SATO M-8400RVe Series User manual

SATO EUROPE

M8400RVe

Operation Manual

SATO Europe

Im Hülsenfeld 13

40721 Hilden

Germany

Tel.:+49 (0)2103 9592-0

Fax.:+49 (0)2103 55322

Issued November 2000

This page is intentionally left blank.

Warning

It is essential that the safety and operating procedures contained

within this manual be brought to the attention of, and are used by,

all personnel likely to operate this printer/product.

This printer/product must only be used for the purpose for which it

was designed.

This is a Class A product. In a domestic environment this product

may cause radio interference in which case the user may be

required to take adequate measures.

Electrostatic discharges on the connector pins and on the memory

card may damage the printer.

In the case of fire, water must not be used on the product to extin-

guish the fire, and the appropriate type of fire extinguisher should

be readily available.

No modifications, either mechanical or electrical, should be made

to this printer/product or accessory without the written consent of

SATO Europe GmbH. Any modifications made without this consent

may invalidate guarantee claims.

Other manuals relating to this printer include additional information

relating to other aspects of the safe operation of the printer, and are

available from your SATO supplier.

All consumable waste, such as the label backing paper and used

carbon ribbon must be disposed of carefully, and in a manner that

will cause the minimum of environmental pollution.

Should you have any doubts regarding the setting, operating or any

safety aspects of this printer/product, please contact your SATO

supplier.

SATO Europe GmbH makes no guarantee that all the features

described in this manual are available in all models, and, due to

SATO’s policy of continuous development and improvement, spec-

ifications are liable to change, without notice.

Consumables

Always use SATO carbon ribbons or equivalent. The use of incor-

rect materials may cause malfunctions of the printer and void the

warranty.

Conventions

Text that appears bold italic and all in capitals such as LABEL

refers to a key or an LED on the operation panel.

Text that appears enclosed in brackets such as <ESC> refers to an

Escape sequence of a data string.

Text that appears bold italic such as On-Line refers to a function or

to a result.

Text that appears in bold such as VR1 refers to electrical compo-

nents like pins, resistors connectors and so on.

Warranty and Copyright

SATO Europe GmbH makes no guarantee of any kind with regard

to this material, including, but not limited to, the implied guaranties

of merchantability and fitness for a particular purpose.

SATO Europe GmbH shall not be liable for errors contained herein

or for any incidental consequential damages in connection with the

furnishing, performance, or use of this material.

This document contains proprietary information which is protected

by copyright.

All rights are reserved.

No part of this document may be reproduced or issued to third par-

ties in any form whatsoever without the express permission of

SATO Europe GmbH.

The information in this document is subject to change without

notice.

