SEA FLIPPER 110V User manual

ELECTROMECHANICAL OPERATOR FOR SWING GATES

FLIPPER 110V

REV 00 - 03/2009

FITTING INSTRUCTIONS

and security advices

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151 Fax: ++1-305.594.7325

Toll Free: 800.689.4716

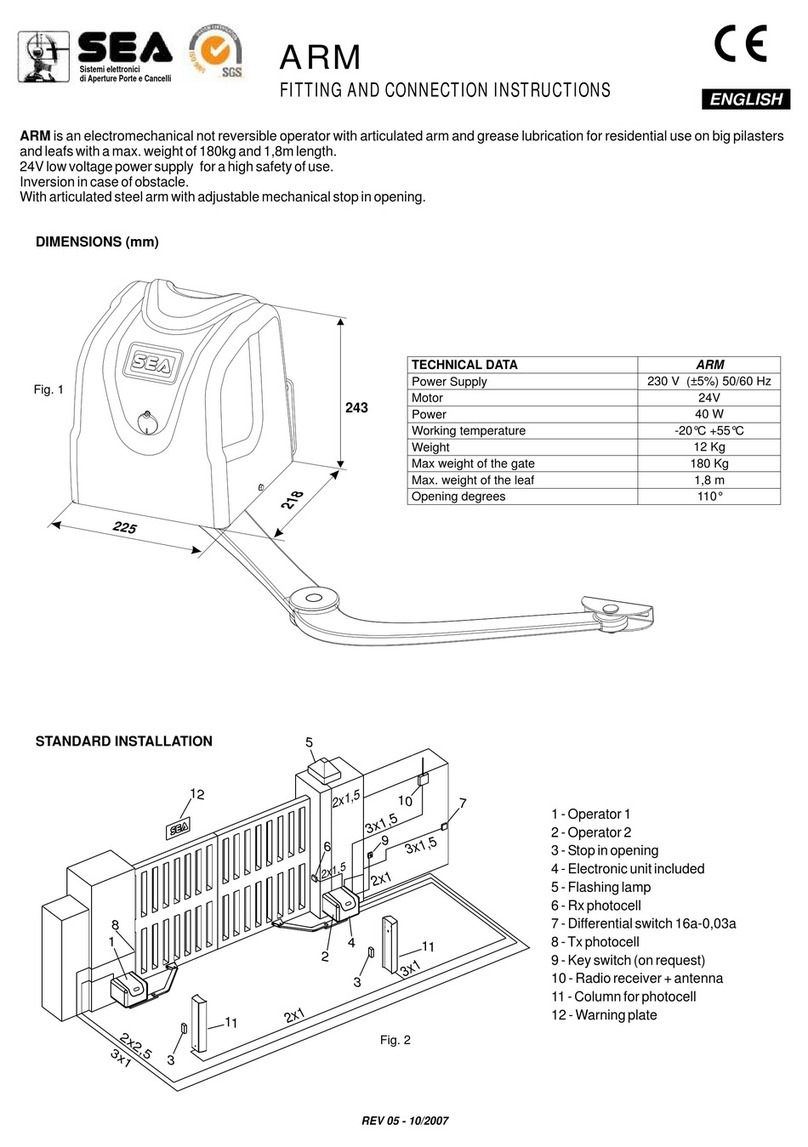

Flipper is an irreversible electromechanical swing gate operator for medium sized piers, maximum leaf length 2 m or 200Kg

weight (see drawing in Fig 4-A)

