SEA USER 1 - 24v DG R1 User manual

USER 1 24V DG MAXI

41121 REV. 4 2/21

CTC CT T D T D

nlis

International registered trademark n. 804888

SEA S.p.A.

ona Indstriale Sant Atto 42 eramo IA

elephone 1 41 a 1 44

.seateam.com

seacomseateam.com

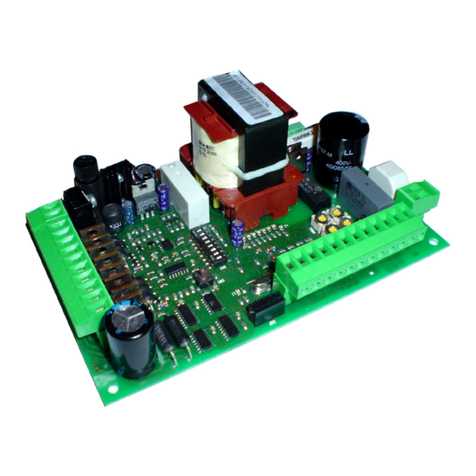

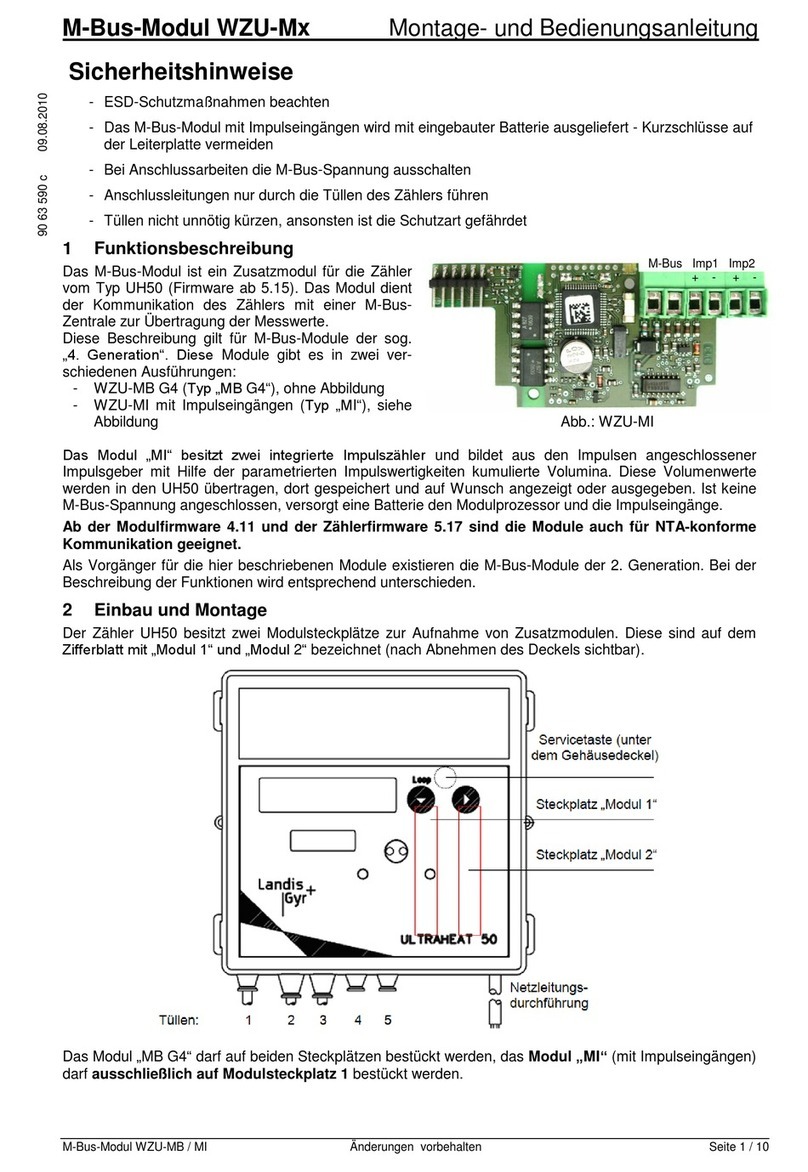

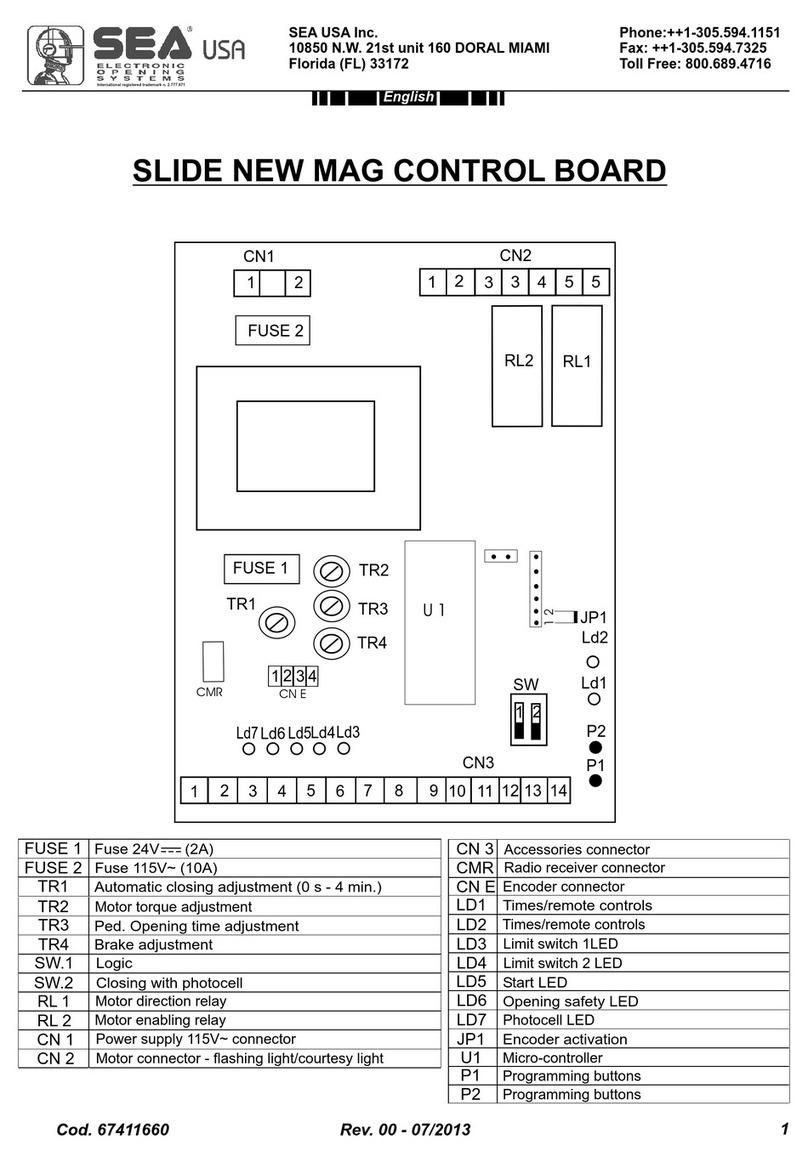

DESCRIPTION OF THE COMPONENTS

CN1 = Input/Output connector

CN2 = Pre-wired limit switch connector

CN3 = Not Pre-wired limit switch connector

CN4 connector= Master/slave

CN5 = Courtesy light output connector

CN6 otors connector= M

CN7 = Batteries connector - Quick connection

CN8 = Power connector

CN9 = Jolly 3 connector

CNA = RX Receiver connector

CNE = Encoder connector

CNP = Programming connector

CNS = RF FIX receiver connector

EXP = External module connector

OK = Programming button

DOWN = Programming button

UP = Programming button

RL1 = Motors control relay

Rl2 = Motors control relay

RL3 = Light/dry output contact relay

PR1 = Rectifier bridge

F1 = Fuse 20 AT

Jp1 = Relay 3 activation

JP2 = Light/dry contact selection

Maximum motor current: 20A

Environment temperature: -20°C +50°C

156 mm

100 mm

RICEVENTE RX

JOLLY3

CN8 F1

CNA

CN9

CN5

CNP

RL1

CN4

UP DOWN OK

PR1

DISPLAY

EXP

POWER FUSE MOTOR LIGHT

MASTER/SLAVE

PROG

RADIO MODULE

JOLLY

CNE

ENCODER

1

CN7

RL2

CNS

CNS CN2

CN3

LIMIT SWITCH

- S +

RL3

JP2

JP1

CN1

CN6

TECHNICAL SPECIFICATIONS

Control unit power supply: 24 V~

Absorption in stand by: 30 mA

Specifications of external enclosure: 305 x 225 x 125 mm - Ip55

English

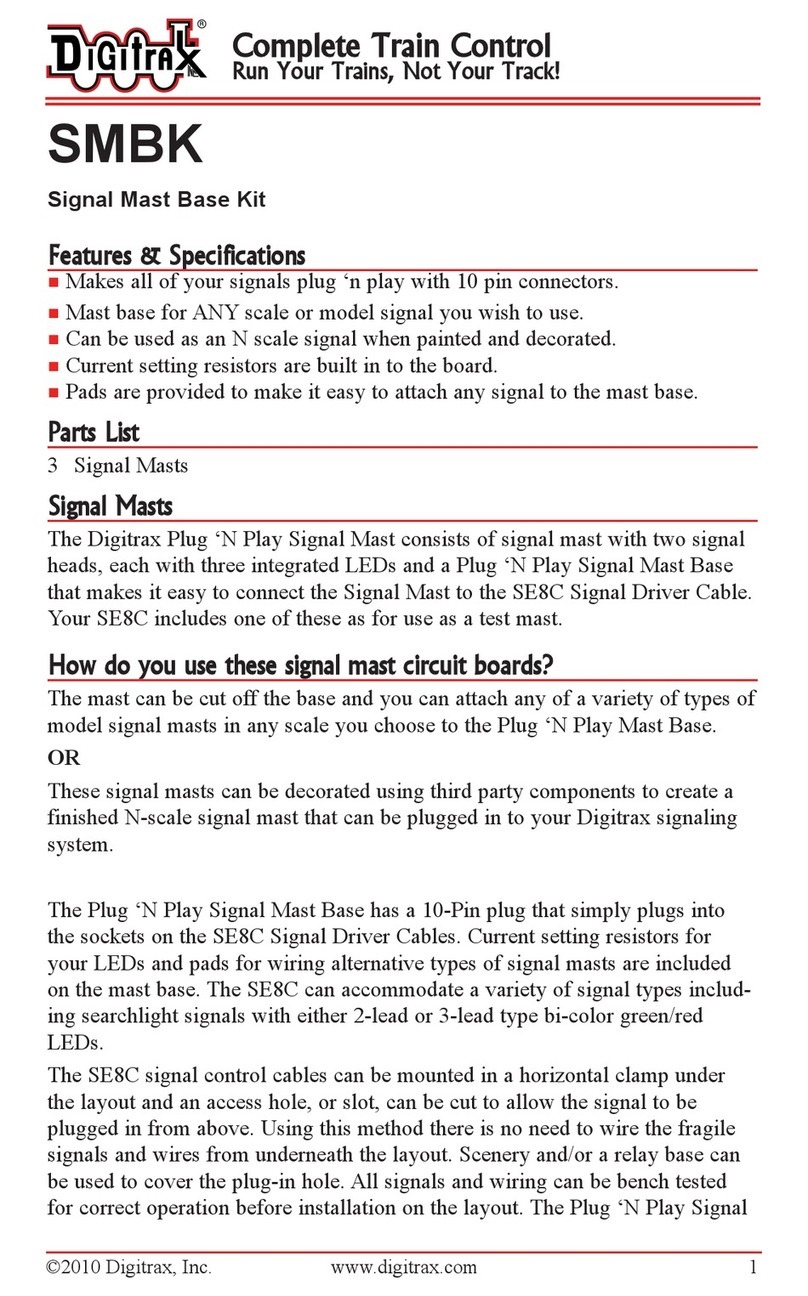