© Copyright 2000 SATO Europe GmbH

i

Contents

1. Overview and Specifications .......................................................... 1

1.1 Overview ............................................................................. 1

1.2 Physical Characteristics ..................................................... 2

1.3 Components ....................................................................... 3

1.4 Ribbon ................................................................................ 5

1.5 Installation Considerations ................................................. 5

1.6 Interface Connections (Rear Panel) .................................. 5

1.7 Switches and Sensors ........................................................ 6

1.8 Operator Panel/Displays ..................................................... 8

1.9 Specifications .................................................................... 10

2. Printer Configuration .................................................................... 13

2.1 DIP Switch Settings .......................................................... 13

2.1.1 RS232 Transmit/Receive Setting ........................... 14

Selecting Protocol Control Codes .......................... 17

2.1.2 External Connector PIN Assignments .................... 21

2.1.3 External Output Signal Types ................................. 22

2.2 Default Settings ................................................................ 23

2.3 Printer Adjustments .......................................................... 24

2.3.1 Normal Mode .......................................................... 24

2.3.2 User Mode .............................................................. 24

2.3.3 Print Darkness Setting ............................................ 25

2.3.4 Print Speed Adjustment .......................................... 25

2.3.5 Pitch Offset and Direction ....................................... 26

2.3.6 Cancel print Job ..................................................... 27

2.3.7 Advanced Settings ................................................. 27

3. Connections ................................................................................. 29

3.1 Bi-directional parallel interface (standard) ........................ 29

3.2 Optional interface (RS-232C) ........................................... 30

3.3 Optional Interface (USB) .................................................. 31

3.4 Optional Interface (LAN) ................................................... 31

4. Media Loading ............................................................................. 33

4.1 Loading the Ribbon .......................................................... 33

4.2 Loading Labels or Tags .................................................... 35

5. Cleaning and Maintenance .......................................................... 39

ii

5.1 Introduction ....................................................................... 39

5.2 Adjusting the Print Quality ................................................ 40

5.3 Cleaning the Print Head, Platen and Rollers .................... 42

6. Troubleshooting ........................................................................... 45

6.1 Overview ........................................................................... 45

6.2 Initial Checklist .................................................................. 45

6.3 Error Signals ..................................................................... 46

6.4 Troubleshooting Tables ..................................................... 47

Appendix A Advanced Settings ......................................................... 51

Appendix B Declaration of Conformity .............................................. 55

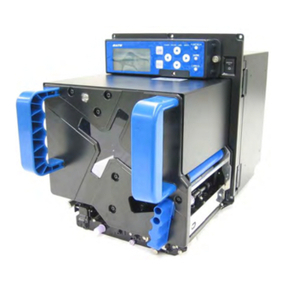

Operation Manual 1. Overview and Specification

M8400RVe1

1. Overview and Specifications

1.1 Overview

The SATO M-8400RVePrinter Operation Manual provides informa-

tion for installing and maintaining the M-8400RVeprinter. Step-by-

step maintenance instructions are included in this manual with typ-

ical problems and solutions. It is recommended that you become

familiar with each section in this manual before installing and main-

taining the printer.

This manual is divided into the following seven sections:

• Section 1 - Overview and Specifications

• Section 2 - Configuration

• Section 3 - Connections

• Section 4 - Media Loading

• Section 5 - Cleaning and Maintenance

• Section 6 - Troubleshooting

2 M8400RVe

1. Overview and Specification Operation Manual

1.2 Physical Characteristics

DIMENSIONS

Width 280 mm

Depth 438 mm

Height 341 mm

Weight 18 Kg

POWER REQUIREMENTS

Voltage 220 V (+/- 10 %)

50/60 Hz (+/- 1%)

Power Consumption 50 Watts Idle

300 Watts Operating

Width

Depth

Height

Operation Manual 1. Overview and Specification

M8400RVe3

1.3 Components

OPERATOR

PANEL

RIBBON UNWIND

SUPPLY

RIBBON REWIND

SPINDLE

PRINT HEAD

ASSEMBLY

PLATEN ROLLER

DIP SWITCH

CONFIGURATION

TABLE AND MEDIA

LOADING DIAGRAM

MEDIA HOLDER

SENSORS AND SWITCHES

Refer to Section 1.7

LCD DISPLAY

POWER ON/OFF

SWITCH

LABEL SENSOR

POSITIONING ADJUSTMENT

TOP ACCESS

DOOR

SIDE ACCESS

DOOR

LABEL ROLL

RETAINER

HEAD LATCH

4 M8400RVe

1. Overview and Specification Operation Manual

TEAR OFF

LABEL COVER

MAIN PC BOARD

POWER

SUPPLY UNIT

LCD BOARD

LED BOARD

(ON BACKSIDE

OF PANEL)

STEPPER MOTOR

SHAFT

TIMING BELTS

Operation Manual 1. Overview and Specification

M8400RVe5

1.4 Ribbon

Use only SATO thermal transfer ribbons which were formulated

expressly for use in all SATO printers. Use of other than approved

ribbons may result in unsatisfactory print quality and/or damage to

the print head and may void your warranty.

1.5 Installation Considerations

Printer operation can be affected by the printer environment. The

location of the printer should be free from dust, humidity, and sud-

den vibrations. To obtain optimum results from the printer, avoid

locations influenced by:

• Direct or bright sunlight since bright light will make the label sen-

sor less responsive and may cause the label to be sensed incor-

rectly.

• Warm temperatures which can cause electrical problems within

the printer.