FLIPPER

110V (±5%) 50/60 Hz

24V

80 W

-20°C +55°C

18 pound

441 pound

6,5 feet

110°

6,5

10

,97

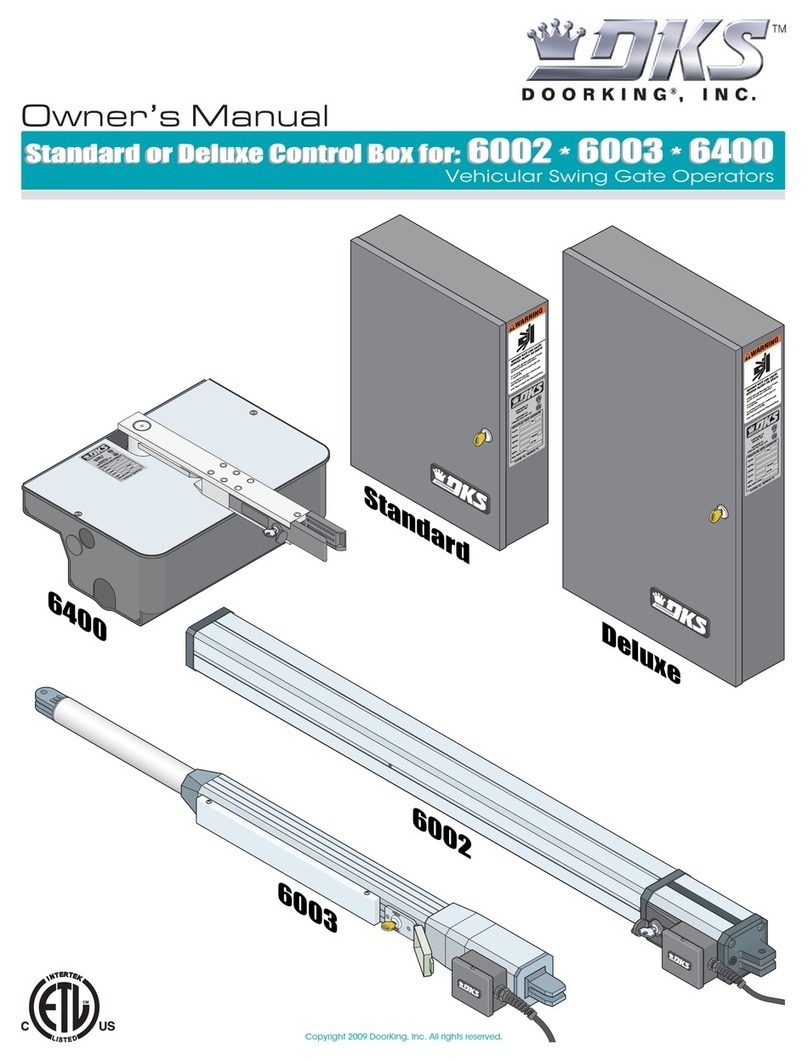

Fig. 1

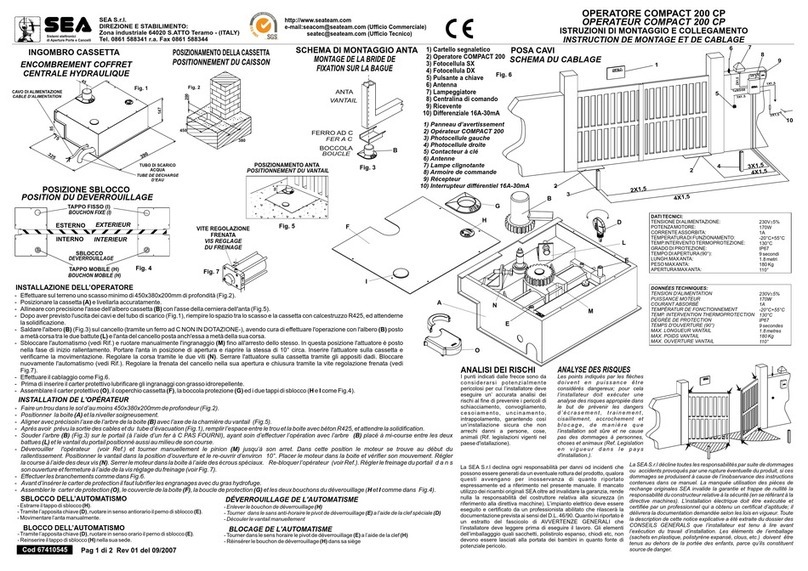

1-Operator 1

2-Operator 2

3-Stop in opening (where

possible)

