Operator's Manual Gritter Gobi

- 1 -

Content Page

1.

IDENTIFYING THE MACHINE .............................................................................................2

2.

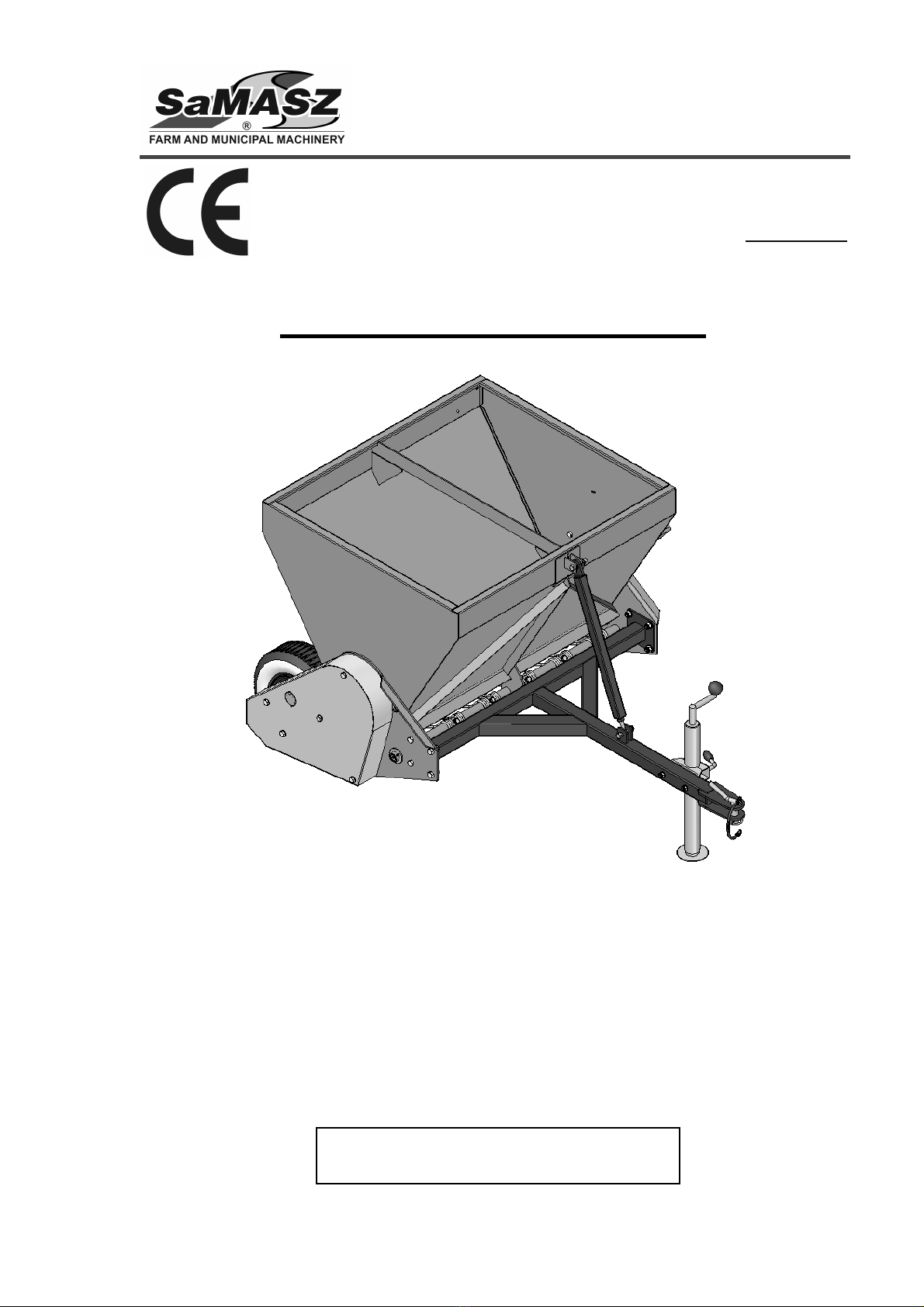

SAFETY PRECAUTIONS.........................................................................................................3

2.1. Safety rules ............................................................................................................................................3

2.2. Safety labels...........................................................................................................................................4

2.3. Risks and prohibitions ...........................................................................................................................5

3.

