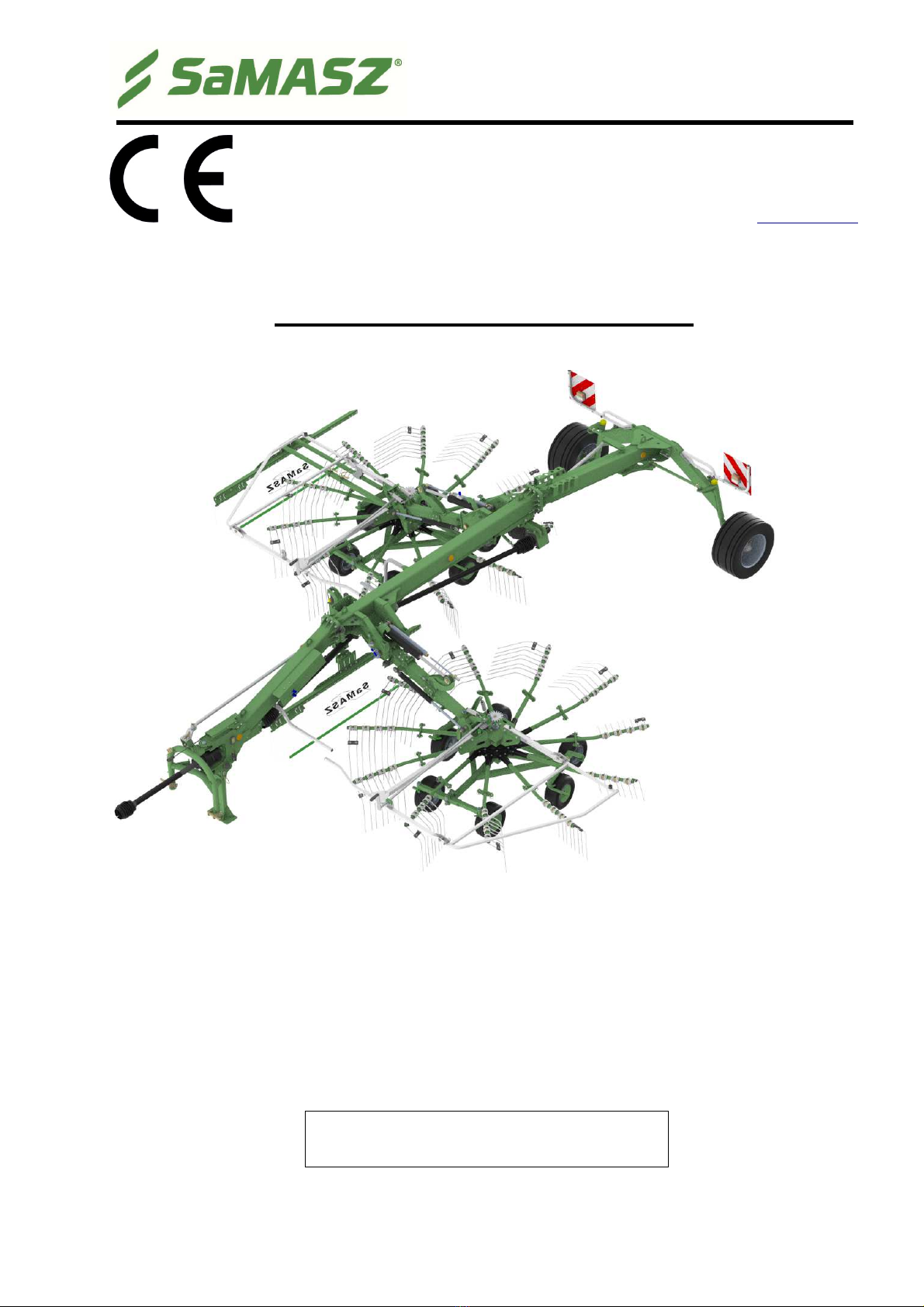

Instruction manual

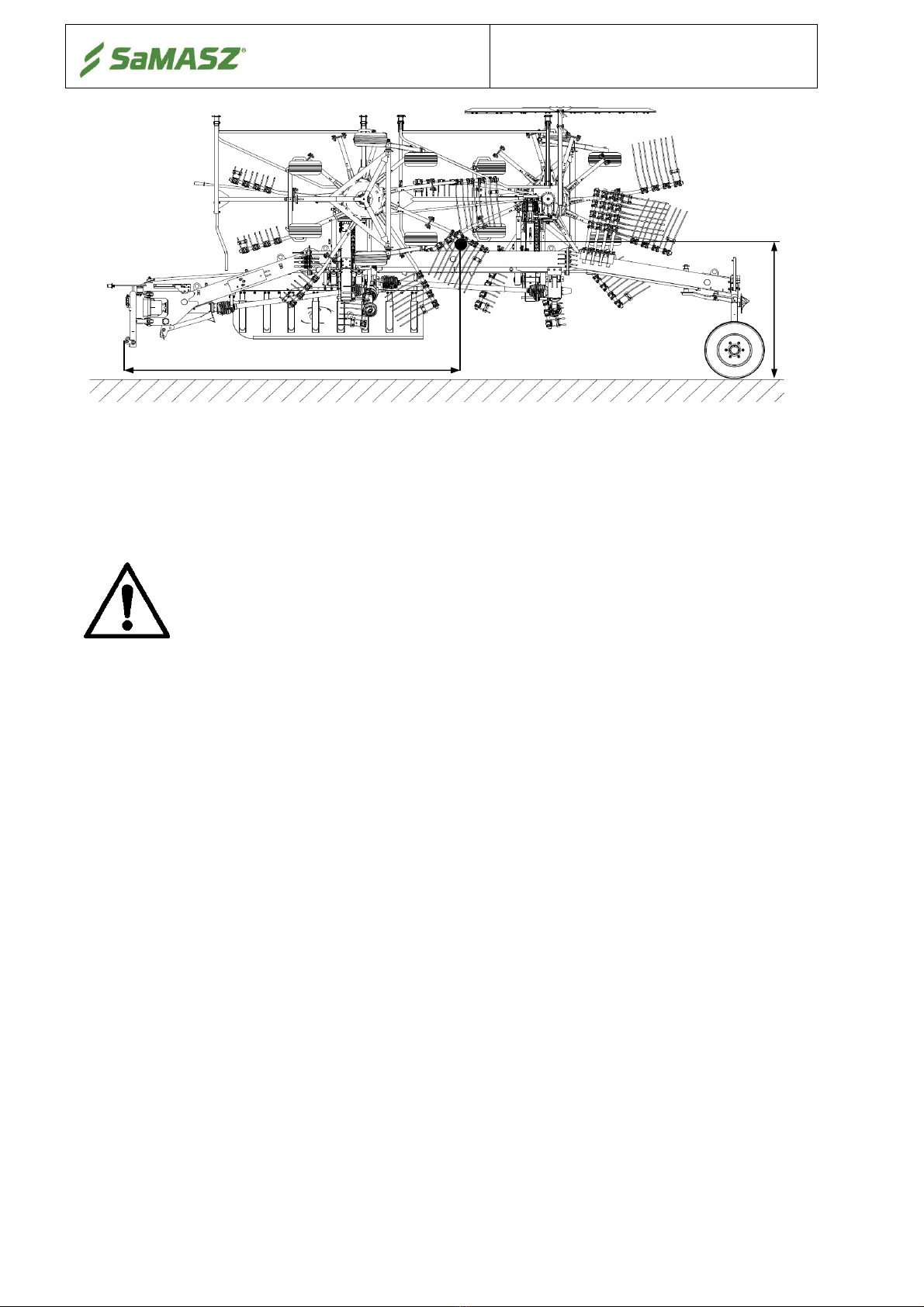

Two rotor rake

TANGO

- 1 -

Contents page

1. IDENTIFYING THE MACHINE..............................................................................................................................2