4-Electronic unit included

5-Flashing lamp +

antenna

6-Photocell Ghost 40

7-Key switch Key Plus

8-Column for photocell

Pilar + Ghost40

9-Warning plate

9

1

6

5

6

3

2

4

8

8

7

3

Fig. 2

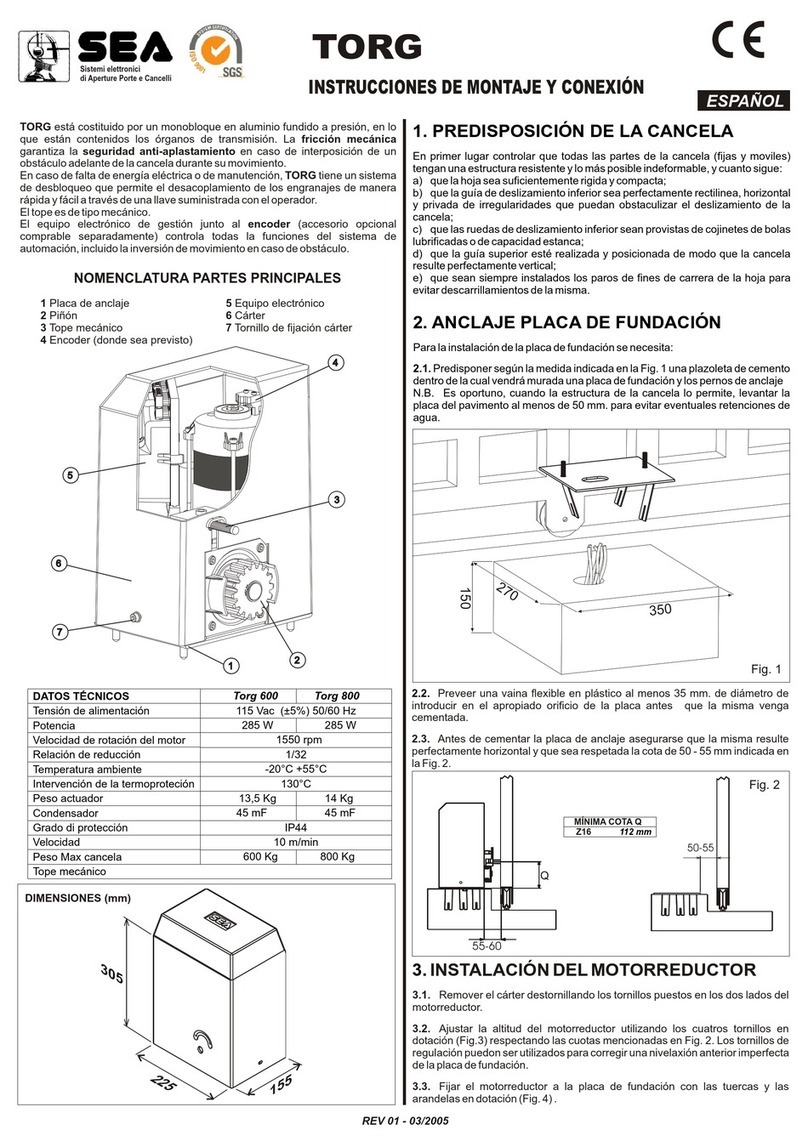

TECHNICAL DATA

Power Supply

Motor

Power

Working temperature

Weight

Max weight of the gate

Max. weight of the leaf

Opening degrees

DIMENSIONS (inches)

STANDARD INSTALLATION

International registered trademark n. 2.777.971

REV 00 - 03/2009 2

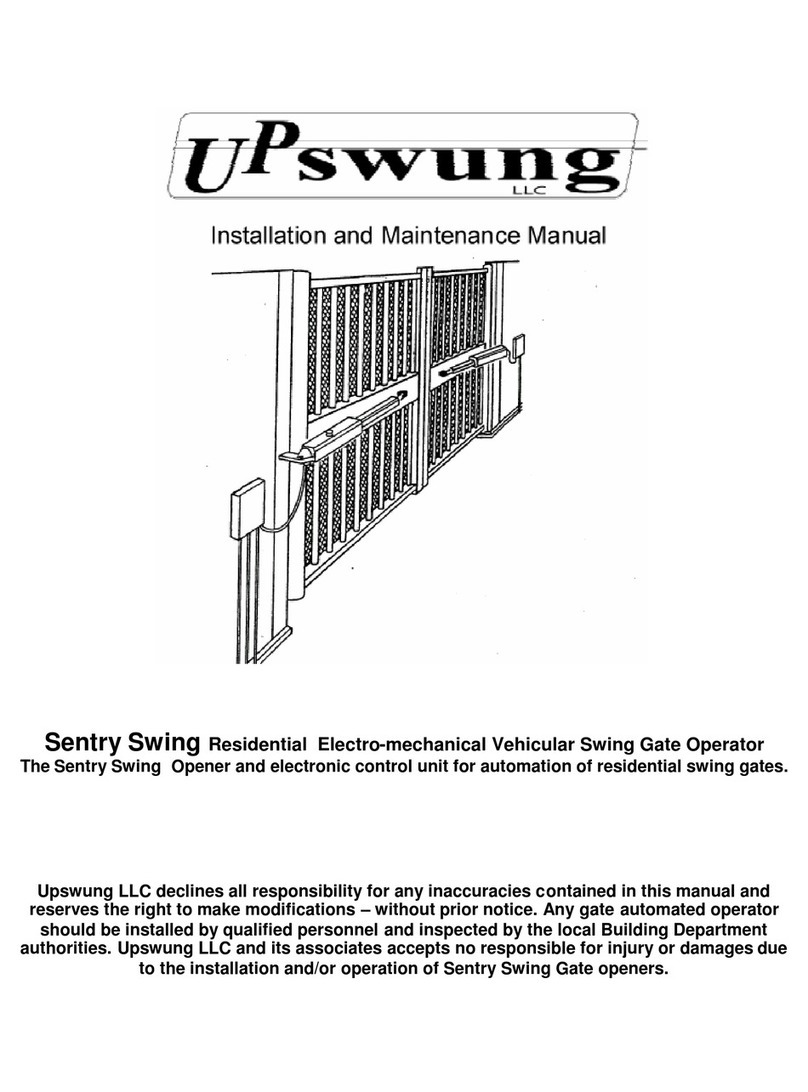

Fig. 3

1. Carter

2. Anchrage plate

3. Fuse

4. Transformator

5. Electronic control unit

6. Battery/card support (battery optional)

7. Mech./electr. Stop (electronical optional)

8. Streight articulated arm

9. Curved articulated arm

10. Back fixation

11. Portection cover

1

2

6

8

10

11

4

5

3

7

9

International registered trademark n. 2.777.971

REV 00 - 03/2009 3

CARTER OFF MOUNTING

Open the little release door and take off the screw on the inside (Fig 4).

Fig. 4

Fig. 5

Fig. 6

Limit switch

opening

Limit switch

closing

Common

Motor

Motor

Fig. 6-A

CONNECTOR

FLIPPER WITH CONTROL UNIT

FLIPPER WITHOUT CONTROL UNIT

0 Kg

264,5 p

309 p

353 p

397 p

441 p

3,2 f 4,1 f 4,9 f 5,7 f 6,5 f

•

•

DRAWING LEAVES DIMENSIONS Fig. 4-A

USING

FIELD

Stop

International registered trademark n. 2.777.971

REV 00 - 03/2009 4

GATE ARRANGEMENT

It is necessary to make controls on the gate to make sure the application of FLIPPER automation can be possible.

