SEA JACK Original instructions

LYRA, JACK 1600

67411785

Underground hydraulic operator

REV 00 - 03/2014

JACK JACK

CARRYING BOX

LYRA

INSTALLATION MANUALS

AND SAFETY INFORMATION

web site: www.sea-usa.com

e-mail: [email protected]

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151 Fax: ++1-305.594.7325

Toll Free: 800.689.4716

TABLE OF CONTENTS

International registered trademark n. 2.777.971

LYRA, JACK

67411785 REV 00 - 03/2014

A) SAFETY AND INSTALLATION INSTRUCTION....................................................................................3

GATE WARNINGS.................................................................................................................................5

PRECAUTIONS .....................................................................................................................................5

B) MECHANICAL INSTALLATION

FEATURES AND SPECIFICATIONS.....................................................................................................6

TECHNICAL DATA.................................................................................................................................6

DIMENSIONS ........................................................................................................................................7

NON CARRYING BOX INSTALLATION ................................................................................................7

INSTALLATION OF THE OPERATOR INSIDE THE NON-CARRYING BOX .......................................8

MOUNTING OF THE LEAF ON NON-CARRYING BOX .......................................................................8

HYDRAULIC UNIT BOX WALL INSTALLATION ...................................................................................9

BLEED CAP REPLACEMENT.............................................................................................................10

FORCE ADJUSTMENT ......................................................................................................................10

BRAKING REGULATION (where present) ..........................................................................................10

BLEEDING OPERATION.....................................................................................................................10

CARRYING BOX INSTALLATION........................................................................................................11

LEAF ASSEMBLING ON CARRYING BOX.........................................................................................12

INSTALLATION OF THE OPERATOR IN THE CARRYING BOX........................................................13

RELEASE MOUNTING .......................................................................................................................13

ADJUSTABLE MECHANICAL STOPS ................................................................................................13

CABLE LAYOUT ..................................................................................................................................14

RISK EXAMINATION ...........................................................................................................................15

PERIODICAL MAINTENANCE ............................................................................................................15

ACCESSORIES FOR JACK ................................................................................................................15

HYDRAULIC UNIT RELEASE SYSTEM ............................................................................................16

RELEASE SYSTEM OF THE LEAVES................................................................................................16

C) SALES CONDITIONS and WARRANTY ............................................................................................17

2

International registered trademark n. 2.777.971

Details

General

An appliance shall be provided with an instruction manual. The instruction manual shall give instructions for the installation,

operation, and user maintenance of the appliance.

The installation instructions shall specify the need for a grounding-type receptacle for connection to the supply and shall stress the

importance of proper grounding.

The installation instructions shall inform the installer that permanent wiring is to be employed as required by local codes, and

instructions for conversion to permanent wiring shall be supplied.

Information shall be supplied with a gate operator for:

a) The required installation and adjustment of all devices and systems to effect the primary and secondary protection against

entrapment (where included with the operator).

b) The intended connections for all devices and systems to effect the primary and secondary protection against entrapment. The

information shall be supplied in the instruction manual, wiring diagrams, separate instructions, or the equivalent.

Vehicular gate operators (or systems)

A vehicular gate operator shall be provided with the information in the instruction manual that defines the different vehicular gate

operator Class categories and give examples of each usage. The manual shall also indicate the use for which the particular unit is

intended as defined in Glossary, Section 3. The installation instructions for vehicular gate operators shall include information on

the Types of gate for which the gate operator is intended.

A gate operator shall be provided with the specific instructions describing all user adjustments required for proper operation of the

gate. Detailed instructions shall be provided regarding user adjustment of any clutch or pressure relief adjustments provided. The

instructions shall also indicate the need for periodic checking and adjustment by a qualified technician of the control mechanism

for force, speed, and sensitivity.

Instructions for the installation, adjustment, and wiring of external controls and devices serving as required protection against

entrapment shall be provided with the operator when such controls are shipped with the operator.

Instructions regarding intended installation of the gate operator shall be supplied as part of the installation instructions or as a

separate document. The following instructions or the equivalent shall be supplied where applicable:

a) Install the gate operator only when:

1) The operator is appropriate for the construction of the gate and the usage Class of the gate,

2) All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to a minimum of 4 feet (1.22

m) above the ground to prevent a 2-1/4 inch (57.2 mm) diameter sphere from passing through the openings anywhere in

the gate, and in that portion of the adjacent fence that the gate covers in the open position,

3)All exposed pinch points are eliminated or guarded, and

4) Guarding is supplied for exposed rollers.

b) The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a separate access

opening. The pedestrian access opening shall be designed to promote pedestrian usage. Locate the gate such that persons will

not come in contact with the vehicular gate during the entire path of travel of the vehicular gate.

c) The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent structures when

opening and closing to reduce the risk of entrapment. Swinging gates shall not open into public access areas.

d) The gate must be properly installed and work freely in both directions prior to the installation of the gate operator. Do not over-

tighten the operator clutch or pressure relief valve to compensate for a damaged gate.

e) (not applicable)

f) Controls intended for user activation must be located at least six feet (6’) away from any moving part of the gate and where the

user is prevented from reaching over, under, around or through the gate to operate the controls. Outdoor or easily accessible

controls shall have a security feature to prevent unauthorized use.

LYRA, JACK

67411785 REV 00 - 03/2014 3

g) The Stop and/or Reset button must be located in the line-of-sight of the gate. Activation of the reset control shall not cause the

operator to start.

h)A minimum of two (2) WARNING SIGNS shall be installed, one on each side of the gate where easily visible.

i) For gate operators utilizing a non-contact sensor:

1) See instructions on the placement of non-contact sensors for each Type of application,

2) Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle, trips the sensor while the gate is

still moving, and

3) One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the

perimeter reachable by a moving gate or barrier.

j) For a gate operator utilizing a contact sensor:

1) One or more contact sensors shall be located where the risk of entrapment or obstruction exists, such as at the leading

edge, trailing edge, and postmounted both inside and outside of a vehicular horizontal slide gate.

2) One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

3) One or more contact sensors shall be located at the pinch point of a vehicular vertical pivot gate.

4) A hardwired contact sensor shall be located and its wiring arranged so that the communication between the sensor and

the gate operator is not subjected to mechanical damage.

5) A wireless contact sensor such as one that transmits radio frequency (RF) signals to the gate operator for entrapment

protection functions shall be located where the transmission of the signals are not obstructed or impeded by building

structures, natural landscaping or similar obstruction. A wireless contact sensor shall function under the intended end-

use conditions.

6) One or more contact sensors shall be located on the inside and outside leading edge of a swing gate.Additionally, if the

bottom edge of a swing gate is greater than 6 inches (152 mm) above the ground at any point in its arc of travel, one or

more contact sensors shall be located on the bottom edge.

7) One or more contact sensors shall be located at the bottom edge of a vertical barrier (arm).

Revised 56.8.4 effective February 21, 2008

Instruction regarding intended operation of the gate operator shall be provided as part of the user instructions or as a separate

document. The following instructions or the equivalent shall be provided:

IMPORTANT SAFETY INSTRUCTIONS

WARNING – To reduce the risk of injury or death:

ATTENTION: pour réduire le risque de dommages ou mort:

1. READAND FOLLOW ALL INSTRUCTIONS.

2. Never let children operate or play with gate controls. Keep the remote control away from children.

3.Always keep people and objects away from the gate. NO ONE SHOULD CROSS THE PATH OF THE MOVING GATE.

4. Test the gate operator monthly. The gate MUST reverse on contact with a rigid object or stop when an object activates the non-

contact sensors. After adjusting the force or the limit of travel, retest the gate operator. Failure to adjust and retest the gate

operator properly can increase the risk of injury or death.

5. Use the emergency release only when the gate is not moving.

6. KEEP GATES PROPERLY MAINTAINED. Read the owner’s manual. Have a qualified service person make repairs to gate

hardware.

