SEA GATE 2 User manual

GATE 2

CONTROL UNIT

67410191

International registered trademark n. 2.777.971

SAFETY INSTRUCTIONS ..........................................................................................................................3

PARTS SPECIFICATIONS..........................................................................................................................5

CONNECTIONS..........................................................................................................................................6

SLOW-DOWN MODE, DIP SWITCHES LOGIC PROGRAM......................................................................7

OPERATING TORQUE ADJUSTMENT ......................................................................................................9

BRAKE (SLOW DOWN) LENGTH ADJUSTMENT .....................................................................................9

PAUSE LENGTH ADJUSTMENT................................................................................................................9

LEDS...........................................................................................................................................................9

RADIO RECEIVER, START BUTTON CONNECTIONS...........................................................................10

PHOTOCELLS, BUZZER CONNECTIONS ..............................................................................................11

ELECTRIC LOCK, MAGNETIC LOCK, SOLENOID LOCK CONNECTIONS...........................................12

SAFETY EDGE, FLASHING LAMP, COURTESY LIGHT, TIMER CONNECTIONS .................................13

POWER SUPPLY, MOTORS, CAPACITORS CONNECTIONS FOR HYDRAULIC OPERATORS ..........14

POWER SUPPLY, MOTORS, CAPACITORS CONNECTIONS FOR ALPHA OPERATORS ...................15

ANTENNA, SAFETY GATE, STOP BUTTON CONNECTIONS................................................................16

SELF-LEARNING OF OPERATING TIME FOR SWING GATES OPERATORS ......................................17

PROGRAMMING A TRANSMITTER ON START......................................................................................20

PROGRAMMING A TRANSMITTER ON PARTIAL START ......................................................................20

LOOP DETECTOR WIRING .....................................................................................................................21

TROUBLESHOOTING ..............................................................................................................................23

SALES CONDITIONS AND WARRANTY .................................................................................................24

GATE 2

TABLE OF CONTENTS

2

International registered trademark n. 2.777.971

REV 05 - 10/2010

GATE 2

WARNING: Not following these instructions may

cause severe injury or death to person

END USER ISTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

WARNING - To reduce risk of severe injury or death:

1) READ AND FOLLOW ALL INSTRUCTIONS

2) Never let children operate or play with door controls. Keep the remote control away

from children.

3) Always keep the moving system in sight and away from people and objects until it is

completely closedor stopped. NO ONE SHOULD CROSS THE PATH OF THE

MOVING SYSTEM.

4) Test the system gate operator monthly. The system MUST reverse on contact with a

rigid object or when an object activates the non-contact sensors. To obtain a reverse on

contact with an object on hydraulic linear and in-ground operators SEA recommend to

install the patented safety device “SAFETY GATE” for each leaf.

After adjusting the force or the limit of the travel, retest the gate operator. Failure to

adjust properly the gate operator properly can increases the risk of severe injury or

death.

5) Use the manual release only when gate is not moving

6) KEEP GATES PROPERLY BALANCED AND MAINTAINED. An improper balancing

or maintenance increases the risk of severe injury or death. Have a qualified service

personal to make repairs to cables, spring assemblies and other hardware.

7)The entrance with a gate operators system is for vehicles only. Pedestrian MUST use

separate entrance.

8) Every gate operator installation MUST have secondary protection devices against

entrapment, such as edge sensors and photo beams more in particularly in places

where the risk of entrapment is more likely to occure.

SAVE THESE INSTRUCTIONS

The installer is responsible for grounding the operator system,

for providing the main power breaker switch, and for making sure

that the entire gate systems meets all applicable electrical codes.

3

International registered trademark n. 2.777.971

REV 05 - 10/2010

GATE 2

GROUNDING

Good grounding and proper surge suppression are an integral part of proper installation for

a gate operator system. One or all of the following may require surge suppressors: high

voltage power lines, low voltage power lines, telephone lines, data lines, low voltage control

lines and loops. How much surge suppression is required depends upon how susceptible

the area is to lightning and power surges. Regardless, good grounding is essential. To

realize maximum protection, proper grounding and proper surge suppression is absolutely

necessary.

If the circuit breaker box is located close to the gate operator system, for example, in a

guard house, then the ground from that circuit can be used to ground the gate operator

system. Eliminate all 90° bends in ground wires and keep a minimum of three feet between

the surge suppressor and the equipment being protected.

If the power source or circuit breaker box is not located close to the gate operator system an

Isolated Ground Zone (IGZ) needs to be created. An IGZ can also be created if the circuit

breaker box is located close by the gate operator system. An IGZ is an imaginary circle

drawn around the gate operator system. The gate operator system not only includes the

gate operators and control panel, but all of the accessories and devices associated with it at

that controlled entry point. This includes loop detectors, card readers, digital entries,

telephone entries, any device that has a ground or requires a ground and ali of the surge

suppressors. The ground bus is a common ground point calied a Single Point Ground

(SPG). It is used to bond all the equipment and device grounds in the IGZ together. The

SPG is very important because it helps eliminate different ground potentials that can be

present on the equipment. In such cases, equipment damage occurs even with surge

suppressors.

Do not use or connect the ground wire coming from the circuit breaker box. By using an

Isolated Ground Zone, you are separating the gate operator system from the house or

building ground. This eliminates ground potentials. It is recommended that the ground bus

be located in a separate NEMA type enclosure. All grounds will be tied to this ground bus.

Some points to remember:

Keep all ground wires as straight as possible. Do not have any sharp 90° bends. Have a

minimum of 3 feet of wire between the surge suppressor and the equipment being

protected.

Equipment ground wire should be a minimum of 12 AWG. The main ground wire from the

bus bar to the ground rod shouid be an 8 or 6 AWG copper wire. Ground rod should be a

minimum of 10 feet in length, longer depending on local soil conditions.

For more information regarding good grounding practices check: National Electric Code

art. 250; IEEE Emerald Book, standard 100; International Association of Electric

Inspectors.