Make sure that: Fig. 7

A. The gate fixed and moving parts have a strong and crush-

proof structure;;

B. The weight of each leaf is not over 441 pound (see drawing

pag. 4, Fig 4-A);

C. The length of each leaf is not over 6,5 feet (see drawing

pag. 4, Fig 4-A);

D. The hinges are strongly anchored and are able to support

the torque of the operator; they do not have irregular

movements and/or any friction during the whole movement of

the leaf;

The FLIPPER operator comes with limit switch stop in opening

and closing, nevertheless it is recommended to install

mechanical limit switch stops to be fixed on the ground in

closing and opening (Fig. 7).

B

A

C4 i h

e/5 nc s

MAX 10 inches

Fig. 8

105°/110°105°/110°

100°/105°100°/105°

90°/100°90°/100°

1212

1111

1010

9.49.4

99

88

77

66

5.55.5

55

44

001122334455667788991010

BB

AA

Limit Switch stop

in opening

Limit Switch stop

in closing

DIMENSIONS FOR THE INSTALLATION

International registered trademark n. 2.777.971

REV 00 - 03/2009 5

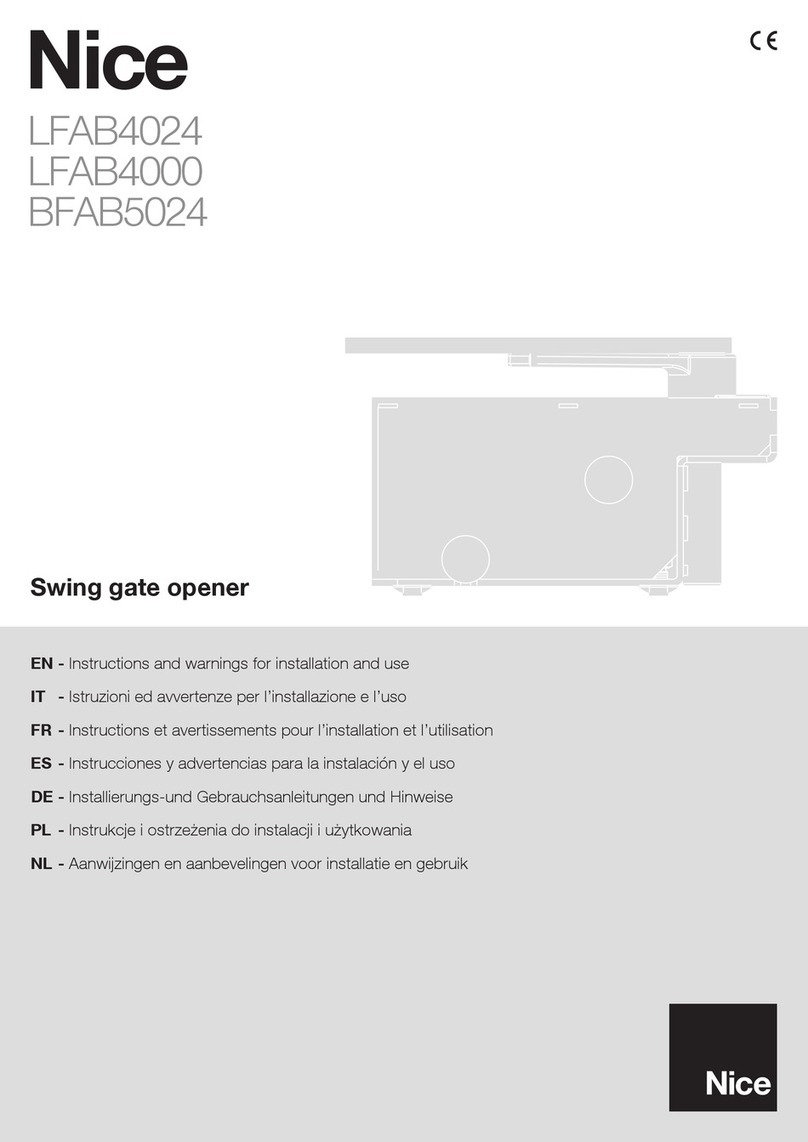

Fig. 9

Fig. 11

Fig. 12

Fig. 10

A

B

0m8 m

42 mm

MOUNTING PLATE ATTACHMENT AND MOUNTING OF THE MOTOR

- Attach the mounting plate to the pilaster with 4 screws and 4

washers not included (Fig. 9).

- Make sure that the plate is in horizontal position (with level).

- Mount the motor on the plate using the 2 furnished screws.

- The two articulated arms must be assembled differently, distinguishing the right arm from the left one.

See Fig. 11 and 12.

Note: Before inserting the pivots lubricate them with water repellent grease

ASSEMBLING OF THE ARTICULATED ARM

RIGHT HAND MOUNTING

LEFT HAND MOUNTING

PIVOTS

PIVOTS

International registered trademark n. 2.777.971

REV 00 - 03/2009 6

- Fit the articulated arm into the motor shaft and lock it with the special screws (Fig. 13).

