SEA FULL TANK 100 User manual

FULL TANK

SEA S.r.l.

Zona Ind. S.Atto 64020 TERAMO Italy

Tel. +39.0861.588341 - Fax+39.0861.588344

e-mail: [email protected]

WEB SITE : www.seateam.com

EnglishEnglish

INSTALLATION MANUAL

and Securit y I nformation

HY DRAU LIC OPERATOR FOR SWING GATE

Cod. 67410845 REV 02 - 06/2009

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

16

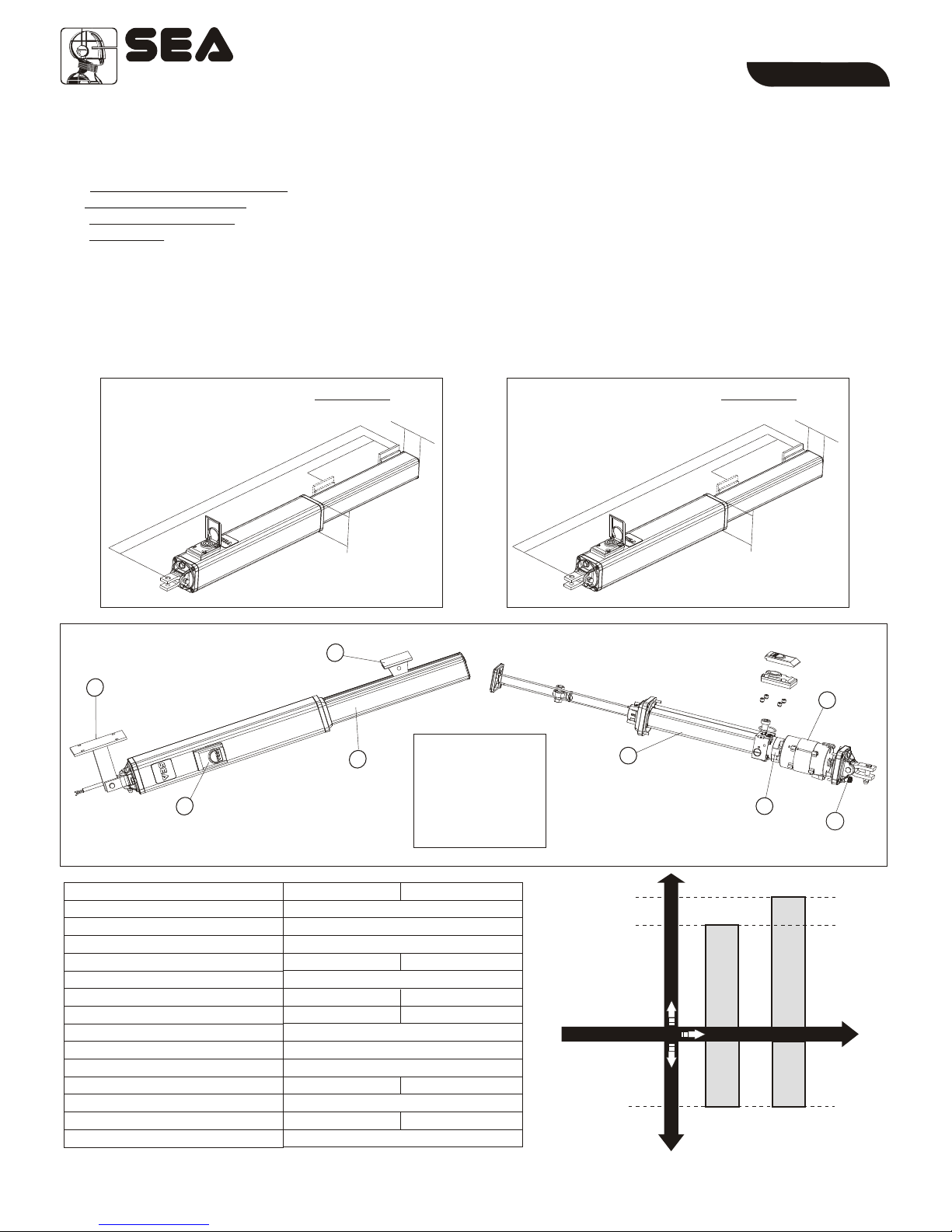

FULL TANK 100 FULL TANK 200

1 A

40 bar 30 bar

130°C

230 V (±5%) 50/60 Hz

220 W

270 mm 390 mm

70

-20°C +55°C

640da N

12,5uF

12,8 Kg 15,2 Kg

Ip55

6 mt 7 mt

90° / 125°

FEATURES AND SPECIFICATIONS

The FULL TANK is a high quality hydraulic operator for condominium use for gates with leaf lengths up to max. 7 m.

SA (with lock only in opening)

The lock is guaranteed for leaf lengths up to 180 m with the 100 version and up to 2,20 m with the 200 version. For leaf lengths

exceeding 2,20 m it is necessery, in all versions, to install an electric lock.

Available in the following versions:

AC (with lock in opening and closing)

SC (with lock only in closing)

SB (without lock)

The Full Tank is supplied with by-pass valves for the power regulation in both opening and closing. Electronic adjustable slow down

in opening and closing with control board GATE 2. For the European laws and directives actually in force it is strongly recommended

to use the Safety Gate (device for the reading of the gate position), for reverse in case of obstacle.