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

4

International registered trademark n. 2.777.971

REV 05 - 10/2010

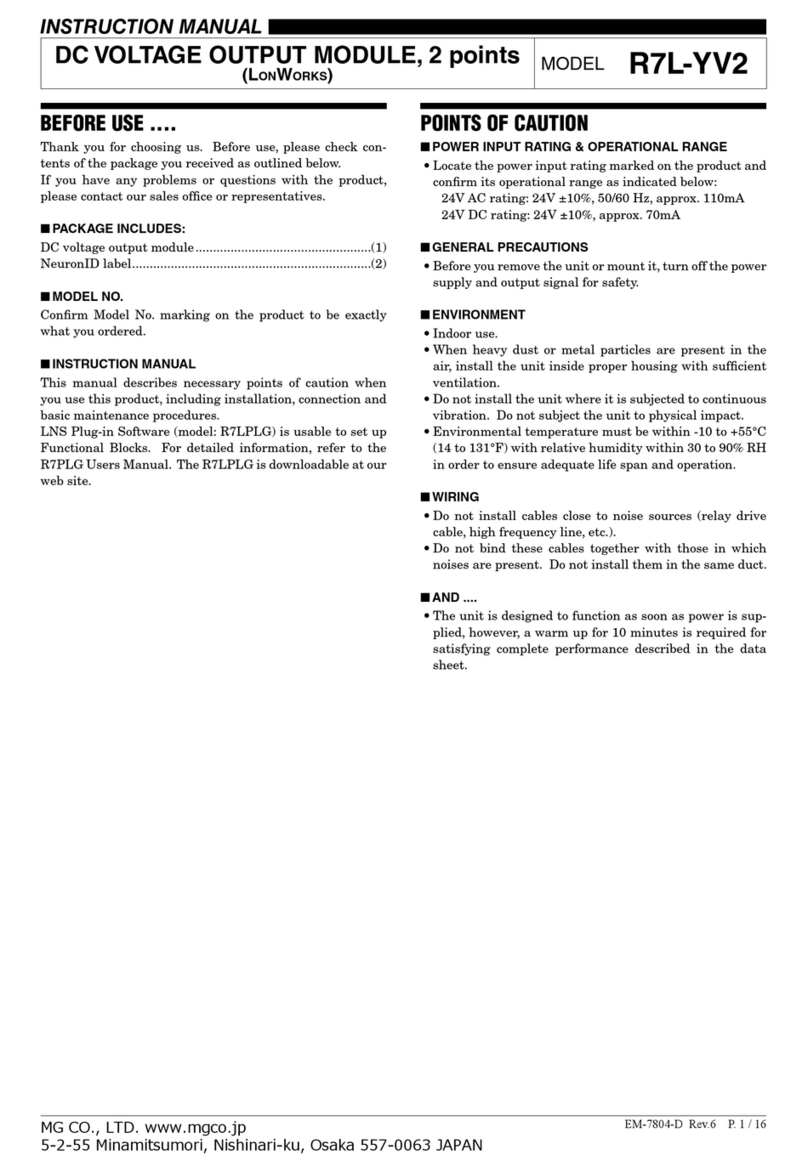

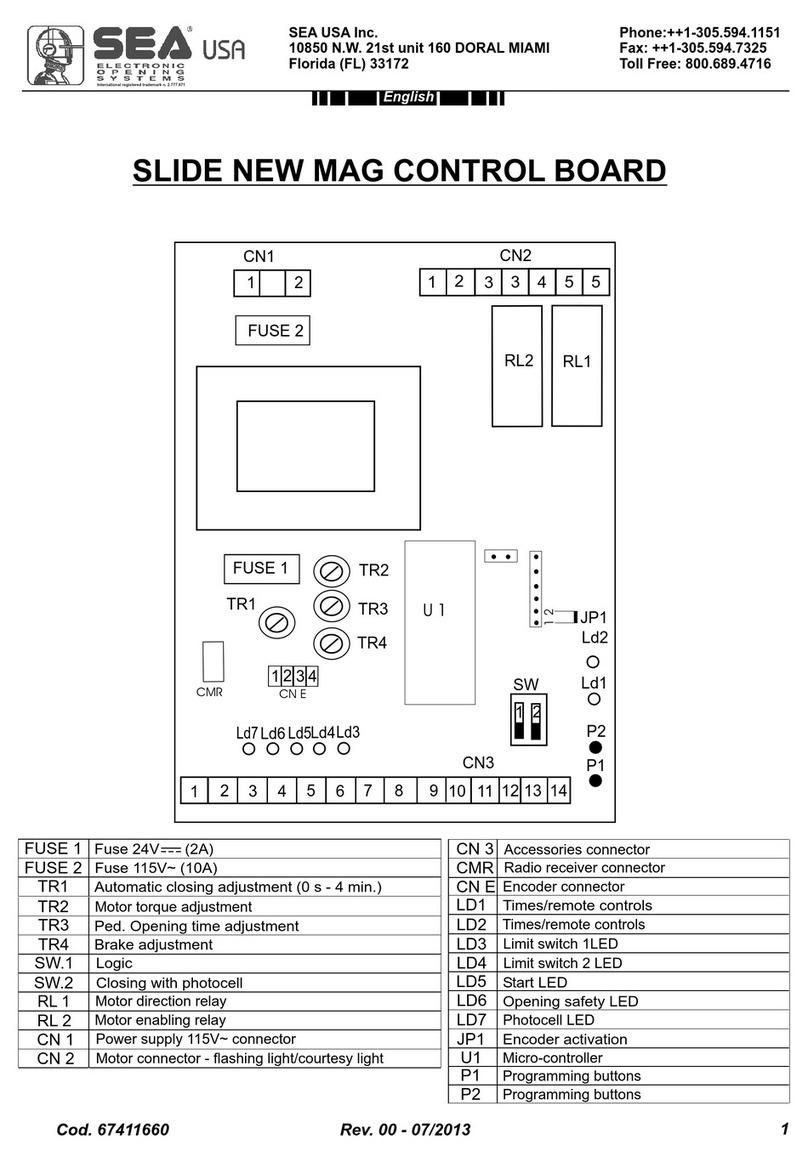

CN3CN2

RL1 RL2

RL3

F1

F2

P1

P2

Rv1

Rv2

Rv3

CN1

U1

U2 DIP

J1

LED5

LED6

LED7

LED8

LED9

LED10

LED11

LED1

LED2

LED3

LED4

LED12

LED13

LED14

LED15

LED16

CMR

LEDPLEDP

CNP CN4

GATE 2

5

PARTS SPECIFICATION

LED1 = Auxiliary input

LED2 = Partial Start

LED3 = Start

LED4 = Limit switch in closing Motor 2

LED5 = Limit switch in opening Motor 2

LED6 = Limit switch in closing Motor 1

LED7 = Limit switch in opening Motor 1

LED8 = Photocell 2

LED9 = Photocell 1

LED10 = 24V Auxiliary output

LED11 = Tx Photocell output

LED12 = Troubleshooting LED

LED13 = Electric Lock

LED14 = Encoder (reversing sensor) 2

LED15 = Encoder (reversing sensor) 1

LED16 = Stop

LEDP = Programming

CN1 = 24V input / output connector

CN2 = 24V input / output connector (green)

