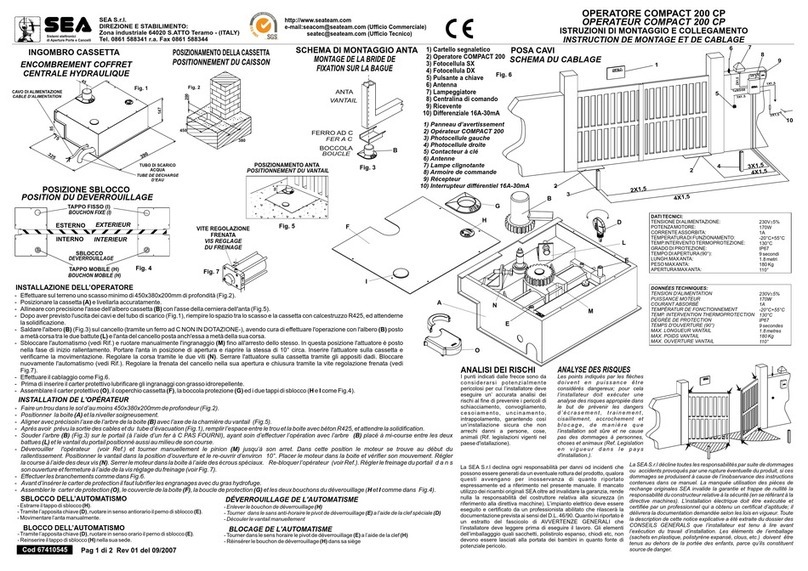

SEA ALPHA 330 STANDARD Original instructions

ALPHA 330

110V STANDARD

INSTALLATION MANUALS

AND SAFETY INFORMATION

web site: www.sea-usa.com

e-mail: [email protected]

REV 03 - 06/200967410780

L

5

I

2

S

3

T

L

E

U

D

/

I

T

S

O

N

A

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151 Fax: ++1-305.594.7325

Toll Free: 800.689.4716

ALPHA

TABLE OF CONTENTS

A)SAFETY AND INSTALLATION INSTRUCTION .................................................3

PERIODICAL MAINTENANCE ...........................................................................7

GATE WARNINGS ..............................................................................................8

PRECAUTIONS ..................................................................................................8

B)INSTALLATION MANUAL

....................................................................................9

DIMENSIONS......................................................................................................9

STANDARD INSTALLATION.............................................................................10

....................................................................................11

............................................................11

DIMENSIONS FOR INSTALLATION.................................................................12

...................................................15

RISK EXAMINATION ........................................................................................15

TECHNICAL FEATURES

GATE ARRANGEMENT

INSTALLATION OF THE OPERATORS

RELEASING SYSTEM OF THE OPERATOR

2

International registered trademark n. 2.777.971

REV 03 - 06/2009

INSTALLATION INSTRUCTION

1) The gate operator system has to be installed only when:

I. Check to be sure this is the proper gate operator system for the construction and the usage UL

class of the gate as specified on the label of the product (see also page 6)

II. All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to a

minimum of 4 feet (1,22 mt) above the groung to prevent a 2-1/4 inch (57.2 mm) diameter

sphere from passing trough the openings anywhere in the gate, and in that portion of the

adjacents fence that the gate covers in the open position

III. ALL EXPOSED PINCH POINTSARE ELIMINATED OR GUARDED and

IV. GUARDING IS SUPPLIED FOR EXPOSED ROLLERS

2) The operator is intended for installation only on gates used for vehicles.

Pedestrian must be supplied with a separate access opening.

3)The gate MUST be installed in a location so that enough clearance is supplied between the gate

and adjacent structures when opening and closing to reduce the risk of entrapment. Swinging gates

shall not open into public access areas.

4) The gate MUST be properly installed and work freely in both directions prior to the installation of

the gate operator. Do not over-tighten the operator clutch or pressure relief valve to compensate for

a damaged gate. Make any necessary repairs to the gate before installing this equipment

5) The gate operator controls MUST be placed so that the user has full view of the gate area when

the gate is moving and away from the gate path perimeter.

6) Controls MUST be far enough from the gate so that the user is prevented from coming in contact

with the gate while operating the controls. Controls intended to be used to reset an operator after 2

sequential activations of the entrapment protection device or device MUST be located in the line-of-

sight of the gate. Outdoor or easily accessible controls shall have security feature to prevent

unauthorized use.