2. INTRODUCTION .......................................................................................................................................................2

3. INTENDED USE .........................................................................................................................................................3

3.1. Technical data .......................................................................................................................................................3

3.2. Design and operating principle .............................................................................................................................4

3.3. Equipment and spare parts ....................................................................................................................................4

4. SAFETY ADVICE AND CAUTION .........................................................................................................................5

4.1. Safety rules and regulations ..................................................................................................................................5

4.2. Transport...............................................................................................................................................................7

4.3. Moving machines onto another vehicle for transport............................................................................................7

4.4. Operating parts......................................................................................................................................................8

4.5. Telescopic articulated shaft...................................................................................................................................8

4.6. Hydraulic assembly...............................................................................................................................................8

4.7. Residual risk..........................................................................................................................................................9

4.7.1. Danger of being caught or pulled in................................................................................................................9

4.7.2. Danger of injury, abrasion and damage of skin...............................................................................................9

4.7.3. Danger of liquid ejection out of hydraulic system ..........................................................................................9

4.7.4. Bans ................................................................................................................................................................9

4.7.5. Residual risk assessment...............................................................................................................................10

4.8. Safety decals and their meaning..........................................................................................................................10

5. USING THE RAKE ..................................................................................................................................................13

5.1. Mounting rake on tractor.....................................................................................................................................13

5.1.1. Control panel................................................................................................................................................14

5.2. Preparing rake for transport ................................................................................................................................15

5.3. Preparing rake for transport on public roads.......................................................................................................16

5.4. Mounting telescopic articulated shaft .................................................................................................................16

5.5. Switching the rake from transport to working position.......................................................................................17

5.6. Preparing rake for operation................................................................................................................................18

5.7. Operation.............................................................................................................................................................21

5.7.1. Setting rake for forming one row ..................................................................................................................21

5.7.2. Switching rake from forming one to forming two single rows .....................................................................23

5.7.3. Adjustment of front safety curtain inclination angle.....................................................................................23

5.8. Mechanism for sequential lifting and lowering of working units ....................................................................... 24

5.8.1. Sequential lifting...........................................................................................................................................24

5.8.2. Sequential lowering.......................................................................................................................................24

5.9. Protection mechanism of front safety curtain......................................................................................................25

5.10.Lifting rake on headlands and transport position ................................................................................................25

5.11.Removing clogging and jams..............................................................................................................................26

5.12.Dismounting machine from tractor .....................................................................................................................27

6. MOUNTING AND ADJUSTMENTS ......................................................................................................................27

6.1. Installing tines.....................................................................................................................................................27

6.2. Replacing connecting rods..................................................................................................................................28

6.3. Daily maintenance...............................................................................................................................................28

6.4. Off-season maintenance and storing ...................................................................................................................29

6.4.1 Restarting the machine after longer idle periods............................................................................................29

7. LUBRICATION ........................................................................................................................................................30

7.1. Gear.....................................................................................................................................................................30

7.2. Joints and bearings..............................................................................................................................................30

7.3. Risks present when lubricating ...........................................................................................................................31

8. DEFINING THE TOTAL WEIGHT, AXIS LOAD, TYRE LOAD CAPACITY AND MINIMUM LOAD ....32

9. POSSIBLE DEFECTS AND THEIR REPAIRS ....................................................................................................34

10. RAKE REPAIR AND WITHDRAWAL FROM USE ...........................................................................................35

10.1.Repair..................................................................................................................................................................35

10.2.Disassembly and withdrawal from use................................................................................................................35

11. WARRANTY CARD................................................................................................................................................. 35

12. WARRANTY TERMS..............................................................................................................................................36

12.1.Warranty claim procedure...................................................................................................................................36

12.2.Warranty repairs record ......................................................................................................................................37