4

Safety Instructions For Jointer/Planer (continued)

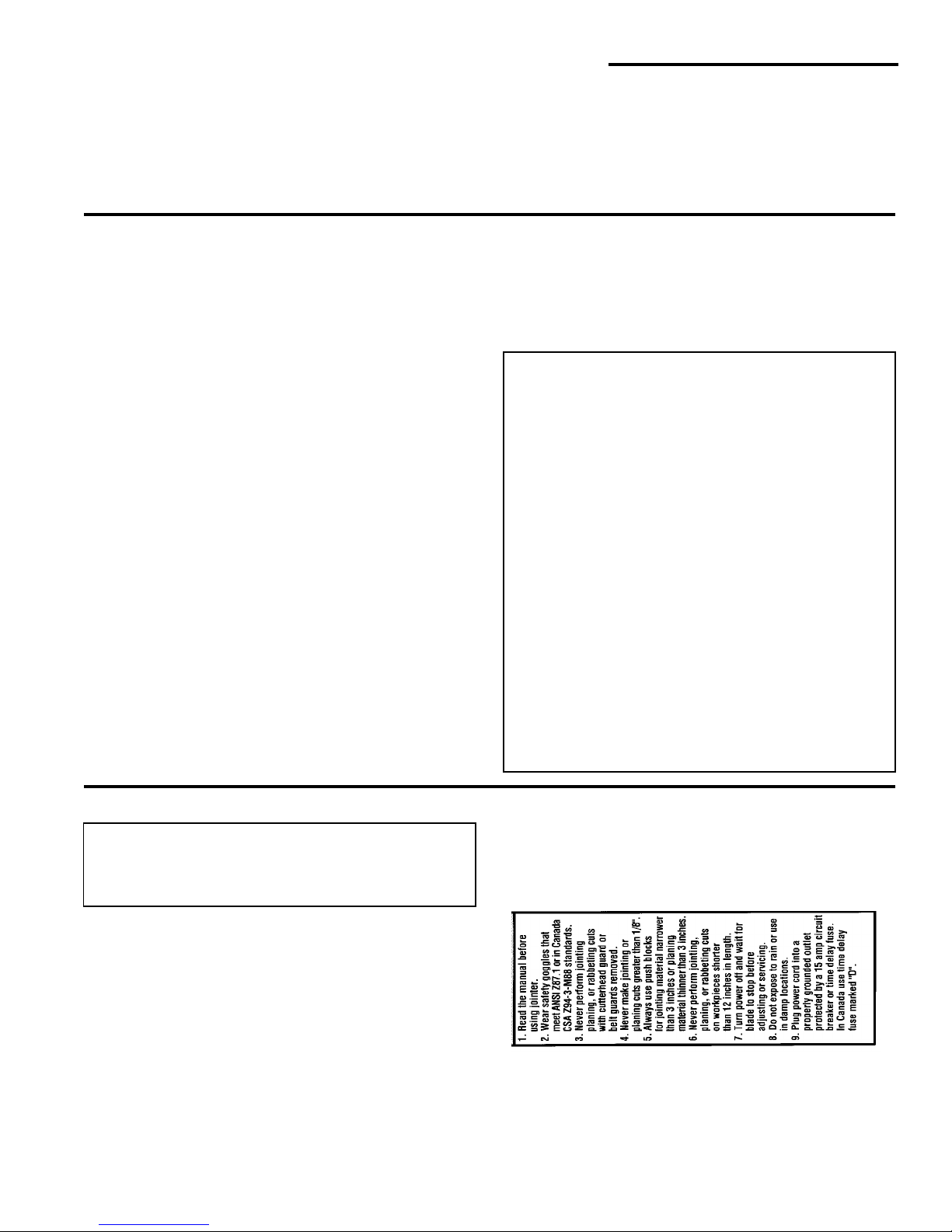

Safety Labels and Indicators on the Jointer/Planer

The following labels and indicators are on your jointer/

planer. Locate, read and follow the safety instructions

and information contained in these labels.