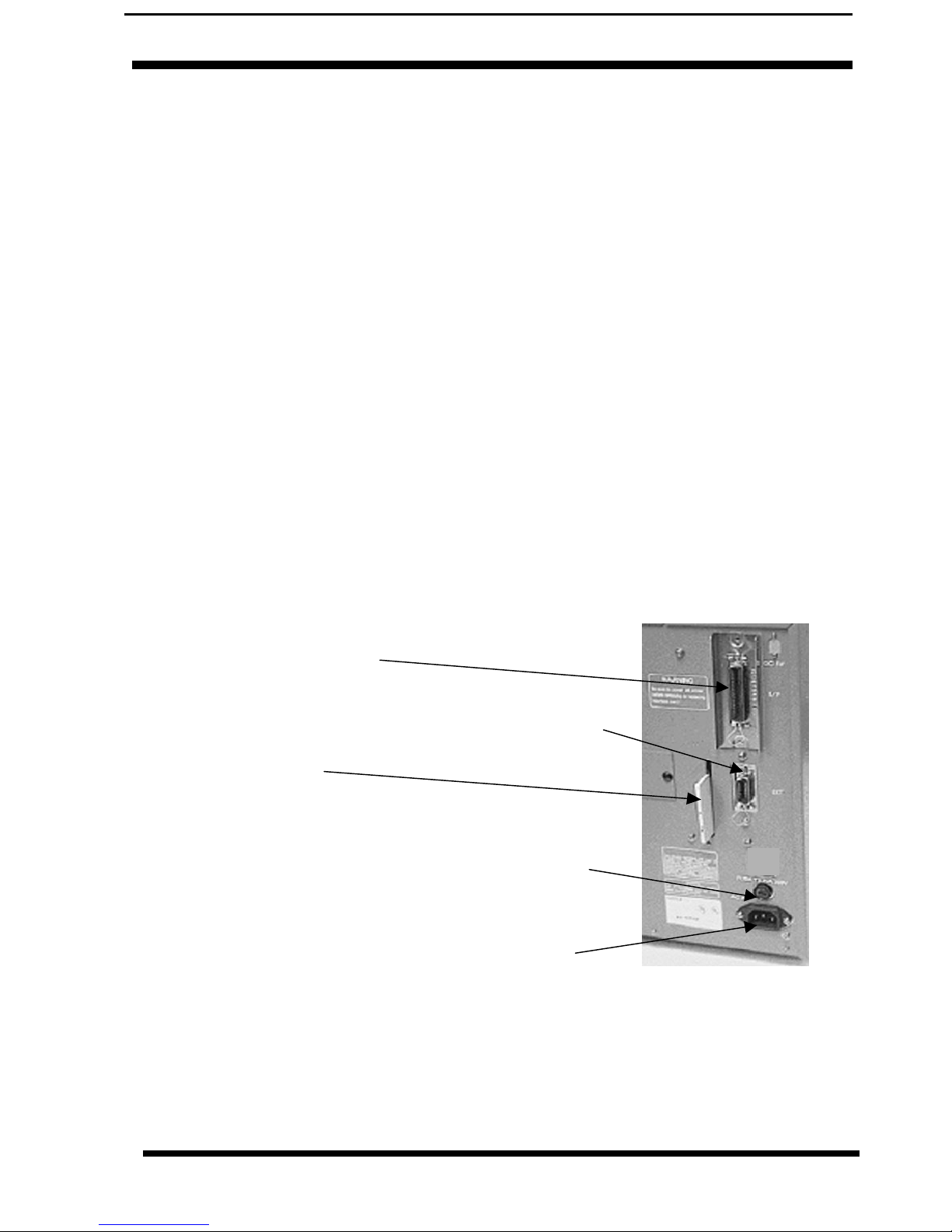

1.6 Interface Connections (Rear Panel)

EXT. PORT CONNECTOR:

External signal connector.

AC FUSE: To protect the machine

from abnormal power input.

Type 3A/250V

AC INPUT CONNECTOR:

Connect to 220V 50/60 Hz.

with cable provided.

MODULAR INTERFACE:

MEMORY CARD:

6 M8400RVe

1. Overview and Specification Operation Manual

1.7 Switches and Sensors

HEAD LATCH LEVER: When the

print head is opened, a micro switch is

activated and the printer will stop

printing. Error message will be

displayed on the LCD operator panel.