CONNECTIONS

JUMPERS

The herein reported functions are available starting from revision 02.02 compatible only with Jolly 3

123 4 5 6 7 8 910 11 12 13

CN1

Start

Stop

Common

Antenna

START Ped.

Common

Photocell 1

Common

ANT COM START

PEDST

STOP COM PH1 PH2

EDGE

AUX

COM 24V (FL)-

24V 750 mA max

(Accessori)

Safety edge

Flash (-)

Photocell 2

+ +

- -

123 4 5 6 7 8 910 11 12 13

CN1

ANT COM START

PEDST

STOP COM PH1 PH2

EDGE

AUX

COM 24V (FL)-

Start

Stop

Common

Antenna

START Ped.

Common

Photocell 1

Common

24V 750 mA max

(Accessori)

Safety edge

Flash (-)

Photocell 2

+ +

- -

Optional

WARNING: The control unit is designed with the automatic detection of not used N.C. inputs (photocells, Stop and Limit

switch) except the SAFETY EDGE input. The exclude inputs in self-programming can be restored in the “Check inputs”

menu without need to repeat the programming

Limit switch Cl.1 (Yellow)

Limit switch Cl.1 (Yellow)

24V (Red)

Common (White)

Limit switch Op.1 (Green)

Limit switch Op.1 (Green)

MOTOR (CN6)

Max 400W

ENCODER (CNE)

1

Brown

White

Green

AUX Programmable

(24V 300 mA max)

AUX Programmable

(24V 300 mA max)

1

LIMIT SWITCH

CN2

CN3

LIGHT (CN5)

Light/Dry contact

M

LIGHT (CN5)

Max 100mA

POWER (CN8)

24V~

RL3

JP2

JP1

*

*

*

*

*The indicated maximum load of 750 mA refers to the maximum load distributed on all 24V

outputs, including the on-board receiver absorption (300 mA)

English

QUICK SELF-EARNING

PROGRAMMING

Start quick programming

You can start the quick programming by

holding UP for 5 s in the “Input check

menu", until the motor starts.