CN3 = Motors and Power supply connector (orange)

CN4 = 24Vac Photosync connector

Rv1 = Motor torque adjustment

Rv2 = Brake length adjustment (slow down length)

Rv3 = Pause time adjustment

P1 = Operating time memory button

P2 = Programming transmitters button

DIP = Dip-switch Function Setting

F1 = Output and motor fuse (6.3AT)

F2 = Accessories fuse (2A)

J1 = Slow-down adjustment

RL1 = Motor Power Supply Relay

RL2 = Motor Operating Direction Relay

RL3 = Garden Light Relay

U1 = Micro-controller

U2 = EEPROM memory

CNP = PALM connector

CMR = Receiver module connector

International registered trademark n. 2.777.971

REV 05 - 10/2010

GREEN ORANGE

CN2

1 2 3 4 5 6 7 8 9 10 1112 13 14 15

m24V Trans itter

photocell

24VcAuxili y

d ar

e

Photoc l 2

l

n n(ope i g)

t

Limi switch

l o or

c osingM t 2

tw

Limi sitch

g o or

openin Mt2

START

xi i y ntAular i pu

C mmono

16 17

iartal START

P

mit sw thLi ic

clingMo or

os t1

mitsw tchLi i

eningMo or

op t 1

Photocel 1

l

(c o i g)

lsn

ck 1VLo2

mm

Coon

C mmo

o n

CN3

M2

~

Opening

Closing

mCom on

a M2

Cap citor

t

Cour esy light

115V

Neutral

haseP

oundGr

1 2 3 4 5 6 7 8 9 10 1112 13 14 15 16 17

Capacito M1

r

M1

~

Opening

Closing

mCom on

lasher

F

115V

Operating logics

Auxiliary input configuration

Pre-flashing

Automatic closing

Photocell autotest

Reversing sensor (Safety Gate)

Soft start

Brake (slow-down)

Leaf locking

Reverse stroke

1122334455667788991010 1111 1212

ONON

ON= Function Active

DIP

Leaf delay in opening and closing

GATE 2

CONNECTIONS

6

CN1

AEIL

R A

R

eesn

vrig

sno

esr2

STOP

1 2 3 4 5 6

een

Rvrs

ig

snoesr

1

Re . se r

v nso

po r sup ly

we p

ee n

Rvr

s

ig

sno

esr

Gr en

e

r

B own

Whte

i

eW h t i

International registered trademark n. 2.777.971

CN4

1122

24V~

Note: For

the power

supply of the

synchronized

photocells.

ATTENTION NOTE: In the configuration of the swing gate double leaf the limit switches must not be bridged.

REV 05 - 10/2010

(Green)

(Orange)

24V

4

0m a

0 Amx

24

uzzerV

B

WORKING LOGICS

Four different working logics can be selected.

The programming takes place using DIP1 and DIP2.

- MANUAL LOGIC

ASTART command opens the gate. Asecond START while it is opening stops the motor.

A START command while it is closing stops the motor.

Important note: For the automatic re-closure, set DIP 6 on ON

- SAFETY LOGIC

ASTART command opens the gate. Asecond START while it is opening reverses the motor.

ASTART command while it is closing reverses the motor.

Important note: For the automatic re-closure, set DIP 6 on ON

- AUTOMATIC LOGIC 1

A START command opens the gate. A second START while it is opening is not accepted. A START while it is closing

reverses the direction.

P. N.: for automatic closing, set DIP SWITCH 6 to the ON position.

Important note: For automatic closing, set DIP SWITCH 6 to the ON position.

Important note: If Dip 6 of the automatic closing is not activated the start in pause will be accepted.

- AUTOMATIC LOGIC 2

ASTART command opens the gate. Asecond START while it is opening is not accepted. ASTART during the pause time closes the

gate immediately. A START while it is closing reverses the direction.

P. N.: for automatic closing, set DIP SWITCH 6 to the ON position.

P. N.: For automatic closing, set DIP SWITCH 6 to the ON position.

OPENED

CLOSED

OFF / OFF

ON / OFF

DIP1 AND DIP2 PROGRAMMING FOR THE SELECTION OF THE WORKING LOGIC

If Dip1 and Dip2 are programmed in this way, the control unit will work with Manual Logic

If Dip1 and Dip2 are programmed in this way, the control unit will work with Safety Logic

DIP

1 / 2

1 / 2

OFF / ON

ON / ON

If Dip1 and Dip2 are programmed in this way, the control unit will work with Automatic 1 Logic

If Dip1 and Dip2 are programmed in this way, the control unit will work with Automatic 2 Logic

1 / 2

1 / 2

GATE 2

DIP

1 2 3 4 5 6 7 8 9

ON

DIP

10 11 12

SLOW-DOWN MODE, DIP SWITCHES,

LOGIC PROGRAM

J1

J1

Slow-down mode

(only DIP 10 ON)

1

2

Choose the slow down

modality which can be

more appropriate for

the installation.

1: Jumper unconnected

2: Jumper connected

7

International registered trademark n. 2.777.971

REV 05 - 10/2010

LEAF DELAY IN OPENING AND CLOSING

Activating this function, the Leaf Delay in opening and closing will be eliminated. Both leaves will

work simultaneously. It is advised to activate this function on single leaf applications and/or in

applications where the Delay is not required.

4

OPENED

CLOSED

OFF

ON

DIP 3 AND DIP 4 PROGRAMMING FOR AUXILIARY INPUT CONFIGURATION

SAFETY EDGE ( N.C. contact)

When the Safety Edge Contact opens, the gate reverses direction and stops after about 1 second. A

START command is required to restart movement

TIMER (N.O. contact)

If a TIMER is connected to this input the gate can be opened and kept open as long as the contact

remains closed. Using a 24-hour or 7-day timer allows gate opening times to be scheduled as

required. When the TIMER contact is open the automatic operation functions according to pre-set

logics.

DIP

3

3

ON

ON

ON

PROGRAMMING OF OTHER DIPS FOR OTHER FUNCTIONS

PRE-FLASHING

When this function is activated the flashing lamp and warning light begin flashing about 3 seconds

before the motor starts, both when closing and opening.