- The protection cover must be mounted on the end of all adjustments.

Fig. 13

For further information see point “External release”.

EXTERNAL RELEASE MOUNTING

ATTACHMENT OF THE ARTICULATED ARM TO THE MOTOR

International registered trademark n. 2.777.971

REV 00 - 03/2009 7

Fig.14

Return spring

Fig. 17Fig. 16

Fig. 15

FIXING OF THE FRONT BRACKET

- Close the leaf completely

- Release the motor (see Fig. 18 e 19)

- Extend the articulated arm (Fig. 8), lean the adjustable front bracket on the gate and make two marks on the center of the two

holes (Fig. 15) respecting the measures in Fig. 8.

- Perforate the leaf and fix the front bracket with the screws (Fig. 16)

- Before tightening the screws move the front bracket to the right or to the left for a good positioning of the arm on the gate (Fig.

17) respecting the measure D in Fig. 8.

International registered trademark n. 2.777.971

REV 00 - 03/2009 8

Fig. 18 Fig. 19

To release operate as follows:

- Take off the protection cap of the lock.

- Insert the key and turn about 90° into clockwise direction (Fig. 18).

- Pull the door until its complete opening (Fig. 19).

- Open manually the leaf

To block again operate as follows:

- close the door again.

- Turn the key about 90° into anti-clockwise direction.

- Extract the key.

- Close the lock again with the protection cap.

90°

Operator locked Operator released

RELEASE SYSTEM

International registered trademark n. 2.777.971

REV 00 - 03/2009 9

- Release the operator.

- Open the leaf completely or up to the desired opening point.

- Position the stop as in Fig. 24 on the stop of the arm and lock the screws as in Fig. 25.

N.B: The delivered screws are selfthreading and have to be locked at 10 Nm.

RIGHT MOTOR

LEFT MOTOR

Closing OpeningOpening Closing

STOP STOP STOP STOP

Fig. 20 Fig. 21

Fig. 25

.0,4 inc

max

LEFTHAND MOUNTING RIGHTHAND MOUNTING

Fig. 22 Fig. 23

4 c0, in .

max

Fig. 24

MECHANICAL POSITIVE STOP ADJUSTMENT IN OPENING

International registered trademark n. 2.777.971

REV 00 - 03/2009 10

Fig. 26

PERIODICAL MAINTENANCE

Grease the moving parts

(Articulated arm, release, etc..)

Check the functioning of the release

Check the lock of the screws

Check the wear of the devices in movement

Check the integrity of the connected cables

Annual

Annual

Annual

Annual

Annual

RISK EXAMINATION

The points pointed by arrows in Fig. 26 are potentially

dangerous. The installer must take a close risk examination to

prevent crushing, conveying, cutting, grappling, trapping so to

guarantee a safe installation for people, things and animals

(

).

Re. Laws in force in the country where the installation has been

made

International registered trademark n. 2.777.971

REV 00 - 03/2009 11

RADIO RECEIVER

PHOTOCELLS

KEY SWITCH

FLIPPER ACCESSORIES

ELECTRIC LOCK

EXTERNAL

LOOP DETECTOR

FLASHING LAMP

TRANSMITTER KIT EXTERNAL LOCK

FLIPPER

SUPPORTS

FOR PHOTOCELLS

KIT LIMIT SWITCH

International registered trademark n. 2.777.971

REV 00 - 03/2009 12

International registered trademark n. 2.777.971

REV 00 - 03/2009

SAFETY PRECAUTIONS

Every change on trimmers and on dip switch must be done with the gate closed, or without

power supply.

All electrical installation work should conform to the current edition of the LEE Regulations

and all electrical work should only be carried out by a competent electrician. A 16A - 0,03A

differential switch must be incorporated into the mains electrical supply of the gates. Earth

bonding of the entire gate system must be correctly carried out.

To prevent mains interference all low voltage cabling (Push button, Photocell, Radio etc.)

should be run in separate cable ducts from main carrying cables.

Note: Use “cable clips” and/or “duct/box pipes” fitting close to the control panel box so to

protect the interconnection cables against pulling efforts.

SPARE PARTS

To obtain spare parts contact:

SEA USA Inc. 10850 N.W. 21st unit 160 DORAL MIAMI Florida (FL) 33172

Phone:++1-305.594.1151 Fax: ++1-305.594.7325 Toll Free: 800.689.4716

INTENDED USE

The USER 2 24V electronic control unit has been designed to be solely used as control unit

for the automation of swing gates.

LIMIT OF GUARANTEE

The USER 2 24V electronic control unit is guaranteed for a period of 24 months. The

guarantee period starts from the date stamp printed on the unit. The USER 2 24V guarantee

will be void if the unit has been incorrectly installed, not used for the intended purpose,

tampered with or modified in any way. The validity of this guarantee only extends to the

original purchaser of the unit.

NOTE: THE MANUFACTURER CAN NOT BE DEEMED RESPONSIBLE FOR ANY

DAMAGE OR INJURY CAUSED BY IMPROPER USE OF THIS PRODUCT.

