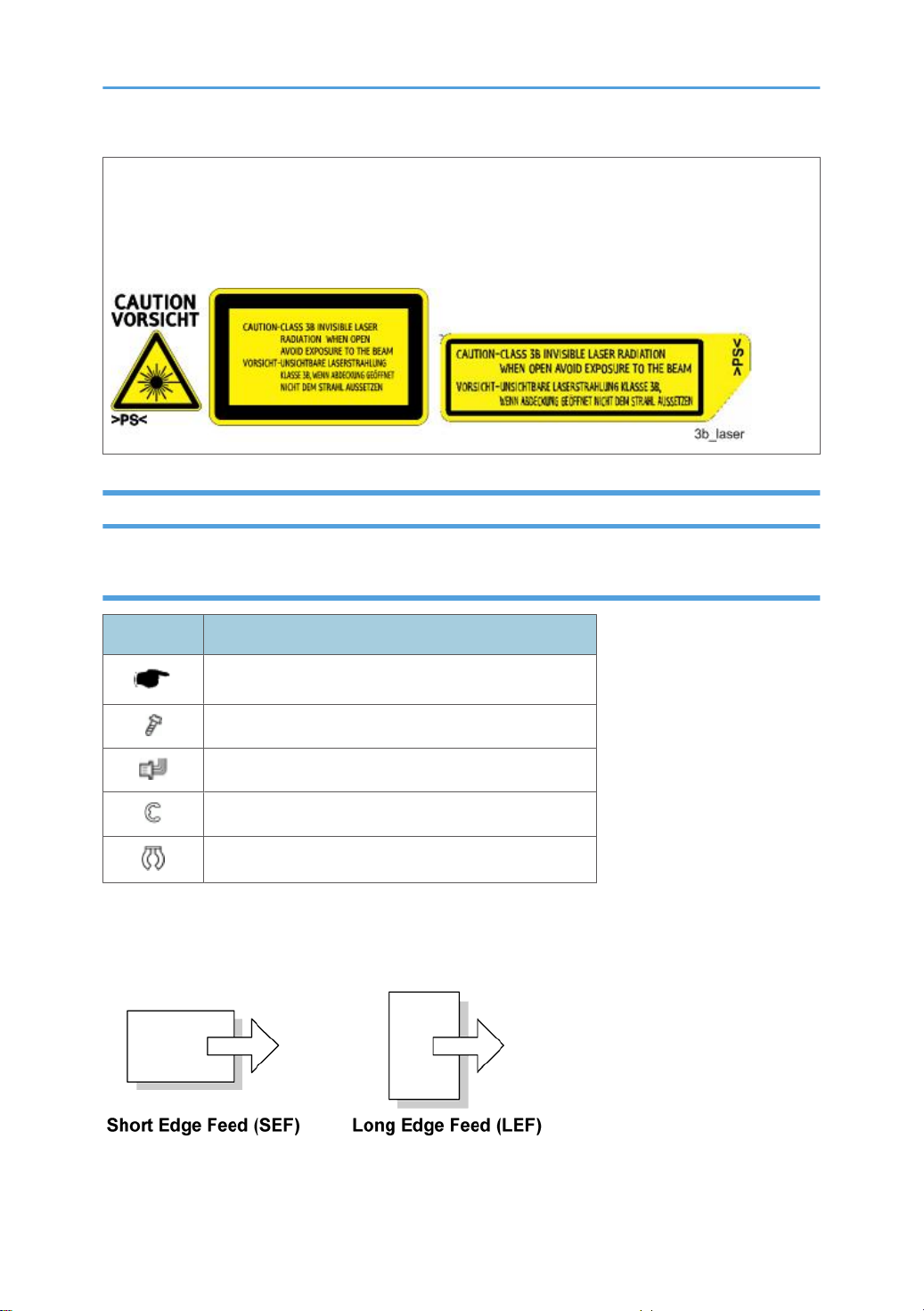

Laser Unit..........................................................................................................................................................35

Caution Decal Location ..............................................................................................................................35

Polygon Mirror Motor ................................................................................................................................36

Laser Unit......................................................................................................................................................36

Laser Diode Unit ..........................................................................................................................................38

Laser Beam Pitch Adjustment ......................................................................................................................39

Image Transfer..................................................................................................................................................41

Transfer Roller .............................................................................................................................................41

Toner End Sensor.........................................................................................................................................41

Fusing................................................................................................................................................................43

Fusing Unit....................................................................................................................................................43

Hot Roller and Fusing Lamp........................................................................................................................43

Pressure Roller..............................................................................................................................................47

Thermistor and Thermostat..........................................................................................................................49

Hot Roller Strippers......................................................................................................................................51

Paper Feed........................................................................................................................................................53

Paper Feed Roller .......................................................................................................................................53

Friction Pad ..................................................................................................................................................53

Paper End Sensor.........................................................................................................................................54

Remaining Paper Sensors............................................................................................................................55

By-pass Feed ...................................................................................................................................................56

By-pass Feed Unit........................................................................................................................................56

By-pass Feed Roller.....................................................................................................................................56

By-pass Friction Pad....................................................................................................................................57

By-pass Paper Set Sensor...........................................................................................................................59

Paper Exit .........................................................................................................................................................61

6