7. The entrance is for vehicles only. Pedestrians must use separate entrance.

8. SAVE THESE INSTRUCTIONS.

International registered trademark n. 2.777.971

LYRA, JACK

67411785 REV 00 - 03/20144

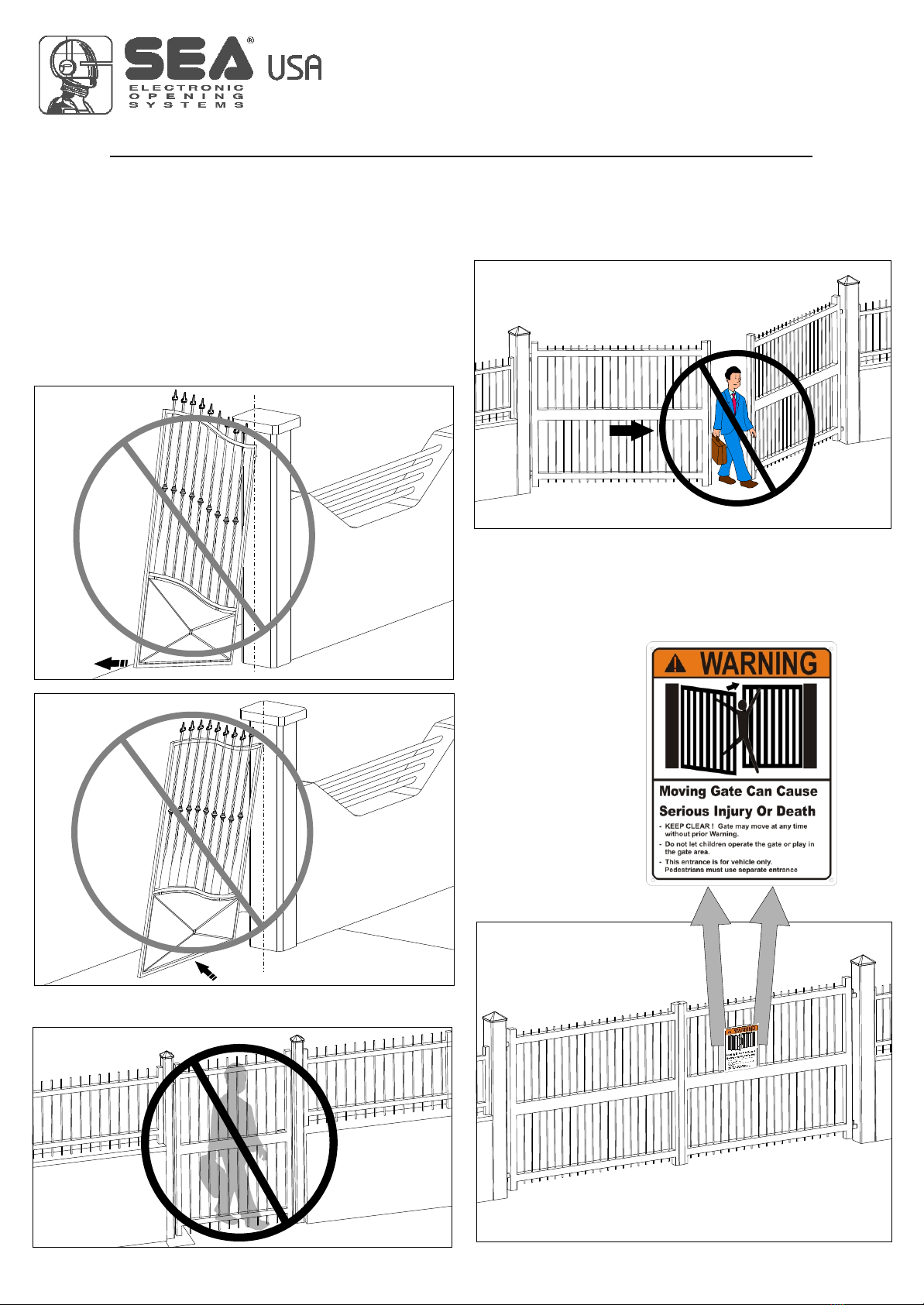

PRECAUTIONS

LYRA, JACK has been created for the automation of gates used by

vehicles only. Be aware to avoid the crossing of the gate path

because it is very dangerous for pedestrians (fig. 4).

Install the warning signs, on each side of the gate and in avisible

zone

Important:

For a higher security, SEA advices to install infrared photocells.

which informs the pedestrians about the danger they run when

passing or resting in the environment of the gate (fig. 5).

GATE WARNINGS AND PRECAUTIONS

- Not for pedestrian opening

Fig. 4

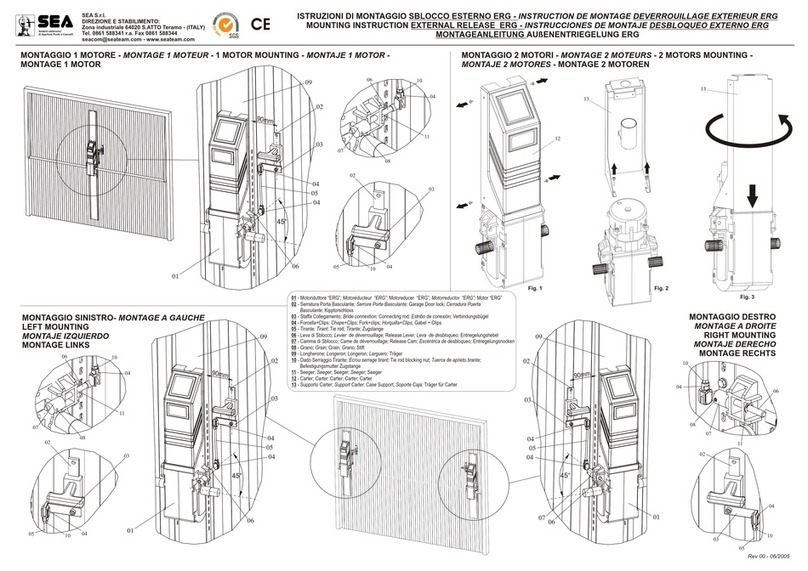

Fig. 1

Fig. 2

Fig. 3

Fig. 3

Fig. 5

International registered trademark n. 2.777.971

GATE WARNINGS

The first thing to check is that the gate is in good running order as

follows:

D. the upper hinge alone is sufficient to install the unit; those which

are unnecessary can be eliminated (the lower and that in the

middle if exists)

A. (Make sure that) the fixed and moving parts of the gate are strong

and non-deformable;

B. the weight of each gate leaf must not exceed 1600 Pound;

C. the hinges and general structure must be in good condition and the

gate must move smoothly throughout its travel;

LYRA, JACK

67411785 REV 00 - 03/2014 5

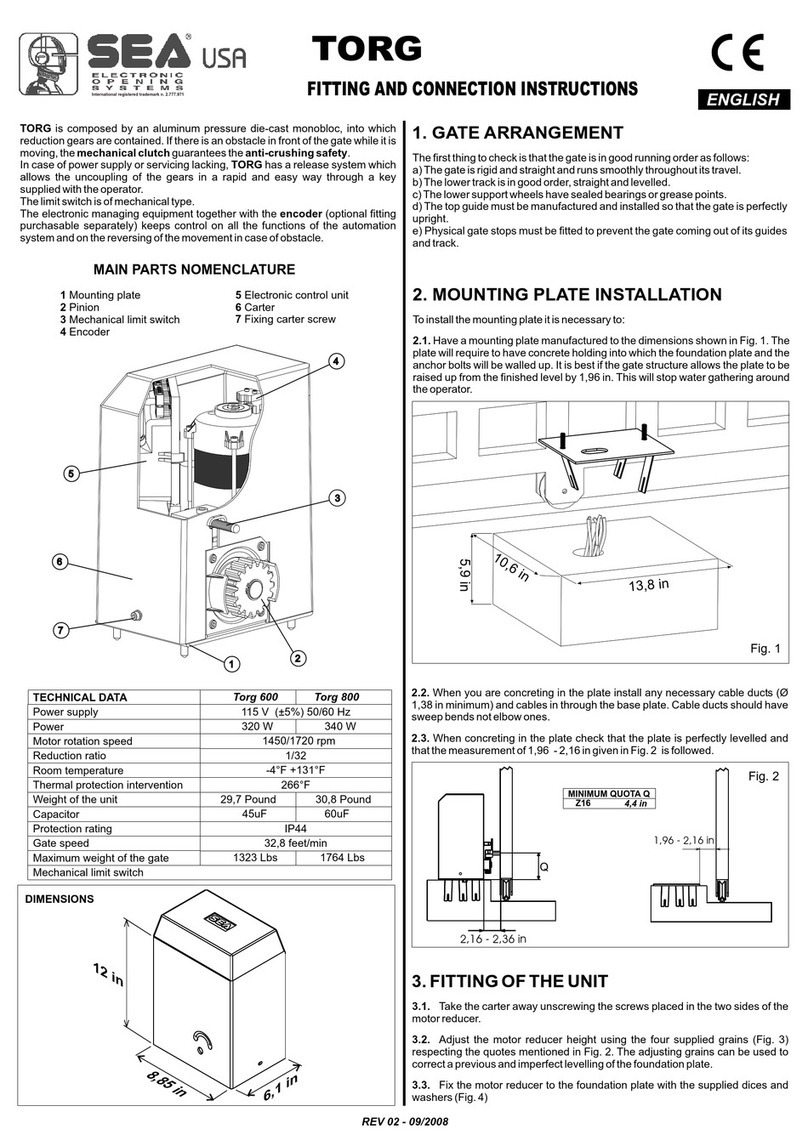

JACK 1600 JACK 1600

Note: The frequency of use is valid only for the first hour at 68°F

room Temperature.

