2

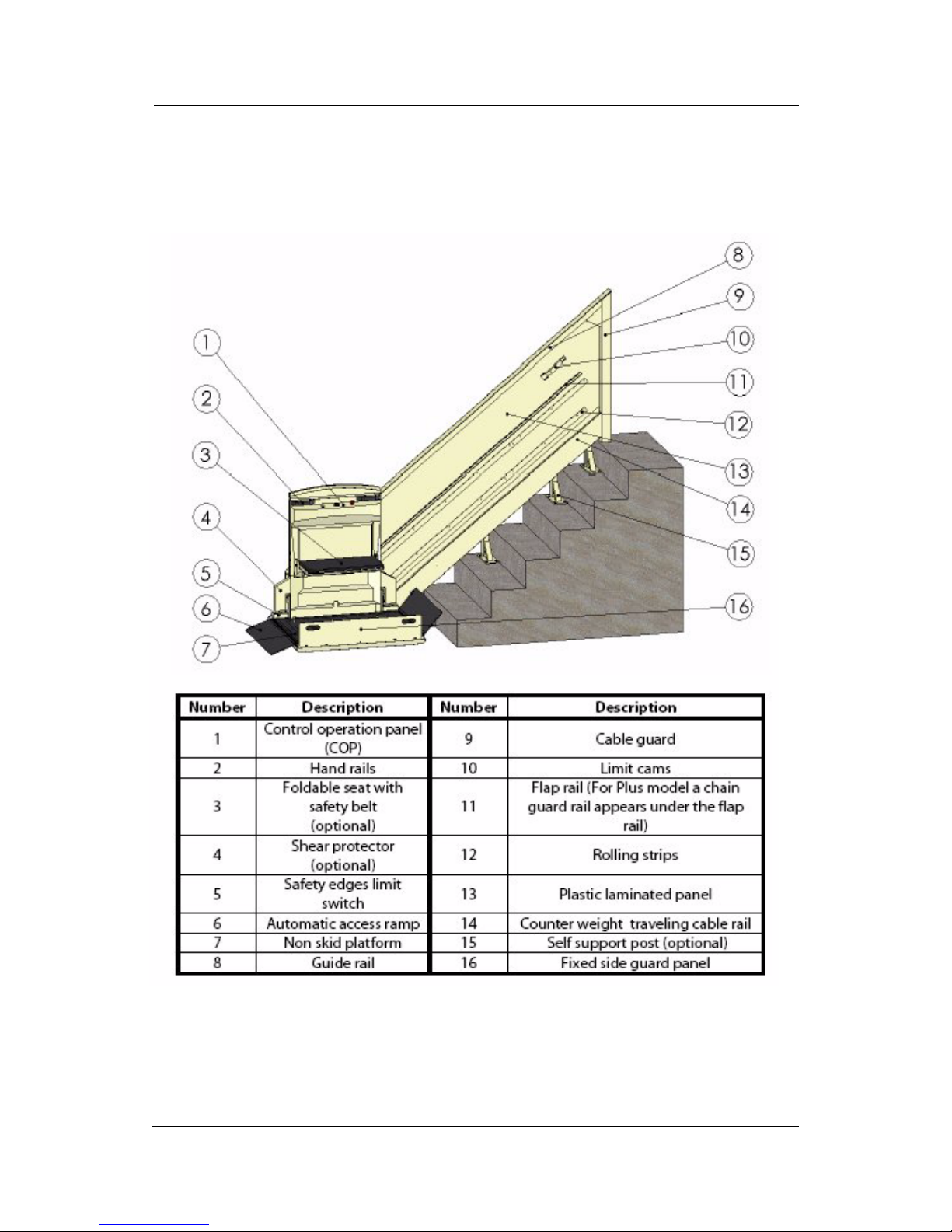

ES-125 Owner’s Manual Part No. 000703, 04-m07-2011

IMPORTANT

Ensure that only an authorized Savaria Dealer installs and services the Savaria™

ES-125 Inclined Platform Lift. Under no circumstances is anyone other than a

dealer with Savaria training and authorization to install, adjust, service or

modify any mechanical or electrical device on this equipment. Failure to follow

this warning can result in safety system compromises or defeat; this can result

in serious injury or death. Savaria accepts no liability for property damage,

warranty claims or personal injury, including death, in this circumstance.

Passenger safety is the result of countless details in the equipment’s design,

manufacture, and installation. After installation, reliable operation and

continual safe operation requires regular service and inspection at least twice

per year, or more frequently where usage, environment, or local jurisdiction

requires. As the Owner, you are responsible for ensuring that regular service

and inspections occur in a timely manner.

Refer to this manual for specifications, operating instructions and maintenance

of the Savaria™ ES-125 Inclined Platform Lift.

Upon completion of installation, the dealer must provide you with the

following information and ensure it is recorded in this manual. In addition,

either the dealer or you must keep any service and/or maintenance records in

the Maintenance Record section of this manual.

WARRANTY

Ensure your Savaria Dealer provides you with a copy of the manufacturer’s

limited parts warranty and documentation relating to any Dealer labour

warranty.

-------------------------------------------------------------------------------------------------

FOR OWNER’S RECORDS

Customer Name: _________________________________________

Installing Dealer: _________________________________________

Dealer’s Telephone Number: _______________________________

Date Installed: ___________________________________________

Serial/Job Number: _______________________________________