TY-JS-211220-009

7

I.

Overview

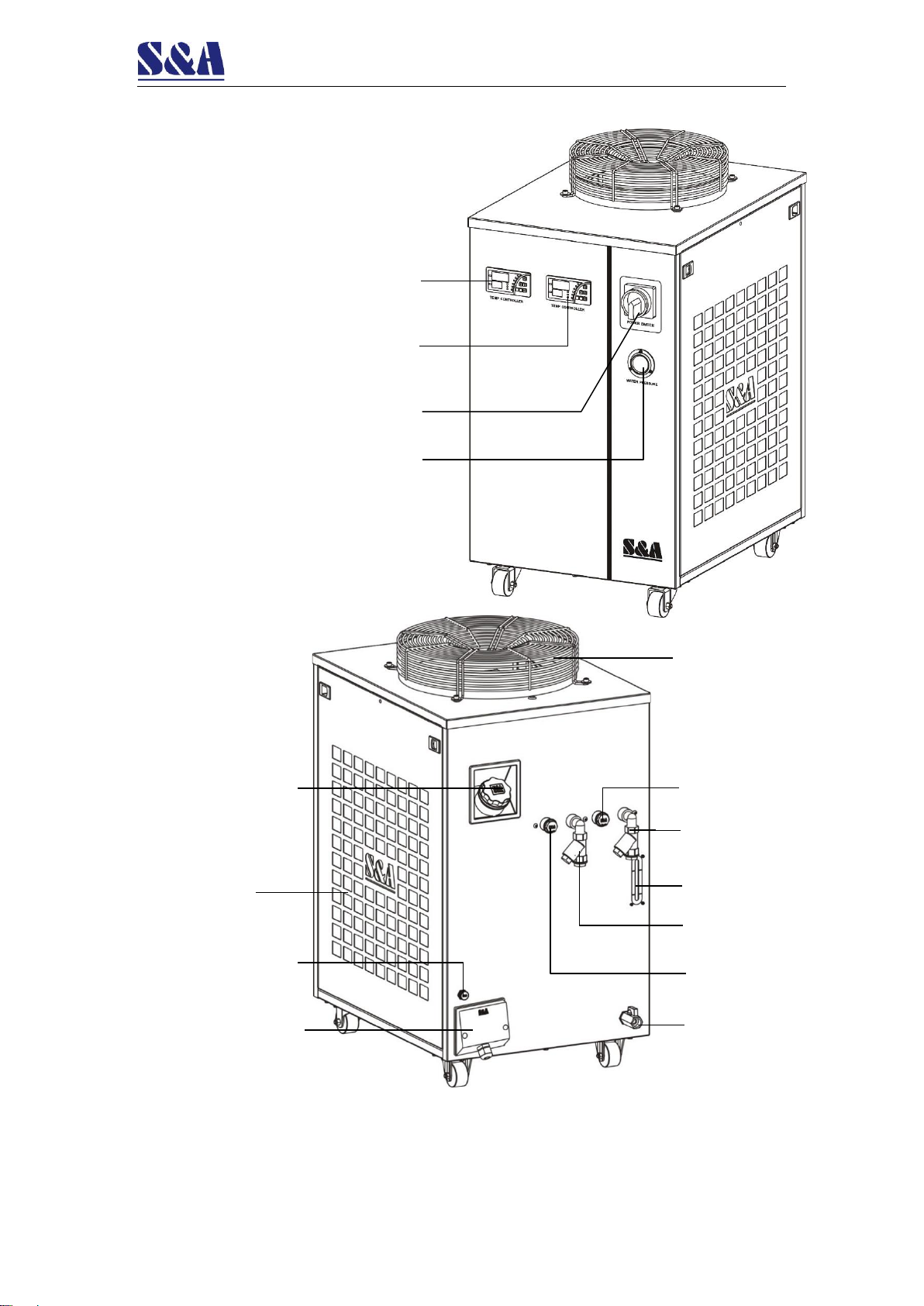

This product is an industrial cooling device designed and manufactured for laser cutting,

laser welding, laser marking, laser engraving and other equipment that uses laser

processing. It can provide a temperature-stable cooling medium for the above application

scenarios.

The chiller is composed of a compressor, a condenser, a throttling device (expansion

valve or capillary), an evaporator, and a water pump. Its working principle is that the

chiller’s refrigeration system cools the water, and the water pump delivers the low-

temperature cooling water to the equipment that needs to be cooled. Then the cooling

water will take away the heat, heat up and return to the chiller, and then be cooled again

and transported back to the equipment. In the refrigeration system of a chiller, the

refrigerant in the evaporator coil absorbs the heat of the return water and vaporizes into

steam. The compressor continuously extracts the generated steam from the evaporator

and compresses it. The compressed high-temperature, high-pressure steam is sent to

the condenser and later will release heat (heat extracted by the fan) and condense into a

high-pressure liquid. After being reduced by the throttling device, it enters the evaporator

to be vaporized, absorbs the heat of the water, and the whole process circulates

constantly. Users can set or observe the working status of the water temperature through

the temperature controller.

II.

Model Illustration

CWFL- 1000 A N

④Water pump

③Electric source type

②Chiller model series

①Chiller application

Note: This model description only contains the description of the company's main product

codes, not all of them are listed. Please confirm with our company before ordering the specific

model, our company has the final interpretation right about it.