Jack 1600 Lyra

13,12 feet

1600 pound

12

13

14

15

15

16 17

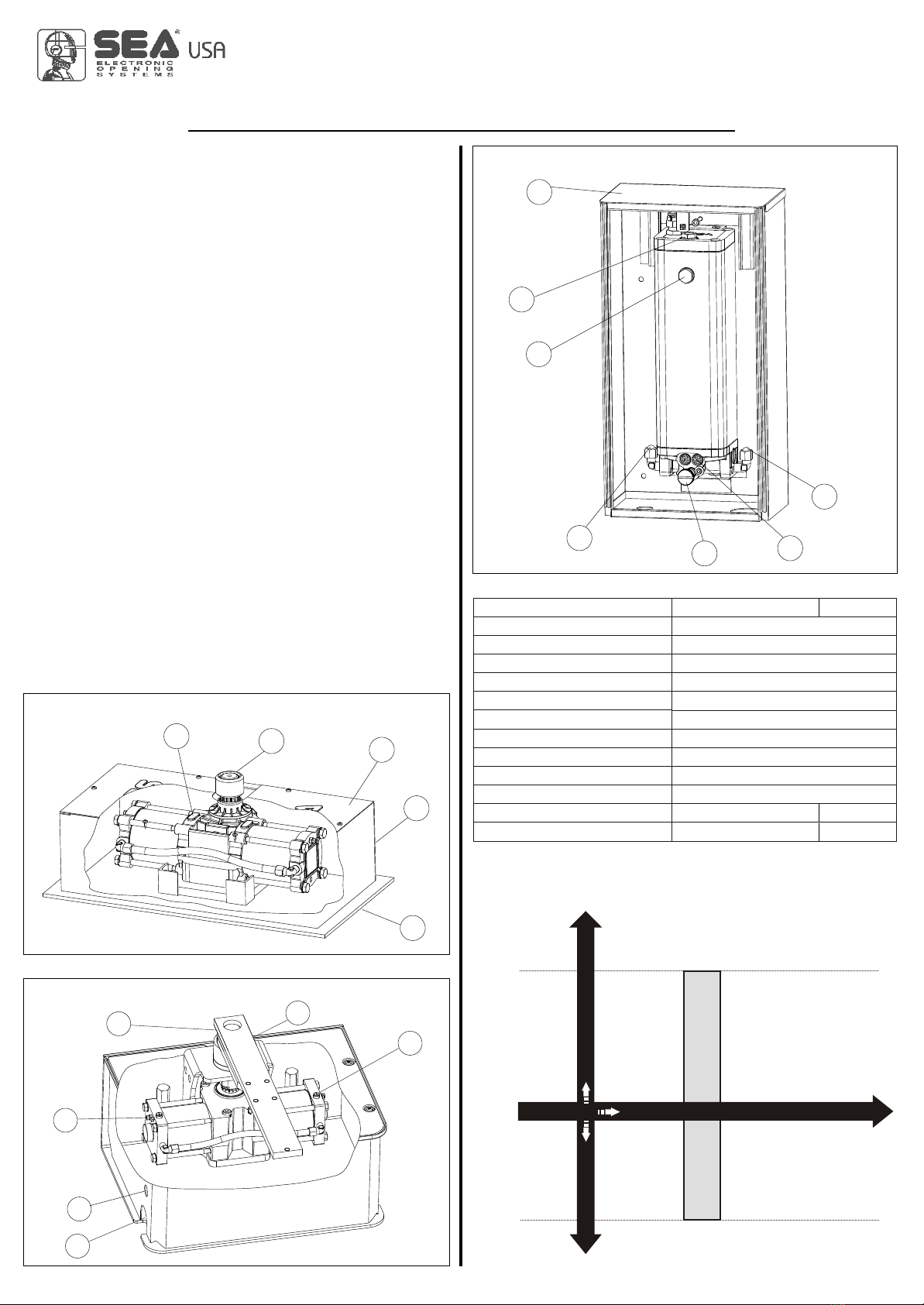

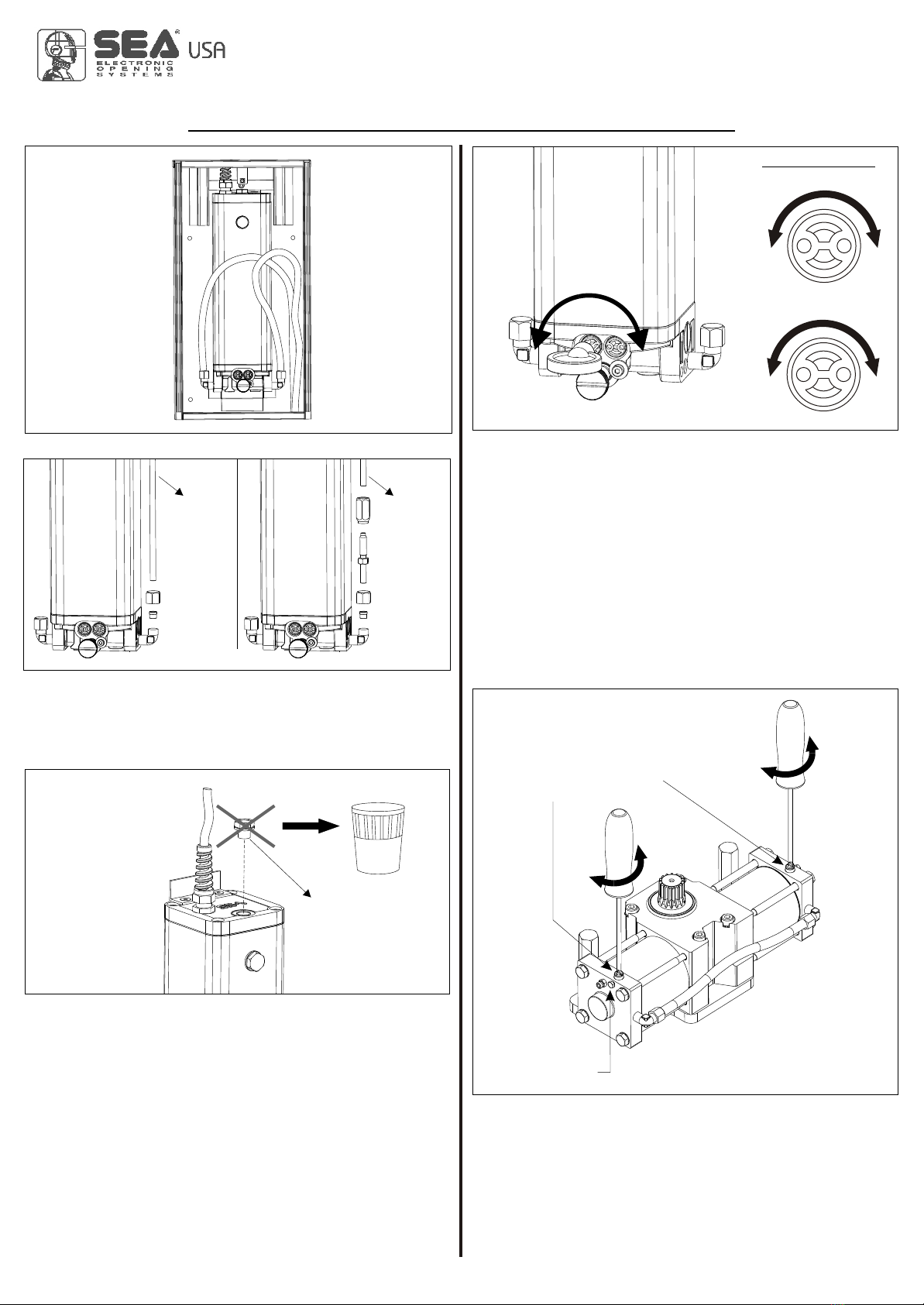

Fig. 8

123

4

5

Fig. 6

6

7

8

9

10

11

CARRYING BOX

Fig. 7

120 V~

220W

500 rpm

45

-4°F +131°F

130°

56 da N

60 µF

1600 Pound

IP67

17,63 Pound

-

REV 00 - 03/2014

100° - 140° - 180° -

MAIN PARTS NOMENCLATURE

TECHNICAL DATA

Power supply

Motor Power

Motor rotation speed

Cycles hour (with a 20°C temp.)