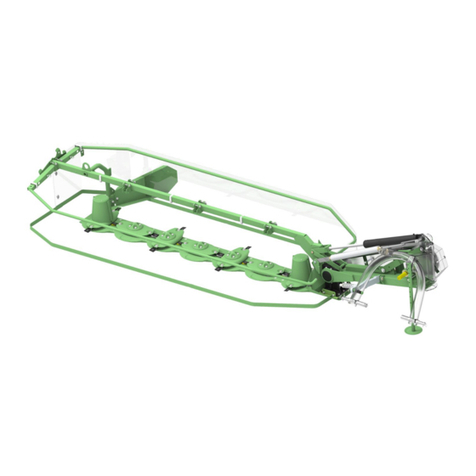

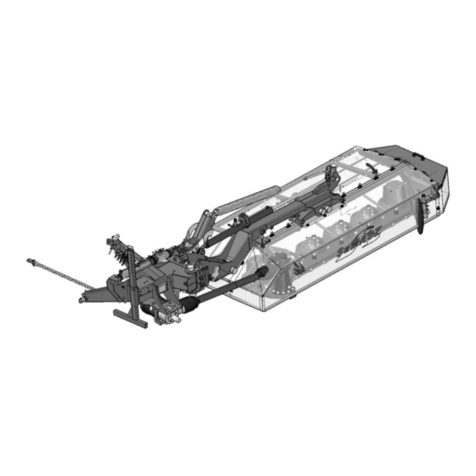

INTENDED USE AND DESIGN...............................................................................................6

4.

EQUIPMENT AND SPARE PARTS ........................................................................................7

4.1. Standard equipment ...............................................................................................................................7

4.2. Spare parts .............................................................................................................................................7

5.

OPERATING GRITTER ...........................................................................................................7

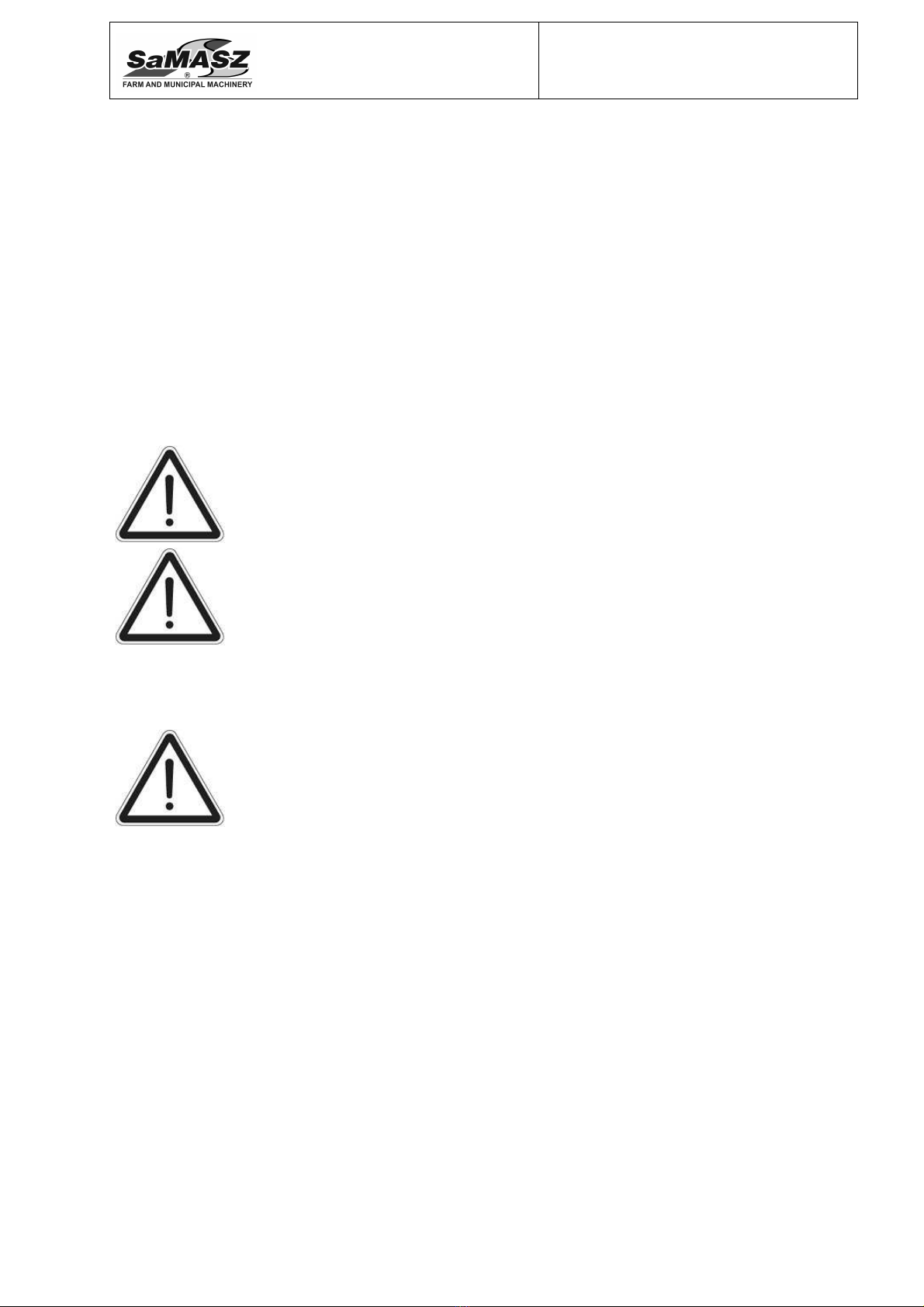

5.1. Mounting gritter to tractor .....................................................................................................................7

