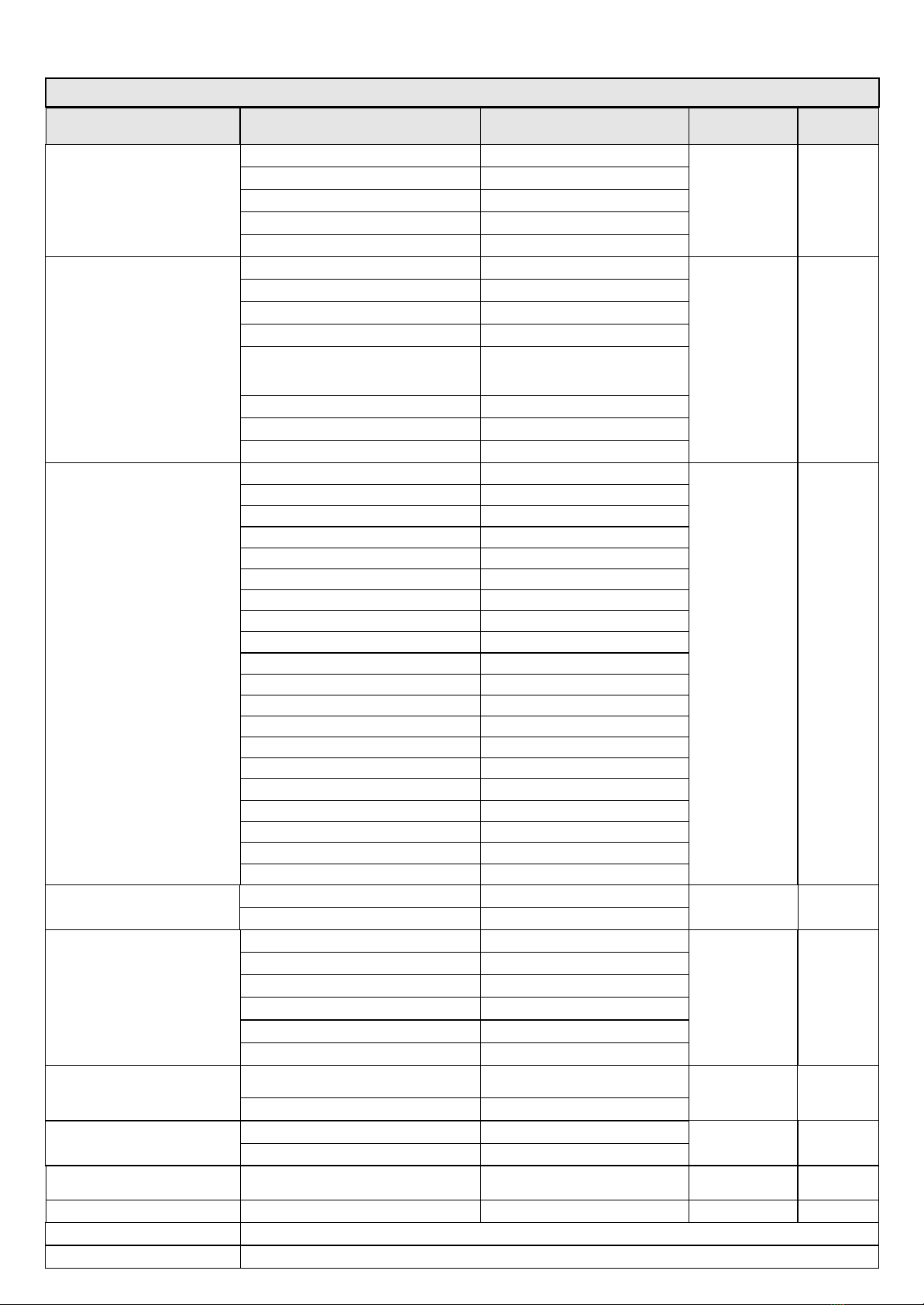

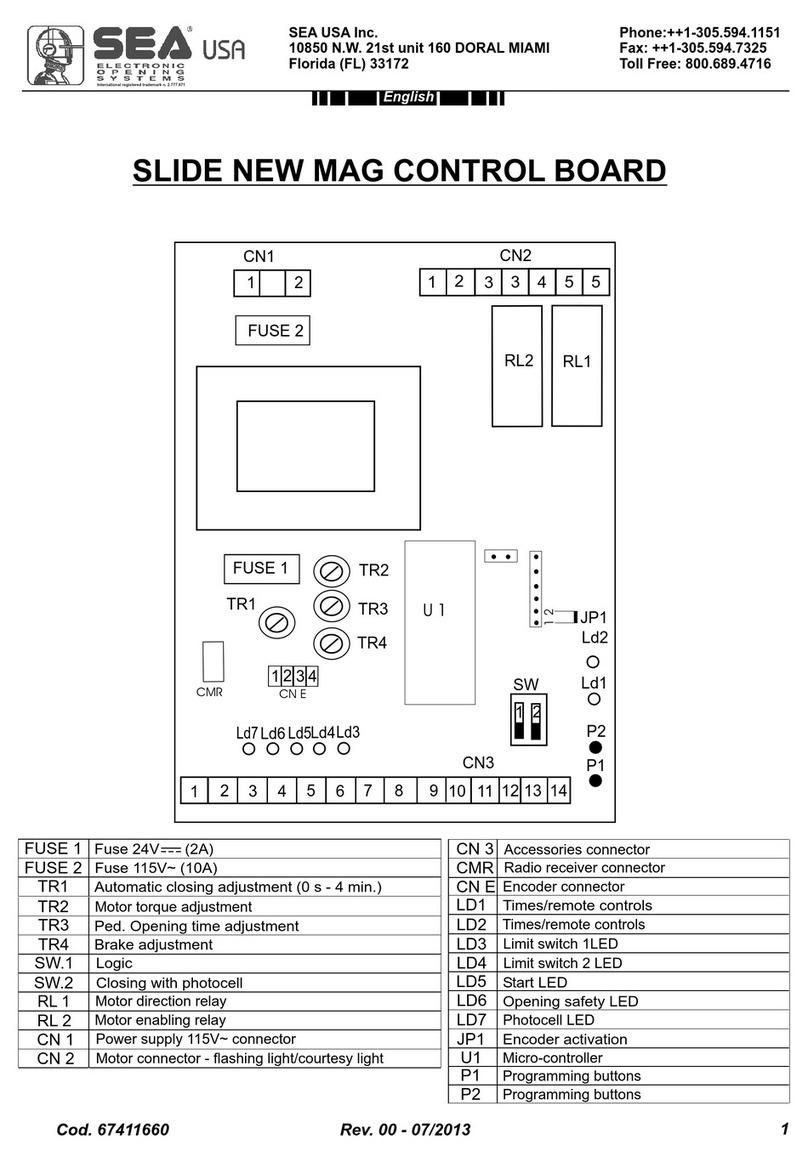

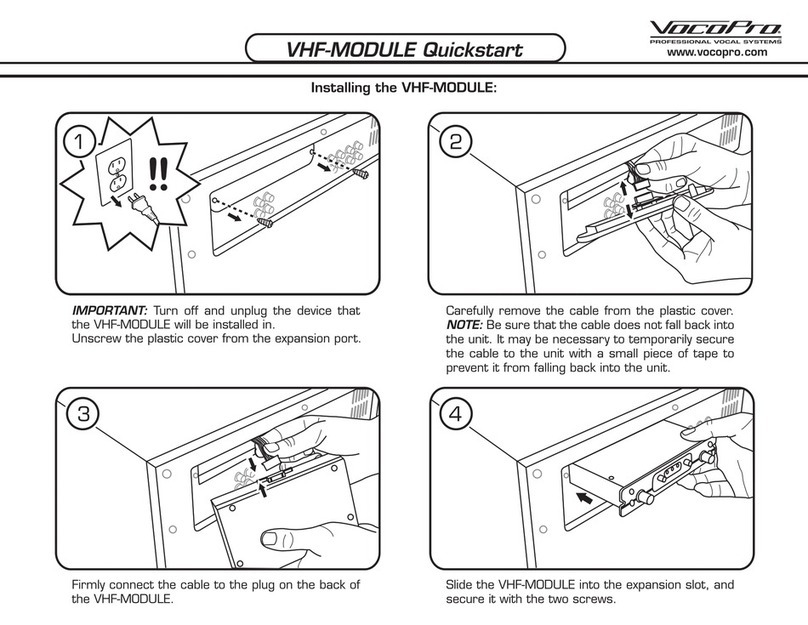

START (N.O.) The

An impulse given to this contact opens and closes the automation depending onthe selected logic it can be given by a key switch, a keypad,

etc. To connect the other devices refer to the related instructions leaflets. (ie. loop detectors and proximity switches).