Operating temperature

Thermal protection intervention

Max torque

Starting capacitor

Weight

Protection class

Maximum weight of the gate

Max leaf weight

Max leaf width

Underground hydraulic operators

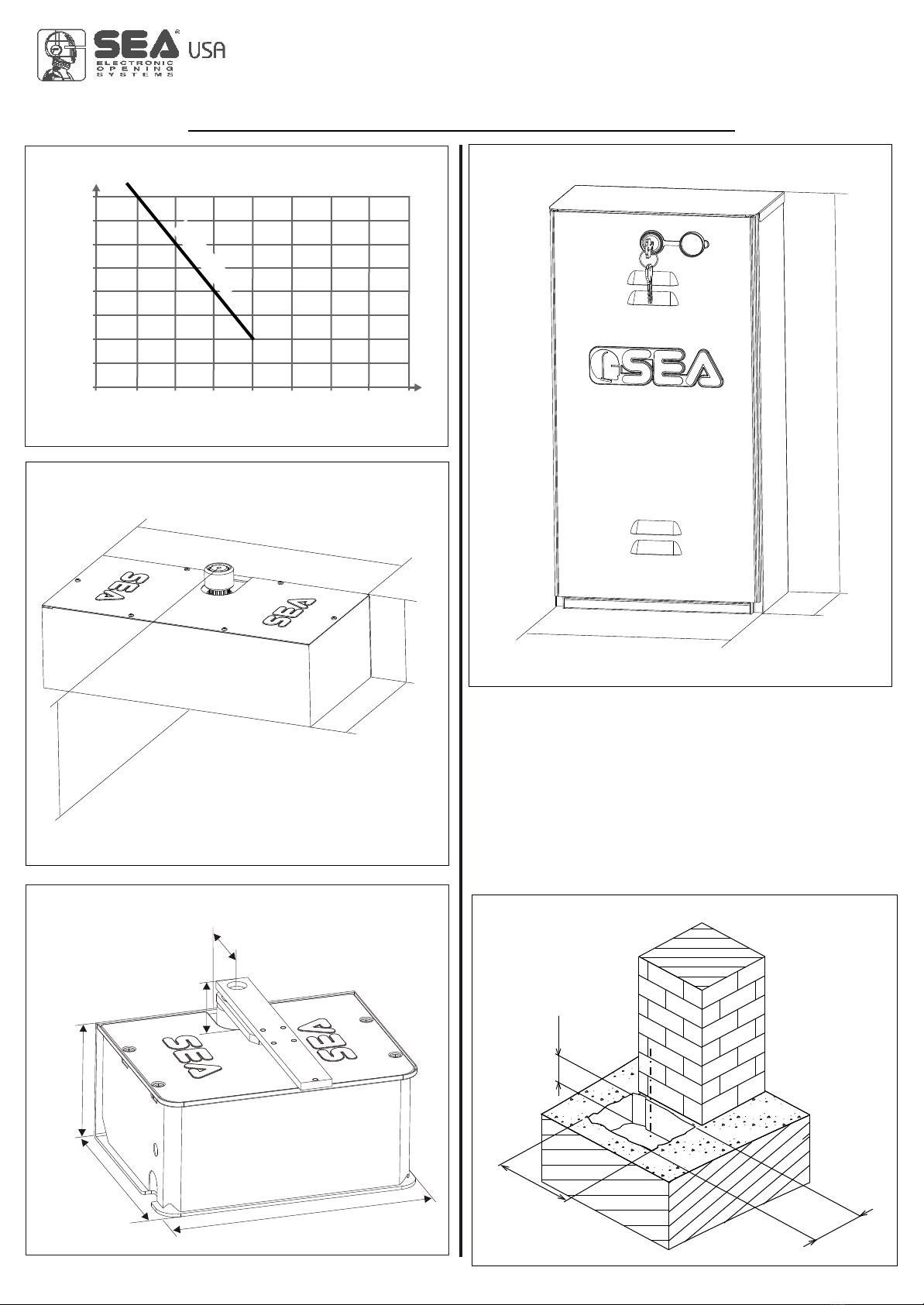

GRAPHIC FOR THE USE OF

JACK 1600 OPERATORS

1Jack

2 Broached bush

3Box lid

4Box

5Foundation base

6Braking screw

(where provided)

7Exit hole for electric cables

8Water draining hole

adjusting

9 Air bleed screw

10

11

12 Hydraulic unit box

13 Oil charge cap

14

15 Hydraulic plug

16 Release screw

17 By pass valves

Greaser

Crank

Oil level cap

NON-CARRYING BOX

LYRA HYDRAULIC UNIT

Jack rotation angle

1. FEATURES AND SPECIFICATIONS

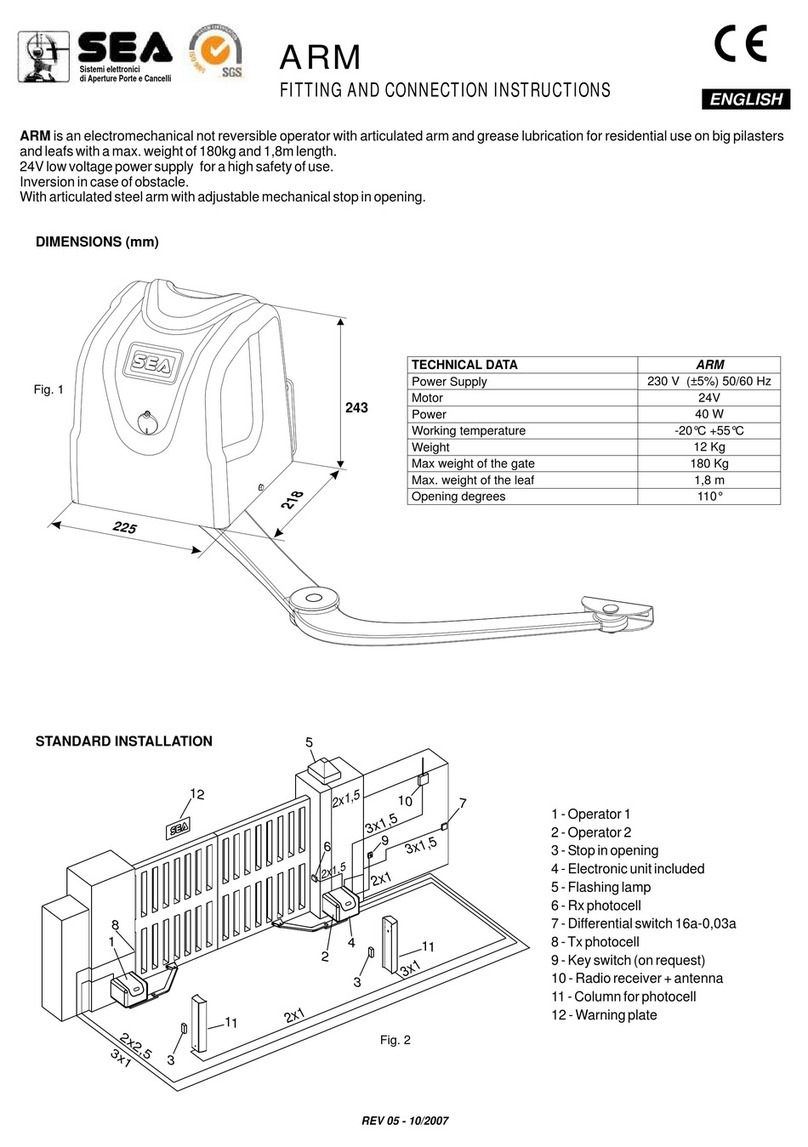

The LYRA JACK consists of a hydraulic pump and a hydraulic

jack. The jack is placed inside a non carrying or carrying box

(inox only for carrying box).

The pump unit casing, which is used as an oil tank, contains the

electric motor, fluid pump, distributor and hydraulic oil. It is also

provided with an adjustable slowing-down device in the two

stop phases of the leaf (versions with slow-down only).

The wheeling unit is composed by a double piston connected to

a rack which engages with the pinion of the leaf dragging shaft.

Gates up to 6,56 feet long can be securely locked using the

operators internal hydraulic locking system, thus ensuring

perfect keeping in closing and in opening. For gate in excess of

stated value: A hydraulic non locking operator should be used in

conjunction with a separate electrical locking device to ensure

keeping in closing.

On the operators with hydraulic slow down it is present

only during the last 15° of rotation. The system comes with a

release which allows the manual opening of the leaves in case of

power failure.

MECHANICAL INSTALLATION

International registered trademark n. 2.777.971

LYRA, JACK

674117856

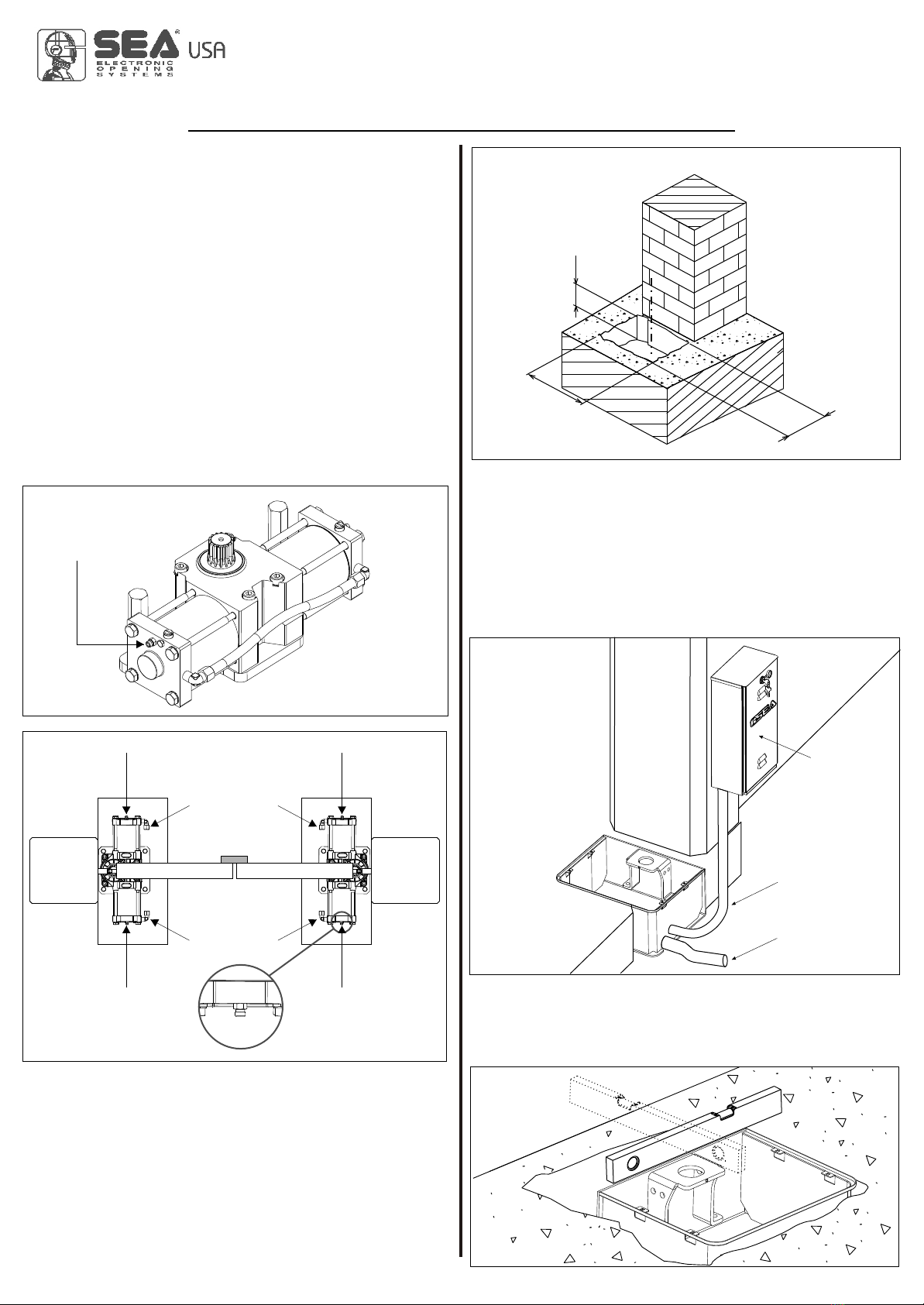

Fig. 12

23,62

81 1 , 1

6,30

Dimensions (inches)