RIBBON SENSOR: The sensor will react

to the ribbon unwind when approximately

45 feet of ribbon remains. This sensor is a

motion detector that signals the printer

when the ribbon supply is turning. This

sensor is used for both the ribbon end and

ribbon near end sensing. When error is

displayed: Ribbon out, not turning.

Operation Manual 1. Overview and Specification

M8400RVe7

MICRO SWITCH (Head Open Switch)

MEDIA HOLD DOWN:

Open by lifting up on the release

tab underneath the green tab

marked “PUSH”.

Close by pushing down on the

same green tab.

LABEL OUT SENSOR: Micro switch is

activated when media stock is out or when the

Media Hold Down is in the up position. All

printer operations stop and an error message is

displayed on the LCD.

LABEL SENSOR UNIT: Both the “I”-

Mark (reflective), and Gap (transmissive)

sensors can be adjusted over a limited

range. They are both located in the label

sensor unit. The assembly can be

adjusted by turning the sensor adjust

knob located underneath the label

transport assembly. The gap sensor can

be adjusted from a minimum of 15 mm to

a maximum of 63 mm, and the “I”- Mark”

from a minimum of 7 mm to a maximum

of 52 mm from the fixed position, inside

label guide. The range of sensor

adjustment can be increased to allow the

Gap sensor to be positioned as close as

3mm from the inside label edge.