Note1: In DEAD MAN logic it is necessary to keep pressed the Start for the opening of the automation.

Note2:

START is connected between the clamps 2 and 3 of the CN 1 terminal.

In 2 BUTTONS logic this button performs the opening.

STOP (N.C.) The STOP is connected between the clamps 2 and 5 of the CN1 terminal .

The pressure on this button immediately stops the motor in any condition/position. A start command is needed to re-start the movement.

After a stop the motor always re-starts in closing.

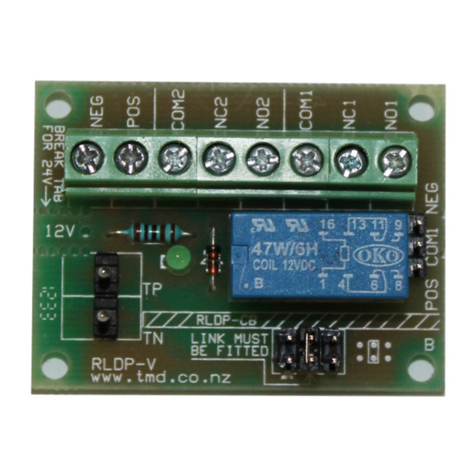

Photocell 1 and Photocell 2 Connections

+ = 24V (Accessories) max 750mA COM = 0V PH1 = Photocell contact 1

PH2 = Photocell contact 2

Note: For the autotest connect the TX to theAUX clamp and activate theAutotest function.

The standard setting of the photocell 1 is in “Closing” and the one of the photocell 2 is in “Opening

and losing” . The photocell 2 can be set also as TIMER (see TIMER function).

Note3: On the 95-FOTOTEST menu you can also activate the self-test even on the single photocell.