15,78

8,26

4,76

Dimensions (inches)

Fig. 11

15,74 -17,32

4,76

8

6

1600

1543

1323

1102

882

661

441

220

00 6,5 8 10 13 16 20 23 26

J 0

ACK 160

15,74 inches ®100° - 140°

17,32 inches ®180°

Dimensions (inches)

Fig. 9

Fig. 10

7,40

612,0

16,14

2,67

2,16

Dimensions (inches)

REV 00 - 03/2014

Weight

(Pound)

Leaf length (Feet)

GRAPHIC (A)

CARRYING BOX

NON-CARRYING BOX

LYRA HYDRAULIC UNIT

2. NON-CARRYING BOX INSTALLATION

2.1. The excavation which contains the non-carrying box must

have the approximate dimensions mentioned in Fig. 12. For a

correct placing, it is obligatory to closely follow the quote of 2,16

inches which corresponds to the minimum distance of the

rotation axis from the pillar.

MECHANICAL INSTALLATION

International registered trademark n. 2.777.971

LYRA, JACK

67411785 7

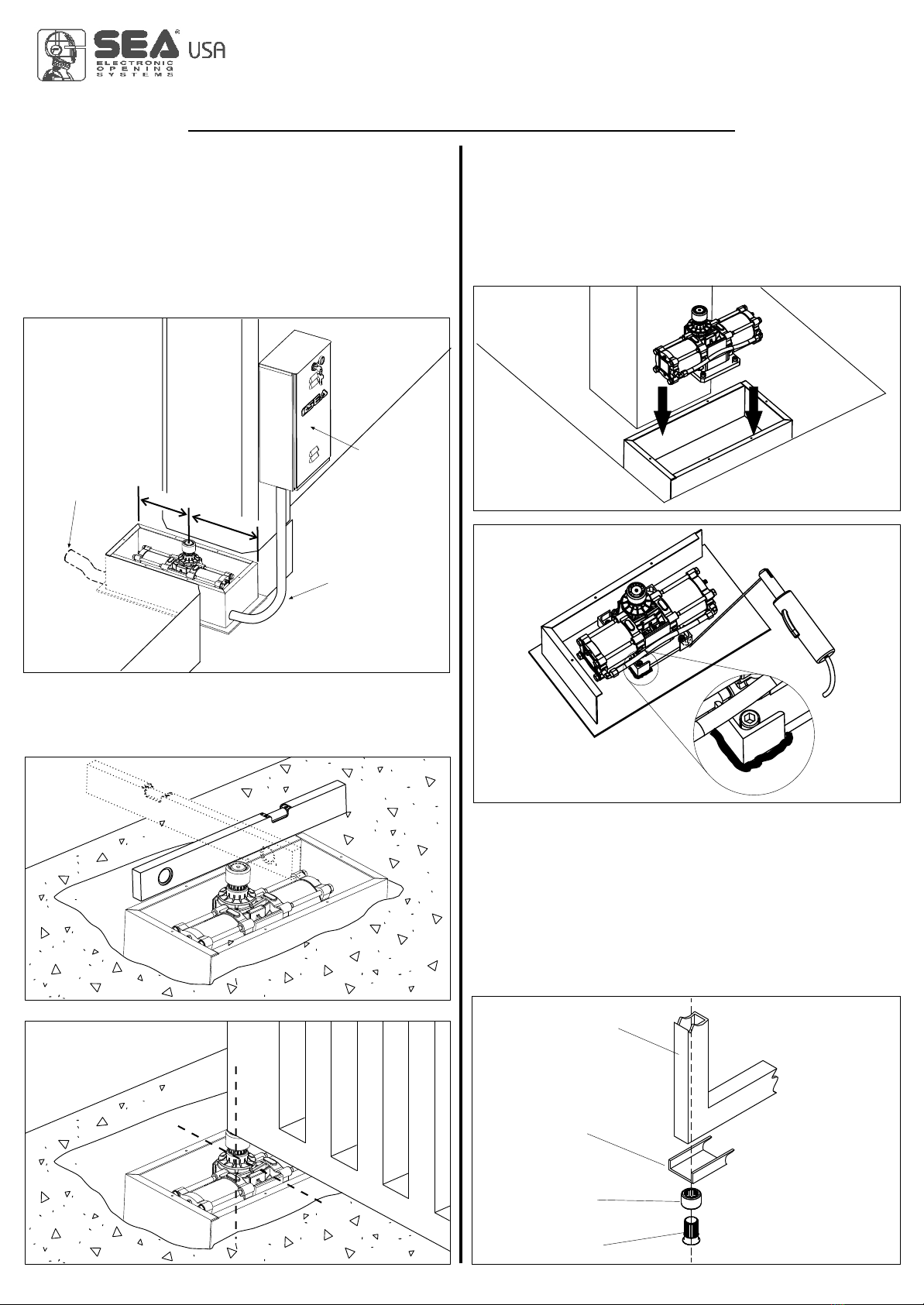

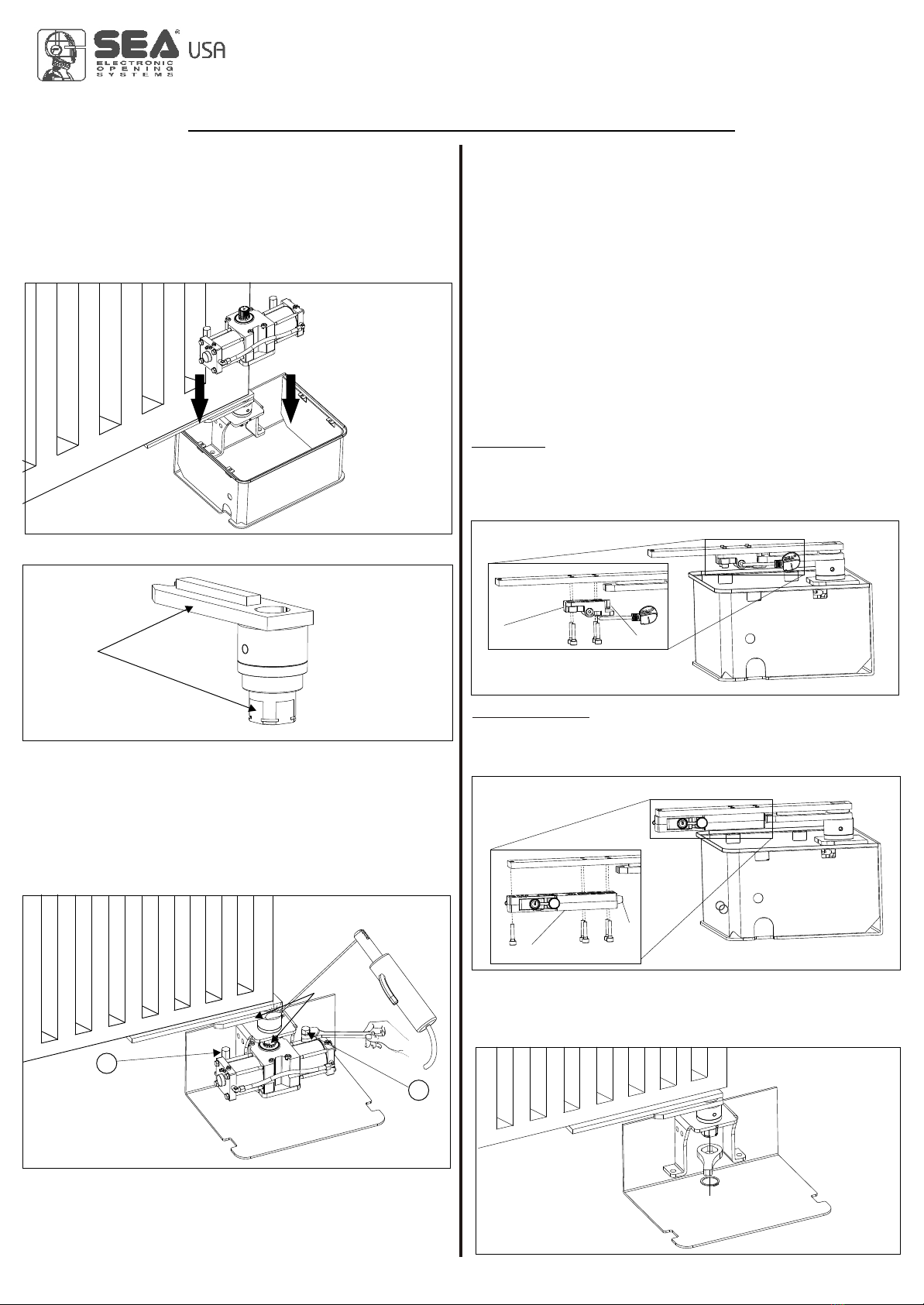

Fig. 14

Fig. 15

Fig. 18

Fig. 16

Fig. 17

REV 00 - 03/2014

Fig. 13

=

=

Flexible pipe

for water

draining

2.2. Inside the excavated pit you have to plan:

- rain water drainage;

- a water waste pipe in flexible plastic of about 1,57 inches of

diameter to put inside the provided hole of the box before it is

concreted (Fig. 13). It must be brought to the drain of the

sewer line;

- a sheath for the passage of the hydraulic tubes of about 1,25

inches of diameter which must be brought to the proximity of

the hydraulic unit box (Fig. 13).