8 M8400RVe

1. Overview and Specification Operation Manual

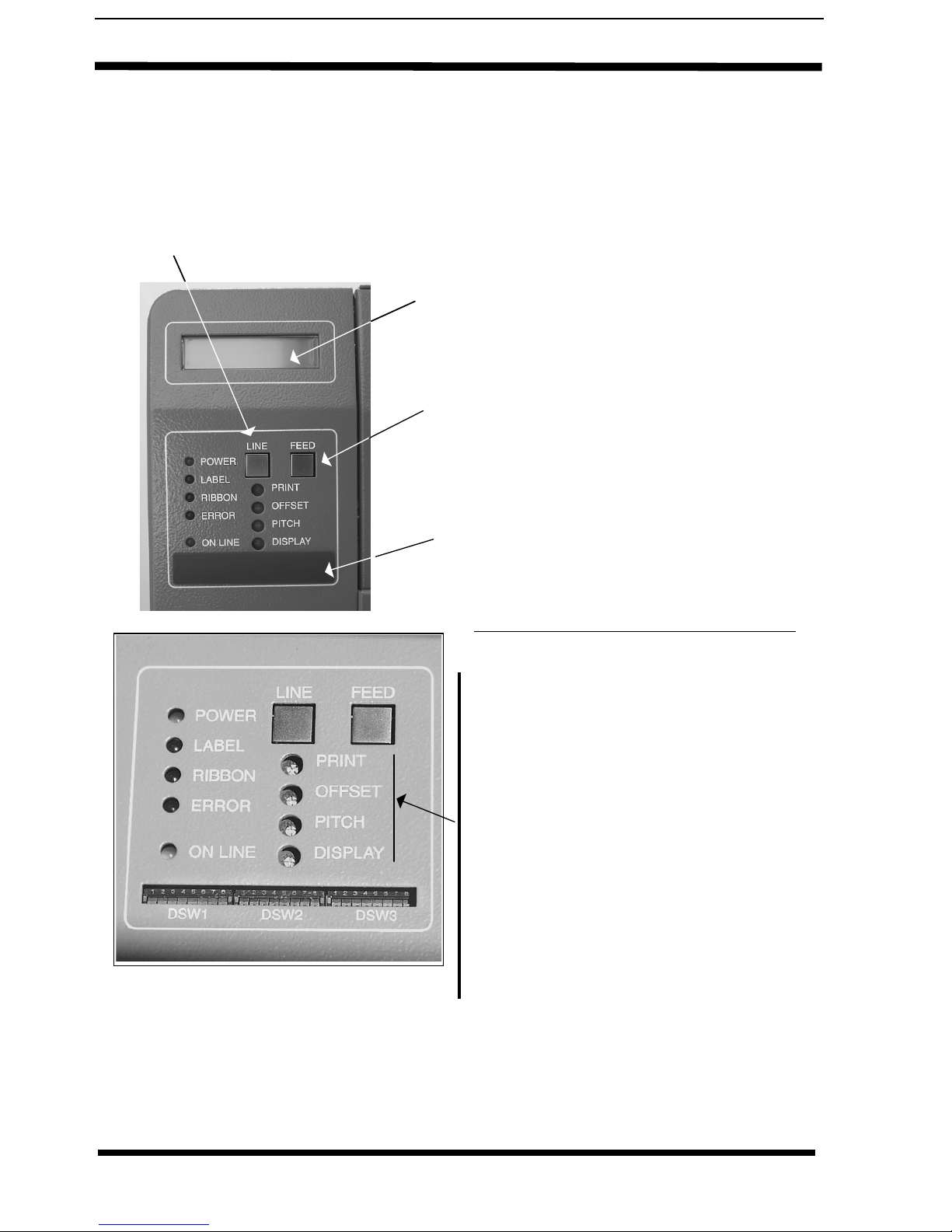

1.8 Operator Panel/Displays

LINE Key: Momentary switch. Pressing this key toggles the printer

between the on-line and off-line mode. When the printer is on-line, it is

ready to receive data from the host. This key acts as a pause during a

print job by taking the printer off-line.

FINE TUNING - USE SOFTWARE FIRST

PRINT POTENTIOMETER: To adjust

print darkness (fine adjustment).

OFFSET POTENTIOMETER: To adjust

back/forward feed for dispenser/cutter/tear

- bar position (+/- 3.75mm).

PITCH POTENTIOMETER: Adjusts home

position of the label(+/- 3.75mm). Affects

stop position of label feed, print position,

and dispense position.

DISPLAY POTENTIOMETER: Used to

adjust the lighting intensity (contrast) of the

Display.

LCD SCREEN:2 Line x 16 Character LCD

display. Used for setting operational parameters

of the printer and displaying error conditions.

FEED Key: Momentary switch.

Pressing this key feeds one blank label

through the printer when it is off-line.

When the printer is on-line, another copy

of the last label will be printed.