1. Safety instruction label on the top of the guard.

2. Cutter rotation indicator is on top of the sliding guard.

3. Cutter position indicator is on top of the fence.

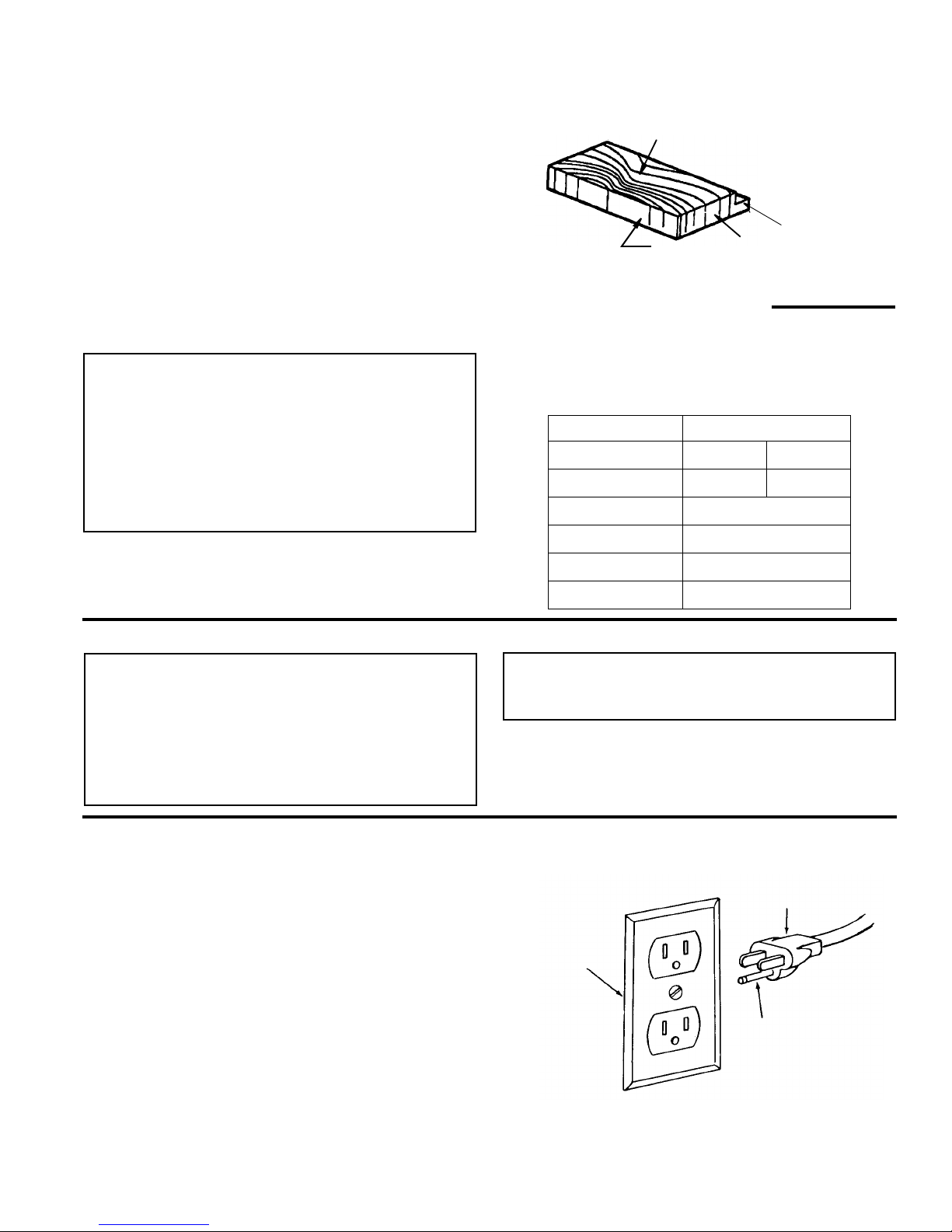

Push blocks and push sticks

Two plastic push blocks are supplied with your jointer/

planer. Use them when practical. The rubber sole of the

push blocks give better traction with the wood than your

hands do. If they become slippery, they can be cleaned

with rubbing alcohol, paint thinner or sandpaper.