“Input check

menu"

Fast self-learning START command by

radio control

You can store the START button of the

remote control while pressing DOWN for 5 s

in the “Input check menu".

Once the writing "Press button" appears,

press the button of the transmitter, which

you want to store for the START command.

By pressing OK, you can exit the menu,

otherwise it will be left automatically after 5

seconds.

DISPLAY

UP DOWN

5 s 5 s

---

--

---

UP DOWN

English

PROGRAMMING

BUTTONS

OK to exit

Menu or press

the button of

the next TX to

be stored

RECEIVER

MISSING

Skip this step if you do not want to program a transmitter

Choose the type of

motor with

UP or DOWN

To confirm and

return

to main menu

Choose "ON" with UP or

DOWN button only if in

programming the motor starts

in opening

With UP or DOWN

choose

the desired logic

With UP or DOWN

choose a delay for

automatic closing

With UP or DOWN

Choose ON

With UP or DOWN choose ON

to start times learning

At the end of the selflearning

the control unit returns automatically

to the main menu

With

UP or DOWN Choose

ON to start test

ALL OTHER PARAMETERS HAVE DEFAULT

SETTINGS WHICH ARE USEFUL FOR THE

90% OF THE APPLICATIONS BUT CAN BE

HOWEVER SET THROUGH THE SPECIAL

MENU. FOR ENTERING INTO THE SPECIAL

MENU MOVE ON ONE OF THE MENU AND

PRESS THE UP AND DOWN BUTTONS AT

THE SAME TIME FOR 5 SECONDS

If on the display

appears the item:

Check if a receiver

has been connceted

The gate will execute a CLOSING-OPENING-CLOSING CYCLE

PROGRAMMING

QUICK START

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

OK

1

2

3

5

6

7

8

9

OK

OK

OK OK

OK OK

OK OK

OK OK

OK OK

UP

UP

UP

UP

UP

UP

UP

OKOK

START

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

OK

UP

LANGUAGE ITALIANO

UP

MENU

SEA

SET

MENU

SEA

SET

OK

END

15

MENU

SEA

SET

OK

SPECIAL

MENU

16

UP

UP

10

OK

DOWNUP

OK

Go back to menu

9-PROGRAMMING,

replace the gate halfway

and repeat the timing

programming

TRANSMITTERS

MOTOR

REVERSE

MOTOR

LOGIC

PAUSE

TIME

START IN

PAUSE

PROGRAM-

MING

TEST

START

If the motor has

magnetic limit switches,

select "Magnetic"

in the special menu:

104 - SELECT LIMIT SWITCH

PRESS

BUTTON STORED

Skip this step

if you want to work

in half-automatic

logic

To confirm and

return

to main menu

To confirm and

return

to main menu

To confirm and

return

to main menu

To confirm and

return

to main menu

To confirm and return

to main menu

Press OK to return to the

display of the inputs state

Press OK to enter the special menu

Press the

button of the

TX to be

stored

Skip this step if a TX has already been stored

English

The SLIM motor has no limit switches and works only with Encoder. For the stroke learning it is necessary

that the motor reaches the mechanical stops. Learning provides a CLOSE-OPEN-CLOSE cycle with

automatic detection of the mechanical stops. During normal cycle the motor will stop at about 1 cm from the

mechanical stop. This space will be regulated through the motor release parameter (menu 82).

Attention:

In case of a STOP command, power failure or obstacle detection, the motor will perform a closing maneuver

at low speed up to the mechanical stop in closing, to retrieve the position.

PROGRAMMING SLIM MOTOR WITHOUT LIMIT SWITCH

Fig. 1 Fig. 2

Fig. 3

Fig.4

1 2 3 4 5 6 7 8 9 1011 1213

WORKING TIMES SELF-LEARNING

WORKING TIME SELF-LEARNING ON MOTORS WITH LIMIT-SWITCH

PRELIMINARY NOTE: When using magnetic limit switches (such as on B-200 model), make sure that

the control unit is set on «magnetic limit switch» before learning:

MENU 104 - SELECT LIMIT SWITCH - “Magnetic”

1) Turn off the power supply, release the motor and place the door (or the barrier) manually at its mid run

2) Reset the mechanical lock

3) Select 9 - PROGRAMMING on the display, press OK and then one of the UP or DOWN buttons.

Now the gate will automatically execute a CLOSING-OPENING-CLOSING cycle

4) The self-learning is done

ATTENTION: If the motor starts in opening, remove and re-put power supply, select on the display

5-REVERSE MOTOR and through the UP and DOWN buttons select ON; if you have the Jolly3 programmer,

activate the motor exchange function and, only if present, limit-switch exchange function. If the motor starts

in closing and then it stops, remove the power supply and reverse the motor cables, then repeat the

programming procedure

ATTENTION: This procedure is potentially dangerous and should only be performed by qualified

personnel in safety conditions

The control unit is pre-set with DEFAULT settings. To start the control unit with the DEFAULT settings

just keep pressed the UP and DOWN buttons at the same time power supplying the control unit

till the display shows the message «INIT». The DEFAULT settings are shown in the Menu table

English

English

FUNCTION LOGIC

AUTOMATIC LOGIC

A start impulse opens the gate. A second impluse during the opening will not be accepted.

A start impulse during closing reverses the movement.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will

be semi-automatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU

the item 7-START IN PAUSE and choosing ON or OFF. By default, the parameter is OFF.

SECURITY LOGIC

A start impulse opens the gate. A second impulse during opening reverses the movement.

A start impulse during closing reverses the movement.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will

be semi-automatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU

the item 7-START IN PAUSE and choosing ON or OFF. By default, the parameter is OFF.

STEP BY STEP TYPE 1 LOGIC

The start impulse follows the OPEN-STOP-CLOSE-STOP-OPEN logic.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will

be semi-automatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU

the item 7-START IN PAUSE and choosing ON or OFF. By default, the parameter is OFF.

STEP BY STEP TYPE 2 LOGIC

The start impulse follows the OPEN-STOP-CLOSE -OPEN logic.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will

be semi-automatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU

the item 7-START IN PAUSE and choosing ON or OFF. By default, the parameter is OFF.

DEAD MAN LOGIC

The gate opens as long as the START button of opening is pressed; releasing it the gate stops. The gate

closes as long as the button connected to the PEDESTRIAN START is pressed; releasing it the gate stops.

To execute complete opening and/or closing cycles the related pushbuttons must be constantly pressed.

2 PUSHBUTTONS LOGIC

One start opens, one pedestrian start closes. In opening the closing will not be accepted. In closing a start

command reopens, a pedestrian start command (closes) will be ignored.

PASSWORD ENTERING MANAGEMENT

With a new control unit all menus can be displayed and set and the password will be disabled.