USING GRAPHIC

FULL TANK OPERATOR

FULL TANK 100

7 mt

70

FULL

TANK 100

1. Shaft cover

2. Release

3. Front bracket

4. Rear bracket

5. Cylinder

6. Electric motor

7. Hydraulic pump

8. Exit electric cables

FULL TAN K

Dimensions (mm)

EnglishEnglish

Dimensions (mm)

FULL

TANK 200 FULL TANK 200

6 mt

TECHNICAL FEATURES

Operating temperatures

Thermal protection

M

P

Power supply

Power

Absorbed current

Stroke

Cycles hour (at a temp. of 20°C)

Max working pressure

ax Thrust

Capacitor

Weight

rotection class

Max leaf lenght

Opening degree of the leaf

CICLES/HOUR

OPERATORS

Max. leaf length

17

Cod. 67410845

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

REV 02 - 06/2009

11

33

44

22

Fig. 3

Fig. 1

FULL TANK 100 FULL TANK 200

Fig. 2

5

6

7

8

01 52

09 8

02 7

90

56

1270

211 5

390

90

65

FU LL TANK

Release

By-pass valves

EnglishEnglish

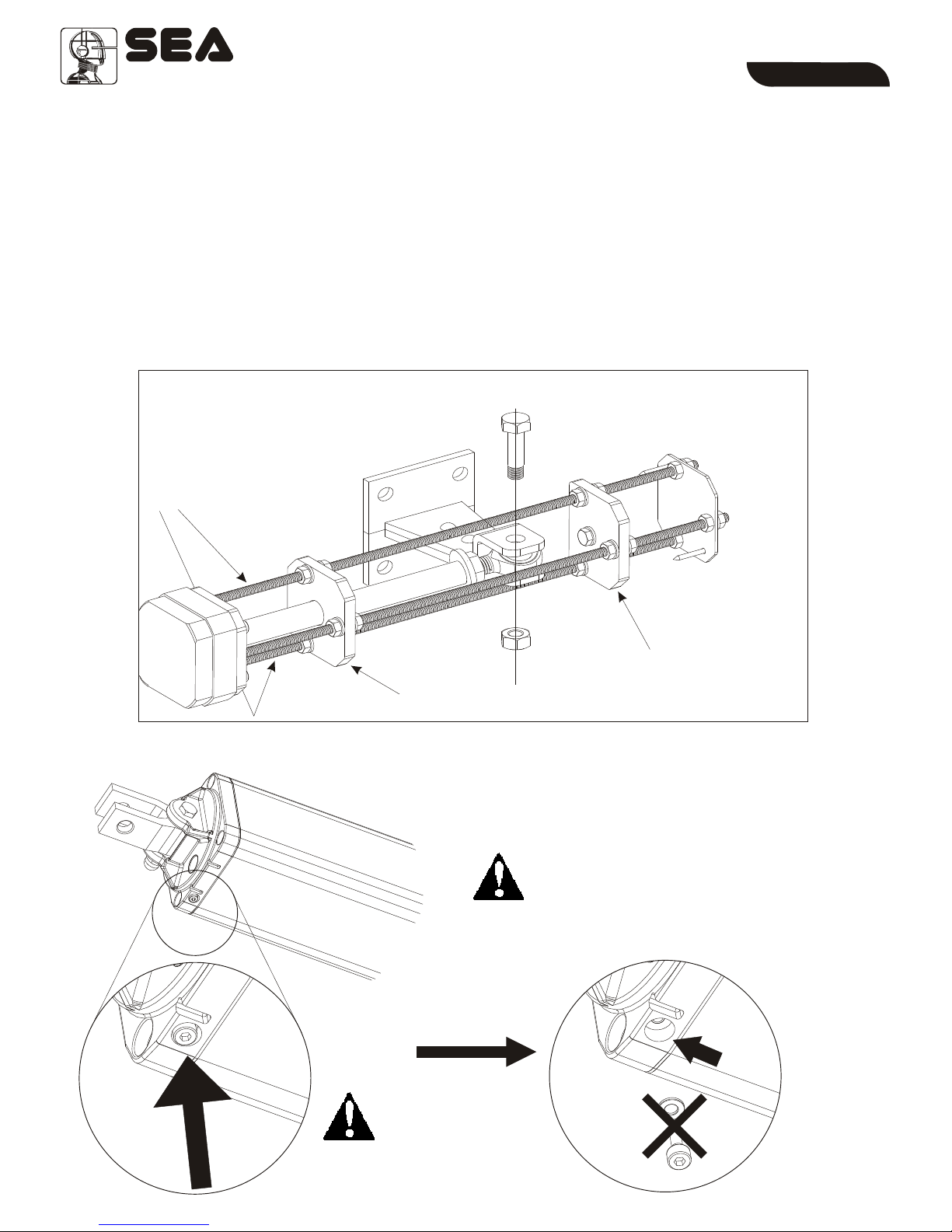

Clevis Attachment

Rear attachment

Breather screw

Pin rear

attachment

(short)

Brass Pin (long)

Front bracket

Shaft Cover

End cover

Cod. 67410845

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

REV 02 - 06/2009

18

Fig. 4

11

33

44

1010

1010

11

77

1212

1212

55

99

88

22

66

22

11

52x1,

2x1

3x1 SCH.