AUTOMATIC CLOSING

Activating this function causes the gate to close automatically, after the time set by the trimmer Rv3.

This function can be activated independently of the operating logic set (DIP SWITCH 1 and 2).

DIP

5

6

ON

ON

PHOTOCELLAUTOTEST

When this function is activated a test is carried out on the photocells before any gate movement

takes place. To enable this function the photocell transmitter must be connected to terminals 13

(24V) and 17 (Negative) of connector CN2.

The flashing lamp and troubleshooting LED will both flash slowly if a malfunction occurs.

7

8

ON

“SOFT” START

When this function is activated, the motor will start at a lower torque to avoid stresses and strains on

the gate's mechanical components. The starting torque is a percentage of the normal operating

torque.

P.N.: It is not advised to operate this function when the gate is very heavy or does not run smoothly.

9

OPENED

CLOSED

ON

12

REVERSING STROKE

This function (to use exclusively on swing gates) is used to facilitate the electric lock release. Before

beginning the opening cycle, as soon as the start order is given, the leaves are supplied for about 1

sec. in closing.

GATE 2

DIP SWITCHES, LOGIC PROGRAM

ON

BRAKING (slow-down) AT LIMIT SWITCH

When this function is activated motor speed reduces slowly before the limit switch is reached or

before the end of the operating time. This function is designed to bring the leaf gently up to the stop

position and prevent the gates clashing. The closing speed is fixed, while the slow-down time can be

adjusted using the trimmer Rv2.

It is necessary to activate this function to choose the slow-down modality through jumper J1.

Remember to set this DIP in Off position in case of mechanical or hydraulic brake.

10

ON

LEAF LOCKING

When this function is activated, at the end of the slow-down phase, and when the leaf is up against

the mechanical stop, the motor is supplied at maximum power for about 1 second. This increases

the oil pressure in the motor and makes the hydraulic lock more effective.

P.N.: this function SHOULD NOT be activated when used on sliding gates since it could

cause over-running of the limit switches and the automation system to jam.

Note2: With the Palm through the function PushOpen it is possible to exclude the tightening

of the leaf during the opening phase.

11

8

International registered trademark n. 2.777.971

!!

ENCODER MANAGEMENT (reversing sensor)

The signals sent from an encoder located on the motor or gate are managed when this function is activated.

This results in any obstacles found in the gate's path being detected and reverses the gate direction of

movement for one second, it stops and waits for commands. The flashing lamp and troubleshooting LED will

both flash slowly if a malfunction occurs. With a following start the automation will proceed in slow down

speed until it reaches the stop. Note:After two consecutive obstacles the BUZZER will be activated.

P.N.: If an encoder is not fitted, set the DIP SWITCH to OFF.

Note: The Encoder sensibility can be adjusted through the PALM or through the pushbuttons Ptime

and Pcode on board of the control unit.

REV 05 - 10/2010

LED1 (AUX INPUT)

LED2 (PARTIAL START)

It must be usually switched off and it must switch on when an partial opening control is given.

LED3 (START)

It must be usually switched off and it must switch on when an opening control is given.

LED4 and LED5 (CLOSING LIMIT SWITCH MOTOR 2) / (OPENING LIMIT SWITCH MOTOR 2)

LED6 and LED7 (CLOSING LIMIT SWITCH MOTOR 1) / (OPENING LIMIT SWITCH MOTOR 1)

They must be usually switched on and they must switch off when the limit switches are started up.

LED8 and LED9 (PHOTOCELL 2) and (PHOTOCELL 1)

It must be usually switched on and it must switch off when the photocell is darkened.

LED10 (24V AUX POWER SUPPLY)

LED11 (TX PHOTOCELL POWER SUPPLY)

LED12 (TROUBLESHOOTING LED)

If the automation stops to work, the Troubleshooting LED will indicate which safety caused the event through many different flashing spaced

out by a second pause.

1 flash = PHOTOCELLS

2 flashes = SAFETY EDGE

3 flashes = ENCODER (reversing sensor)

4 flashes = STOP

5 flashes = PHOTOCELLSELF-TESTING

6 flashes = TRIAC TEST

The flashing sequence will be repeated even on the flashing lamp for 15 seconds.

LED13 (ELECTRIC LOCK)

LED14 and LED15 (ENCODER2) and (ENCODER 1)

LED16 (STOP)

It must be usually switched on and it must switch off when a STOP control is given.

LEDP (Programming)

Rv1

Rv2

Rv3

OPERATING TORQUE ADJUSTMENT

This trimmer is used to adjust the motor torque. This

adjustment is essential for operators without

mechanical or hydraulic anti-crush devices and must

be carried out so that there is no risk of people or

objects being crushed. It must always be executed in

accordance with current legislation on the subject.

BRAKE (slow-down) LENGTH

ADJUSTMENT

This trimmer is used to adjust the length of the slow-

down.

PAUSE LENGTH ADJUSTMENT

This trimmer allows the PAUSE time to be adjusted

between 0 and 120 seconds.

Set DIP SWITCH 6 to the ON position to enable

automatic closing.

P.N.: TURNING THE TRIMMERS CLOCKWISE

INCREASES THE TIMES/VALUES

+

-

GATE 2

TRIMMER REGULATION, LEDS

Rv1

Rv2

Rv3

+-

+-

+-

LED1

LED2

LED3

LED4

LED5

LED6

LED7

LED8

LED9

LED10

LED11

LED12

LED13

LED14

LED15

LED16

9

International registered trademark n. 2.777.971

Number of lightning

1

2

3

The sequence of lightning, intervals of pause, are shown on the flashlight (for ca. 20 sec.) and on the control lamp (until a new START).

ALARM INDICATION BOARD ON CONTROL UNITS GATE

Number of lightning

4

5

6

Type of alarm

Stop

Photocell self-testing

Triac test

Type of alarm

Photocell

Safety edge

Encoder

REV 05 - 10/2010

10 11 12 13 14 15 16 17

1 2 3 4 5 6 7 8 9

Start Button

An impulse given to this entrance commands

the opening/closing of the automation. It can

be given by a key switch, a loop detector, a

keypad, etc.

To connect the supplied devices (for ex. Loop

detector) see the related instructions.

-+

C

Partial Start

To obtain a partial opening (7 second gate opening) connect the

key-button wires as in the picture. It is possible to connect other

command devices (push button board, radio receiver, keypad).

