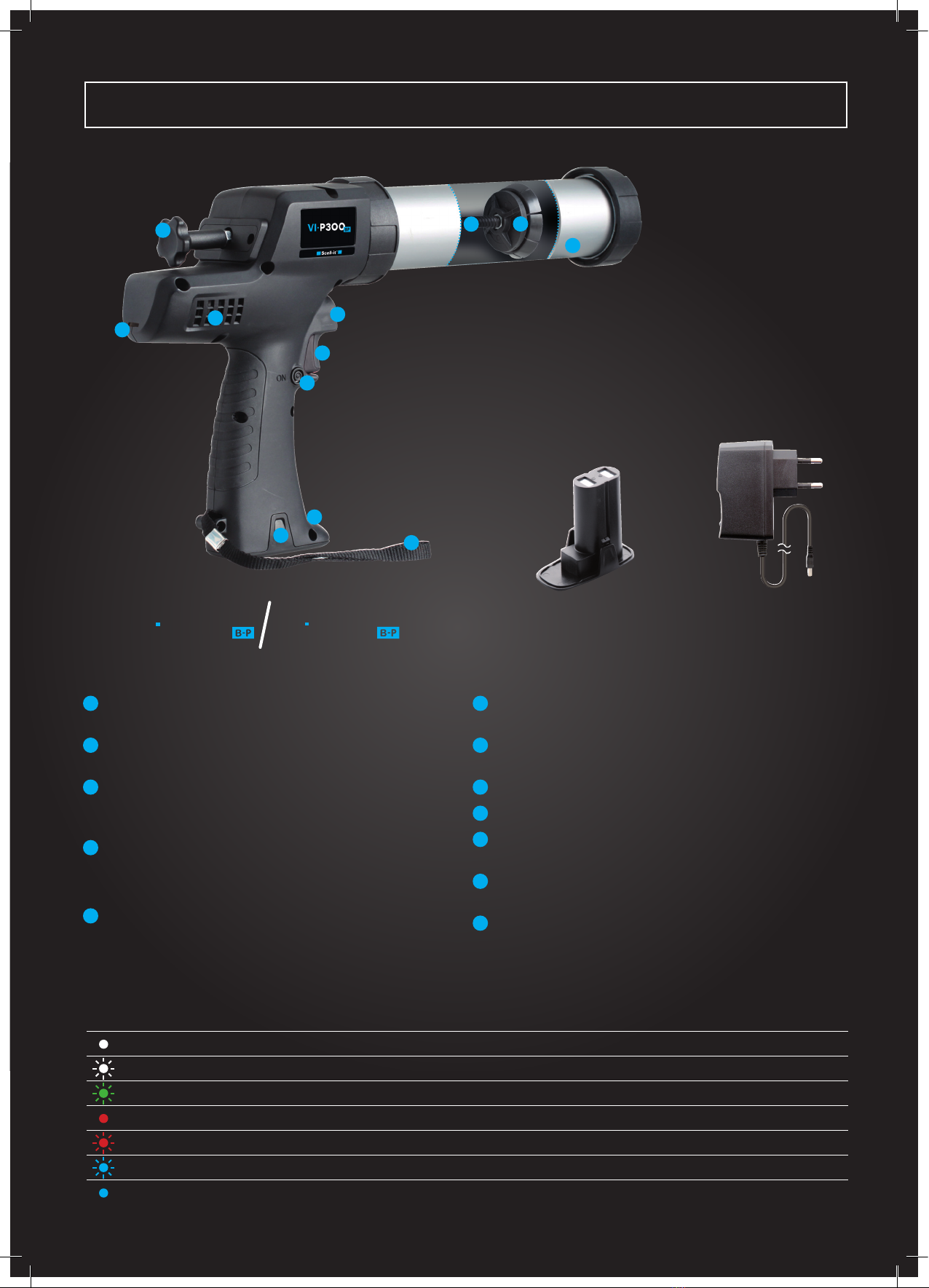

BATTERY CHARGING

IMPORTANT

Connect the power core to the DC terminal at bottom of

the battery first, and then plug the compact transformer

into the A.C. power outlet.

It takes approximately 1~1.5 hours to get fully charged

battery.