3 1 Hx SC .

3x1,5

2x1

RG 58

3x1,5

3x1,5

2x1

13 x

FULL TAN K

EnglishEnglish

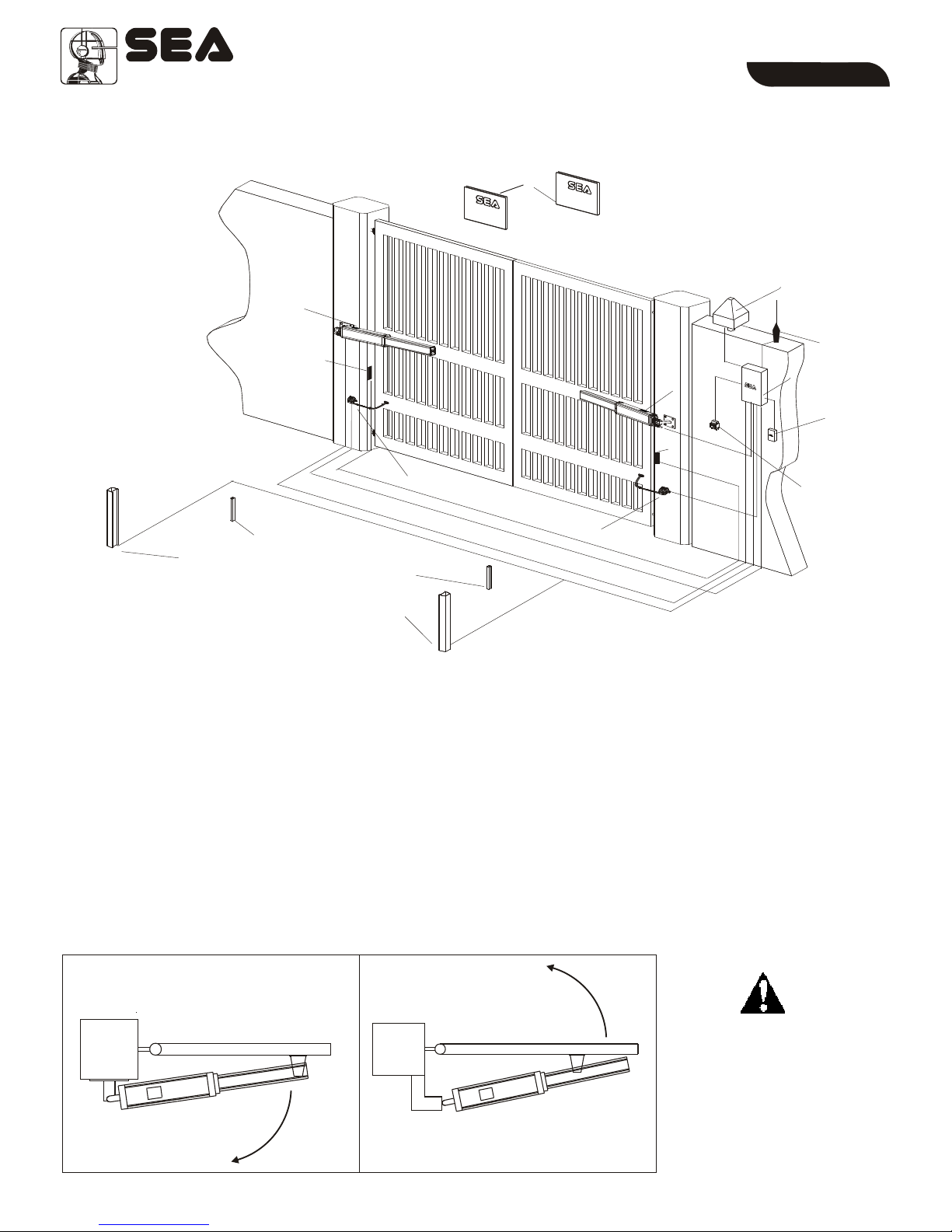

TYPICAL INSTALLATION

INSIDE

OUTSIDE

1. Full Tank operator

2. Mechanical stop

3. Gate 2 control board

4. Warning lamp

5. Photocell tx

6. Differential switch 16A-0,03A

7. Photocell rx

8. Key switch start-stop

9. Antenna

10. Column for photocells

11. Warning notice

12. Safety Gate

TYPE OF INSTALLATION

It is possible to install the Full Tank with opening inside (Fig.5) or opening outside (Fig.6).