Note1: the contact for the partial opening is a N.O. Contac

(Normally opened)

Note2: the partial opening will be always executed on the M1 motor.

Com

GATE 2

RADIO RECEIVER, START BUTTON

CONNECTIONS

1

1

4

15

1

3

1

4

1

4

CN2

10

International registered trademark n. 2.777.971

REV 05 - 10/2010

Connection of a radio receiver

This connection allows to command the total

opening/closing of the automation. For the

receiver connection make reference to the

related instruction manual.

+ = 24V ,

- = 0V ,

C = Contact

Com = Common

10 11 12 13 14 15 16 17

1 2 3 4 5 6 7 8 9

CN2

-+

Photocell

self-testing

+C C

+

-

Com

N.C.

RX

TX

+

-

Com

N.C.

RX

TX

IMPORTANT: UL325 standards requires an audible alarm to go OFF after 2 consecutive events

detected by the primary entrapment protection of the gate operator (for ex. reversing sensor).

!

GATE 2

PHOTOCELLS, BUZZER, CONNECTIONS

17

14

15 17

15 17

9

10

11

International registered trademark n. 2.777.971

REV 05 - 10/2010

Buzzer (24Vdc) Audible Alarm

Use a buzzer 24V of 100 dB. The buzzer will be switched on

after two consecutive activations of the anticrush sensor. To

reset the allarm it is necessary to push the button STOP. Anyway

after 5 minuts the buzzer will stop to sound and the automation

stands still waiting for commands.

Photocells 2 Connection

When the photocells beam is crossed, the automation

reverses its movement if in closing phase. In opening

it causes the stop of the gate until it is occupied, when

released the gate returns into open postion.

Note: When not used make a jumper between

contact 9 and the common.

Note : With the PALM device it is possible to set as

PHOTOSTOP, that means that it does not allow to

the gate to open, while it does not intervene

during the remaining opening.

+ = 24V - = 0V C = Contact

Com = Common

Photocells 1 Connection

When the photocells beam is crossed, the automation

reverses its movement if in closing phase.

To use the photocells self- testing connect the (+) of the

TX photocell 1 with contact 13 instead of 15.

Note: When not used make a jumper between contact

10 and the common.

Note: With the PALM device it is possible to set this

photocell as PHOTOCLOSE, that means, that if

occupied during the pause, the automation

interrupts the same and recloses immediately.

+ = 24V - = 0V C = Contact Com = Common

10 11 12 13 14 15 16 17

1 2 3 4 5 6 7 8 9

CN2

-

GATE 2

ELECTRIC LOCK, MAGNETIC LOCK

SOLENOID LOCK CONNECTIONS

16

1

1 2 3 4 5 6 7

-

Magnetic Lock wiring

16

17

Magnetic Lock

Power for

Magnetic Lock

N.C.

1 2 3 4 5 6 7

Solenoid Lock wiring

16

17

Solenoid Lock

Power for

Solenoid Lock

N.O.

The Power Supply is not provided.

The Power Supply is not provided.

optional board

optional board

12

International registered trademark n. 2.777.971

REV 05 - 10/2010

Electric lock exit

An electric lock of 12V or of 24 Vdc 15W

max can be connected .The electric lock

activates at every opening cycle for about

1,5 s.

CN3

10 11 12 13 14 15 16 17

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17

1 2 3 4 5 6 7 8 9

-

Afurther safety can be obtained making a connection with the safety edge mentioned on the side.

If it is start up, the safety edge reverses the movement of the gate for two seconds and it stops.

To use the safety edge, place dip-switches 3 on OFF.

Notice: if the safety input is not used, make a Jumper between 1 and 2 .

Safety edge input

Timer

Flashing Lamp (115V)

The flashing lamp is an important accessory which warns the

gate operating.

To connect it, connect the wires of the flashing lamp as in the

picture.

It is possible to activate a pre-flashing of 3 seconds before

activating the automation placing Dip 5 on ON.

Notice: The warning lamp gives the same warning signals

as the LED 12 described in pag. 9

Courtesy Light (115V max 100W)

During the working phase, courtesy light stays switched on.

Note: With the Palm it is possible to modify this time from

15 to 240 s.

GATE 2

SAFETY EDGE, FLASHING LAMP, COURTESY

LIGHT, TIMER CONNECTIONS

1

2

12

12

11

13 14

CN2

13

International registered trademark n. 2.777.971

With DIP3 on ON it is

possible to connect a

timer. The Timer

executes the timed

opening and keeps the

gate open for the

whole adjusted time.

REV 05 - 10/2010

CN3

10 11 12 13 14 15 16 17

1 2 3 4 5 6 7 8 9

Example

Motor 1

Output for Motor 1 connection

M = OPEN/CLOSED

Com = COMMON

Motor 2

Output for Motor 2 connection

M = OPEN/CLOSED

Com = COMMON

M1

M2

Capacitor 1

Capacitor 2

Com

PGN

Example

Power input

Input for the connection of the electric power.

P = PHASE

N = NEUTRAL

G = GROUND NOTICE: for the connection to the

electric power see the law in force.

M M

GATE 2

HYDRAULIC MOTORS, POWER SUPPLY,

CAPACITORS CONNECTIONS

2

1

7

634516

8

9

10

16

16 1715

Com

M M

14

White

White

Black

Black

Green

Green

Violet

Violet

International registered trademark n. 2.777.971

REV 05 - 10/2010

CN3

10 11 12 13 14 15 16 17

1 2 3 4 5 6 7 8 9

GATE 2

MOTORS, CAPACITORS, POWER SUPPLY

CONNECTIONS for ALPHA

15

Motor 1

Output for Motor 1 connection

M = OPEN/CLOSED

Com = COMMON

Motor 2

Output for Motor 2 connection

M = OPEN/CLOSED

Com = COMMON

M1

M2

Capacitor 1

Capacitor 2

ALPHA

ALPHA

Power input

Input for the connection of the electric power.

P = PHASE

N = NEUTRAL

G = GROUND NOTICE: for the connection to the

electric power see the law in force.

4

5

5

4

1 12 23 3

Com

GNM M

Com

M M P

16 1715

International registered trademark n. 2.777.971

REV 05 - 10/2010

CN1

1 2 3 4 5 6

-+

SAFETY GATE

SAFETY GATE

1

2

234

23

5

2

6

CN4

P1

P2

LEDP

ANTENNA, SAFETY GATE, STOP BUTTON

CONNECTIONS

White

Brown

Green

White

Antenna

Connect the

antenna as in the

picture.