13

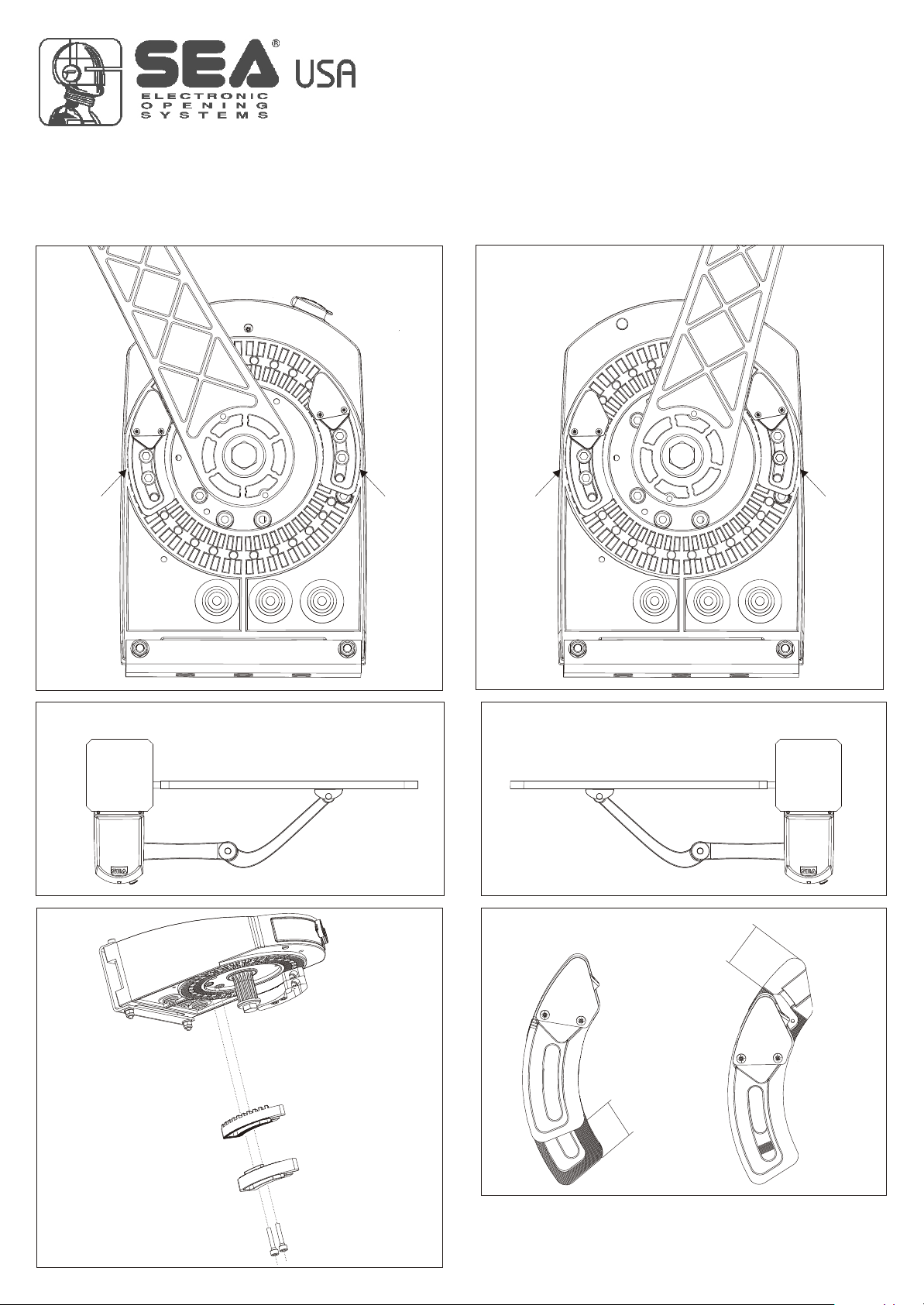

MECHANICAL /

ELECTRONIC

LIMIT SWITCH

3131

3737

6262

7070

99

1313

6060

2323

6868

4343

3434

4949

2727

1212

1111

6565

6464

2828

1919

7474

3636

3939

7373

2121

2424

7575

1414

5252

5353

3030

4646

5959

33

11

1010

88

7979

3232

4040

4747

44

4545

22

4848

5757

6969

6666

6767

3838

2929

5050

2626

6363

77

1717

8383

5858

5454

7171

1515

8181

8282

7878

1818

4444

4242

7272

2222

2525

6161

7676

7777

2020

66

8080

3535

4141

3333

1616

1515

5656

5555

5151

55

2929 6680121166801211 SCREW TCCR M3X10 SEZ.TRILOB. ZNSCREW TCCR M3X10 SEZ.TRILOB. ZN

3030 6630161566301615 BATTERY CARD SUPPORTBATTERY CARD SUPPORT

3131 2302401523024015 USER 2 24V W/BOXUSER 2 24V W/BOX

3232 6630165566301655 COVER FOR ELECTR. CARD FLIPPERCOVER FOR ELECTR. CARD FLIPPER

3333 6680106766801067 SCREW AUT.TCCR 3,5X8 ZN UNI9707SCREW AUT.TCCR 3,5X8 ZN UNI9707

3434 6530237565302375 PIVOT FLIPPERPIVOT FLIPPER

3535 6680154266801542 ELAST. FIXING W./CALOTTE D.5ELAST. FIXING W./CALOTTE D.5

3636 6600131566001315 PIN RELEASE FLIPPERPIN RELEASE FLIPPER

3737 5470110554701105

CONNECTOR 3 WAYS+FUSE SUPPORTCONNECTOR 3 WAYS+FUSE SUPPORT

3838 6680113466801134 SCREW TCCR 2.9X19 ZINC. UNI6954SCREW TCCR 2.9X19 ZINC. UNI6954

3939 6600132066001320 PIN BALL RELEASE FLIPPERPIN BALL RELEASE FLIPPER

4040 6640103566401035 SPRING D.8 L.46 F.1,1 SP.15 ORSPRING D.8 L.46 F.1,1 SP.15 OR

4141 6680154166801541 ELASTIC. FIXING W/CALOTTE D.4ELASTIC. FIXING W/CALOTTE D.4

4242 6680603966806039 PIN CyLIND. 5X32 UNI6364-APIN CyLIND. 5X32 UNI6364-A

4343 6530237065302370

ROD FLIPPERROD FLIPPER

4444 6680602166806021 PIN CYL. 4X28 UNI6364-APIN CYL. 4X28 UNI6364-A

4545 6640119066401190 SPRING FLIPPERSPRING FLIPPER

4646 6630162066301620 EXTERNAL RELEASE FLIPPEREXTERNAL RELEASE FLIPPER

4747 6640118066401180

SPRING EXTERNAL RELEASE FLIPPERSPRING EXTERNAL RELEASE FLIPPER

4848 6650101466501014 BEARING 16003 2ZBEARING 16003 2Z