2.3. Before concreting the box, use a level to make it perfectly

horizontal to the ground (Fig. 14) and perpendicular to the axis of

the gate (Fig. 15).

Hydraulic tubes

sheath

Hydraulic unit

Pivot

Bush

U-shaped bar

Leaf

4. MOUNTING OF THE LEAF ON NON-

CARRYING BOX

4.1. Insert the broached bush on the shaft of the jack.

Turn the shaft of the jack toward closing until it stops.

WARNING: For operators with brake make sure that the jack

has reached the stop and not the beginning of the

slowdown.

4.2. Go back about 5° and weld the bush to the U-shaped bar

(not supplied) and to the leaf of the gate (Fig. 18).

3. INSTALLATION OF THE OPERATOR

INSIDE THE NON-CARRYING BOX

3.1. Place the jack inside the foundation box (Fig.16)

positioning the axis of the output shaft aligned with the axis of

the hinge of the gate and weld the four angular ends to fix the

same (Fig. 17).

MECHANICAL INSTALLATION

International registered trademark n. 2.777.971

LYRA, JACK

674117858

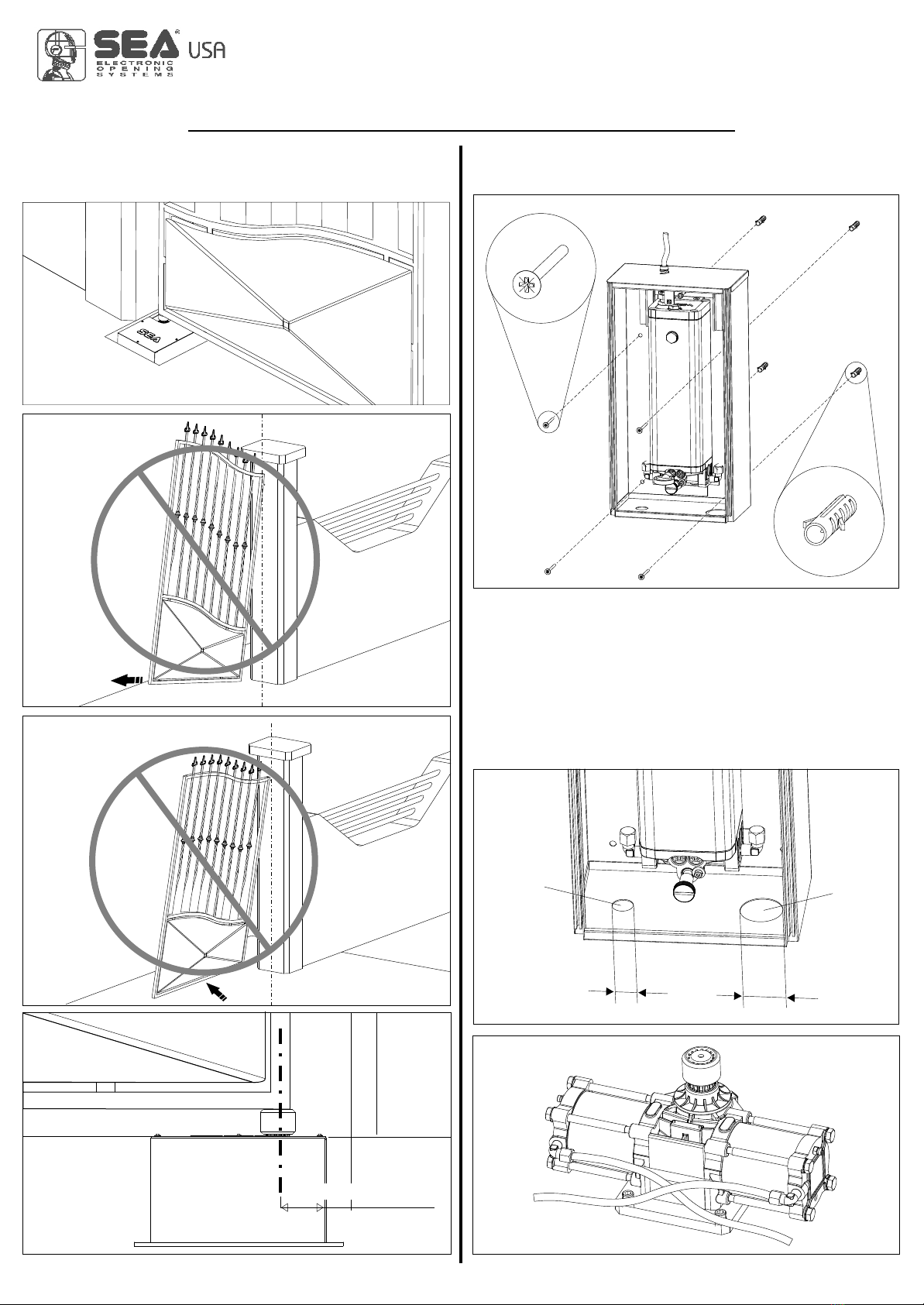

Fig. 19

2,16 inches min.

Fig. 20

Fig. 21

Fig. 22

REV 00 - 03/2014

1,57’’

0,78’’

Fig. 23

Fig. 24

Fig. 25

4.3. Be careful not to place the leaf outside the axis (Fig. 20

and 21) and make sure that the shaft corresponds to the

rotation axis of the jack.

5. HYDRAULIC UNIT BOX WALL

INSTALLATION (Fig.23)

5.1. Connect the hydraulic tubes with the hydraulic unit and the

jack (Fig.25, Fig.26, Fig.27).

After having installed the box, the gate and the operator, try to

slowly move the gate by hand to make sure that there are no

irregular frictions and that the movement is uniform for the whole

range.

Notice: To do this last operation, release the operator as

described in the related paragraph.

Hydraulic

tubes

inlet

Cable

inlet

MECHANICAL INSTALLATION

International registered trademark n. 2.777.971

LYRA, JACK

67411785 9

8. BRAKING REGULATION (where present)

8.1. It is possible to regulate the leaf slowdown in opening and in

closing, through the braking adjusting screw (Fig. 30).

8.2.To regulate slowdown operate as follow:

- Loosen the blocking screw of braking regulation;

- Act on the adjusting screw clockwise to have a higher braking

and a speed decrease;

- Act on the adjusting screw anti-clockwise to have a lower

braking and a speed increase;

-After the regulation fix the blocking screw of braking regulation.

On the operators with hydraulic slow down it is prensent

only during the last 15° of rotation.

Fig. 30

+

-

+

-

Fig. 27

Fig. 26

REV 00 - 03/2014

Fig. 28

-+

By-Pass Valves

Fig. 29

+-

Grey

n

e

t

m

t

s

i

u

n

j

d

o

a

p

e

e

n

c

r

i

n

o

g

F

+-

Yellow

e

t

n

m

t

s

i

u

n

j

d

c

a

l

o

e

s

c

r

i

n

o

g

F

Braking regulation screw

Opening/closing

Blocking screw for

braking regulation

Copper

tube

Flexible

tube

6. BLEED CAP REPLACEMENT (Fig.28)

Remove the red cap and replace it with the supplied black one

after startup.

7. FORCE ADJUSTMENT

If necessary the thrust force of the leaf can be adjusted by the

two adjusting screws (grey and yellow) placed on the front lower

place of the hydraulic pump unit (Fig. 29).

*The operator is adjusted at 33 pound force ex works so to

guarantee the anti-crush safety.

We recommend to adjust it only in case of necessity.

Red cap

9. BLEEDING OPERATION

During the connection phase between hydraulic unit and jack, air

will inevitably enter into the system and cause an irregular

operation of the operator. The irregular operation shows by an

abnormal movement of the leaf and excessive noise during

operation. To solve this problem it is necessary to proceed as

follows:

MECHANICAL INSTALLATION

International registered trademark n. 2.777.971

LYRA, JACK

6741178510

Air bleed screw

Fig. 31

CLOSING

OPENING EXT

INT

A A

B B

Fig. 32

Fig. 33

23,62

17,71

8,46

Dimensions (inches)

10. CARRYING BOX INSTALLATION

10.1. The hole which contains the carrying box must have the

approximate dimensions mentioned in Fig. 33.

For a correct placing, it is obbligatory to follow closely the quote

of 2,16 inches which corresponds to the minimum distance of

the rotation axis from the pillar.

Fig. 35

10.3. Before concreting the carrying box, use a level to make it

perfectly horizontal to the ground (Fig. 35) and perpendicular to

the axis of the gate (Fig. 36).

The axis of the upper hinge of the gate must correspond exactly

to the axis of the carrying box shaft.

REV 00 - 03/2014

Fig. 34

a) command opening of the gate;

b) during opening of the gate, loosen the air bleed screw related

to opening (Fig.32-rif.A);

c) release any air from the hydraulic circuit until non-emulsified

oil appears;

d) tighten the air bleed screw before the operator completes the

opening cycle;

e) command closing of the gate;

f) during closing of the gate, loosen the air bleed screw related to

closing (Fig.32-rif.B);

g) release any air from the hydraulic circuit until non-emulsified

oil appears;

h) tighten the air bleed screw before the operator completes the

closing cycle.