Selecting one of the Menus and keeping UP and DOWN pressed at the same time for 5 seconds, you will

access the SP Menu containing the 34-PASSWORD Menu. Pressing OK in the 34-PASSWORD Menu, you

will proceed with the entering of the numeric code of the 4-digit password. Use UP and DOWN to increase or

decrease the number, press OK to confirm it and you will pass automatically to the entering of the next

number. Pressing OK after the last entered number the word “Sure?” appears, confirm the activation of the

password and the message OK appears, pressing UP or DOWN instead you can cancel the operation and

“No operation” will appear on the display. Once entered the password, it will be definitively activated, once

the display switch off timeout has expired, or by turning off and on again the control unit. Once the password

has been activated, the menus of the display can be only displayed but not set. To unlock them you must

enter the correct password in the 34-PASSWORD menu, if the password is wrong the message “Error” will

appear. At this point, if the password has been entered correctly, the menus will be unlocked and it will be

possible to change the parameters of the control unit again. If the control unit has been unlocked through 34-

PASSWORD Menu, it is possible to enter a new and different password, using the same entering process as

for the first one; at this point, the old password will no longer be valid. If the password has been forgotten, the

only way to unlock the control unit is to contact the SEA technical assistance, which will assess whether to

provide the procedure to unlock the control unit or not.

Note: The password cannot be set through the Jolly 3 terminal.

SET DESCRIPTION

DEFAUL

T

SET

VALUE

Italiano

Italian

English

English

Français

French

Español

Spanish

Dutch

Dutch

Start

Start

Partial opening

Partial opening

External module

External module

Stop

Stop

Bistable Stop

Pressed once, it stops the gate. Pressed twice,

it reactivates the START input

Unloch

Storing of a command for unlocking the

electric brake

Delete a transmitter

Delete single transmitter

Clear memory

Delete transmitter memory

End

“Transmitters” menu output

Saturn Fast

Saturn Super Fast

Saturn Fast

Saturn Super Fast

Joint * Joint

Hydraulic Unit Hydraulic Unit

Lepus Box Chain * Lepus Box Chain

Slim * Slim

B-800 * B-800

Saturn 1500

Lepus 2000

Saturn 1500

Lepus 2000

Barrier FC slow-down

Barrier with limit-switch as electronic slow-

down

Orion Box Fast Orion Box Fast

On

In On reverses the opening with the closing

and/or vice-versa (Note: both motors and limit-

swich are reversed)

Off Off

Automatic

Automatic

Open-stop-close-stop-open

Step by step type 1

Open-stop-close-open

Step by step type 2

2 button

Two buttons

Safety

Safety

Dead man

Dead man

Off

OFF (semi-automatic logics)

1 240

Setting from 1 second to 4 minutes

Off

The Start is not acceped during pause

On

The Start is acceped during pause

9

PROGRAMMING Off On Times learning start Off

10

TEST START Off On Start command Off

14

RESET

15

END

16

SPECIAL MENU

USER 1 24V DG MAXI MENU FUNCTIONS TABLE

MENU

1

LANGUAGE

English

5

REVERSE MOTOR

Off

2

TRANSMITTERS

Start

Partial

Opening

3

MOTOR

Saturn

1500

Lepus

2000

8

START IN PAUSE

Off

A count-down of 5 seconds will start by keeping pressed the UP button; at its end "INIT" will

appear on the display as confirmation of the control board reset

Press OK to return to the display of the firmware version

and to the one of inputs state

6

LOGIC

Open-

stop-

close-

open

7

PAUSE TIME

Off

Press OK to enter the special menu

SET DESCRIPTION

DEFAUL

T

SET

VALUE

17 OPENING SPEED 1 30 100 Setting from 30 to 100 70

18 CLOSING SPEED 1 30 100 Setting from 30 to 100 70

21

SLOWDOWN SPEED IN

OPENING 1

30 100 Setting from 30 to 100 40

22

SLOWDOWN SPEED IN

CLOSING 1

30 100 Setting from 30 to 100 40

25 LEARNING SPEED 30 100 Setting from 30 to 100 75

28

OPENING TORQ 1 10 100

Opening torque Motor 1: by increasing the

torque, more strenght will be required to

execute the inversion in case of obstacle.

Note: with hydraulic motors the torque will be

on 100%

Self

learned

during

Program-

ming

29

CLOSING TORQ 1 10 100

Closing torque Motor 1:by increasing the

torque, more strenght will be required to

execute the inversion in case of obstacle.

Note: with hydraulic motors the torque will be

on 100%

Self

learned

during

Program-

ming

32

ENCODER On In ON enables the Encoder, in OFF it's disabled On

47 ENCODER PAR. 1 xxx.

48 ENCODER TOT. 1 xxx.

32

ENCODER Potentiometer

Enables the reading of the potentiometer with

LE card

Off

51 I.PAR.M1 - - - - - - - -

52 I.AP.M1

From the value learned

to ± 100 pulses

53 I.CH.M1

From the value learned

to ± 100 pulses

32

ENCODER Off

ON enables the Encoder; OFF shows working

times learnt

Off

10% (Fast intervention)

99% (Slow intervention)

Adjusts the Encoder or Potentiometer

intervention time on Motor 1 in opening

Off (Intervention excluded)

Disabled

10% (Fast intervention)

99% (Slow intervention)

Adjusts the Encoder or Potentiometer

intervention time on Motor 1 in closing

Off (Intervention excluded)

Disabled

10% (Fast intervention)

99% (Slow intervention)

Adjusts the amperometric sensitivity in

slowdown. Active only on barriers

(300ms - 3s)

30%

Total

In case of obstacle or edge it totally rever-ses

the movement during the closing. If active, the

automatic reclosing will be attempted 5 times

Partial

It partially reverses the direction (of about 30

cm) in case of obstacle or edge or

potentiometer, then it stops

SPECIAL MENU

PRESS AT THE SAME TIME FOR 5 SECONDS TO ENTER OR TO EXIT THE SPECIAL MENU

SPECIAL MENU FUNCTIONS TABLE USER 1 24V DG MAXI

For entering into the special menu move on one of the menu and press the UP and DOWN buttons at the same time for 5 seconds

For exiting the special menu press END or move on one of the menu and press the UP and DOWN at the same time for 5 seconds

MENU

Impulses read by Encoder during operation (Motor1)

Impulses stored during programming (Motor 1)

33

OPENING SENSITIVITY

MOTOR 1

35%

Reports the current position of the potentiometer on the leaf

of motor 1. This parameter is useful for seeing if the

potentiometer is read correctly

Reports the impulses stored by the control unit when the leaf

of Motor 1 is fully open

Reports the impulses stored by the control unit when the leaf

of Motor 1 is fully close

37

SLOWDOWN SENSITIVITY

MOTOR

(For Barriers only)

34

CLOSING SENSITIVITY

MOTOR 1

35%

46

CLOSING INVERSION

Partial

For menu 47 and 48 see menu 32-Encoder = On

For menu from 51 to 53 see menu 32-Encoder = Potentiometer

UPDOWN

SET DESCRIPTION

DEFAUL

T

SET

VALUE

57

WORKING CURRENT 1 _ _ _ _ _

Shows the absorbed current by the motor

during the movement. The letter H at the

left of the current value indicates the

exceeding of the set inversion threshold

59

OPENING SLOWDOWN 1 Off (*) 100 From OFF to 50% of the stroke 30

60

CLOSING SLOWDOWN 1 Off (*) 100 From OFF to 50% of the stroke 30

63

DECELERATION

Only on *marked motors

0 %

100%

Adjust the passage between normal speed and

slowdown speed

According to

the motor

64

ACCELERATION 0 %

100%

Acceleration ramp.