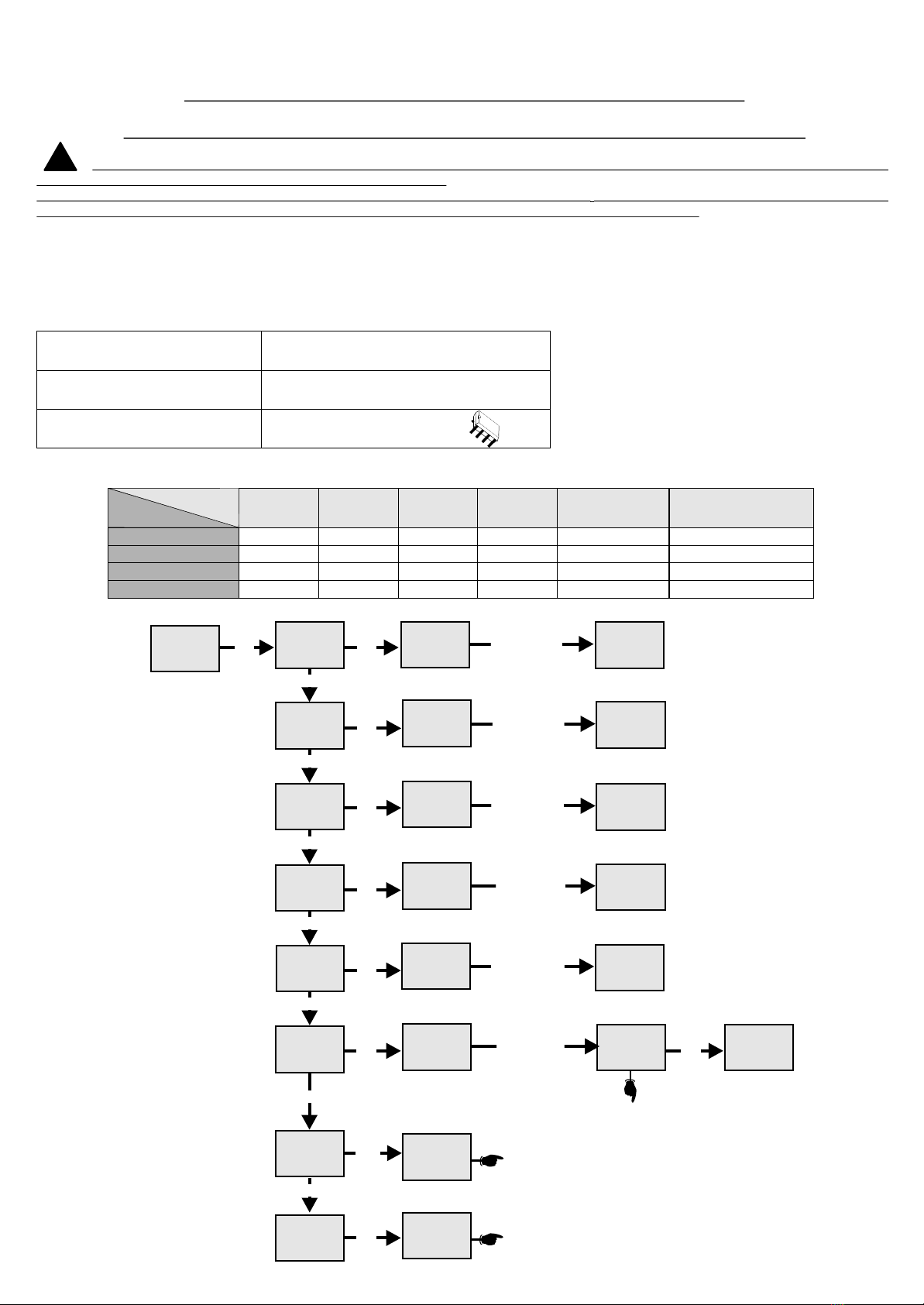

START - STOP - PEDESTRIAN START - ANTENNA -

PHOTOCELL

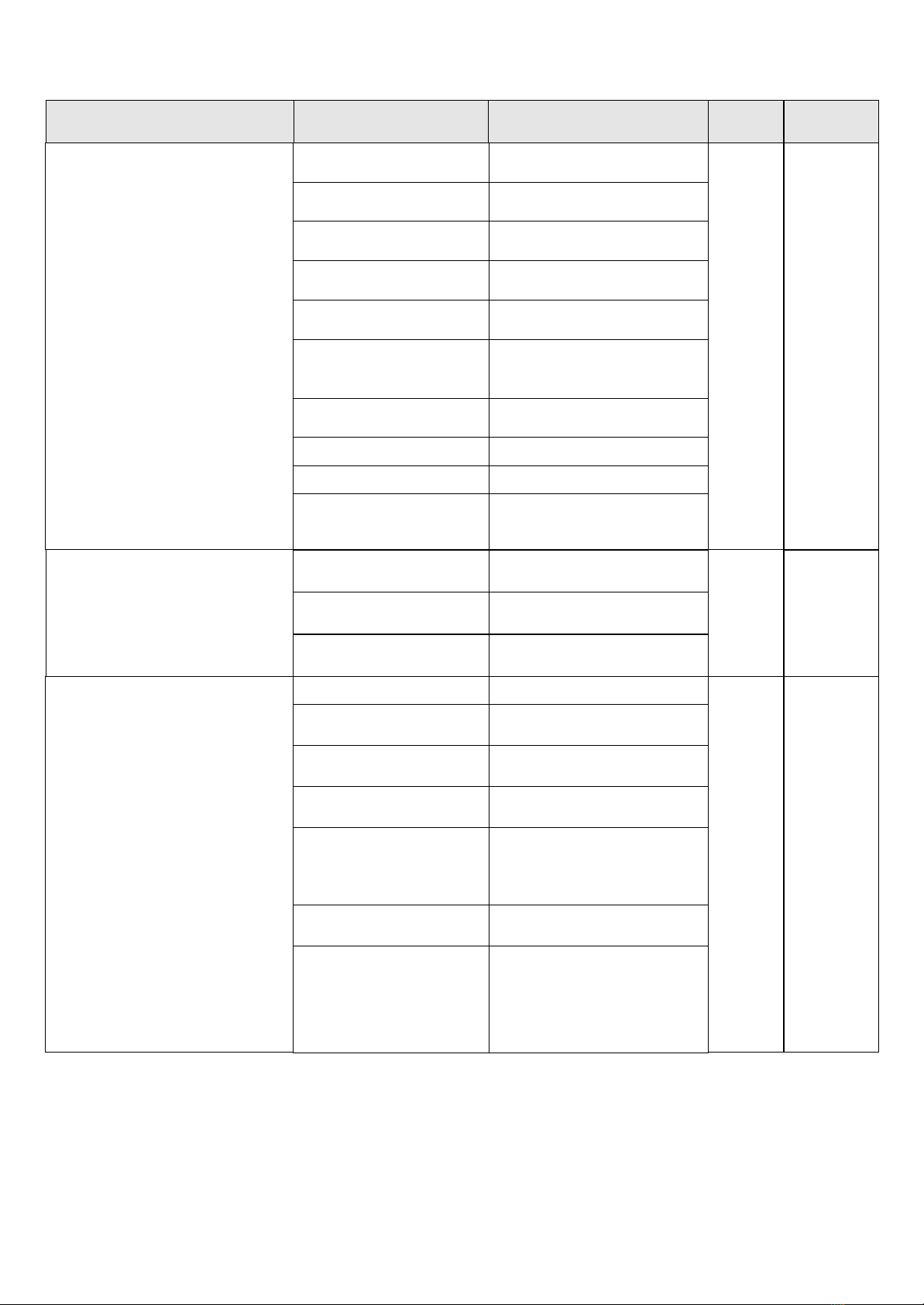

Can be activated through on-board display or through the Jolly programmer. In both cases it’s a N.O. contact which provoques

the opening of the automation keeping it open until it is activated. When it’s released, the gate attends the set pausing time

and executes the reclosing. The TIMER command can be activated on the inputs FOTO2, START PEDESTRIAN.

Note1: When activated on the pedestrian entry, the pedestrian will be disabled also on the radio transmitter.

Note2: In case of intervention of a security device during the timer (Stop, Ammeter, Edge), to restore the movement it will be

necessary to give a start impulse.

Note3: In case of no power supply with open gate and active Timer the control unit will restore its use, otherwise if during

restore of the power supply the TIMER is not activated it will be necessary to give a start impulse for the reclosing.