It is recommended to repeat this operation on both air bleed

screws at intervals of 2/3 opening and closing cycles.

i) Replace the oil from the oil filler cap. Any top-ups should be

performed only with oil SEA0x29 (supplied).

10.2. Inside the excavated pit you have to plan:

- rain water drainage;

- a water waste pipe in flexible plastic of about 1,57 inches of

diameter to put inside the provided hole of the box before it is

concreted (Fig. 34). It must be brought to the drain of the

sewer line;

- a sheath of about 1,25 inches diameters for the passage of

hydraulic tubes must be brought to the proximity of the

hydraulic unit box (Fig. 34).

Hydraulic

unit

Hydraulic tubes

sheath

Flexible pipe

for water

draining

MECHANICAL INSTALLATION

International registered trademark n. 2.777.971

LYRA, JACK

67411785 11

Fig. 38

Fig. 37

Fig. 41

2,16 inches min.

Fig. 40

11. LEAF ASSEMBLING ON CARRYING BOX

Before installing the gate make sure that the concrete has

hardened into the foundation hole.

11.1. Position the leaf of the gate on the leaf device making

reference to the rotation axe of the leaf hinge (Fig. 38);

11.2. Weld with care the leaf device to the leaf of the gate

realizing a tract fixation of ca. 1,18-1,57 inches along the surface

of the contact, avoiding the welding next to the threaded

Fig. 36

10.4. Introduce the buckle of creeping in the box and fix it with

the special screws (Fig. 37).

10.5. Insert the units as in Fig. 37.

N.B.: During the insertion of the units lubricate

them with the supplied grease.

holes, furthermore it is necessary to respect the perpendicularity

to the axe of rotation (Fig. 39)

Fig. 39

11.3. Be careful not to place the leaf outside the axis (Fig. 20

and 21), but make sure the shaft corresponds to the hinge

rotation axis remembering that the minimum distance from the

pillar is 2,16 inches (Fig. 41).

REV 00 - 03/2014

Leaf device

Leaf rotation axe

Leaf

Crank shaft Crank

MECHANICAL INSTALLATION

International registered trademark n. 2.777.971

LYRA, JACK

6741178512

RELEASE PLUS

13.2. Grease the hinge (A) and mount the release system under

the leaf device using the 5 furnished screws (Fig. 46).

Fig. 42

Fig. 44

2

Fig. 43

Fig. 45

A

12. INSTALLATION OF THE OPERATOR IN

THE CARRYING BOX

12.1. Insert manually the operator into the carrying box (Fig. 42)

also insert the splined shaft of the operator into the splined bush

of the box and fix the operator with the special screws as in

Fig.44.

N.B.: It is advisable to weld the crank with the crank shaft after

having also installed the Jack, to use the whole available run and

the point of beginning of the desired slowdown (version with

hydraulic slowdown).

Before welding, make sure that one of the level of the crank shaft

corresponds with a side of the crank (see fig.43 and 44) to

guarantee the maximum angle with the mechanical stops Kit.

N.B.: If the Jack is not installed immediately but in a second time,

it is recommended to weld the crank shaft and the crank during

the installation of the Jack.

Carry out the electrical connections to the control unit as

described in the instructions supplied with SEA control unit.

Fig. 46

A

Fig. 47

REV 00 - 03/2014

1

Release

Release Plus

14. ADJUSTABLE MECHANICAL STOPS

12.1. Connect the hydraulic tubes with the hydraulic unit and the

jack (Fig.25, Fig.26, Fig.27).

After the installation of the above mentioned carrying box, of the

gate and the operator, try to move the gate slowly by hand

verifying that there are no irregular frictions and that the

movement is uniform for the whole range.

Notice: To do this last operation, release the operator as

described in the related paragraph.

13. RELEASE MOUNTING

For the Jack are foreseen two types of release:

RELEASE (with personalised key) and RELEASE PLUS

(with DIN key).

RELEASE

13.1. Grease the hinge (A) and mount the release system under

the leaf device using the 4 furnished screws (Fig. 45).

MECHANICAL INSTALLATION

International registered trademark n. 2.777.971

LYRA, JACK

67411785 13

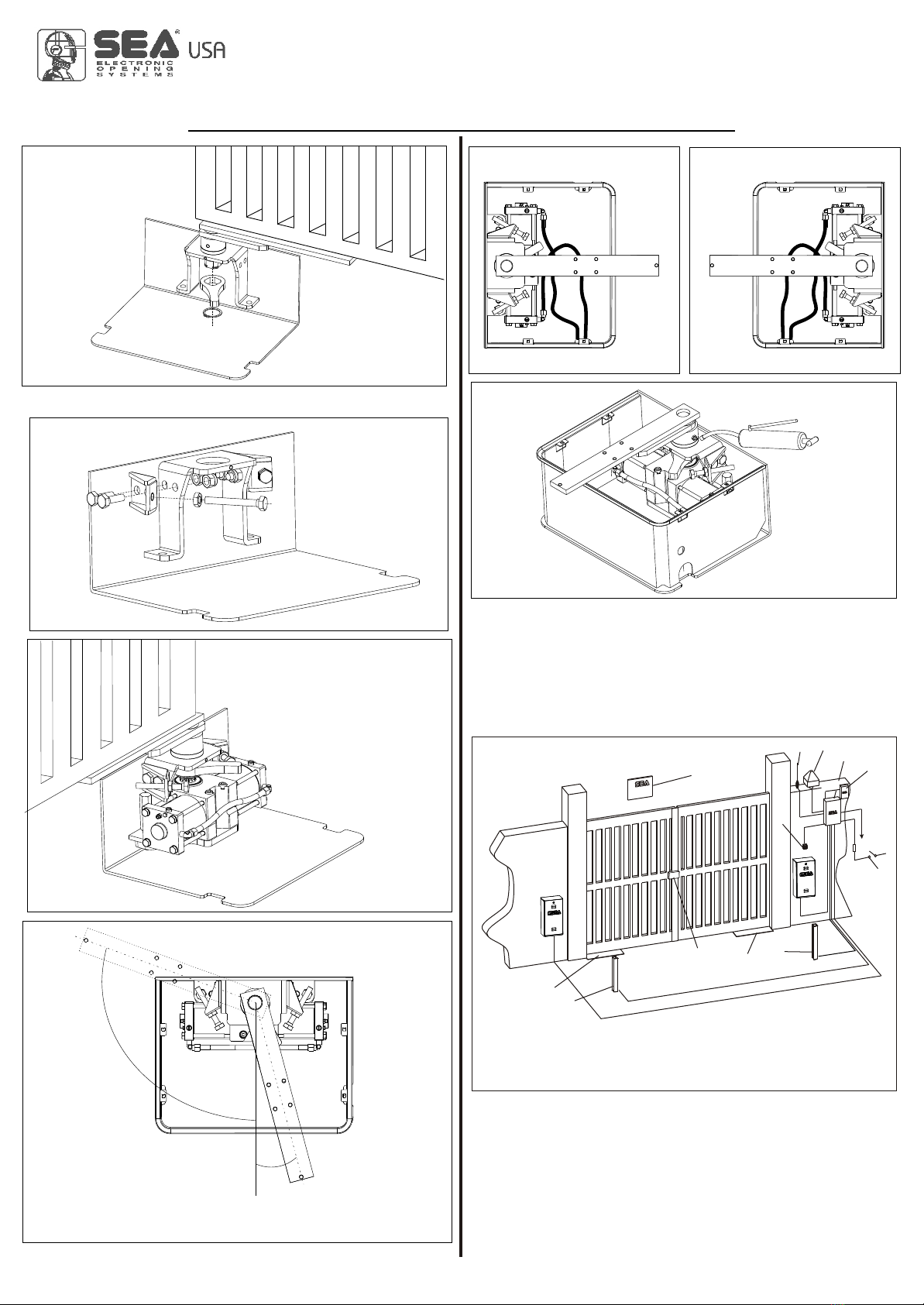

Fig. 49

Fig. 48

Fig. 51

0

-15°

105°

Fig. 52 Fig. 53

Fig. 50

When putting in function the installation it is peremptory to

lubricate the box as in Fig. 54 until the grease comes out.

se grease typeDIN 51502 KP 2 N-20 - K 2 K-20).(U

Fig. 54

Fig. 55

1

23

4

2

5

6

789

10

11

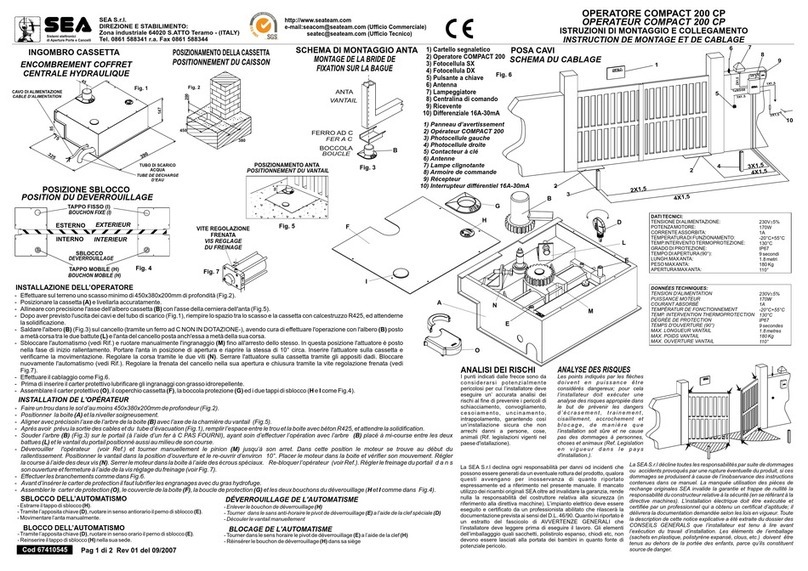

15. CABLE LAYOUT (Fig. 55)

REV 00 - 03/2014

Max. Angle with mechanical stops kit

RIGHT

LEFT Outside

Inside

Outside

Inside

1) Warning notice

2) Jack 1600

3) Left photocell

4) Right photocell

8) Electronic control unit

9) Receiver

10) Differential switch

11) Electric lock (SB version only)