Adjusts the motor start 70%

70

OPENING POSITION

RECOVERY

0 15 seconds

Retrieves the inertia of the motor in opening

after Stop or reversing

6s

71

CLOSING POSITION

RECOVERY

0 15 seconds

Retrieves the inertia of the motor in closing

after Stop or reversing

6s

72

OPENING TOLERANCE

MOTOR 1

0 100

Adjust the tolerance between stop and

obstacle on Motor 1 in opening

0

73

CLOSING TOLERANCE

MOTOR 1

0 100

Adjust the tolerance between stop and

obstacle on Motor 1 in closing

0

Only opening

Only closing

Opening and closing

Off

Off Disabled

1 100 Ajustable from 1 to 100

Only closing

Pre-flashing only active before closing

0.0 5.0 s

Pre-flashing

Normal

Normal

Light

Control lamp

Always

Always ON

Buzzer

Buzzer

Off

The flashing light remains OFF with the active

timer and open gate

On

The flashing light remains ON with active timer

and open gate

1 240

Courtesy light setting from 1sec. to 4min.

In cycle

Courtesy light in cycle

Dry contact

Activation 1 second after every Start pulse in

cycle, for the time set

Always

Activation always 1 second after every Start

pulse, independently of settings

89

TRAFFIC LIGHT

RESERVATION

Off On

If ON, the partial input will be activated to

work on the auxiliary board "SEM" (traffic light

management)

Off

90

PARTIAL OPENING 20 100 Setting from 20 to 100 30

= Start

Pause in partial opening same as in total

opening

Off

Disabled

1 240

Setting from 1second to 4 minutes

Off

On photo2

On partial entry

* For motors with hydraulic brake (CF) or double hydraulic brake (2CF) this parameter must be on Off

79

ANTI INTRUSION

If you force the gate manually, the control unit

starts the motor to restore the state of the

gate before forcing (only with limit switch)

Off

86

FLASHING LIGHT

Normal

87

FLASHING LIGHT AND

TIMER

Off

82

MOTOR RELEASE

Off

85

PRE-FLASHING

Off

92

TIMER

Turn the selected input into an input to

connect an external clock to

Off

88

COURTESY LIGHT

91

PARTIAL PAUSE

= Start

MENU

SET DESCRIPTION

DEFAUL

T

SET

VALUE

Always

AUX output always Power supplied

In cycle

AUX output active only during cycle

Opening

AUX power supplied only during opening

Closing

AUX power supplied only during closing

In pause

AUX power supplied only during pause

Fototest

Security test

In cycle and phototest

AUX output only during cycle with fototest

function active

Positive brake management

Positive Electric-brake (24V in On with

stationary gate )

Negative brake management

Negative Electric-brake (24V in On with gate in

cycle and 1 sec. before the Start)

Negative brake and Photocell

management

Negative electric-brake not active on

intervention of the photocell

Open gate warning Light

1 flash per second in opening

2 flashes per second in closing

Steady lit in Stop or Open

Start 3 s

If active, the 24VAUX output is activated for 3

seconds at every Start input, every photocells

or edge intervention

Barrier Led lights

the 24Vaux output will pilot the lights on the

barrier so that, with the beam closed the light

is on, with the beam opened the light is

switched off and with the moving beam the

light is blinking

Photo 1

Self-test active only on photo 1

Photo 2

Self-test active only on photo 2

Photo 1 and 2

Self-test active on photo 1 and 2

Closing

If the photocell is occupied, it reverses the

movement in closing; during the pause, it

prevents the reclosing

Opening and closing

The photocell blocks the movement as long as

it is occupied;when released, the opening

movement continues

Stop

If the photocell is occupied before the Start

input, the Start will be ignored. If the photocell

is occupied after the Start input, the photocell

will be ignored. If the photocell is occupied

during closing, the gate will reopen

97

PHOTOCELL 1

SHADOW LOOP 1

Stop and close

In closing, the photocell stops the movement

until it is occupied; when released the closing

movement continues

Closing

Close

The photocell stops the gate until it is oc-

cupied in both opening and closing; when

released, it gives a closing command (it closes

one second after its release)

Pause reload

If occupied during pause the photocell

recharges the time of pause. In closing it

reverses the movement

Delete pause time

If occupied during opening, pause or closing,

the gate reopens completely and closes

without observing the pause time

94

24V AUX

(Max. 500 mA)

Always

95

FOTOTEST

Off

MENU

SET DESCRIPTION

DEFAUL

T

SET

VALUE

Closing

If the photocell is occupied, it reverses the

movement in closing; during the pause, it

prevents the reclosing

Opening and closing

The photocell blocks the movement as long as

it is occupied;when released, the opening

movement continues

Stop

If the photocell is occupied before the Start

input, the Start will be ignored. If the photocell

is occupied after the Start input, the photocell

will be ignored. If the photocell is occupied

during closing, the gate will reopen

Stop and close

In closing, the photocell stops the movement

until it is occupied; when released the closing

movement continues

Close

The photocell stops the gate until it is oc-

cupied in both opening and closing; when

released, it gives a closing command (it closes

one second after its release)

Pause reload

If occupied during pause the photocell

recharges the time of pause. In closing it

reverses the movement

Delete pause time

If occupied during opening, pause or closing,

the gate reopens completely and closes

without observing the pause time

Stop and open

If the photocell is activated during opening,

the gate will stop and will continue opening

movement only when the photocell is

released. The photocell is ignored during

closing

Security edge 2 Photo 2 input can also work as security edge

99

PHOTO OFF IN CLOSING 0 % 50% Setting from 0% to 50% of the learnt space 0

Normal

Normal N.C. contact

8K2

Edge is active and protected by a 8K2 resistor

8K2 Double

Allows to connect two 8K2 protected edges

Photo 1 10K

Edge works as a photocell protected by a10K

resistor

Opening and closing

Active in opening and closing

Only opening

Active only in opening

Only closing

Active only in closing

Opening and closing

Active in opening and closing

Only opening

Active only in opening

Only closing

Active only in closing

Mechanical

Mechanical limit-switch

Magnetic

Magnetic limit-switch

Slow-down

It uses the limit switch inputs as starting point

of slow-down, so the limit switch impulse

must be given manually or detected by the

stop

102

SECURITY EDGE 1

DIRECTION

Opening

and

Closing

98

PHOTOCELL 2

SHADOW-LOOP2

Stop

and

open

100

SECURITY EDGE 1

Normal

MENU

103

SECURITY EDGE 2 DIREC-

TION (only if menu-98 is set

on "Security edge 2")

Opening

and

Closing

104

SELECT LIMIT SWITCH

Automa-

tic

SET DESCRIPTION

DEFAUL

T

SET

VALUE

Master

On applications with two motors in master-

slave, it allows to set the control unit as

master

Slave

On applications with two motors in master-

slave, it allows to set the control unit as slave

Off Disabled

106

DIAGNOSTICS 1 10 Shows last event (See alarms table)

107

MAINTENANCE CYCLES 100 240000 Setting from 100 to 240000 100000

108

PERFORMED CYCLES 0 240000

Reports the executed cycles. Keep pressed OK

to reset the cycles

0

112

PASSWORD - - - -

Allows the entering of a password blocking the

control unit parameters modification

- - - -

Off Disabled

Emergency

Without main power but batteries connected,

the gate will open fully and will remain open.