TIMER

Antenna

Common

Start

Start ped.

Stop

Common

Photocell 1

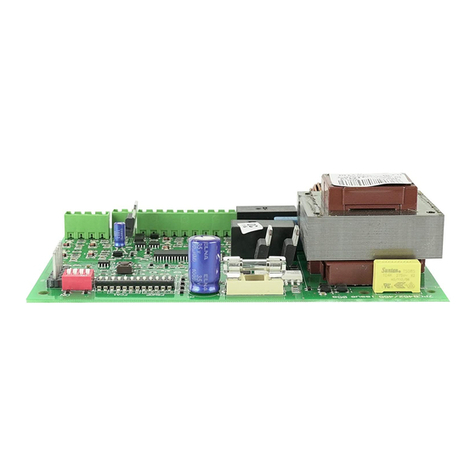

CN1

1 2 3 4 5 6 7 8

Photocell 2

RX1

RX2

TX1

TX2

CN1

9 10 11 12 13

Common

24V (Accessories)

PEDESTRIAN START (N.O.) The pedestrian start can be connected

between the clamps 2 and 4 of the CN1 terminal .

This input allows a partial opening the opening space can be set through

the on-board display or through the JOLLY device.

Note1: The contact for partial opening is a N.O. Contact (Normally open).

Note2:In 2 BUTTONS logic it is necessary to press the Start Ped. to re-

close the automation.

Note3: In dead man logic this button executes the re-closing if you keep it

pressed.

Note4: When closed during pause, the gate will reclose only after this

input has been reopened.

TIMER activation: This input can be transformed into TIMER (See

TIMER).

Options AUX 24V max 300mA can be set with on-board

Display or with Jolly device.