7) All warning signs and placards must be installed where visible in the area of the gate. A minimum

of two (2) placards shall be installed.

8) For gate operator utilizing a non-contact sensors ( Photo Beam or like) in accordance with section

31.1.1 of the UL 325 standards:

I. See instruction on the placement of non-contact sensors for each type of application (see

page 13)

II. Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle, trips

the sensor while the gate is still moving, and

III. One or more non-contact sensors shall be located where the risk of entrapment or obstruction

exist, such as the perimeter reachable by a moving gate or barrier

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

ALPHA

3

International registered trademark n. 2.777.971

REV 03 - 06/2009

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT: SEA recommend to install at least 2 separate non contact sensor as on the

post close to the gate as at furthest point of the opened gate where the risk of entrapment

exists in order to avoid any risk of damage/injury (see pg. 11 Typical Installation). SEA also

recommend to install infrared Photo beam for a higher performance of use.

9) For a gate operator utilizing a contact sensor (Edge sensor or like) in accordance with section

31.1.1 of the UL 325 standards:

I. One or more contact sensors shall be located where the risk of entrapment or obstruction

exists, such as at leading edge, trailing edge, and post mounted both inside and outside of a

vehicular horizontal slide gate.

II. One or more contact sensor shall be located at the bottom edge of a vehicular vertical lift

gate.

III. One or more contact sensor shall be located at the pinch point of a vehicular vertical pivot

gate.

IV. A hardwired contact sensor shall be located and its wiring arranged so that the

communication between the sensor and the gate operator is not subject to mechanical

damage.

V. A wireless contact sensor such as one that transmits radio frequency (RF) signals to the gate

operator for entrapment protection functions shall be located where the transmission of the

signals are not obstructed or impeded by building structures, natural landscaping or similar

obstruction.A wireless contact sensor shall function under the intended end-use conditions.

VI. In case of a swing gate one or more contact sensors shall be located on the inside and

outside leading edge of the gate. Additionally, if the bottom edge of a swing gate is greater

than 6 inches (152mm) above the ground at any point in its arc of travel, one or more contact

sensors shall be located on the bottom edge (see pg..for Typical Installation)

VII. One or more contact sensors shall be located at the bottom edge of a vertical barrier (arm)

SEA warns that the gate operator system with an A.C. power electric motor shall have a

reversing sensor (encoder) on the drive shaft of the motor as additional safety device. In

case of swing linear/in-ground hydraulic operator SEA recommend to install the “SAFETY

GATE” as an additional reversing sensor.

11) The professional installer has to check that the main power supply circuit breakers are

separate, intended solely for this equipment and rated for 15 AMPS. Visually check that the circuit

breakers are in the "OFF" position and mark the circuit breakers "USED" prior to installation.

12) During service the main power MUST always being disconnected.

13) If this gate operator system includes a battery backup, the battery backup system needs to be

disconnected first, prior to disconnecting main power supply during installation, maintenance and

servicing procedures.

14) After installation The professional installer has to check that the gate operator system is

working properly, that the open and close force are properly adjusted, that the piston does not

bottom out in either direction, that breather screws have been removed, that the positive stops used

are sufficient for stopping the gate properly, and that all pinch points and potential entrapment

areas are reduced.

ALPHA

SAVE THESE INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

4

International registered trademark n. 2.777.971

REV 03 - 06/2009

GROUNDING

Good grounding and proper surge suppression are an integral part of proper installation for

a gate operator system. One or all of the following may require surge suppressors: high

voltage power lines, low voltage power lines, telephone lines, data lines, low voltage control

lines and loops. How much surge suppression is required depends upon how susceptible

the area is to lightning and power surges. Regardless, good grounding is essential. To

realize maximum protection, proper grounding and proper surge suppression is absolutely

necessary.

If the circuit breaker box is located close to the gate operator system, for example, in a

guard house, then the ground from that circuit can be used to ground the gate operator

system. Eliminate all 90° bends in ground wires and keep a minimum of three feet between

the surge suppressor and the equipment being protected.