4949 6530238065302380 FRAME CAP FLIPPERFRAME CAP FLIPPER

5050 6680126166801261 SCREW TCEI M6X95 8.8 ZINCATASCREW TCEI M6X95 8.8 ZINCATA

5151 5420010054200100 TRANSFOR.110VTRANSFOR.110V

5252 6630111166301111 LOGO SEA FOR FLIPPER (ABS)LOGO SEA FOR FLIPPER (ABS)

5353 6630161066301610 CARTER FLIPPERCARTER FLIPPER

5454 6680103766801037 SCREW AUT.TCCR3X10 ZINC.UNI9707SCREW AUT.TCCR3X10 ZINC.UNI9707

5555 6680156366801563 SCREW TCCR M5X20 ZN UNI8112SCREW TCCR M5X20 ZN UNI8112

5656 -------------- --------------

5757 6650106566501065 BEARING 6205 2ZBEARING 6205 2Z

5858 6680137366801373 V.TSPCR M4X10NIC SZ.TR.UNI8113V.TSPCR M4X10NIC SZ.TR.UNI8113

5959 6630162566301625 EXTERNAL RELEASE PLATEEXTERNAL RELEASE PLATE

6060 6530235565302355 BASE FLIPPERBASE FLIPPER

6161 6700122567001225 SEAL.PARAOIL 25X35X5 TYPE GPSEAL.PARAOIL 25X35X5 TYPE GP

6262 5470111554701115 CABLE PRESS SR 2M-1 NYLONCABLE PRESS SR 2M-1 NYLON

6363 6680124166801241 SCREW TCEI M6X20 ZN SEC.TRILOB.SCREW TCEI M6X20 ZN SEC.TRILOB.

6464 6530240565302405

STOP HANDLE SX FLIPPERSTOP HANDLE SX FLIPPER

6565 6530240065302400 STOP HANDLE B SX FLIPPERSTOP HANDLE B SX FLIPPER

6666 6670011066700110 LOCK D.15 RELEASE PLUSLOCK D.15 RELEASE PLUS

6767 6670012166700121 TCAP LOCK COVER RELEASE PLUSTCAP LOCK COVER RELEASE PLUS

6868 6530236565302365 RELEASE LEVER FLIPPERRELEASE LEVER FLIPPER

6969 6670001566700015

TONGUE WITH HOLE FOR LOCK LEPUSTONGUE WITH HOLE FOR LOCK LEPUS

7070 5471015054710150

MICRO OMRON V-163-1A6/LONG. LEVERMICRO OMRON V-163-1A6/LONG. LEVER

7171 6680154966801549 SCREW TCCR AUT3X18 UNI9707 ZNSCREW TCCR AUT3X18 UNI9707 ZN

7272 6681000066810000 PIN 2X12 UNI1336PIN 2X12 UNI1336

7373 6600132566001325 PIN D.6X50 X RELEASE LEVERPIN D.6X50 X RELEASE LEVER

7474 6600131066001310 PIVOT ARM FLIPPERPIVOT ARM FLIPPER

7575 6620096066200960 BRACKET ARM/GATEBRACKET ARM/GATE

7676 65302345L65302345L

CURVED ARM FLIPPER LAV.CURVED ARM FLIPPER LAV.

7777 65302350L65302350L STRAIGHT ARM FLIPPER LAV.STRAIGHT ARM FLIPPER LAV.