Install the operator always

inside the property

inside inside

Outside

Outside

Inward installation Outward installation

Cod. 67410845

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

REV 02 - 06/2009

Fig. 5 Fig. 6

19

a

d

b

c

Fig. 7

a

d

b

c

Fig. 7 encore

FULL TAN K

EnglishEnglish

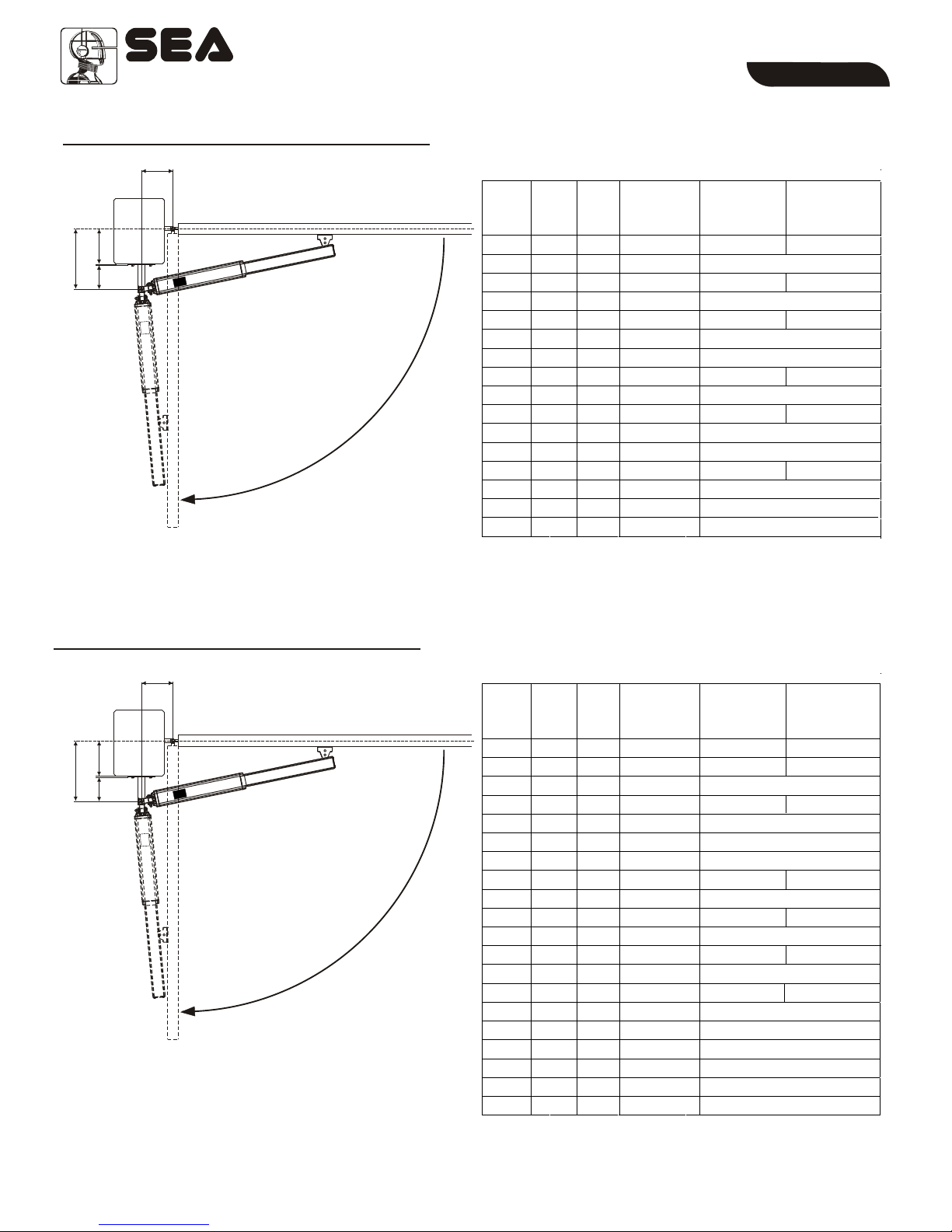

INSIDE OPENING INSTALLATION

To obtain 110° with d > 55 mm it is necessary to make a niche in the gate.

INSIDE OPENING INSTALLATION

To obtain 125° with d > 55 mm it is necessary to make a niche in the gate.

Outside

Outside

Inside

Inside

Total stroke 270 mm - max. recommended stroke 250 mm

a b d

max Max.

Opening

Angle

(mm) (mm) (mm)

250 215

250

250

215

250 225

250 235

255 242

250 242

250

250

100

100

105

105

120

120

125

140

140

145

145

150

155

160

170

180

115

150

110

145

105

130

125

95

110

95

105

100

85

90

75

65

50

50

55

55

70

70

75

90

90

95

95

100

105

110

120

130

110°

90°

110°

90°

106°

90°

90°

100°

90°

100°

90°

90°

96°

90°

92°

92°

250

250

250

250

250

253

245

Max. Stroke

(mm)

Stroke

for 90°(mm)

Total stroke 390 mm - max. recommended stroke 370 mm

a b d

max Max.

Opening

Angle

(mm) (mm) (mm)

368 295

372 300

372

370

370

310

370 330

370

371

355

355

370

370

360

365

369

370

370

125

130

140

145

145

160

175

185

185

195

195

240

240

250

250

260

260

270

280

295

170

170

235

165

230

210

195

145

190

140

175

110

125

105

115

95

100

90

80

65

75

80

90

95

95

110

120

130

130

140

140

185

185

195

195

205

205

215

230

245

125°

125°

90°

120°

90°

90°

90°

110°

90°

110°

90°

100°

90°

95°

90°

95°

90°

90°

90°

90°

370

370

370

370

370

370

369

Stroke

max (mm)

Stroke

for 90°(mm)

Cod. 67410845

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

REV 02 - 06/2009

20

a

d

b

c

Fig. 8

a

d

b

c

Fig. 8 encore

FULL TAN K

EnglishEnglish

OUTSIDE OPENING INSTALLATION

OUTSIDE OPENING INSTALLATION

Inside

Outside

Inside

Outside

a b Max.