If the power source or circuit breaker box is not located close to the gate operator system an

Isolated Ground Zone (IGZ) needs to be created. An IGZ can also be created if the circuit

breaker box is located close by the gate operator system. An IGZ is an imaginary circle

drawn around the gate operator system. The gate operator system not only includes the

gate operators and control panel, but all of the accessories and devices associated with it at

that controlled entry point. This includes loop detectors, card readers, digital entries,

telephone entries, any device that has a ground or requires a ground and ali of the surge

suppressors. The ground bus is a common ground point calied a Single Point Ground

(SPG). It is used to bond all the equipment and device grounds in the IGZ together. The

SPG is very important because it helps eliminate different ground potentials that can be

present on the equipment. In such cases, equipment damage occurs even with surge

suppressors.

Do not use or connect the ground wire coming from the circuit breaker box. By using an

Isolated Ground Zone, you are separating the gate operator system from the house or

building ground. This eliminates ground potentials. It is recommended that the ground bus

be located in a separate NEMA type enclosure. All grounds will be tied to this ground bus.

Some points to remember:

Keep all ground wires as straight as possible. Do not have any sharp 90° bends. Have a

minimum of 3 feet of wire between the surge suppressor and the equipment being

protected.

Equipment ground wire should be a minimum of 12 AWG. The main ground wire from the

bus bar to the ground rod shouid be an 8 or 6 AWG copper wire. Ground rod should be a

minimum of 10 feet in length, longer depending on local soil conditions.

For more information regarding good grounding practices check: National Electric Code

art. 250; IEEE Emerald Book, standard 100; International Association of Electric

Inspectors.

IMPORTANT SAFETY INSTRUCTIONS

ALPHA

The installer is responsible for grounding the operator system,

for providing the main power breaker switch, and for making sure

that the entire gate systems meets all applicable electrical codes.

5

International registered trademark n. 2.777.971

REV 03 - 06/2009

RESIDENTIAL VEHICULAR GATE

OPERATOR

CLASS I

A vehicular gate operator (or system) intended

for use in a home of one-to four single family

dwelling, or a garage or parking area

associated therewith.

COMMERCIAL/GENERALACCESS

VEHICULAR GATE OPERATOR

CLASS II

A vehicular gate operator (or system) intended

for use in a commercial location or building

such as a multi-family housing unit (five or

more single family units), hotels, garages,

retail store, or other building servicing the

general public.

INDUSTRIAL/LIMITED ACCESS

VEHICULAR GATE OPERATOR

CLASS III

A vehicular gate operator (or system) intended

for use in a industrial location or building such

as a factory or loading dock area or other

locations not intended to service the general

public.

RESTRICTED ACCESS VEHICULAR GATE

OPERATOR

CLASS IV

A vehicular gate operator (or system) intended

for use in a guarded industrial location or

building such as an airport security area or

other restricted access locations not servicing

the general public, in which unauthorized

access is prevented via supervision by

security personnel.

CLASS I

CLASS II

CLASS III

CLASS IV

IMPORTANT SAFETY INSTRUCTIONS

ALPHA

SAVE THESE INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

UL325 GATE OPERATOR CLASSIFICATION

Install the gate operator only when:

The operator is appropriate for the construction of the gate and the Usage Class of the gate.

6

International registered trademark n. 2.777.971

REV 03 - 06/2009

PERIODICAL MAINTENANCE

1) Check the release function

2) Check the fixing pin

3) Check the integrity of the connection cables

4) Check the function and the limit switch condition in opening and closing

5) Clean the hinge of the leaf and lubricate it with recommended lubricant

6) Check for all corroded parts and replace them

7) Check the tight of the hardware of the gate

8) Check the operating of all accessories. Especially the functioning of all safety devices and

Safety Gate (if installed).

All the above described operations MUST be made exclusively by an

authorized installer.

ALPHA

7

International registered trademark n. 2.777.971

REV 03 - 06/2009

GATE WARNINGS

The first thing to check is that the gate is in good running order as

follows:

A. The gate is rigid and straight and runs smoothly throughout its travel.

B. The length of each leaf is not over 6,6 feet (ALPHA 200), 10,8 feet

(ALPHA330).

C. The weight of each leaf is not over 440 Pound (ALPHA 200), 661

Pound (ALPHA330).

D. The hinges are hardly anchored and are able to support the torque of

the operator; they do not have irregular movements and/or any friction

during the whole movement of the leaf.

PRECAUTIONS

ALPHA has been created for the automation of gates used by vehicles

only. Be aware to avoid the crossing of the gate path because it is very

dangerous for pedestrians (fig. 4).