Stop Button

The pressure of this button stops immediately the motors in any

condition /position. With the following start impulse the gate will always

go in closure.

Note: if it is not used, make a jumper between terminals n° 2 and 6.

Encoder adjustment procedure on board of the control unit

1. Keep pressed both Ptime and Pcode buttons for 3 seconds until ledP turns on..

2. The led turns on and stays on for 1 second, afterwards it reproduces the number of

flashes corresponding to the level of the set encoder sensibility (from 1 to 15, where 15

stands for the maximum insensibility)

3. If the set level is not suitable, press the push-button Pcode to increase or Ptime to

decrease it. Every impulse corresponds to the increase or the decrease of one unity.

4. After 1 second from the last pressure of the push-button the set sensibility level will be

shown through the corrisponding number of flashes.

5. After 3 seconds from the visualization, the procedure will be left and the ledP

switches off.

Note: Execute the adjustment with still- standing gate.

International registered trademark n. 2.777.971

GATE 2

Encoder (reversing sensor) on motor 2 (DIP8

ON)

The encoder or Safety Gate is a system which

detects any obstacle during the operating of the

gate.

When activated the motor reverses for 1 sec. It is

set in the factory on a middle level but can be

modified. Low sensibility levels do not allow a fast

inversion as required by the En12453 rules.

Note: After two consecutive inversions the

BUZZER will be activated.

Encoder (reversing sensor) on motor 1 (DIP8

ON)

The encoder or Safety Gate is a system which

detects any obstacle during the running of the

gate.When activated the motor reverses for 1 sec.

Note: With the PALM device or through the

pushbuttons Ptime and Pcode on board of the

control unit. it is possible to adjust the

sensibility of the encoder on a scale from 0 to

15, where 0 indicates the max. sensibility

during the inversion.

Note: Every time when there is no current

supply and after every osbstacle the

automation, when no limit switches are

installed, will proceed slowly until it reaches

the stop.

16 REV 05 - 10/2010

STEP 1 (Note: On swing gates with two leaves the limit switches have not to be bridged)

Make all the electrical connections and jumpers on all the unused N.C. contacts (photocells, limit switches,

etc).

If a geared motor equipped with a mechanical or hydraulic anti-crush safety device is being used, set the

operating torque (trimmer Rv1) to the maximum value and then adjust the motor torque using the special by-

pass valves or clutch adjustment screws located on the actuators.

If a motor without a mechanical or hydraulic anti-crush safety system is being used, set the operating torque

to the maximum value ONLY for the self-learning process. Immediately afterwards, set a torque value that

will ensure anti-crush safety, in accordance with current legislation.

ATTENTION!

THIS PROCEDURE IS POTENTIALLY DANGEROUS AND MUST BE CARRIED OUT ONLY BY

SPECIALIZED PERSONNEL, ADOPTING ALL SAFETY PRECAUTIONS.

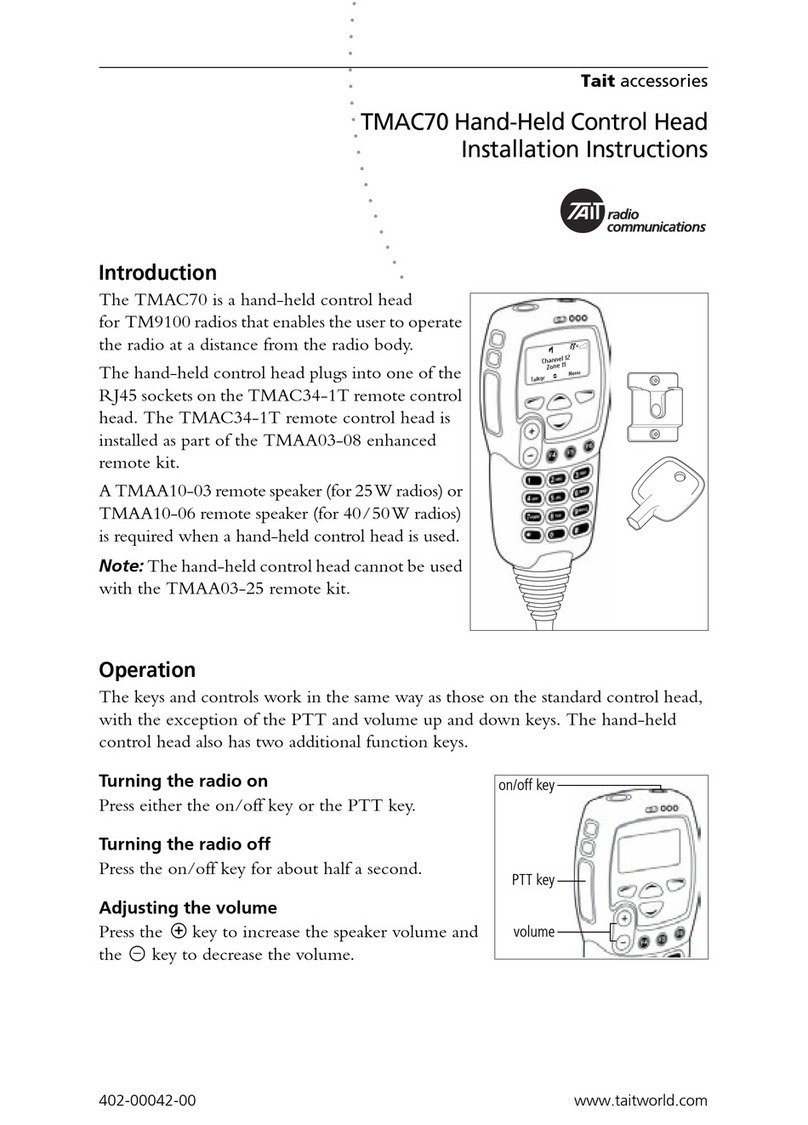

STEP 2

Disconnect the power supply (Fig. 1), release the gate operator (Fig. 2) and stop the leaves in the half-open

position (Fig. 3). Lock the motor (Fig. 4) and turn ON the power (Fig. 5).

Fig. 2

Unlock

Fig. 1

Fig. 3

M1

Fig. 4

M2

FF

O

Fig. 5

NO

2

1

GATE 2

SELF-LEARNING OF OPERATING TIMES

FOR SWING GATES OPERATORS

17

Lock

Example

Example

International registered trademark n. 2.777.971

Notice: Encoder activation

With the safety gate (encoder 1 and encoder

2) on both motors put dip 8 on ON before

programming.