Opening

Angle

(mm) (mm)

250 240

250

250

243

241

150

160

165

175

180

180

90

90

80

80

70

65

95°

90°

95°

90°

90°

90°

250

249

Stroke

max (mm)

Stroke

for 90°(mm)

Total stroke 270 mm - max. recommended stroke 250 mm

a b Max.

Opening

angle

(mm) (mm)

356 342

345 336

330

335

319

250

255

265

270

275

275

100

95

95

90

90

90

100°

95°

95°

90°

90°

90°

325

342

Max. Stroke

(mm)

Stroke for

90°(mm)

Stroke 390 mm - max. recommended stroke 370 mm

Cod. 67410845

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

REV 02 - 06/2009 21

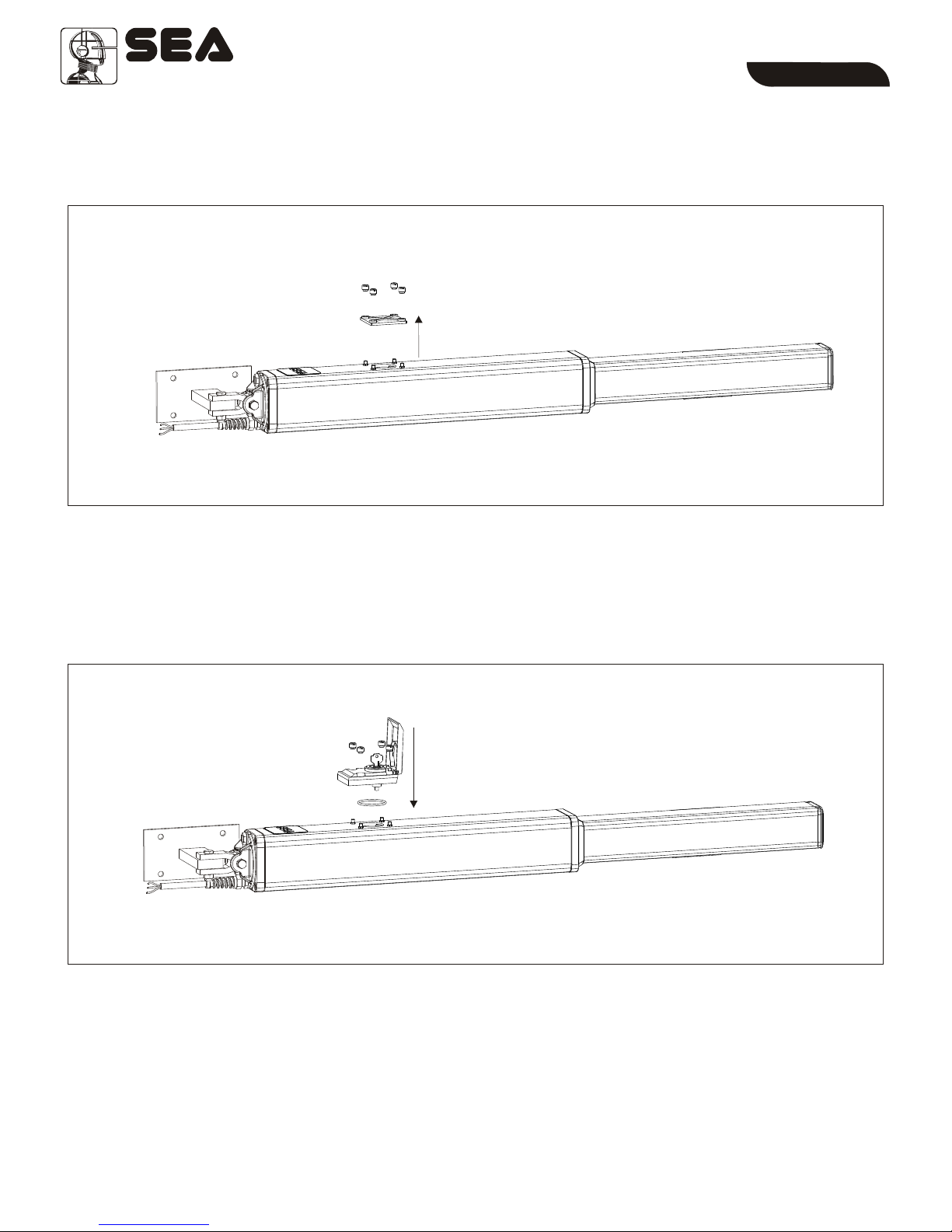

RELEASE MOUNTING

Remove the transporting plate as shown in Fig. 9.

Mount the release as shown in Fig. 10.