DIP SWITCH COVER

Operation Manual 1. Overview and Specification

M8400RVe9

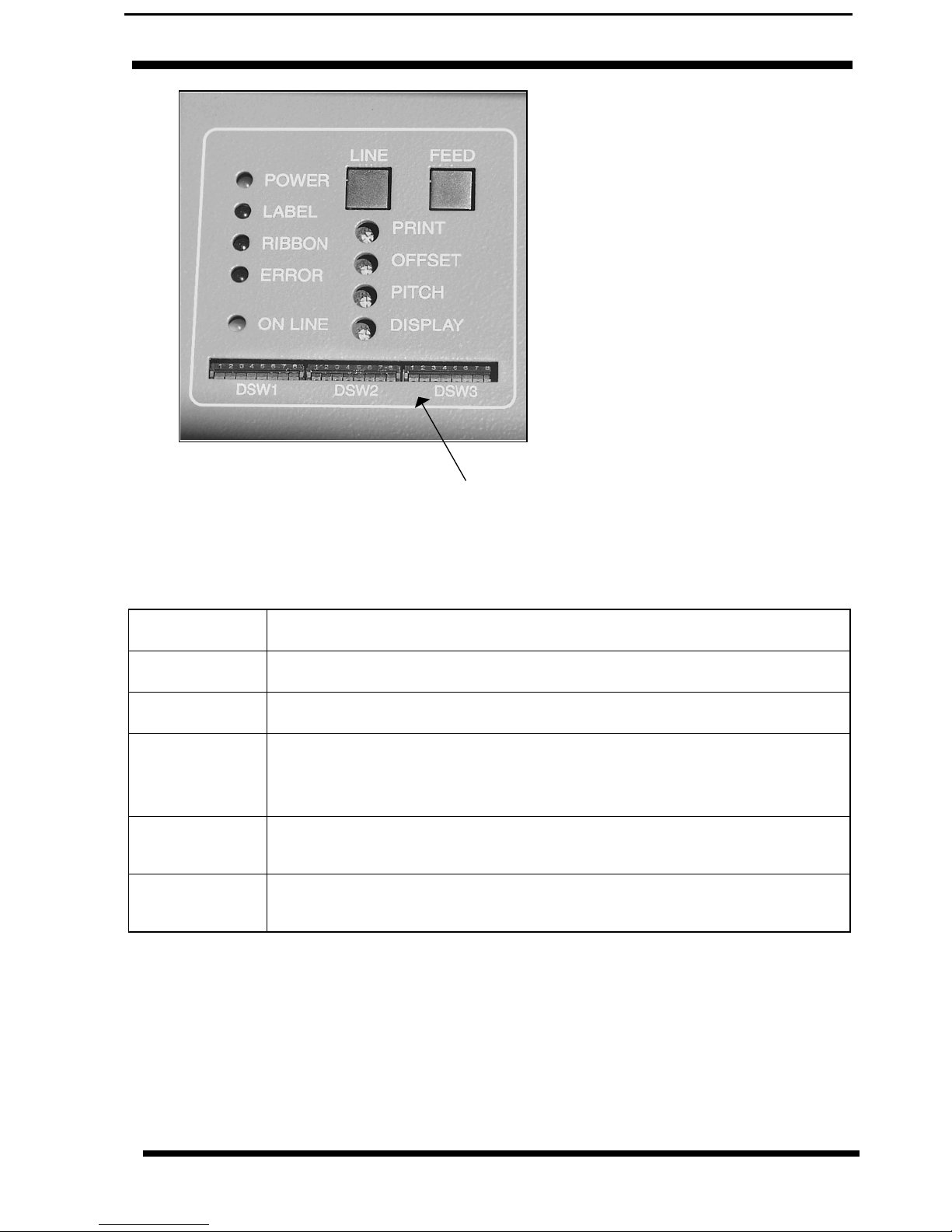

LED’S: - STATUS INDICATORS

POWER LED, illuminated when the power is on.

LABEL LED, illuminated when label supply is out.

RIBBON LED, illuminated when ribbon motion sensor does not detect

any ribbon motion (ribbon out), or the LED blinks when ribbon

is near end.

ERROR LED, illuminated when there is a system fault such as an open

print head.

ON LINE LED, illuminated when printer is ready to receive data. Turn

ON/OFF by toggling the LINE key.

DSW 2 & 3: DIP Switches used to set

operational parameters of printer. Refer

to Section 2 for settings.

10 M8400RVe

1. Overview and Specification Operation Manual

1.9 Specifications

Print Type Direct Thermal, Thermal Transfer

Resolution 8 dot/mm (203 dpi) 0,125 mm/dot

Speed User selectable from 50 mm/sec to 250 mm/sec

Darkness 5 steps; selectable by printer driver (<ESC> codes) or via display

Print Area Pitch: 178mm Width: 104mm Standard

356mm 104mm <AX>

1249mm 104mm Option <EX>

Media

Label Sizes Pitch: 6–356 mm; optional max:1249 mm

17–356 mm; optional max:1249 mm

Width: 22–128 mm Standard

22–128mm Cutter or Dispenser

Label Roll I.D. 38mm (1,5”) or 76 mm (3”); O.D. 220mm (8,6”);

Thickness 0,1-0,18 mm

Media Types Die-Cut Label, Continuous Material, Tag Material, Roll Type - Face-In, Fan-Fold

Type.

Carbon

Ribbon

Width: 111 mm max. Length: 450 metres, Thickness: 4,5 µ,

Type: Black and Colour, Back Coated

Barcodes UPC A/E, EAN 8 & 13, Code 39, Code 128, UCC/EAN 128, Interleaved 2 of 5,

Industrial 2 of 5, Matrix 2 of 5, NM-7, MSI, Bookland, Postnet.