The gate recloses when the power is back

Last opening

Without main power, if batteries are lower

than 22V the gate opens and stay opened. The

gate recloses when the power is back

Last closing

Without main power, if batteries are lower

than 22V the gate closes and stay closed until

the power is back

117 ALWAYS CLOSE Off 240 seconds

In the event of a power failure, if the door has

been manually opened, it closes only after the

set time has elapsed (from 0 to 240 s), as soon

as the power is restored

Off

119

DISPLAY WRITING SPEED From 30% to 100% See Note 3 below 80%

120

BASIC MENU

MENU

Note 1: The *indicates that the default value or the menu may change depending on the selected motor type.

Note 2: After initialization the parameters "motor type" and "limit switch type" remain on the value chosen in the setup

program.

Note 3: Display writing speed set on 30% keeps writing slow; Display writing speed set on 100% keeps writing fast.

Please note that speed does not change on JOLLY 3 display.

Press OK to exit the special menu.

The special menu switches off automatically after 20 minutes

105

MASTER-SLAVE

Off

113

EMERGENCY

(This fuction involves the

use of "STAR 1000" with

"LB" unit)

Off

Initial system

Software Version

Programming example

DISPLAY INPUT STATUS

W h e n t h e

segment is ON

d u r i n g s e l f -

le a rni n g, th e

input status is

closed or OFF

Start

pedestrian

Photocell 1

Photocell 2

Edge 1

MENU

SEA

SET

- - -

- -

- - -

Start

Stop

Limit

Switch

opening

motor 1

Limit

Switch

closing

motor 1

VERG

UP

OK

UP

UP

UP

DOWN

DOWN

DOWN

OK

OK

OK

DOWN

SLIDING

JOINT

UP

U.001

MOTOR

LIMIT SWITCH

CLOSING

LIMIT SWITCH

OPENING

MENU

START

Description Description

EDGE

PHOTO1

PHOTO2

END

Start test

Safety edge

test

Photocell 1

test

Photocell 2

test

Opening

limit switch

test

Closing

limit switch

test

The contact must be a N.O. Contact . When activating the related

command on the display SET lights up, the input works.

If SET is always on, check the wirings.

The contact must be a N.C. Contact. When activating the related

command on the display SET lights up, the input works.

If SET is always on, make sure that the contact is a N.C. Contact

The contact must be a N.O. Contact. When activating the related

command on the display SET lights up, the input works.

If SET is always on, check the wirings.

The contact must be a N.C. Contact. When activating the related

command on the display SET lights up, the input works.

If SET is always on, make sure that the contact is a N.C. Contact

Ithe contact must be a N.C. Contact. When activating the related

command on the display SET lights up, the input works.

If SET is always on, make sure that the contact is a N.C. Contact

The contact must be a N.C. Contact. When activating the related

command on the display SET lights up, the input works.

If SET is always on, make sure that the contact is a N.C. Contact

Exit menu

OK

OK

MENU FUNCTION TABLE CHECK USER 1 24V DG MAXI INPUTS

To access the Menu for input check keep pressed OK for about 5 seconds.

OK

0.0V

Batteries

Voltage

Level

Note: If the Stop, Photocell 1 and Photocell 2, Edge 1 contacts are not bridged in self-learning,

they will be deactivated and can be reactivated through this menu, without repeating times self-learning

The contact must be a N.C. Contact. When activating the related command on

the display SET lights up, the input works. If SET is always on, make sure that

the contact is a N.C. Contact. Menu active only on version with limit switches

Enabled

Enabled

Blocked

Blocked

Enabled

Blocked

Enabled

Blocked

Pedestrian

Start test

STOP OK

OK

START

PEDESTRIAN

OK

Enabled

Blocked

Enabled

Blocked

Stop test

Batteries charge level indicator

The contact must be a N.C. Contact. When activating the related command on

the display SET lights up, the input works. If SET is always on, make sure that

the contact is a N.C. Contact. Menu active only on version with limit switches

INPUT CHECK MENU

The settings of the control unit are made through the UP, DOWN and OK buttons. The UP and DOWN

buttons to scroll through the MENUS and SUBMENUS. By pressing OK you enter from MENU into

SUBMENU and confirm the choice. Moving in the 1-LANGUAGE menu pressing the UP and DOWN buttons

at the same time you access the SP MENU for special settings. Moving in the 1-LANGUAGE menu pressing

the OK button for 5 seconds, you enter the CHECK MENU, where you can check the operating status of all

inputs.

English

RADIO TRANSMITTER SELF LEARNING

WITH RECEIVER ON BOARD OF CONTROL UNIT

!

WARNING: Make the radio transmitters programming before you connect the antenna and insert

the receiver into the special CMR connector (if available) with turned off control unit. With RF UNI

and RF UNI PG module it will be possible to use both Coccinella Roll Plus transmitters and radio

transmitters with fixed code. The first memorized radio transmitter will determine the type of the

remaining radio transmitters. If the receiver is a Rolling Code, press twice the button of the radio

transmitter that you want to program to memorize the first TX. In the case of transmitters with fix code it is

necessary to press 1 time the button of the transmitter you want to program to store the first remote control

Notes:

- Enter radio transmitters learning only when the working cycle stops and the gate is closed.

- You can store max. 2 of the available 4 functions. If the control unit receives a code which was already

associated to another function it will be updated with the new function.

TABLE EXAMPLE

Transmitter

button

Memory

location

Serial

number Customer

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

SET

START

PEDESTRIAN

START

EXTERNAL

MODULE

STOP

DELETE A

TRANSMITTER

0OK? OK

CLEAR

MEMORY OK

PRESS

BUTTON STORED

STORED

STORED

STORED

PRESS

BUTTON

PRESS

BUTTON

PRESS

BUTTON

If you want to program the

pedestrian start as second

channel

If you want to delete

a single transmitter

If you want to delete

the whole memory

If you want to program the

activation of the LIGHT

output as second channel

Press the

button of the

transmitter

to be stored

Press the

button of the

transmitter

to be stored

Press the

button of the

transmitter

to be stored

Select with

UP or DOWN

the memory

location

to be deleted

and press OK

Press the

button of the

transmitter

to be stored

If you do not want to execute the

cancellation, press UP or DOWN to

return to the 2-TRANSMITTER menu

Confirm the cancellation

If you want to program the

UNLOCH as second channel

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

UNLOCH STORED

PRESS

BUTTON

Press the

button of the

transmitter

to be stored

If you want to program the

STOP as second channel

OK

for 10 s.