CAUTION: Use rubbing alcohol or paint thinner

only as described on their containers. Use only in

well ventilated areas away from open flames,

sparks or heat sources.

Push blocks can’t always be used. With larger work-

pieces, you may have better control fo the workpiece

using your hands. Always make a test pass first to deter-

mine which method gives you better control.

Before you make any cut, plan your hand positions. If a

kickback should occur, plan so that your hands will not fall

or be forced into the cutters.

Three Inch Rule (3")

Generally, if your hands are closer than three inches to

the blade as you feed the wood, use push blocks. This

gives extra protection to your hands by placing the push

blocks between your hands and the cutters.

Always Use Push Blocks When Planing, Beveling Or

Chamfering

When jointing, test for workpiece stability before actually

jointing, and use push blocks when you can without sacri-

ficing control.

When Installing Or Moving the Jointer/Planer

Reduce the Risk of Dangerous Environment.

• Use the jointer/planer in a dry, indoor place protected

from rain.

• Keep work area well lighted.

To reduce the risk of injury from unexpected jointer/

planer movement.

• Bolt or clamp the jointer/planer to firm level surface

where there is plenty of room for moving the workpiece

through the entire cut.

• Support the jointer/planer so the tables are level and

the jointer/planer does not rock.

• Put the jointer/planer where neither operators nor

bystanders must stand in line with the wood while plan-

ing or jointing it.