5) Key switch

6) Antenna

7) Flashing warning lamp

MECHANICAL INSTALLATION

International registered trademark n. 2.777.971

LYRA, JACK

6741178514

Fig. 56

REV 00 - 03/2014

17. PERIODICAL MAINTENANCE

Check the oil level

(Trasparent cap n.14 in Fig. 8) Annual

Change the oil

Verify the functionality of the by-pass valves

(check the force in opening and closing)

Check the release function

Verify the slowdown regulation (where present)

Check the correct drain of the rainwater

Check the integrity of the connection cables

Grease all the moving parts

Grease the rotation axis of the box as in Fig.54

4 years

Annual

Annual

Annual

Annual

Annual

Annual

Annual

SAFETY GATE

18. ACCESSORIES FOR JACK

CARRYING BOX INOX

RELEASE

RELEASE PLUS

KIT MECHANICAL STOP

MECHANICAL INSTALLATION

International registered trademark n. 2.777.971

16. RISK EXAMINATION

The points pointed by arrows are potentially dangerous.

The installer must take a thorough risk examination to prevent

crushing, conveying, cutting, grappling, trapping so as to

guarantee a safe installation for people, things and animals. (

).

in fig. 56

Re.

Laws in force in the country where installation has been made

As for misunderstandings that may arise refer to your area

distributor or call our help desk. These instructions are part of the

device and must be kept in a well known place.The installer shall

follow the provided intructions thoroughly.

products must only be used to automise doors, gates and lwings.

Any initiative taken without explicit authorization

will preserve the manufacturer from whatsoever responsibility.

The installer shall provide warning notices on not assessable

further risks. in its relentless aim to improve the

products, is allowed to make whatsoever adjustment without

giving notice. This doesn’t oblige to up-grade the

past production. can not be deemed responsible

for any damage or accident caused by product breaking, being

damages or accidents due to a failure to comply with the

instructions herein. The guarantee will be void and the

manufacturer responsibility will be nullified if

original spare parts are not being used.

Packaging

materials such as plastic bags, foam polystyrene, nails etc must

be kept out of children’s reach as dangers may arise.

SEA USA Inc.

SEA USA Inc.

SEA USA Inc.

SEA USA Inc.

SEA USA Inc.

SEA USA Inc.

The electrical installation

shall be carried out by a professional technician who will release

documentation as requested by the laws in force.

LYRA, JACK

67411785 15

20. RELEASE SYSTEM OF THE LEAVES

RELEASE

20.1. To release act as follows:

-Insert the enclosed key into the keyhole (S) and turn the handle

about 180° against the centre of the gate (Fig. 58) .

-Keep the key locked and move the leaf, now turn back the key to

the normal position and extract it.

20.2. To stop again act as follows:

-Move the leaf until the lock has coupled again.

S

Fig. 58

180°

RELEASE PLUS

20.3. To release act as follows:

-Insert the enclosed key into the keyhole and turn it about 90° in

clockwise direction (Fig. 59).

- Pull the key against the external of the release making come

out the handle of the lock until it reaches the stop (Fig.60).

- Move the leaf and make return the handle of the release in its

original position and extract the key.

21.4. To stop again act as follows:

-Move the leaf until the lock has coupled again.

Fig. 59

90°

Stop

Release handle

Fig. 60

Hydraulic pump

manual release

Fig. 57

REV 00 - 03/2014

To the attention of users and technicians

Release Lock

19. HYDRAULIC UNIT RELEASE SYSTEM

19.1. To release do as follows:

- Open the door with the delivered special key.

- Turn the release srew, placed on the hydraulic unit.about 90°

into anti-clockwise direction.

- Move the beam with the hand.

19.2. To re-lock do as follows:

- Turn the release screw, placed on the hydraulic unit.about 90°

into clockwise direction

- Close the door.

½ turn

MECHANICAL INSTALLATION

International registered trademark n. 2.777.971

LYRA, JACK

6741178516

GENERAL WARNING: Installation must be realized using parts and accessories approved by SEA. SEA is not

responsible for incorrect installations and/or non-compliance with safety standards according to the law in-force. SEA is in

no way liable for any damages and/or malfunctioning due to using parts and accessories non-compliant with the UL325

safety standards.

ORDERS: Orders are processed upon approval by SEA. Buyers must confirm orders by sending a written Purchase

Orders to SEA. Purchase Orders are intended as confirmation of orders and binding for the buyer, which accepts SEA

sales condition.

QUOTATION: Quotation and special offers with a non-specified duration expires automatically after 30 days.

PRICES: Prices are based on the Price List in force. Discounts and quotation from Sales Rep. and other selling branches

must be approved by SEA. Prices are F.O.B SEA Warehouse in Miami and do not include shipments costs. SEA reserves

the right to modify the price list at any time and provide notice to its sales network.

PAYMENT: Method of payments and terms are notified by SEAand displayed on the commercial invoice.

DELIVERY: The delivery time on the invoice is not binding and represents an estimated delivery. Shipments costs will be

charged to the buyer and SEAis not responsible for delays and/or damages occurred to the products during shipment.

COMPLAINS: Complains and/or claims must be notified to SEA within 7 business days after receiving the products.

Claims and complains must be supported by original documents. Customer must contact the factory for instructions and

authorization. Merchandise returned for credit must be current, uninstalled and unused and returned in its original

packaging. Freight must be pre-paid on all authorized returns.

REPAIRS: Repairs and parts are subject to the availability in stock. Shipment of products for repairs must be pre-paid by

the customer. Products shipped without authorization, sender’s details and description of the problems will be refused.

Customers must contact SEAfor instructions.

WARRANTY: for the original buyer only:

Hydraulic and oil-bath motors: 36 months warranty from the date of invoice on manufacturing, assembling and

workmanship defects.

Electro-mechanic motors and electronic control systems: 24 months warranty from the date of invoice on manufacturing,

assembling and workmanship defects.

Lepus and Full Tank Standard model: 60 months warranty from the date of invoice on manufacturing, assembling and

workmanship defects.

No warranty will be recognized for damages due to incorrect installation and/or improper use for which the product was

intended. SEA warranty obligations shall be limited to repair or replace the defective product/parts at SEA option, upon

examination of the products by SEAtechnical Staff. All replaced parts must remain property of SEA. The warranty status of

the product remains an unquestionable assessment of SEA. Buyer must ship pre-paid defective products. Products under

warranty will be returned pre-paid by SEA. Recognized defects, whatever their nature, will not produce any responsibility

and/or damage claims to SEA USA Inc and SEA s.r.l. Warranty shall not cover any required labor activities. Warranty will in

no case be recognized if alterations and any other changes will be found on products. Warranty will not cover damages

caused by carriers, expendable materials and faults due to improper use with the products specifications. No indemnities

are recognized during repairing and/or replacing of the products under warranty. SEA USA Inc. and SEA s.r.l. decline any

responsibility for damages to person and objects deriving from non-compliance with safety standards, installation

instructions or use of the products sold. It is intended that warranty will be recognized only on products bought through the

SEA authorized network. Products must be installed by professionals. No warranty will be recognized if products are

installed directly by the final user. Warranty does not apply in case of unexpected events such as fire, flood, electrical

power surge, lightning, vandalism and others.

SEA USA Inc. is not responsible for errors in technical information printed in catalogs and installation manuals.

SALES CONDITIONS and WARRANTY

International registered trademark n. 2.777.971

LYRA, JACK

67411785 REV 00 - 03/2014 17

web site: www.sea-usa.com

e-mail: [email protected]

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151 Fax: ++1-305.594.7325

Toll Free: 800.689.4716

®

International registered trademark n. 2.777.971

This manual suits for next models

2

Table of contents

Other SEA Gate Opener manuals

SEA

SEA GATE 1 DG R2BF User manual

SEA

SEA Libra Mini Tank User manual

SEA

SEA SCUTI User manual

SEA

SEA TORG Series Instruction manual

SEA

SEA MARK TANK E 270 User manual

SEA

SEA FLIPPER User manual

SEA

SEA Cougar 270 User manual

SEA

SEA ARM Instruction manual

SEA

SEA GATE 2 DG INVERTER User manual

SEA

SEA HALF TANK User manual

SEA

SEA COMPACT 200 CP Instruction manual

SEA

SEA Boxer 1000 User manual

SEA

SEA KITE User manual

SEA

SEA LYRA User manual

SEA

SEA LYRA Instruction manual

SEA

SEA UNIGATE 1I User manual

SEA

SEA SUPER FULL TANK 20 G6 380V User manual

SEA

SEA SATURN User manual

SEA

SEA EASY 20 User manual

SEA

SEA SURF 350 Reversible User manual