5.2. Controlling gritter..................................................................................................................................8

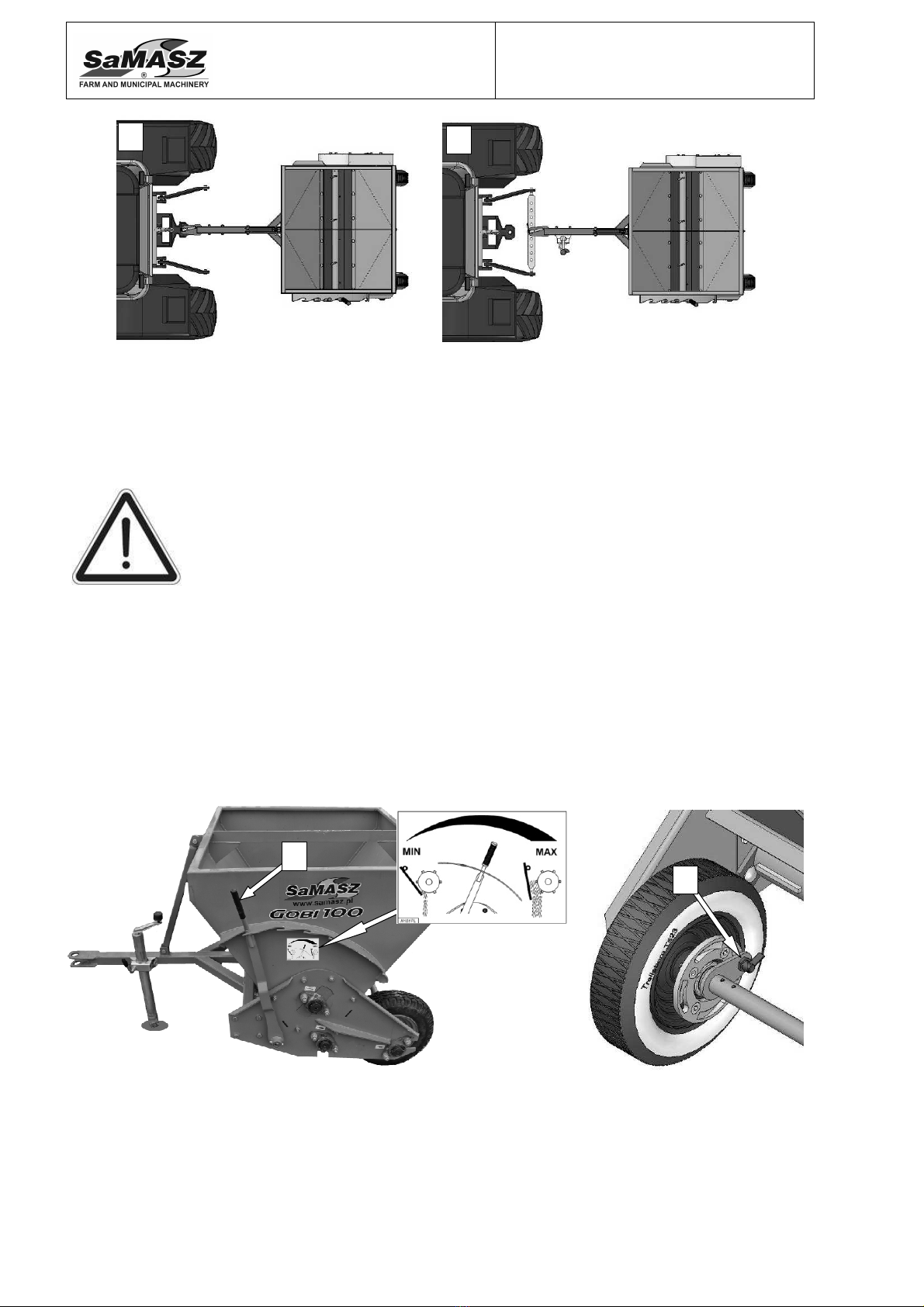

5.3. Preparing gritter for operation ...............................................................................................................9

5.4. Operation ...............................................................................................................................................9

5.5. Transport and standstill position of gritter ..........................................................................................10

6.

OPERATING SERVICE..........................................................................................................10

7.

MAINTENANCE AND STORAGE........................................................................................11

8.

TRANSPORT AND DELIVERY ............................................................................................11

9.

SPECIFICATIONS...................................................................................................................13

10.

REPAIR AND WITHDRAWAL FROM USE .......................................................................13

10.1. Repair................................................................................................................................................13

10.2. Withdrawal from use.........................................................................................................................13

10.3. Environment......................................................................................................................................13

11.

WARRANTY.............................................................................................................................14

11.1. Warranty card ...................................................................................................................................14

11.2. Warranty terms .................................................................................................................................14

11.3. Warranty repairs record ....................................................................................................................15

12.

LIST OF PARTS .......................................................................................................................15