Install the warning signs, on each side of the gate and in avisible

zone

Important:

For a higher security, SEA advices to install infrared photocells.

which informs the pedestrians about the danger they run when

passing or resting in the environment of the gate (fig. 5).

GATE WARNINGS AND PRECAUTIONS

ALPHA

- Install the operator in the correct position

- Do not Install the front bracket in a weak part of the gate

- Not for pedestrian opening

8

Fig. 4

Fig. 3

Fig. 2

Fig. 5

International registered trademark n. 2.777.971

REV 03 - 06/2009

Fig. 1

ALPHA

9

110Vac (±5%) 50/60 Hz

280W

2,7 A

15 3/4 inches

20

-4°F +141°F

21 pounds

10 feet

90° - 120°

7/10 inches/sec.

60uF

250 daN

IP54

662 pounds

TECHNICAL FEATURES

Power Supply

Power

Absorbed current

Stroke

Cycle/hour

Operating temperature

Weight

Max leaf lenght

Opening angle

Speed

Capacitor

Thrust force max.

Protection class

Max leaf weight

Limit switch

DIMENSIONS (inches)

Fig. 7

5

L

C

8

ALPHA 200 ALPHA 330

L

C (stroke)

38 in

11 in

46 in

16 in

The ALPHA is provided with a mechanical locking system that grants the operator locking in the opened and closed position

avoiding any needs for electric locks and/or magnetic locks. The torque intensity and the anti-crushing safety are adjustable through

the control board.

Key-locked that must be used only in case of emergency and/or power failure to manually operate the gate.