Charging

Complete charge

RECHANGABLE BATTERY POWER

TOOL USE AND CARE

• Ensure the lock switch is in « off « position before

inserting battery pack.

• Use only original manufacturer supplied charger to

charge original manufactured battery.

• Use of any other battery packs may cause damage

or fire.

• When battery pack is not in use, keep it away from

other metal objects like paper clips, coins, keys, nails,

screws or other small metal objects that can make a

connection from one terminal to another. Shorting the

battery terminals may cause burns or a fire.

• Under abusive conditions, liquid may be ejected

from the battery, please avoid contact. If contact

accidentally occurs, flush and clean with water.

If liquid contacts eyes, look for medical help

immediately. Liquid ejected from the battery may

cause irritation or burns.

• If the performance of the battery diminishes

substantially even it has been fully charged, the life

of battery is terminated, please replace a new one.

• Do not keep the battery in recharge for more than 2

hours. This could reduce battery life.

• Wet or overheat condition will reduce battery life.

• When discarding batteries, environmental issues

must be considered. The local rules or laws governing

the disposal of battery must be followed strictly.

Maintaining battery pack

The battery packs will operate for years and/or

hundreds of cycles when they are maintained and

used according to these instructions.

• A battery pack that is stored for six months without

using will discharge itself. Batteries discharge at a

rate of about 1% per day. Charge the battery every

six months even it is unused to maximize battery life.

Replace this battery pack until it no longer performs

the power needed for your application.

• Store your battery pack in a cool, dry place. Do

not store at place where the temperature may exceed

50°C such as in a vehicle or metal storage during the

summer. High temperature will overheat the battery

pack, and reduce battery life. If it is stored for several

months, the battery pack will gradually lose its power.

During the life of the battery pack, the operating time

between charges becomes shorter. If the operating

time becomes extremely short after a proper charge,

the life of the battery pack has been terminated and it

should be replaced.

GENERAL SAFETY RULES

Work area safety

Keep work area clean and well lit. Cluttered or dark

areas cause accidents easily.

• Do not operate power tool in explosive atmospheres,

such as in the presence of flammable liquids, gases

or dust. Power tools create sparks which may ignite

the dust or fumes.

• Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose

control.

Electrical safety

Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs

with earthed (grounded) power tools. Correct plugs

and matching outlets will reduce risk of electric shock.

• Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is

grounded.

• Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk

of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric

shock.

Personal safety

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result

in serious personal injury.

• Use safety equipment. Always wear eye protection.

Safety equipment such as dust mask, non-skid

safety shoes, hard hat or hearing protection used for

appropriate conditions will reduce personal injuries.

• Avoid accidental starting. Ensure the switch is in

the off-position before plugging in. Carrying tools with

your finger on the switch or plugging in power tool

that have the switch on invites accidents.

• Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, clothing and gloves away from

moving parts. Loose clothes, jewelry or long hair can

be caught in moving parts.

• If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of these devices

can reduce dust-related hazards.

• Working at high place with this caulking gun, please

notice working environment safety.