To exclude its function put dip 8 on OFF

avoiding to repeat the selflearning

procedure.

REV 05 - 10/2010

STEP 3

(from STEP 2) When the leaf reaches the closing mechanical stop, press button P1 (Fig. 6).

Motor M1 will also start a closing cycle.

When the gate reaches the closing mechanical stop, press P1 again (Fig. 7). Do not execute this operation if limit

switches are installed.

Note: If the safety gate is installed you must give the impulse exactly on the stop.

3

The leaf stops and M1 starts an opening cycle.

After a few seconds press P1 once more to set the Leaf Delay in Opening. (The number of seconds waited will result in the

delay of the leaf in opening) NOT TO DO IF DIP 4 IN “ON” POSITION.

When the leaf reaches the opening mechanical stop, press P1 again (Fig. 8). Do not execute this operation if limit switches

are installed. Motor M2 will also start an opening cycle. When it reaches the opening mechanical stop, press P1 again (Fig.

9). Do not execute this operation if limit switches are installed.

Press and Hold button P1 (LED P will come ON)

until motor M2 will start to close the gate*.

Release P1.

P1

LEDP

P1 M2M1 P1

If the motor start to open the gate, take OFF the power and reverse the motor phases.

Make the same type of connection on motor M1 as well.

Repeat the programming procedures (STEP 2).

*

Fig. 6

P1 P1

M2M1

Fig. 7

M2M1

Fig. 8

P1 P1

M2M1

Fig. 9

M2M1

GATE 2

SELF-LEARNING OF OPERATING TIMES

FOR SWING GATES OPERATORS

18

International registered trademark n. 2.777.971

U1U1

U2U2

RV1RV1

RV2RV2

RV3RV3 P1P1

P2P2

F1F1

F2F2

CN1CN1

CN2CN2 CN3CN3

RL1

RL1

2L

R2L

R

R3

L

R3

L

ED1

LED1

L

LE 2D

LE 2D

LE3

D

LE3

D

LE 4D

LE 4D

5LED5LED

L6

E

D

L6

E

D

DL E 7 DL E 7

LE8

D

LE8

D

LED9

LED9

LED10

LED10

1L E1 D1L E1 D

L12

ED

L12

ED

ED

L 13

ED

L 13

LE14

D

LE14

D

E

LD15

E

LD15

D

LE 16

D

LE 16

DIPDIP T1T1

CN4CN4

DL E P DL E P

REV 05 - 10/2010

Motor M2 will start a closing cycle automatically.

After a few seconds press P1 once more to set the Leaf Delay in closing. (The number of seconds waited will result in

the delay of the leaf in closing) NOT TO DO IF DIP 4 IN “ON” POSITION

When the leaf reaches the closing mechanical stop, press P1 again (Fig. 10). Do not execute this operation if limit

switches are installed.

At this point motor M1 will start a closing cycle.

When the closing mechanical stop is reached, press P1 again (Fig. 11). Do not execute this operation if limit switches are

installed.

When motor M1 reaches the closing mechanical Stop, press P1 for the last time.

Programming is completed.

Check that the times are saved properly by giving a START command or pressing button P1.

If necessary repeat the learning procedure from stage 2.

P1 P1

Fig. 10

M2M1 M2

M1

Fig. 11

STEP 4

If used with a motor without a mechanical or hydraulic anti-crush safety device, adjust trimmer Rv1 to values that will

ensure anti-crush safety, in accordance with current legislation.

If, after adjusting the operating torque, the operating time is insufficient (e.g. the leaf fails to open or close completely),

repeat STEP 2 with the motor torque value set for the normal use of the system.

Adjust the slow-'down length (if enabled), using trimmer Rv2.

4

GATE 2

SELF-LEARNING OF OPERATING TIMES

FOR SWING GATES OPERATORS

19

PALM FUNCTIONS:

International registered trademark n. 2.777.971

GATE 1-GATE 2 Administration

• Visualisation and modification of the following parameters:

• Working times

• Leaf delay

• Partial opening time

• 2 n. maintenance cycles adjustment

• Antisqueezing sensibility SAFETY GATE

• PhotoStop

• PhotoClose

• PushOpen (excludes the pushover during opening phase)

