WARNINGS

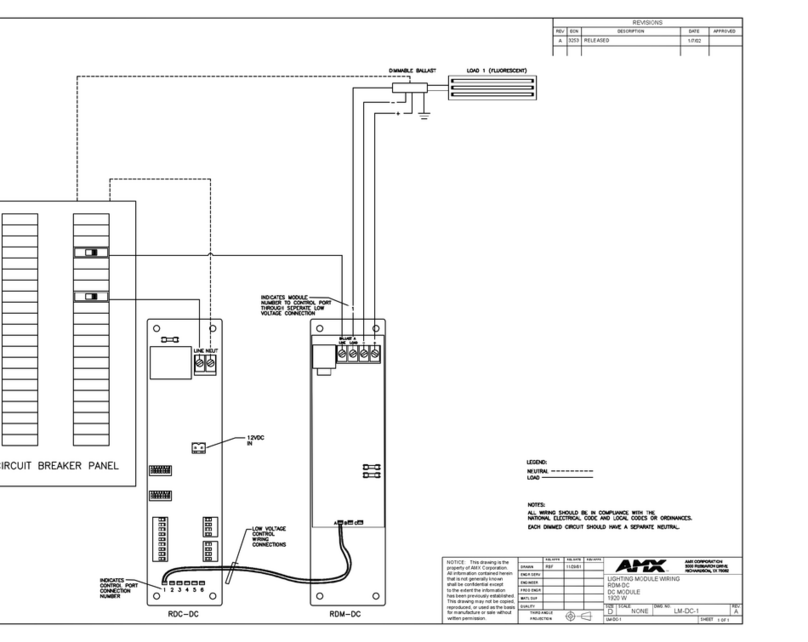

The electric installation and the functioning logic choice must agree with the laws in force. In any case you must foresee a 16A

and threshold 0.030A differential sw

Materials handling must be made with appropriate vehicles..

itch. Keep the power cables (motors, power supply) separate from the command cables

(push buttons, photocells and so on). In order to avoid any interference it’s preferable to use two separate cables and ducts.

REPLACEMENTS

Any request for spare parts must be sent to:

SEA s.r.l. - Zona Ind.le, 64020 S.ATTO - Teramo - Italia or SEA UK Limited Tel : 0121 706 9629

PRODUCT USAGE

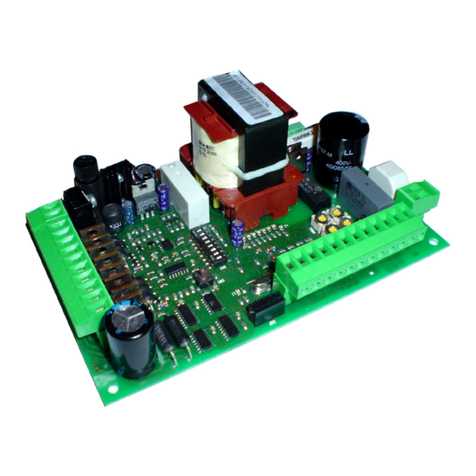

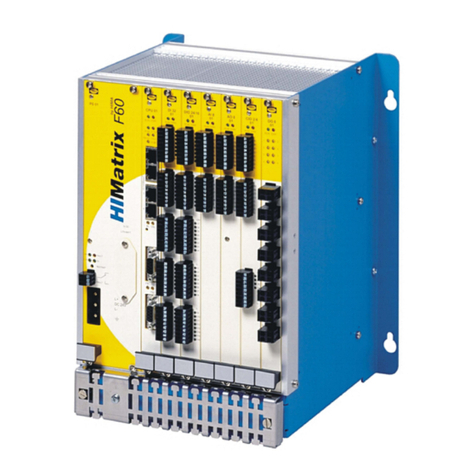

The electronic equipment 23001135 has been designed to be used exclusively as management equipment for sliding gates

automation, swing gates, sectional doors, overhead doors, barriers.

SAFETYAND ENVIRONMENTAL COMPATIBILITY

Disposal of the packaging materials of products and/or circuits should take place in an approved disposal facility.

REGULAR PRODUCT DISPOSAL (electric and electronic waste)

(It’s applicable in EU countries and in those ones provided with a differential rubbish collection)

The brand that you find on the product or on documentation signals that the product must not be disposed off together with

other domestic rubbish at the end of life cycle. In order to avoid any possible environmental or health damage because of the

irregular waste disposal, we ask you to separate this product from other forms of rubbish and to recycle it in a responsible way

in order to provide the sustainable re-use of material resources. Domestic users are invited to contact the retailer where the

product has been purchased or the local office in charge of all the information related to differential collection and recycling of

this kind of product.

STORING

REPLACEMENT AND MAINTENANCE

The replacement and/or putting out of service and/or maintenance of the electronic equipment 23001135 must be made only

and exclusively by authorised and qualified staff.

WARRANTY LIMITS

The warranty form of the electronic equipment 23001135 is valid for 24 months starting from the printed date on the product.

The mentioned product will be considered under warranty if it doesn’t show any damage caused by an irregular use or by any

modification or breaking. The warranty is valid only for the original buyer.

NOTE:THE MANUFACTURER IS NOT CONSIDERED RESPONSIBLE FOR ANY DAMAGE CAUSED BY IRREGULAR,

WRONG OR UNREASONABLE USE.

SEA reserves the right to make any required modification or change to the products and/or to this manual without any

advanced notice obligation.

WARNINGS AND WARRANTY

16

WAREHOUSING TEMPERATURES

Tmin TMax Dampnessmin DampnessMax

- 40°C + 85°C 5% Not condensing 90% Not condensing

REV 04 - 11/2006

GATE 2 - 24V PLUS

Automazione

Porte e Cancelli