FULL TAN K

EnglishEnglish

Cod. 67410845

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

REV 02 - 06/2009

Fig. 9

Fig. 10

22

Fig. 13

Fig. 14

98 mm

8 m5 m

55 mm

65 mm

FULL TAN K

EnglishEnglish

ØOpen carefully the package, making sure

not to loose parts which are listed in fig. 4

ØAttach the rear oscillating bracket as shown

in fig. 12

Attention: Do not use a hammer for the

insertion of the short brass pin; its fitting into

the bracket and clevis attachment must be

done by the simple pressure of the hands.

Attention: Do not incline the hydraulic

operator further than the allowed angle of the

oscillating bracket (1), risks the possible

braking of it.

INSTALLATION OF THE OSCILLATING REAR BRACKET

Adjustable rear bracket (with screws)

(Accessory on demand)

INSTALLATION OF REAR BRACKET

According to the type of opening that you have chosen

(inside or outside) and to the chosen leaf rotation (see

pag. 20-21), the rear bracket must first be cut respecting

the quote “a” on pag. 20-21 and then welded as in fig. 13.

The support must be positioned so that the operator is

perfectly levelled (Fig. 13, Fig. 15)

Cod. 67410845

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

REV 02 - 06/2009

Fig. 11

Fig. 12

(1)

23

Fig. 17 Fig. 18

70 mm 70 mm

6m

3,5 m

46 mm

POSITIONING OF THE FRONT BRACKET

Once the operator is attached to the post and the leaf set in the closed position execute the following

operations:

1. Release the operator (as in fig. 24 pag.12)

2. Pull-out completely the chromate shaft and push it back in 1cm

3. Attach the shaft to the front bracket (Fig. 16)

4. Set the operator perfectly levelled and mark the position of the front bracket (Fig.15)

Attention: avoid the welding of the front bracket to the shaft of the hydraulic operator already attached;

the welding scraps (daps) could ruin the chromium plating of the shaft.

Front bracket welded

Front bracket screwed

WELDING OF THE FRONT BRACKET TO THE GATE

The front bracket must be positioned so that the operator is perfectly levelled

According to the nature of the gate the front bracket (wood, steal, Aluminium) can be:

FULL TAN K

EnglishEnglish

Cod. 67410845

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

REV 02 - 06/2009

Fig. 16

Fig. 15

24

Fig. 19

Disc 1

Disc 2

INSTALLATION OF POSITIVE STOPS

ØRelease the unit (as in fig. 24 of page 27)

ØMake the shaft come out for ¾ of its stroke

ØPut the positive stops into the front flange of the unit with the two tie rods (of the three present on the stops)

which are parallel to the gate (Fig.19)

ØFix the positive stops with the provided screws

Ø

ØAt this point couple the shaft to the front bracket

ØTo adjust the positive stops in opening act on disk 1 and in closing act on disk 2.

Attention: The mounting of the mechanical positive stops does not cause the reduction of the shaft

stroke.

Insert the ball joint after having installed the stops.

rods parallel to the gate

BREATHER SCREW

Up

down

Unscrew and

remove at the

end of installation

ATTENTION

It is obligatory to remove the breather

screw at the end of the installation.

FULL TAN K

EnglishEnglish

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Fig. 20

Fig. 21

OK

Cod. 67410845 REV 02 - 06/2009 25

+-

+-

Fig. 22

TORQUE ADJUSTMENT (by pass valves)

By-Pass Valves

s

u

s

e

r

r

e

p

i

n

g

n

o

i

t

p

a

e

r

n

e

i

n

p

g

O

u

s

s

e

r

r

e

p

i

g

n

n

i

c

t

l

o

a

r

s

e

i

n

p

g

O

Grey

Yellow

Grey Yellow

Adjust the opening and closing forces of the gate so that the diagram of the force is respected (present in the

regulation EN 12453); Anyway the max. thrust force should never be superior of 15 KgF.