MENU

SEA

SET

OK

TRANSMITTERS

OK

MENU

SEA

SET

If you want to exit the

2-TRANSMITTERS menu

END

MENU

SEA

SET

OK

UP

OK

OK

OK

OK

OK

OK

OK

Menu output

RF UNI 16 USERS Whitout memory

800 USERS With additional memory MEM

RF UNI PG 100 USERS Fixed code

800 USERS Roll Plus

RF UNI PG 800 UTENTI Fixed code

800 UTENTI Roll Plus

New model

Old Model

12 3 4

0

1

2

3

English

RADIO TRANSMITTER SELF LEARNING

WITH RF FIX RECEIVER ON BOARD OF CONTROL UNIT

Connect the receiver on

the CNS connectors,

making sure that the

direction is the

one shown in the

illustration

WARNING: Make the radio transmitters programming before you connect the antenna

and insert the receiver into the special CNS connector (if available) with turned off control unit.

With the RF FIX module it will be possible to use only radio controls with fixed code.

Select through the display 2-TRANSMITTERS and press OK, now select with the UP and DOWN buttons,

the command to which you want to associate the button (it is possible to associate max. 2 commands) and

press OK to confirm the choice, now press the button of the radio transmitter which you want to associate. If

the storage is successful, the display will show “Stored” .

In the 2-TRANSMITTERS MENU it is possible to select “Start” (to associate a Start command), “Pedestrian

start” (to associate a Pedestrian Start ), “External Module” (For the activation of a contact on the EXP

output), “Stop” (To associate the STOP command to the TX), “Unloch” (to associate the release of the

electric brake to the transmitter), “Delete a transmitters” (To delet the single transmitter only if it is a Rolling

Code Plus), “Clear memory” (To delete all TX), “End” (To exit menu 2-TRANSMITTERS). To release the

electric brake it is necessary to give three consecutive pulses, the 4th will reactivate the lock of the electric

brake.

Notes:

- Enter radio transmitters learning only when the working cycle stops and the gate is closed.

- It will be possible to memorize up to max. 16 codes (buttons) adding the MEM memory it will be possible to

store up to 496 different codes.

- You can store max. 2 of the available 4 functions. If the control unit receives a code which was already

associated to another function it will be updated with the new function.

DELETE TRANSMITTERS FROM THE RECEIVER

With modules different from RF FIX, it will be possible to delete only the entire memory of the receiver.

Proceed as follows: select from the menu 2-TRANSMITTERS: “Clear memory” and hold the OK button until

the display shows the message “OK”.

!

CNS

CNS

English

START - STOP - PEDESTRIAN START - ANTENNA - PHOTOCELL

SAR .. he SAR is connected eteen the clamps 2 and of the 1 terminal.

An impulse given to this contact opens and closes the automation depending onthe selected logic it can be given b a e switch,

a epad, etc. To connect the other devices refer to the related instructions leaflets. (ie. loop detectors and proximit switches).

ote1: In DEAD MAN logic it is necessar to eep pressed the Start for the opening of the automation.

ote2: In 2 BUTTONS logic this button performs the opening.

S .. he S is connected eteen the clamps 2 and of the 1 terminal .

The pressure on this button immediatel stops the motor in an condition/position. A start command is needed to re-start the

movement. After a stop the motor alwas re-starts in closing.

Can be activated through the on-board displa or through the oll programmer. In both cases its a N.O. contact which

provoques the opening of the automation eeping it open until it is activated. hen it is released, the gate attends the

set pausing time and executes the reclosing. The TIMER command can be activated on the inputs PHOTO2, PARTIAL

OPENIN START

ote1: hen activated on the pedestrian entr, the pedestrian will be disabled also on the radio transmitter.

ote2: In case of intervention of a securit device during the timer (Stop, Ammeter, Edge), to restore the movement it will be

necessar to give a start impulse.

ote: In case of no power suppl with open gate and active Timer the control unit will restore its use, otherwise if during restore

of the power suppl the TIMER is not activated it will be necessar to give a start impulse for the reclosing.

EDESRIA SAR .. he pedestrian start can e connected eteen the clamps 2 and 4 of the 1 terminal .

This input allows a partial opening the opening space can be set through the on-board displa or through the OLLY device.

ote1: The contact for partial opening is a N.O. Contact (Normall open).

ote2:In 2 BUTTONS logic it is necessar to eep pressed the Start Ped. to re-close the automation.

ote: In dead man logic this button executes the re-closing if ou eep it pressed.

ote4: hen closed during pause, the gate will reclose onl after this input has been reopened.

IMER actiation: This input can be transformed into TIMER (See TIMER).

hotocell 1 and hotocell 2 onnections

+ 24 (Accessories) max 750mA COM 0

PH1 Photocell contact 1 PH2 Photocell contact 2

ote: Self-test: connect the T to the AU clamp and activate the Autotest function. The

photocell 1 default setting is FOTO CLOSE and the photocell 2 one is FOTO OPEN. The

photocell 2 can be set also as TIMER (see TIMER function).

ote On the 26-FOTOTEST menu ou can also activate the self-test even on the single

photocell.

IS 1 and 2 adstale on displa see men or oll

SE actiation losin: if occupied, reverses the movement in closing,

during pause it prevent the closing.

Actiation repeat pase ase reload: If occupied, during pause it recharges the

timer of pause. In closing it reverses the movement.

E AD SE actiation penin and closin If activated the

photocell blocs the movement as long as its bus, when released the opening

continues.

AR actiation Stop and close : in opening it is not active in pause are

activated it commands the closing when released, otherwise its not active in closing it

stops the movement as long as it is bus, when released the closing continues.

S actiation Stop: hen activated before the opening the photocell

blocs the automation as long as it is bus, during the opening it will be ignored. In

closing the intervention of the photocell causes the reopening.

Actiation SE IMMEDIAE lose: The photocell stops the gate as

long as it is occupied in both opening and closing, when released, it gives a closing

command (Closing one second after release of the photocell ).

Common

Partial opening

Common

ptions AUX 24V ma 2mA can e set on displa

see men 4 or oll

Through the oll programmer it is possible to chose when having tension on

the AU output. The options are: Alwas, In ccle, Opening, Closing,

In pause, Fototest and In ccle and fototest. hen using control units

with batteries and/or solar panels, we recommend connecting the accesso-

ries which are not used when operator stands still (e.g. photocells) to a AU

output, setting the option In ccle. ith this setting ou can save energ b

lowering power consumption in stand-b, increasing the autonom of the

sstem.