Through the Jolly programmer it is possible to chose when having

tension on the AUX output. The options are: Always,

pening,

When using control units with batteries and /

or solar panels, we recommend connecting the accessories which

are not used when operator stands still (e.g. photocells) to a AUX

output, setting the option “ ”. With this setting you can save

energy by lowering power consumption in stand-by, increasing the

autonomy of the system.

In cycle,

O Closing, In pause, Fototest, In cycle and fototest,

Positive brake management, Negative brake management, Gate

open warning light.

In cycle

16

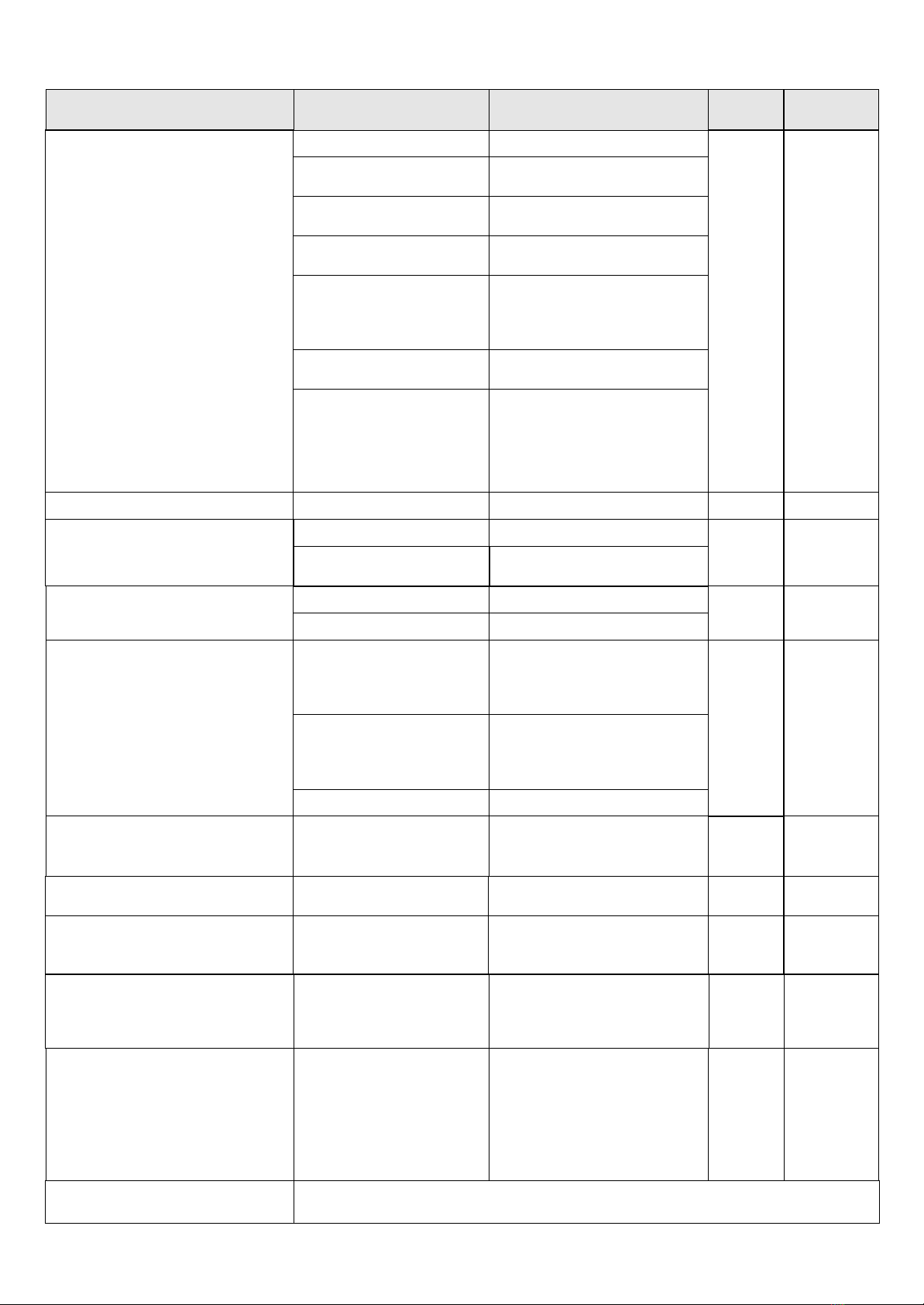

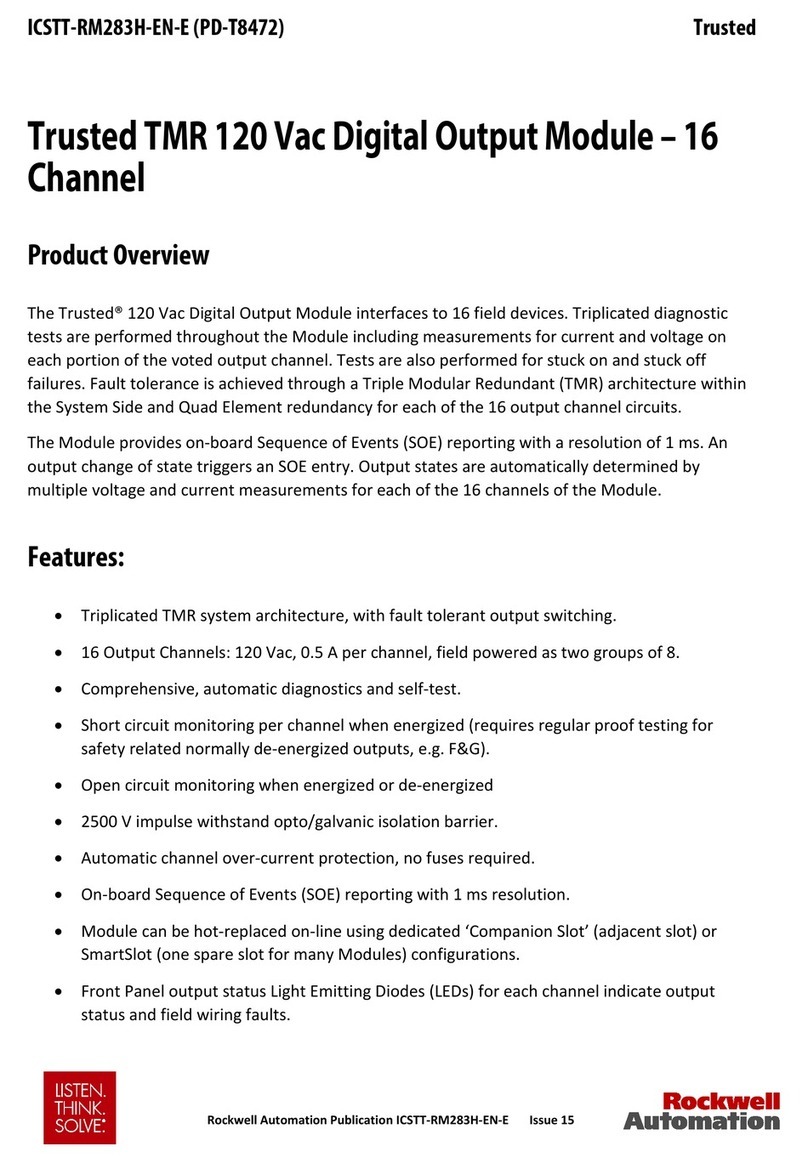

OPTIONS ON FOTO1 and FOTO2 adjustable on on- board display or with JOLLY

terminal.

“Closing”: if occupied, reverses the movement in closing, during pause it prevent the

closing.

“Opening and closing”: If activated the photocell blocks the movement as long as it’s busy,

when released the opening continues.

“Stop”: When activated before the opening the photocell blocks the automation as long as it

is busy, during the opening it will be ignored. In closing the intervention of the photocell

causes the reopening.

“Stop and close”: in opening it is not active; in pause are activated it commands the closing

when released, otherwise it’s not active; in closing it stops the movement as long as it is busy,

when released the closing continues.

“Close”: The photocell stops the gate as long as it is occupied in both opening and closing,

when released it gives a closing command (Closing one second after release of the

photocell).

“Pause reload”: If occupied, during pause it recharges the timer of pause. In closing it

reverses the movement.

“Delay pause time”: If the photocell is occupied during opening, pause or closing, the gate

reopens completely and closes without observing the pause time.

USER 1 - 24V DG R1B