INSTALLATION OF THE CHROME PLATED SHAFT COVER

FULL TAN K

EnglishEnglish

Cod. 67410845

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

REV 02 - 06/2009

Fig. 23

26

Fig. 25

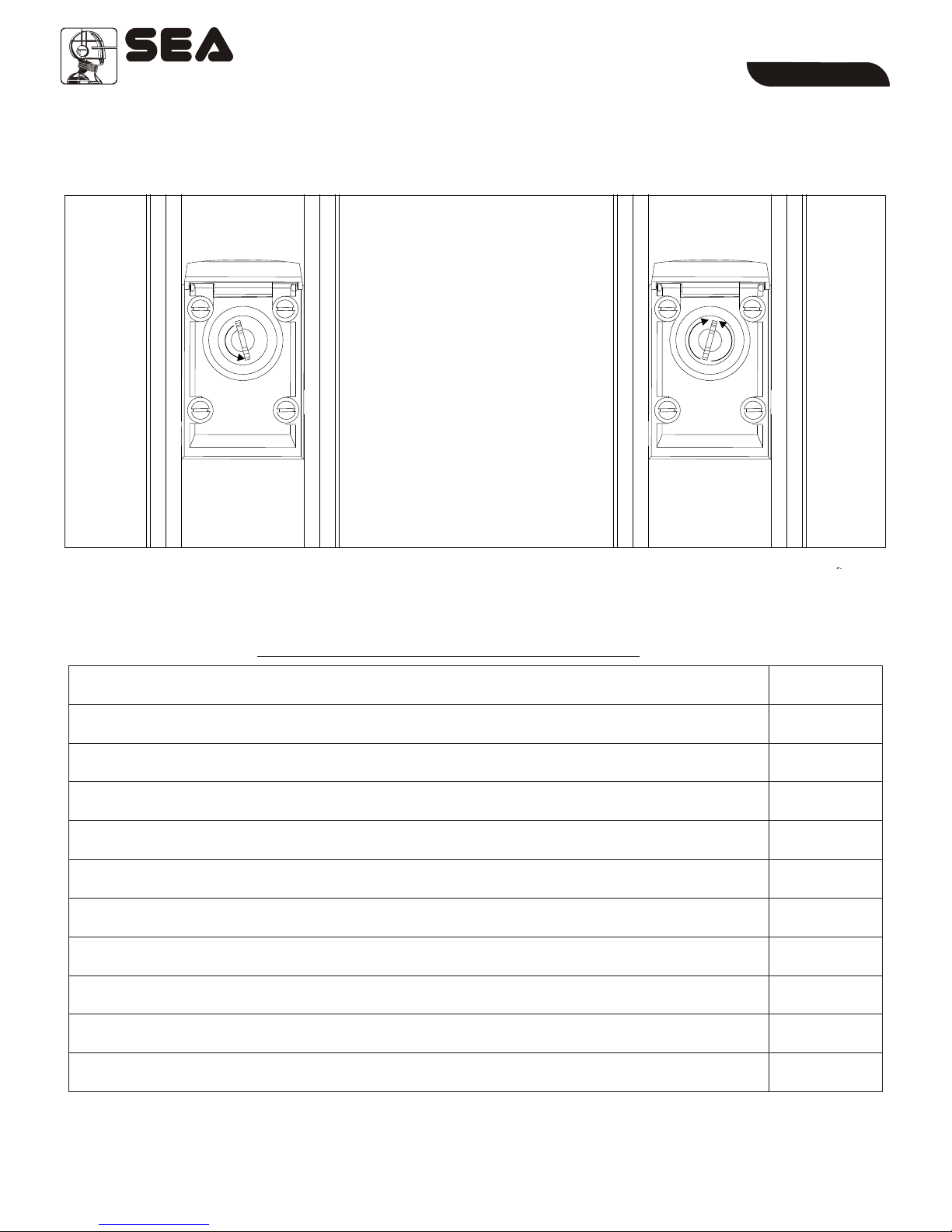

To release, open the lid, insert the

key, rotate starting from the stop of

departure from ½ turn to a

maximum of 1 turn (360°) in anti-

clockwise direction (see fig.24).

Attention: Turning the key over 1

turn (360°) could damage the

release .

To re-lock, turn the key into

clockwise direction to the

maximum, afterwards bring back

the key into the position 0, turn it

again in anti-clockwise direction

(see fig. 25), remove the key and

close the little door again.

Fig. 24

0

WARNING: SEA recommends to the end user to release the operator only after having switched off the electric power.

Always contact a professional installer in case of not correct working of the operator.

MANUAL RELEASE SYSTEM

WARNING: Always switch off the main power (110V or 230V) before servicing the operator.

All the above described operations MUST be made exclusively by an authorized installer.

1) Check the solidity and the stability of the gate, especially the points of support and/or rotation of

the gate (pivots).

2) Check the oil level of the hydraulic/in oil bath operators (cap on rear cover of the Full Tank)

3) Change the hydraulic oil with the one recommended from the head company

4) Check the release function

5) Check the by-pass valves function

6) Check and lubricate the fixing pins

7) Check the integrity of the connection cables

8) Check the function and the positive stops condition in opening and closing (where there is

present a mechanical positive stop accessory)

9) Check the good status of all parts which are forced (rear bracket, oscillating bracket and front

bracket).

10) Check the operating of all accessories, especially the function of all safety devices and of the

Safety Gate.

11) After having executed the periodical maintenance operations it is necessary to repeat the

test and the putting in service of the automation

PERIODI CAL MAI NTENANCE

Annual

Annual

4 years

Annual

Annual

Annual

Annual

Annual

Annual

Annual

Annual

FULL TAN K

EnglishEnglish

Cod. 67410845

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

REV 02 - 06/2009 27

Fig.26

RISK EXAMINATION

The points pointed by arrows are potentially dangerous. The installer must take a thorough risk examination

to prevent crushing, conveying, cutting, grappling, trapping so as to guarantee a safe installation for people, things

and animals.

(

)

As for misunderstandings that may arise refer to your

area distributor or call our help desk. These instructions

are part of the device and must be kept in a well known

place.The installer shall follow the provided intructions

thoroughly. products must only be used to automise

doors, gates and lwings. Any initiative taken without

explicit authorization will preserve the manufacturer

from whatsoever responsibility. The installer shall

provide warning notices on not assessable further risks.

in its relentless aim to improve the products, is

allowed to make whatsoever adjustment without giving

notice. This doesn’t oblige to up-grade the past

production. can not be deemed responsible for any damage or accident caused by product breaking, being

damages or accidents due to a failure to comply with the instructions herein. The guarantee will be void and the

manufacturer responsibility will be nullified if original spare parts are not being used.

