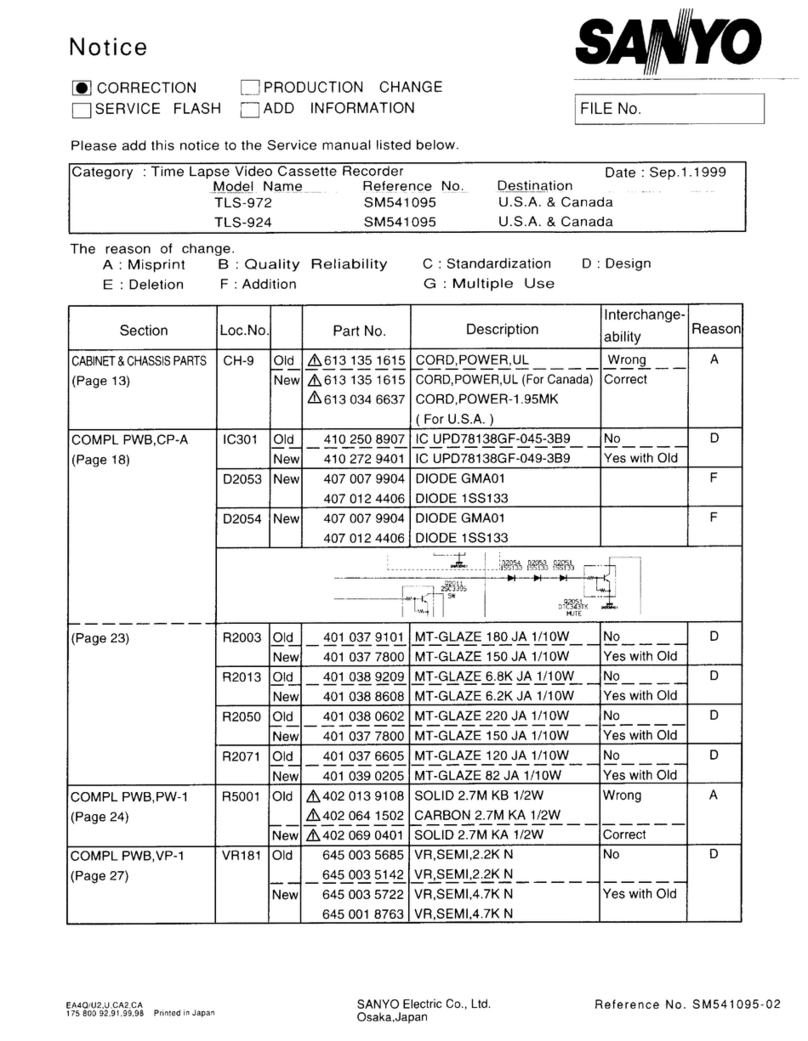

155w(N) D1

~

jSELF-DIAGNOSIS DISPLAY f

/,,,,,,,,,,,,,,,,,,,..,/.,..,.,/,,.,//,//./,//,/,//,,A

MechanismMode Display/HeadOutput Drop Warning Display/CylinderRotationAccumulated

TimeDisplay

This unit displays the diagnosis contents of abnormalities and the mechanism mode on its display panel in 2-digit numbers.

When the head playback output has dropped, the “L” sign will be blinked. Some models (listed later) will also display the cylinder

rotation accumulated time.

These display shows the outline of the problems. Use it as a reference when servicing the unit.

1.Self-DiagnosisContentsand MechanismMode Display

.

.

.

When the STOP button on the remote control is pressed for about 10 seconds continuously, the self- diagnosis number will be

displayed on the reception channel display of the display panel and number indicating the failed mechanism mode (changed

mode when being shifted) on the tape counter “seconds” display for 3seconds each.

During self-diagnosis display, displays other than the diagnosis number/mechanism mode number and the cylinder

accumulated rotation time display described later (some models only) will be turned off and when displays end, the normal

display will be returned automatically.

Refer to “Self-Diagnosis Contents” for the self-diagnosis numbers and the “Mechanism Mode Display Contents” for the

mechanism mode numbers.

Self-Diagnosis number Mechanism mode number

(Reception channel display) (Tape counter “Seconds” display)

Self-Diagnosis Contents

No. Problem Main Possible Cause Mechanism Operations and

State After Occurrence

00 There is no abnormality in the mechanism.

The cylinder motor does not rotate. ●The cylinder motor isfaulty. Shifts to the STOP mode.

01 ●The control of the cylinder motor is

faulty.

●The tape winds around the cylinder.

The take-up reel does not rotate.

02 ●The take-up reel is caught. Shifts to the STOP mode.

●The reel belt is faulty.

●The take-up torque has decreased.

The capstan motor does not rotate.

03 ●The capstan motor is faulty. Shifts to the STOP mode.

●The control of the capstan motor is

faulty.

The tape cannot be loaded with the .Error in the operations of the tape Unloads, shifts to the INITIAL mode,

cassetta inserted. loading mechanism.

(But unloading can be performed.) and tha power goes off.

●Foreignparticlesin the tape Ioad-ing

04 mechanism.

●The tape end sensor is faulty.

●The reel brake of the tape cassette

has not been released.

Tape loading and unloading cannot be ●The tape guide is caught. The powar isforcibly turned off with the

05 performed with the cassatte inserted. ●The loading motor is faulty. mechanism at its current position.

●The control of the loading motor is

faulty. —

–2–