7878 6680500566805005 SEEGER EST.D.12 GALV.SEEGER EST.D.12 GALV.

7979 6630165066301650 COVER ARTICULATED ARM FLIPPERCOVER ARTICULATED ARM FLIPPER

8080 6680153766801537 SCREW TCCR M4X10 ZN SEC.TRILOB.SCREW TCCR M4X10 ZN SEC.TRILOB.

8181 6680401966804019 WASHER P.10,5X30X2,5 UNI6593 ZNWASHER P.10,5X30X2,5 UNI6593 ZN

8282 6680415066804150

ELAST. WASHER M10 TIPOA UNI8840 ZNELAST. WASHER M10 TIPOA UNI8840 ZN

8383 6680129566801295 SCREW TE TE M 10 X20 GALV.SCREW TE TE M 10 X20 GALV.

11

6630163566301635 CAP FLIPPERCAP FLIPPER

226640119566401195 SPRING CAP FLIPPERSPRING CAP FLIPPER

336630163066301630 PUSHBUTTON MICRO INTERRUPTERPUSHBUTTON MICRO INTERRUPTER

446640118566401185

SPRING PUSHBUTTON MICRO FLIPPERSPRING PUSHBUTTON MICRO FLIPPER

556680123866801238

SCREW TCEI M6X30 ZN SEZ.THREELOB.SCREW TCEI M6X30 ZN SEZ.THREELOB.

666680105566801055

SELFCUT. SCREW TC CR. 2,2X13 NICH.SELFCUT. SCREW TC CR. 2,2X13 NICH.

776620163566201635 PLATE MICRO STOP FLIPP.PLATE MICRO STOP FLIPP.

886630164566301645 SEMISHELL INF. MICRO FLIPPERSEMISHELL INF. MICRO FLIPPER

995471015854710158 MICROINT. AH1662 X FLIPPERMICROINT. AH1662 X FLIPPER

1010 6630164066301640 SEMISHELL UP. MICRO FLIPPERSEMISHELL UP. MICRO FLIPPER

1111 6530239565302395 STOP ROD B DX FLIPPERSTOP ROD B DX FLIPPER

1212 6530239065302390 STOP ROD FLIPPER DXSTOP ROD FLIPPER DX

1313 5471018054710180 CABLE PASSAGE IN PVC D. 20CABLE PASSAGE IN PVC D. 20

1414 6620153566201535 FIXING PLATE FLIPPERFIXING PLATE FLIPPER

1515 6680300666803006 SELFLOCKING NUT HIGH M6 GALV.SELFLOCKING NUT HIGH M6 GALV.

1616 6680403566804035 WASHER P.6,4X12,5X1,6 UNI6592 ZNWASHER P.6,4X12,5X1,6 UNI6592 ZN

1717 6680124966801249 SCREW TCEI M6X100 GALV.SCREW TCEI M6X100 GALV.

1818 6680502566805025 SEEGER EST.D.25 ZNSEEGER EST.D.25 ZN

1919 6600122666001226 SLOW SHAFT FLIPPERSLOW SHAFT FLIPPER

2020 6680412566804125 CUTTING RING 34,5X25,15X0,3CUTTING RING 34,5X25,15X0,3

2121 6610237566102375 WHEEL Z40 ARM PROWHEEL Z40 ARM PRO

2222 6681003666810036 BALL DIAMETER 10 UNI100 Cr6BALL DIAMETER 10 UNI100 Cr6

2323 6530236065302360 FRAME FLIPPERFRAME FLIPPER

2424 6610238066102380 ENDLESS SCREW M1,5 FLIPPERENDLESS SCREW M1,5 FLIPPER

2525 6700016567000165 SEAL OR 2125(31,47X1,78)VITONSEAL OR 2125(31,47X1,78)VITON

2626 6680124066801240 SCREW TCEI M6X20 8.8 GALV.SCREW TCEI M6X20 8.8 GALV.

2727 6530238565302385 MOTOR FLANGE FLIPPERMOTOR FLANGE FLIPPER

2828 6580224665802246 MOTOREDUCER FLIPPER 11NMMOTOREDUCER FLIPPER 11NM

14

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151 Fax: ++1-305.594.7325

Toll Free: 800.689.4716

International registered trademark n. 2.777.971

Table of contents

Other SEA Gate Opener manuals

SEA

SEA full tank User manual

SEA

SEA EASY 20 User manual

SEA

SEA COMPACT 200 CP Instruction manual

SEA

SEA 1110 User manual

SEA

SEA ORION BOX 24V User manual

SEA

SEA TAURUS BOX 1000 User manual

SEA

SEA SUPER FULL TANK 20 G6 380V User manual

SEA

SEA JOINT Original instructions

SEA

SEA TORG Instruction manual

SEA

SEA ARM Instruction manual

Popular Gate Opener manuals by other brands

On Automation

On Automation Crono SL600.24 instruction manual

Palfinger

Palfinger Minifix K1Plus Series troubleshooting guide

JOYTECH

JOYTECH PY500AC user manual

Viking

Viking X-390 installation instructions

Centurion

Centurion D5-EVO REPAIR Programming manual

Pujol

Pujol Radius Installation and adjustment instructions