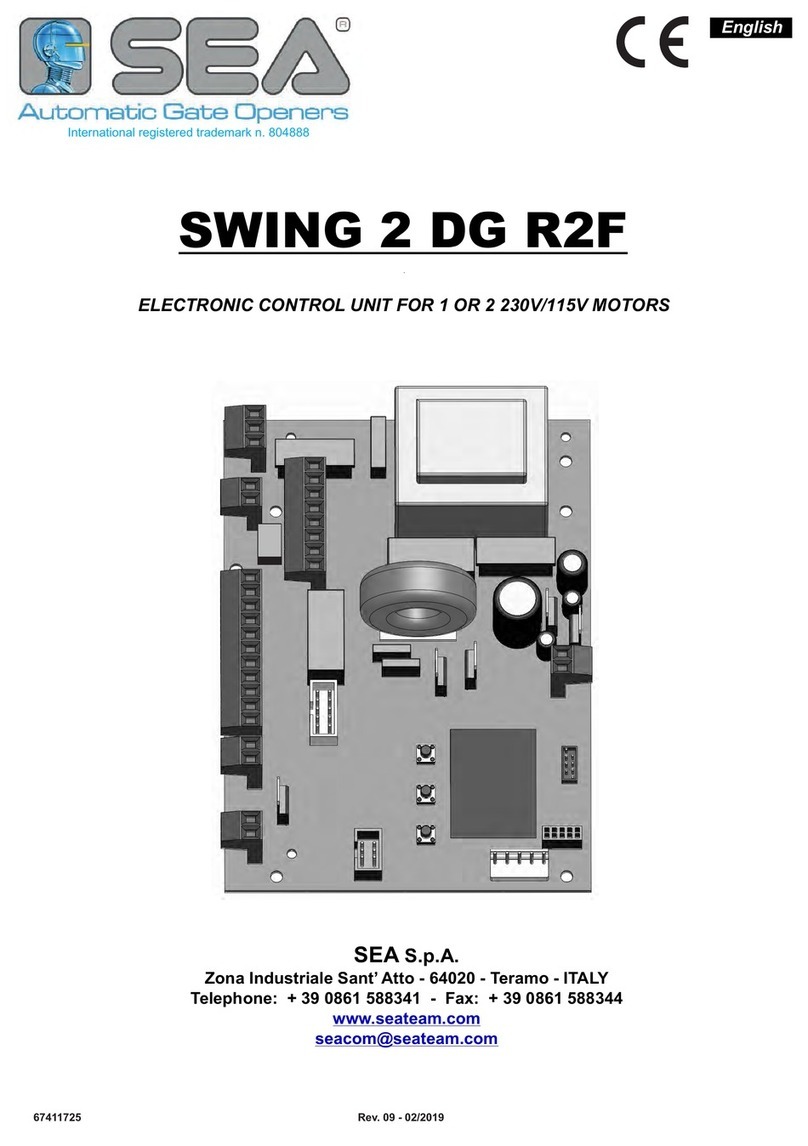

CN3CN2

RL1 RL2

CN4

RL3

F1

F2

P1

P2

Rv1

Rv2

Rv3

CN1

U1

U2 DIP

J1

LED5

LED6

LED7

LED8

LED9

LED10

LED11

LED1

LED2

LED3

LED4

LED12

LED13

LED14

LED15

LED16

LEDP

FUNCTION OF THE CONTROL UNIT GATE 2 FOR ONLY ONE MOTOR

The Gate 2 control unit can be used for the movement of one single leaf, when swing leaf it’s without limit switch. To

prepare the control unit for the programming of this function it is sufficient to PUT A JUMPER between the limit switch

contacts of the motor M1 (connected motor) and to exclude the leaf delay (Dip 4 ON). Keep pressed P1 until the motor

starts to close, when it reaches the stop in closing press P1 again, and the motor will open. Press P1 after the stop in

opening has been reached, the motor will start a closing cycle, when it reached the stop in closing press P1 and the

programming is finished.

FUNCTIONING OF THE GATE2 CONTROL UNIT FOR A DOUBLE SLIDING GATE

It is possible to use the GATE2 control unit also to move a double sliding gate with limit switch. To predispose the unit for

the programming of such functioning modality it is sufficient to connect the limit switch connectors of the motors M1 and

M2 and to exclude the leaf delay (Dip 4 on ON )

Press and keep pressed P1 until the motor starts, now the automation continues autonomously with the selflearning of

the times.

REV 05 - 10/2010

GATE 2

PROGRAMMING A TRANSMITTER

WARNING: The default card will only accept ROLLING CODE radio transmitters (Ladbird Roll and and Smart Roll)

associated with the RF ROLL (433 Mhz Code 23120470, 868 Mhz Code 23120480). To program “NOT ROLLING

CODE” transmitters (Smart Dual, Ladybird Dip and Copy and Head) it is necessary to replace the microprocessor

with the appropriate kit (Code 23120419) and to insert on the control unit the RF module (433 Mhz Cod.23120420, 868

Mhz Cod . 23120425).

Note: The RF ROLL receivers will be manageable with the SP40 management software (Code 23105295) and with the

OPEN sytem (Code 23105290).

PROGRAMMING A TRANSMITTER ON START

Press button P2 (PCode) until LEDP turns ON.

If no further code is memorized within 10 seconds, the LED automatically goes OFF and exits the programming procedure.

ATTENTION: If the code entered is already in the memory, it will be deleted. LedP flashes 4 times to confirm this procedure.

PROGRAMMING A TRANSMITTER ON PARTIAL START

1) Press button P2 (PCode) until LEDP turns ON.

2) Press button P1 (PTime). LEDP will start to flash quickly

If no further code is memorized within 10 seconds, the LED automatically goes OFF and exits the programming procedure.

ATTENTION: If the code entered is already in the memory, it will be deleted. LedP flashes 4 times to confirm this procedure.

CANCELLATION OF ALL RADIO TRANSMITTERS

Press and keep pressed button Pcode, ledP will start to flash. Wait until the ledP stops to flash and release the Pcode. LedP

will flash 6 times to confirm the cancellation.

Give a START with the transmitter, using the button chosen for the start

command.

The LED will flash twice to confirm that the transmitter code has been memorized

and will remain ON waiting for further transmitters.

Give a START with the transmitter, using the button chosen for the start

command.

The LED will flash twice to confirm that the transmitter code has been memorized

and will remain ON waiting for further transmitters.

P2

LEDP

P1

LEDP

LEDP

1) 2)

20

International registered trademark n. 2.777.971

P2P2

P2

LEDP

LEDP

U1U1

U2U2

RV1RV1

RV2RV2

RV3RV3 P1P1

P2P2

F1F1

F2F2

CN1CN1

CN2CN2 CN3CN3

RL1

RL1

R2

L

R2

L

RL3

RL3

LD

E1

LD

E1

LED2

LED2

LED3

LED3

EL D 4

EL D 4

LED5

LED5

LD

6

ELD

6

E

7

LED7

LED

EL D8

EL D8

EL 9D

EL 9D

1

LED01

LED0

LED11LED11

L D12

EL D12

E

E1

LD

3

E1

LD

3

L D14

EL D14

E

1

LED 5

1

LED 5

EL D16

EL D16

DIPDIP T1T1

CN4CN4

LDPELDPE

REV 05 - 10/2010

Other manuals for GATE 2

2

Table of contents

Other SEA Control Unit manuals

SEA

SEA GATE 1 DG R1 User manual

SEA

SEA 23001157 User manual

SEA

SEA SWING 2 DG R2F User manual

SEA

SEA USER 1-24V User manual

SEA

SEA USER 1 - 24v DG R1 User manual

SEA

SEA GATE 2 - 24V PLUS User manual

SEA

SEA USER 2 24V DG R1B ALL-IN User manual

SEA

SEA GATE 1 DG R1 User manual

SEA

SEA USER 1 - 24v DG R1 User manual

SEA

SEA GATE 2 DG R1B User manual

SEA

SEA GATE 1 DG R2BF User manual

SEA

SEA GATE 1 DG R2BF User manual

SEA

SEA USER1-24V User manual

SEA

SEA SWING 2 User manual

SEA

SEA USER 2 24V DG ALL IN User manual

SEA

SEA SLIDE NEW MAG User manual

SEA

SEA Orion User manual

SEA

SEA CUBE R. NW User manual

SEA

SEA GATE 1 DG R1 User manual

SEA

SEA USER 1 - 24v DG R1 User manual