Antenna

Start

Stop

Photocell 1

1 2 4

Photocell 2

RX1

RX2

X1

X2

1 11 12 1

Common

24V (Accessories)

IMER

1

1

Dela pase timeactiation: If the photocell is occupied during

opening, pause or closing, the gate reopens completel and closes

without observing the pause time.

nlis

English

WARNING LAMP - SAFETY EDGE - 10K PHOTOCELL - BUZZER

Edge

Common

24V (Accessories)

Example of a Flashing Lamp

and an Edge connections

10K

Photocell

9 10 11 12 13

Edge

BROWN

Common

FL(-)

24V (Accessories)

-

+

BUZZER

BLU

WHITE

GREY

E

Example of a 10K Photocells

and a Buzzer connections

MENU

SEA

SET

100-EDGE 1

MENU

SEA

SET

PHOTO 10K

.

OK

MENU

SEA

SET

OFF

Setting

10K Photocell

MENU

SEA

SET

100-EDGE 1

OKOK

MENU

SEA

SET

PHOTO 10K

.

MENU

SEA

SET

UPUP

OFF

SAFETY EDGE 9 and 11

Between clamps 9 and 11 on the terminal CN1 it is possible to connect an active Safety Edge. When

pressed, the Safety Edge opens the contact causing a partial inversion of the movement both in opening

and in closing. The Safety Edge output can be set «only in closing», «only in opening» or both directions

Note1: Note1: Through the on-board display or the JOLLY 3 programmer it is possible to activate the

balanced edge 8K2, in this case the edge contact is controlled by a special resistance value revealing the

eventual involuntary short- circuit of the device. In case of imbalance of the device a special alarm will be

shown on the on-board dispaly or on the JOLLY programmer.

Note2: Self-test can be made also on a radio powered Edge (See Auto-test Menu)

BUZZER 24V - Audible Alarm - 12 and 13

Use an autoswinging buzzer 24V of 100 dB. The buzzer will be switched on after two consecutive

activations of the entrapment protection. To reset the allarm it is necessary to push the button STOP.

Anyway after 5 minutes the buzzer will stop to sound and the automation stands still waiting for commands.

!

24V FLASHING LAMP 3W MAX 12 and 13

Flashing Lamp 24V (Accessories) 3W Max (Control lamp)

The Flashing Lamp can be connected between the 24V clamps

(Accessories) and FL (-) of CN1. The Flashing lamp advises that the

automatic gate is moving with 1 flash/second in opening and 2

flashes/second in closing. During pause it remains switched on.

Through the warning lamp it is also possible to identify alarms lied to

the STOP, PHOTOCELL 1, PHOTOCELL 2 and EDGE devices.

Through the display or the JOLLY 3 programmer it is possible to acti-

10K PHOTOCELL 9 and 11

Between clamps 9 and 11 on the terminal CN1 it is also possible to

connect a 10K Photocell. In this case it is necessary to set it on menu

100 - EDGE as Photo10K, then it will run following settings on menu

97 - PHOTO 1.

Nota1: The use of a 10K Photocell allows to get further protection in

case of short-circuit on the cables.

FL(-)

9 10 11 12 13

CN1

vate the pre-flashing function and/or to modify

the function of the warning lamp choosing

between fix flashing or control lamp.

The pre-flashing can be timed from 0 to 5

seconds otherwise it is possible to set it

before closing only

CN1

Safety edge

If Buzzer does not work, check the 86-FLASHING LIGHT menu is set on “Buzzer”

IMPORTANT NOTE:

INSTEAD OF THE FLASHING LAMP, IT IS POSSIBLE TO CONNECT A BUZZER;

REMEMBER TO SET THE 86 - MENU ON « BUZZER »

nlis

SAFETY LOOP CONNECTIONS

MAGLOCK 12V CONNECTIONS

DRAIG SS

EVEUA E E

MAGEI

Safety exit

loop 1

Loop1

Loop2

Loop3

Shadow

loop 2

Free exit

loop 3

1 11 12 1

1 2 4

1

12

Safet eit loop loop 1

Connecting scheme of

loop detector 1 reader

7 Contact photocell 1 (N.C.)

6 Common

Shado loop loop 2

Connecting scheme of

loop detector 2 reader

8 Contact photocell 2 (N.C.)

6 Common

ote lease set

TC

men to ado loop

ree eit loop loop

Connecting scheme of loop

detector reader

3 Contact start (n.o.)

6 Common

1 A E

2 A SED

12 24 V

V

Brown

Green

Pink

Yellow

Grey

T

or ot elay Card

types it is

necessary to set

men

on neatie rake

manaement MagLoc

M

1 11

1 2 3 4 5 6 7

AUX

1 1

M

M

12V D

MagLoc

M

1

AUX

1 24Vdc

M

M

Eternal poer sppl 12V / 24V D

elay Card

Type

elay Card

Type

Eternal

poer sppl

12V / 24V D

-C2

C1

C

C2

+

(BAT)

+

-

GND

PSOL

BAT 28VGND

1

+

-

S

+

ND

Solar Panel

Batteries

12 12

= charge 200mA

~

~

= charge 360mA

= charge 800mA

~

ode 2111

ode 21114

E SU

E SU

S 28VGND

1

+

ND

Solar Panel

PSOL

GND

+ Bat- Bat

= charge 200mA

~

~

= charge 360mA

= charge 800mA

~

USER 1

24V DG

MAXI

+

-

+

-

Batteries

12 12

ote To connect

the USER 1 24

D MAI control

unit with quic

connectable

charger to an old

batter charger,

ou must use the

CN adapter

cable

IMRA o connect the atteries alas se the atter charer

CONNECTION OF BATTERIES TO BATTERY CHARGER CARD

28 Batter charger

Positive batter

Negative batter charger

atter crrent mA atter Ah

Insert two 12 batteries connected in series

800

360

200

12 or 16

7

2

Specifications of optional atteries 24 Pb

EXTERNAL RECEIVER

Eample onnection

of a radio receier

For the connection of

the receiver refer to the

relative instructions

manual

Common

Common

24V (Accessories)

1 2 4 1 11 12 1

1

Start

Start ped.

+

-

nlis

Other manuals for USER 1 - 24v DG R1

5

Table of contents

Other SEA Control Unit manuals

SEA

SEA SLIDE NEW MAG User manual

SEA

SEA USER 2 24V DG R1B ALL-IN User manual

SEA

SEA SLIDE DG R2F User manual

SEA

SEA SLIDE DG R2F User manual

SEA

SEA USER 1 - 24v DG R1 User manual

SEA

SEA 23001157 User manual

SEA

SEA 9521 User manual

SEA

SEA GATE 1 DG R2BF User manual

SEA

SEA GATE 1 DG R1 User manual

SEA

SEA GATE 1 DG R1 User manual

Popular Control Unit manuals by other brands

Dungs

Dungs GasMultiBloc MB-VEF B01 instructions

National Instruments

National Instruments 9220 CALIBRATION PROCEDURE

WEG

WEG CFW500 Series Installation, configuration and operations guide

Lenze

Lenze i500 Series Mounting instructions

Norgren

Norgren HERION G1/4 manual

Blue Square Labs

Blue Square Labs Q360 Installation and maintenance guide