Riso HC Series Operating instructions

Other Riso Printer manuals

Riso

Riso ComColor 9150 User guide

Riso

Riso HC5500T User manual

Riso

Riso HC5500 User manual

Riso

Riso ComColor FT Series User manual

Riso

Riso HC5000T User manual

Riso

Riso RZ9 Series User manual

Riso

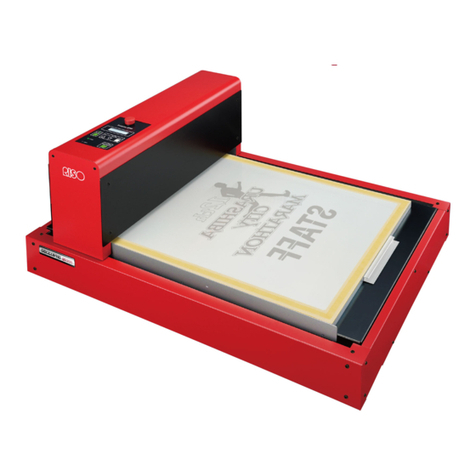

Riso GOCCOPRO QS200 User manual

Riso

Riso MZ970 User manual

Riso

Riso EZ Series User manual

Riso

Riso 9450 User manual

Riso

Riso GR2750 User manual

Riso

Riso ComColor FW5230 User manual

Riso

Riso GOCCOPRO QS2536 User manual

Riso

Riso RZ 970 Series User manual

Riso

Riso ComColor FT Series User manual

Riso

Riso ComColor FT Series User manual

Riso

Riso HC5500 User manual

Riso

Riso GR 3770 User manual

Riso

Riso MZ870 User manual

Riso

Riso HC5500 User manual