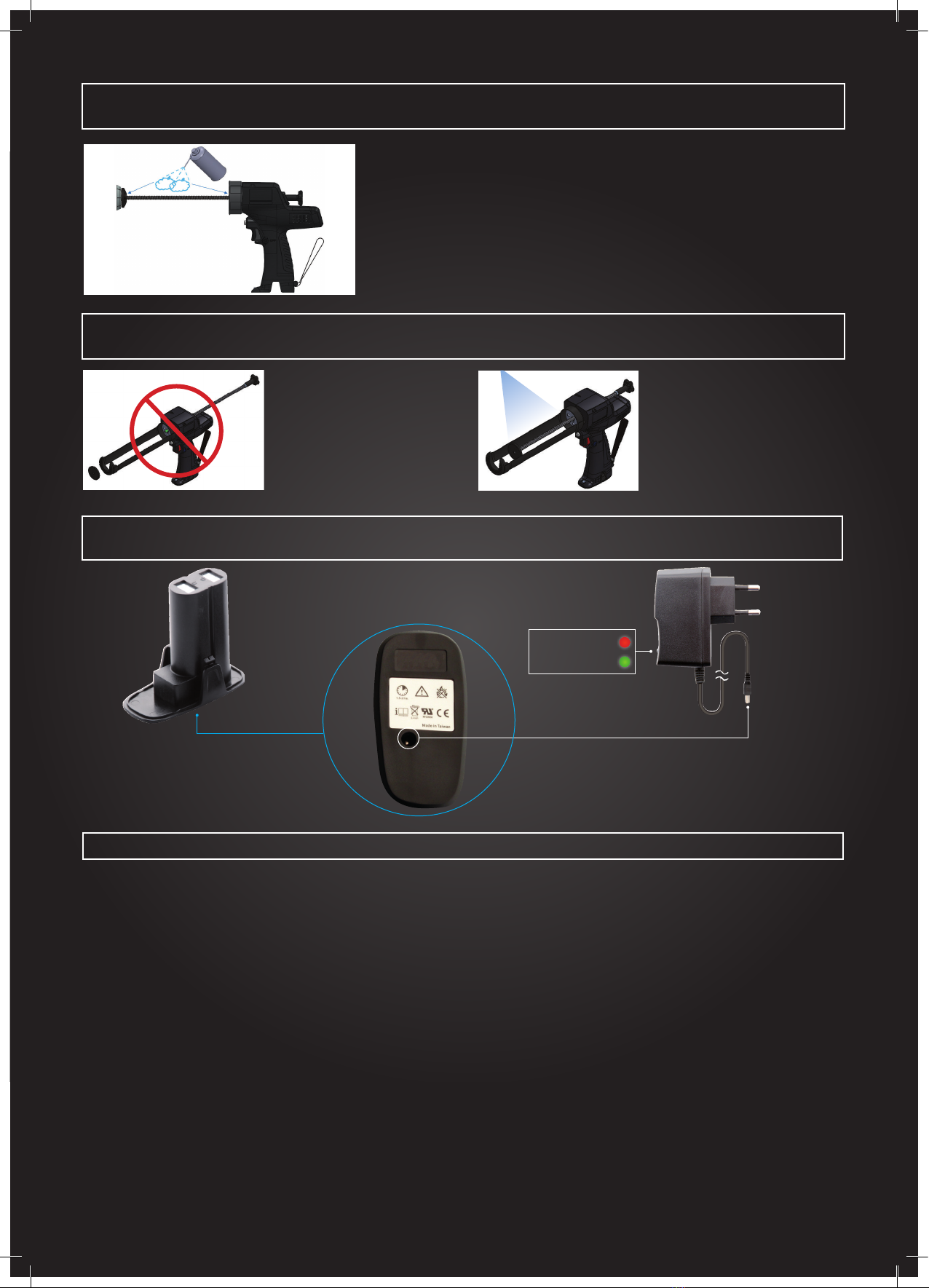

WARNING

Never remove the plunger rod off the tool in any

case, otherwise it will cause failure of spheres

locating which makes the gun fail to work. Keep

the plunger rod clear and neat at all times. A

plunger rod covered with adhesive may damage

the whole mechanism. The warranty expires when

adhesive goes into the mechanism; in addition,

any maintenance fee occurred will be charged by

the repair service facility. détergents ménagers

contiennent de l’essence, de la térébenthine, du

diluant pour vernis et peintures ou de l’ammoniac.

In case of that residual material left on the plunger

rod, please clean it up thoroughly before pulling

the rod to the backward position. The purpose

is to prevent the material from entering the inner

mechanism and keeping the tool in good condition.

MAINTENANCE & CLEANING

• If the tool does not start or operate at full power with a

fully charged battery pack, clean the contacts on the battery

pack. If the tool still does not work properly, return the tool,

charger and battery pack to service facility for repairs.

• Clean dust and debris from charger and tool vents. Keep

tool handles clean, dry and free of oil or grease. Use only

soap and a damp cloth to clean the tool, battery pack and

charger since certain cleaning agents and solvents are

harmful to plastics and other insulated parts. Some of these

include gasoline, turpentine, lacquer thinner, paint thinner,

chlorinated cleaning solvents, and ammonia, which may

consist in household detergent.

• Never use flammable or combustible solvents on tools.

• After daily application or continuous

several hours usage, please grease the

plunger rod and bearings located on the

plunger rod connector.

7.2 V Li-Ion Battery