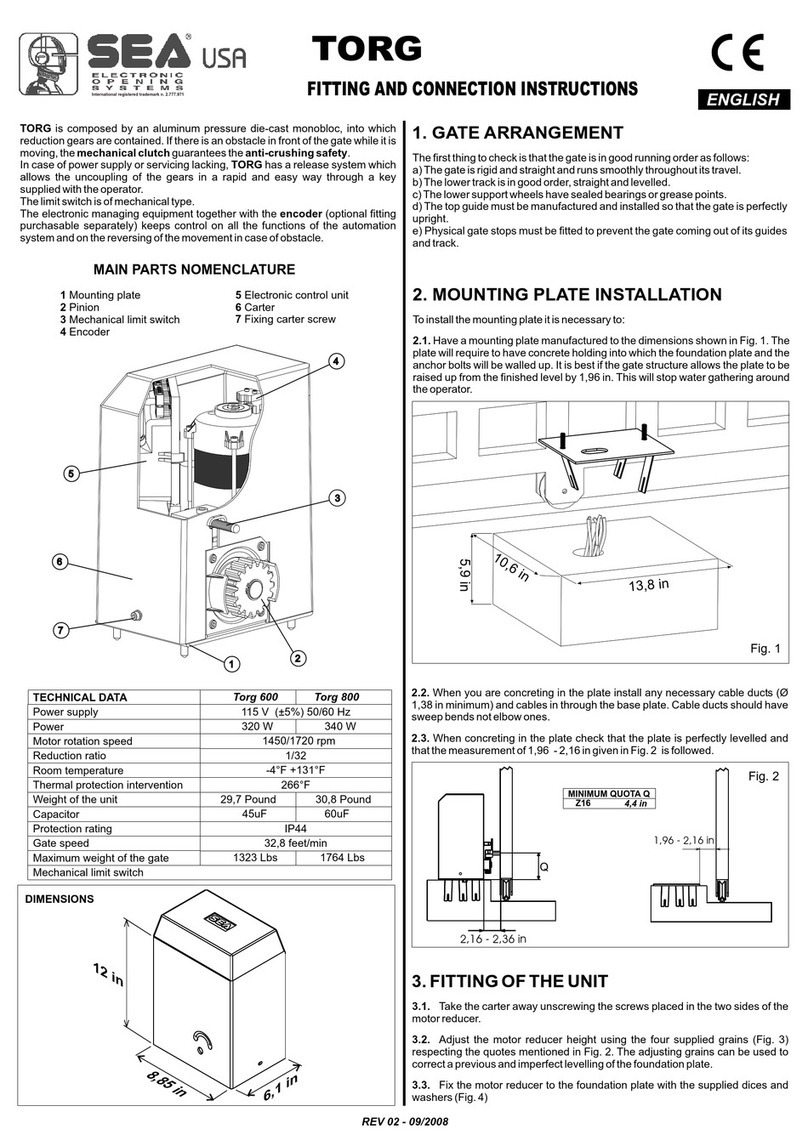

MAIN PARTS

1Back bracket

2Electric motor

3 Endless screw

4Front bracket

5 Aluminum shaft-cover

6 Capacitor housing (230V version)

7Manual Releasing

Fig. 6

11

22

33

44

77

55

66

International registered trademark n. 2.777.971

REV 03 - 06/2009

MECHANICAL INSTALLATION

ALPHA

1) Operator

2) Warning notice inside

3) Electronic Unit

4) Tx Photocell

5) Rx Photocell

6) Key Switch

7) Radio Receiver

8) Antenna

9) Column for photocells

10) Warning notice outside

TYPICAL INSTALLATION

Fig 8

11

33

99

99

11

44

55

88

22

66

77

SAFETY LOOP

EX TLOOPI

O

CENTER L OP

FY LSA ET OOP

IN

OUT

1010

Notice:

The operator must be installed with the motor facing

upward (Fig. 9)

Fig. 9

10

International registered trademark n. 2.777.971

REV 03 - 06/2009

MECHANICAL INSTALLATION

1. GATE ARRANGEMENT

It is necessary to make controls on the gate to make sure the

application ofALPHAautomation can be possible.

Make sure that:

A. the gate fixed and moving parts have a strong and crush-proof

structure;

B. the length of each leaf is not over 79 inches (Alpha 200), 130

inches (Alpha 330);

C. the weight of each leaf is not over 441 pounds (Alpha 200),

661 pounds (Alpha 330);

D. the hinges are hardly anchored and are able to support the

torque of the operator; they do not have irregular movements

and/or any friction during the whole movement of the leaf;

E. the stops of the leaf are fixed to the ground (Fig. 10).

Fig. 10

Limit Switch stop

in opening

Limit Switch stop

in closing

Fig. 11 Fig. 12

2. INSTALLATION OF THE OPERATORS

2.1. Fix the holed mounting plate to the post using screws as shown in Fig 11. The plate must be positioned perfectly horizontal and

perpendicular to the post,

2.2. Weld the back bracket to the plate (Fig 12) following the dimensions shown in Fig 13 and 14. If it is necessary, cut the bracket

without going over the minimum limit of 2 inches (Fig 15).

NOTICE:

ALPHA operator is not provided with mechanical torque regulation. The control board must be provided with electronic

torque regulation (unless presence detectors are installed) to install it in conformity with the DIRETTIVA EN12453 and

EN12445.

ALPHA

11

International registered trademark n. 2.777.971

REV 03 - 06/2009

MECHANICAL INSTALLATION

DIMENSIONS FOR INSTALLATION Fig. 13

A

C

B

3 in

ALPHA 200 STANDARD

ALPHA 330 STANDARD

A

B

A

B

90°

110°

6,29

4,33

4,33

4,33

5,51

5,11

4,33

4,72

4,72

5,90

4,72

4,33

A

B

A

B

90°

120° 5,51

7,08

7,48

5,90

6,69

7,87

6,69

6,29

6,29

8,66

6,29

(See Fig. 15)

"

A

C

Fig. 14

in .2 MIN

Fig. 15

Opening

angle

"

During selection, prefer the higher dimensions of A and B.

The above mentioned dimensions are in inches.

Opening

angle

"

ALPHA

12

5,90

5,90 7,48

International registered trademark n. 2.777.971

REV 03 - 06/2009

MECHANICAL INSTALLATION

Fig. 17 Fig. 18

½ min. turn

Fig. 19

2.3. Attach the operator on the previously installed back-bracket and fix it with the provided pivot (Fig 16)

2.4. Release the arm (see paragraph 3)

2.5. WARNING: Turn the shaft up to its max. extension, afterwards turn it about at least half turn into the opposit direction (screw it) see Fig.

17 and 18.

Note: After installation, in opening, leave minimum 0,59 inches of working stroke, to avoid that the operator goes into mechanical lock (if

necessary install the stops on the ground or the optional special mechanical stops forAlpha).