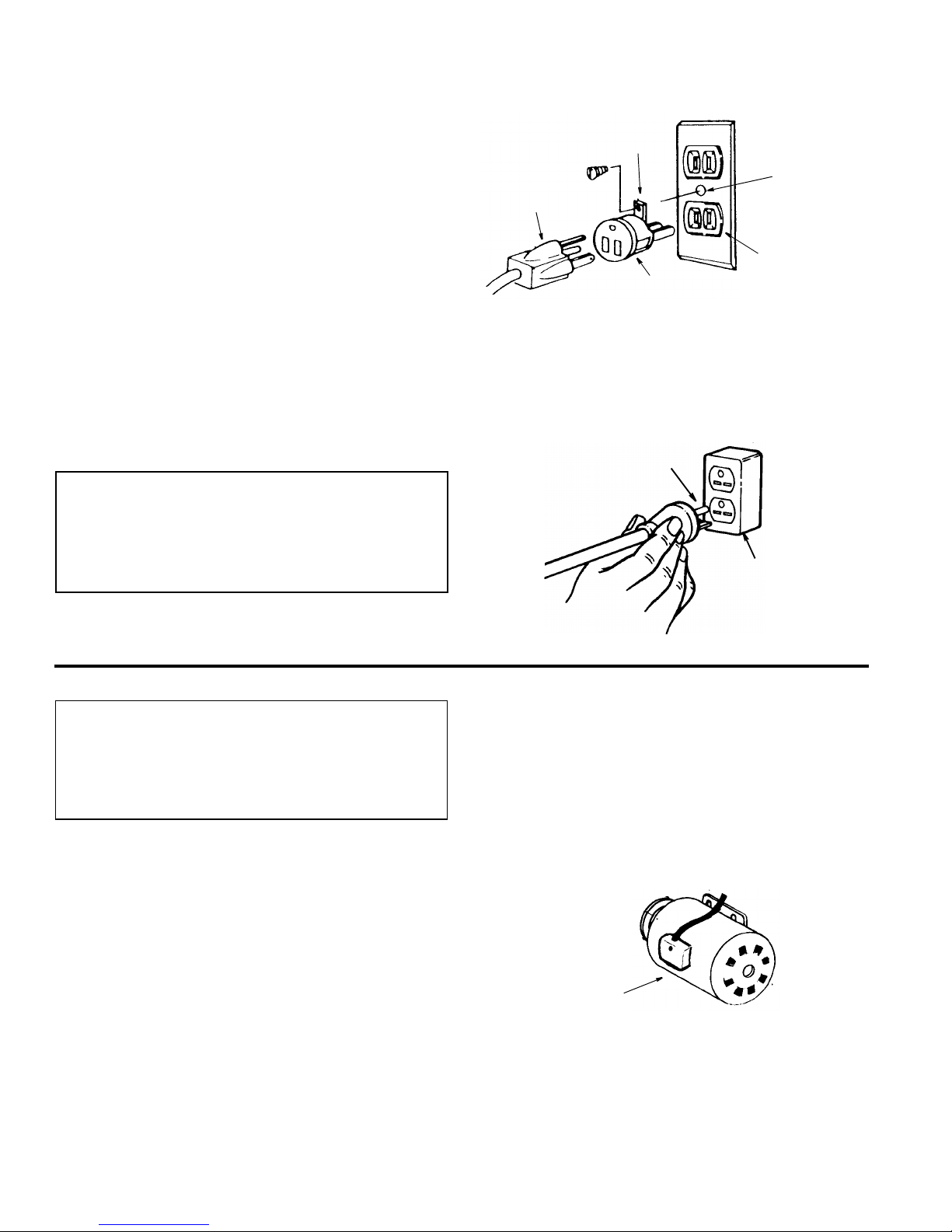

• To reduce the risk of injury from electrical shock, make

sure your fingers do not touch the plug’s metal prongs

when plugging in or unplugging the jointer/planer.

• Turn off and unplug the jointer/planer before moving it

to a new area. To reduce the risk of back injury, get

help when you need to lift or move the jointer/planer.

• Bolt the jointer/planer to the floor if it tends to slip, walk,

slide or tip over. Be especially aware of movement

when jointing/planing long heavy boards.

•Never Stand On Tool. Serious injury could occur if the

tool tips or you accidentally hit the cutter head. Do not

store anything above or near the tool where anyone

might stand on the tool to reach them.

Before Each Use

Inspect your jointer/planer.

WARNING: The 2-1/2

inch jointer/planer pulley and

the 3-1/2 inch motor pulley furnished will run the

cutter head at about 5000 RPM when used with a

3450 RPM motor. Use of different types of pulleys

or motors will change this speed and could cause

jamming, binding, kickback, thrown knives or

other dangers.

• To reduce the risk of injury from accidental starting, turn

the switch off, unplug the jointer/planer, and remove the

switch key before moving the cutter head guard, chang-

ing the blades, changing the setup, or adjusting any-

thing.

• Check for alignment of moving parts, binding of moving

parts, breakage of parts, unit stability, and any other con-

ditions that may affect the way the jointer/planer works.

• Don’t force the tool. It will do the job better and safer at

the rate for which is was designed.

• If any part is missing, bent or broken in any way, or any

electrical part does not work properly, turn the jointer/

planer off and unplug the jointer/planer.

• Replace damaged, missing or failed parts before using

the jointer/planer again.

• Make sure the cutter guard works properly. With the

switch off and key removed, pull the cutter guard open

and let go. If the guard doesn’t smoothly swing closed,

contact an Authorized Service Center.

• Make sure the cutter head turns in the right direction.

The top should move toward the infeed table. If the cut-

ter head turns the wrong direction, contact an Autho-

rized Service Center.

• Keep Jointer/Planer interior free of wood chips and

dust buildup around motor and switch box.

• Keep knives sharp. Dull or nicked knives tend to

“pound” and chew at the wood, causing kickbacks.

• To reduce the risk of injury from unsafe accessories,

use only recommended accessories.