Packaging materials such as plastic bags, foam polystyrene, nails etc must be kept out of children’s reach as dangers

may arise.

in fig. 26

Re. Laws in force in the country where installation has

been made.

SEA

SEA

SEA

SEA

SEA

SEA The electrical installation

shall be carried out by a professional technician who will release documentation as requested by the laws in force.

INITIAL TESTAND STARTING OF THE AUTOMATION

After having completed the necessary operations for a correct installation of the Full Tank product, as

described in this manual, and after having valuated all resting risks which could arise in any installation, it is

necessary to test the automation to guaranty the maximum security and, in particular way, to guaranty

that the laws and norms of this sector are fully respected. Especially the test must be executed following

the norm EN 12445 which establishes the methods of tests for checking the gate automations respecting the

limits established by the rule EN 12453.

SAFETY GATE

For a correct and safe installation it is

strongly recommended to install a

Safety Gate, which allows the

fulfilment of the force diagram

included in the norm EN 12453 and

consequently the test and start of the

whole installation.

FULL TAN K

EnglishEnglish

Cod. 67410845

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

REV 02 - 06/2009

28

SELF INSTALL - NEED TECHNICAL

ASSISTANCE?

OPTION 1: DIRECT WITH THE SERVICE DESK – QUICKEST AND MOST EFFECTIVE METHOD

Submit your enquiry direct with the service desk at – service@automaticsolutions.com.au

The service desk has the most experienced staff in Australia to help with your problem but they need your help.

Describe your problem in detail and as clearly as possible. Don’t forget to include a telephone number.

Be certain to detail which model or models of you are working with.

Send photos of the installation – they love photos. The people at the service desk are good but they are

even better when they can see the installation. Send photos of the overall scene so they can see the

entire installation. Also send photos of the wiring to the control board and any other part of the

installation you think is relevant.

Send video if appropriate. Smartphone’s these days take remarkably good video in small file sizes which

can be emailed in a moment. If your problem needs a video to show the issue please feel free to send it.

NOTE: THIS IS BY FAR THE FASTEST AND MOST SUCCESFUL WAY TO SOLVE YOUR PROBLEM

PHOTOS AND VIDEOS ARE THE NEXT BEST THING TO BEING THERE

OPTION 2: LODGE YOUR ENQUIRY LOCALLY - SLOWER BUT CAN STILL BE EFFECTIVE

Make contact with the store of purchase. Branch staffs are typically not technicians and dependent on their length

of service will have varying degrees of technical knowledge. If they cannot help however they will certainly either

source help locally from their technicians or make contact with the service technicians on your behalf.

OPTION 3: SERVICE CALL WITH AUTOMATIC SOLUTIONS TECHNICIAN – SLOWEST METHOD

If you fall within the local branch service area it may be possible to book a local technician to look at your

installation. Wait times will vary dependent on local workloads. The cost is a service fee which includes the first

half hour and the hourly rate thereafter. If any Automatic Solutions provided parts are found to be defective and

within warranty these will be provided free of charge.

(NOTE: If you suspect that any parts are defective and within warranty you may wish to consider option 4)

A note on this option: If you decide on this option you will be asked to sign an “authorisation to proceed” which

will provide legal authority and payment security. This form has three options available of which only the first two

are available to you. The third option is for warranty repairs only for full install customers. Self install customers

requiring warranty only service need to refer to option four below.

IMPORTANT: IN SHORT THIS OPTION WILL INCUR CHARGES

OPTION 4: RETURN THE PRODUCT IF BELIEVED TO BE FAULTY

As a self install customer who has purchased product if you believe the product to be faulty rather than an

installation or site problem you have the option of returning the product for evaluation and to exercise your right

to a replacement, repair or refund as applicable. All returned product is forwarded immediately to the service

technicians for evaluation and response. There are two main methods available to return product –

Direct to the service centre – this is the quickest method as it cuts out the branch delay

Via the branch of purchase – slower because of the delay at the branch

When choosing this option you need to complete a product return form. This form gives you all the information

on procedure involved and where to send to. These are available at the branch of purchase, can be emailed to

you (contact your branch), or available here - http://automaticsolutions.com.au/page/warranty.php

This manual suits for next models

1

Table of contents

Other SEA Gate Opener manuals

SEA

SEA SURF 350 Reversible User manual

SEA

SEA FLIPPER User manual

SEA

SEA EASY 20 User manual

SEA

SEA COMPACT Series Original instructions

SEA

SEA HALF TANK User manual

SEA

SEA MINI TANK User manual

SEA

SEA JOINT Original instructions

SEA

SEA LIBRA Series Original instructions

SEA

SEA SURF User manual

SEA

SEA MARK TANK E 270 User manual

SEA

SEA SCUTI User manual

SEA

SEA TAURUS BOX 1000 User manual

SEA

SEA ORION BOX 24V User manual

SEA

SEA LYRA Instruction manual

SEA

SEA JOINT Original instructions

SEA

SEA SUPER FULL TANK Series Original instructions

SEA

SEA LEPUS Series User manual

SEA

SEA FLIPPER 110V User manual

SEA

SEA ERG User guide

SEA

SEA 1110 User manual