2.6. Attach the front bracket to the

extremity of the shaft (Fig 19)

2.7. Close the gate

Fig. 16

ALPHA

13

International registered trademark n. 2.777.971

REV 03 - 06/2009

MECHANICAL INSTALLATION

Fig. 21Fig. 20

Fig. 22

2.8. Drill a hole into the gate (Fig 20) to be able to attach the front bracket with the supplied bolts being careful to place the operator

perfectly horizontal (Fig 21).

NOTE:

if it is not possible to attach the

front bracket with the bolts,

weld it to the gate (Fig 22),

being careful to protect the

shaft from welding waste.

ALPHA

14

International registered trademark n. 2.777.971

REV 03 - 06/2009

MECHANICAL INSTALLATION

Fig. 23

Mechanical stop in closing Mechanical stop in opening

INSTALLATION OF POSITIVE STOPS

On request mechanical stop in opening and closing available.

When inserting the lids (1) make sure that the

gaskets (2) are correctly installed.

2

1

Op.

Cl.

Cl.

Op.

BLU

Common

MOTOR

CONTROL UNIT

GROUNDING

ALPHA

International registered trademark n. 2.777.971

CONNECTIONS

Fig. 25

Fig. 26

2.9. Release the arm (see paragraph 3)

2.10. Remove the pull tongue from the shaft-cover (Fig 25) and mount it on the operator through the two tie-rods without excessively

tightening the two cover-nuts (Fig 26).

Tie-rod 1

Tie-rod 2

Cover-nuts

Cover-nuts

Fig. 24

REV 03 - 06/2009 15

MECHANICAL INSTALLATION

3. RELEASING SYSTEM OF THE OPERATOR

3.1. To release the operator follow the instruction below

1. put the red T-shaped release key into the hexagonal hole as in Fig. 27

2. turn the release key of 90° toward right or left until it stops without forcing (Fig. 28).

Fig. 29

3.2. To lock the actuator again bring the line in the horizontal position through the release key (Fig. 27) and move the leaf manually

until the clutch of the automation.

RISK EXAMINATION

The points pointed by arrows in . 29 are potentially dangerous. The installer must take a thorough risk examination to prevent

crushing, conveying, cutting, grappling, trapping so as to guarantee a safe installation for people, things and animals (

).

Fig

Re. Laws in

force in the country where installation has been made.

NOTICE

SEA s.r.l can not be deemed responsible for any damage

or accident caused by product breaking, being damages or

accidents due to a failure to comply with the instructions

herein. The guarantee will be void and the manufacturer

responsibility (according to Machine Law) will be nullified if

SEASrl original spare parts are not being used.

This is a quotation from the

GENERAL DIRECTIONS that the installer must read

carefully before installing.

Packaging materials such as plastic bags, foam

polystyrene, nails etc must be kept out of children’s reach

as dangers may arise.

The electrical installation shall be carried out by a

professional technician who will release documentation as

requested by the laws in force.

12

Fig. 27 Fig. 28

Line in

horizontal position:

Operator locked Line in

vertical position:

Operator released

90°

90°

ALPHA

16

International registered trademark n. 2.777.971

REV 03 - 06/2009

MECHANICAL INSTALLATION

web site: www.sea-usa.com

e-mail: [email protected]

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151 Fax: ++1-305.594.7325

Toll Free: 800.689.4716

International registered trademark n. 2.777.971

Table of contents

Other SEA Gate Opener manuals

SEA

SEA FLIPPER 110V User manual

SEA

SEA JACK Original instructions

SEA

SEA UNIGATE 1I User manual

SEA

SEA EASY 20 User manual

SEA

SEA Cougar 270 User manual

SEA

SEA SURF K 500 User manual

SEA

SEA ERG User guide

SEA

SEA FIELD Series User manual

SEA

SEA COMPACT 200 CP Instruction manual

SEA

SEA ALPHA 200 PLUS User manual

SEA

SEA TAURUS Instruction manual

SEA

SEA LEPUS Series User manual

SEA

SEA ORION BOX 24V User manual

SEA

SEA FLIPPER User manual

SEA

SEA SATURN User manual

SEA

SEA SURF 350 Reversible User manual

SEA

SEA SUPER FULL TANK 20 G6 380V User manual

SEA

SEA Field Original instructions

SEA

SEA COUGAR 270 User manual

SEA

SEA SEAGEAR 1180MEC0 Original instructions