Barcode

Ratio

1:2, 1:3, 2:5

Barcode

Sizes

Height: 4 dots to 600 dots; width – user definable

Rotational

Capacity

90° steps

2-D Codes Data Matrix, Maxicode, PDF 417, QR-Code

Fonts U, S, M, WB; WL; XU; XS; XM; XB; XL; OCR-A/B; Outline Font (50-999)

Rasterizer Font Triumvirate®& Times®(08 – 99 points or 16 – 999 dots)

Label Sens-

ing

Reflective Sensor (I-mark) bottom reading, movable

See-through Sensor (Gap), movable

CPU 32 bit SH3 RISC Processor/ 133MHz

Memory

Capacity

Standard Memory:

Optional Memory Expan-

sion:

16MB SDRAM; 2,9MB Input Buffer; 2MB Flash Mem-

ory

I n t e r n a l - 4 M B F l a s h M e m o r y S I M M C a r d

External - up to 4MB S-RAM Card or up to 16MB

Flash Card

Interfaces ECP Parallel (IEEE 1284),Centronics Parallel,RS232C Standard (2400 – 19.200

Baud), RS232C Highspeed (9600 – 57.600 Baud), USB (12Mbit/s),LAN (TCP/IP

protocol 10/100 Base T), Twinax/Coax,RS422/485.

Operation Manual 1. Overview and Specification

M8400RVe11

Front Panel Operation Switches:

Setting Switches:

LED:

LCD:

Online Key, Feed Key

2 x 8 Dip-Switches

Power, Label, Ribbon, Error, Online

Menu Controlled Printer Configuration and Error Messages

Supported Languages:

English (default), German, French, Spanish, Italian, Portu-

guese

Dimensions Height: 321 mm Width: 271 mm Depth: 430 mm

Weight 19 kg (standard)

Power 110 - 240V +/- 10%, 50/60 Hz, 130W

Environmen-

tal

Operating: +5 ~ +40°C, humidity 15 ~ 85% RH non-condensing

Storage: -20 ~ +55°C, non-condensing

Approvals C E, TÜV-GS, UL, CSA,

Options Rotary Cutter, Dispenser, External Label Rewinder R400, Memory Expansion,

Keyboard, Real Time Clock

12 M8400RVe

1. Overview and Specification Operation Manual

This page is intentionally left blank.

Operation Manual 2. Configuration

M8400RVe13

2. Printer Configuration

2.1 DIP Switch Settings

Two DIP switches DSW2 and DSW3 are located on the Operator

Panel at the front and a DSW1 switch is located on an optional

RS232 serial interface board.

These switches can be used to set:

• RS232C transmit/receive parameters

• Thermal transfer or direct thermal mode

• Label sensor enable/disable

• Head check mode

• Hex dump mode

• Receive buffer size

• Operation mode

To set the switches, first power the unit Off, then position the DIP

switches. After placing the switches in the desired positions, power

the printer back on. The switch settings are read by the printer

electronics during the power up sequence. They will not become

effective until the power is cycled.

DIP Switch Panel Layout for DSW1

Located on RS232 Interface Board

14 M8400RVe

2. Configuration Operation Manual

2.1.1 RS232 Transmit/Receive Setting

Data Bit Selection (DSW1-1)

This switch sets the printer to receive either 7 or 8 bit data bits for

each byte transmitted.

Parity Selection (DS1-2, DS1-3)

These switches select the type of parity used for error detection.

Stop Bit Selection (DS1-4)

Selects the number of stop bits to end each byte.

Baud Rate Selection (DS1-5, DS1-6)

Selects the data rate(bps) for the RS232 port.

* Factory Default

DSW1-1 SETTING

*OFF 8 Data Bits

ON 7 Data Bits

12 345678

ON

OFF

DSW1

12 345678

ON

OFF

DSW1

DSW1-2 SETTING SETTING

*OFF *OFF No Parity

OFF ON Even

ON OFF Odd

ON ON Unused

DSW1-4 SETTING

*OFF 1 Stop Bit

ON 2 Stop Bits 12 345678

ON

OFF

DSW1

DSW1-5 DSW1-6 SETTING

*OFF *OFF 9600

OFF ON 19200

ON OFF 38400

ON ON 57600

12 345678

ON

OFF

DSW1

Other manuals for M-8400RVe Series

3

Table of contents

Other SATO Barcode Reader manuals

SATO

SATO CG412DT User manual

SATO

SATO GL408e User manual

SATO

SATO ARGOX AS-9400BT User manual

SATO

SATO S8400 User manual

SATO

SATO Argox D4 Series User manual

SATO

SATO iGT400 Series User manual

SATO

SATO MB 200i User manual

SATO

SATO DR308e User manual

SATO

SATO Argox AR-3201 User manual

SATO

SATO MB 200i User manual