SEA GATE 2 DG INVERTER User manual

Other SEA Gate Opener manuals

SEA

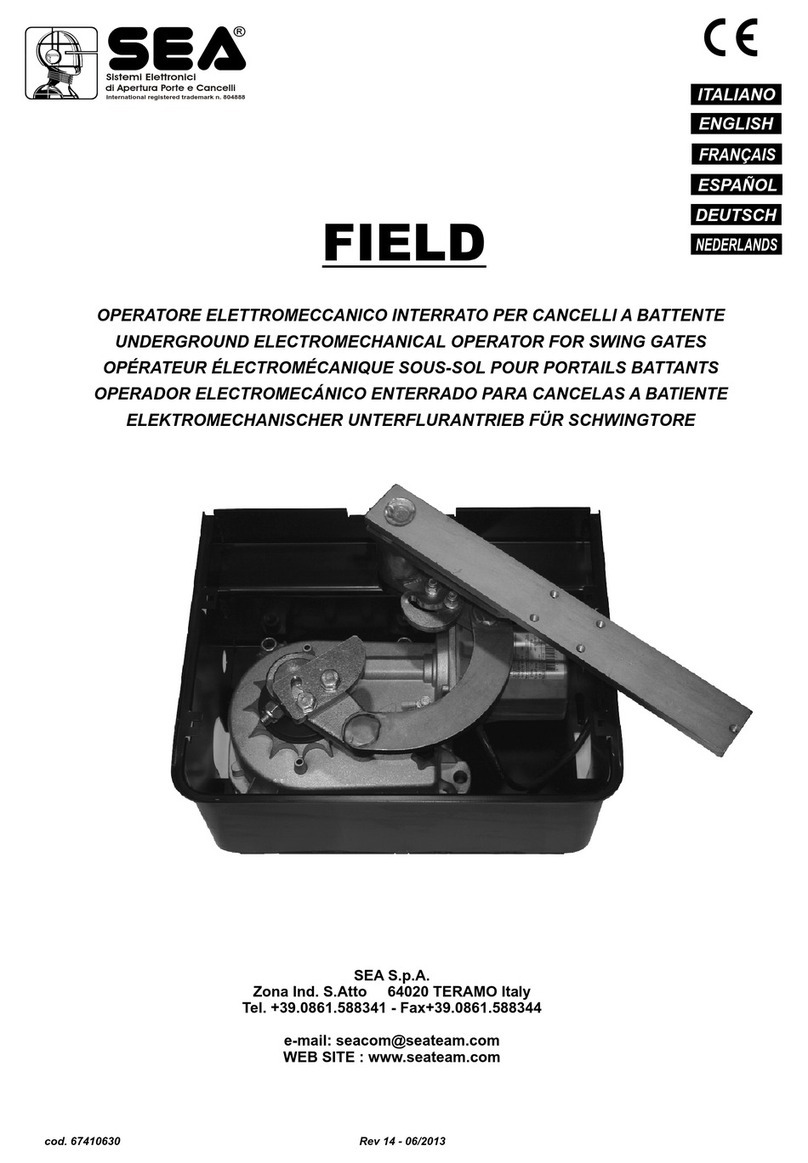

SEA FIELD Series User manual

SEA

SEA LIBRA Series Original instructions

SEA

SEA JOINT Original instructions

SEA

SEA JOINT Original instructions

SEA

SEA ALPHA 200 STANDARD User manual

SEA

SEA LYRA Instruction manual

SEA

SEA SURF 350 Reversible User manual

SEA

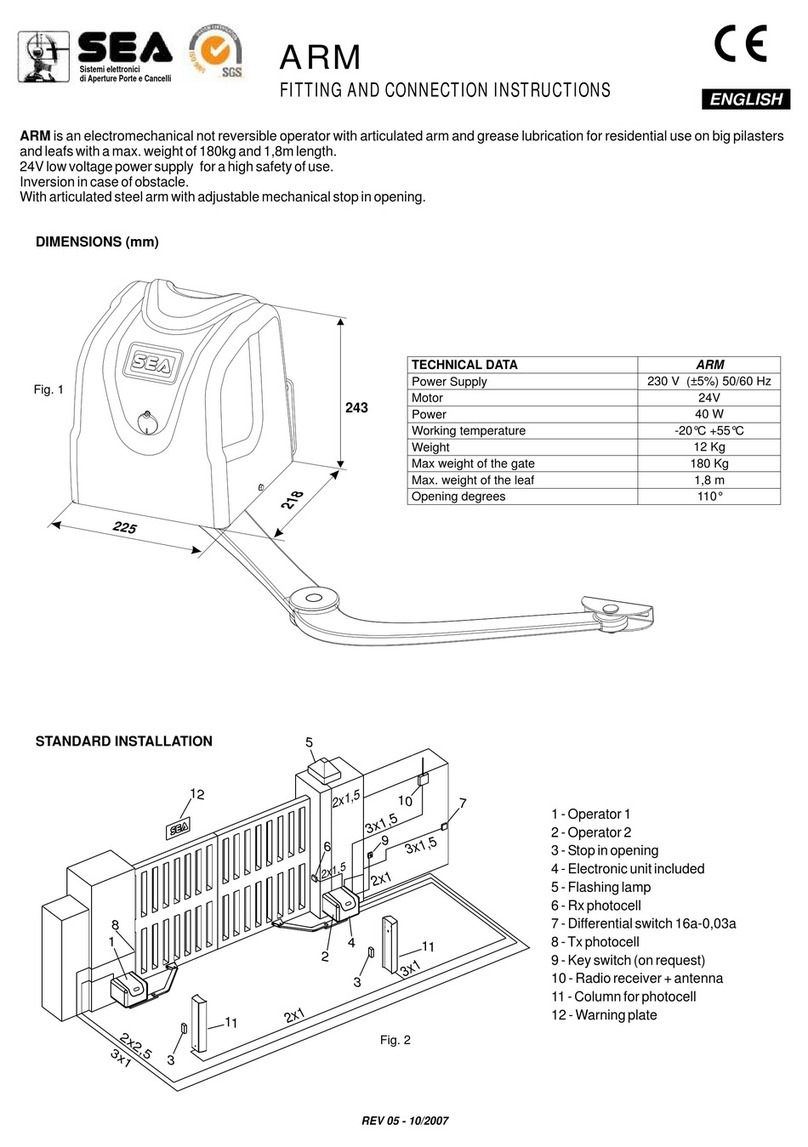

SEA ARM Instruction manual

SEA

SEA ORION BOX 24V User manual

SEA

SEA GATE 1 DG R2BF User manual

SEA

SEA Boxer 1000 User manual

SEA

SEA MARK TANK E 270 User manual

SEA

SEA FULL TANK 100 User manual

SEA

SEA SCUTI User manual

SEA

SEA MINI TANK User manual

SEA

SEA SUPER FULL TANK 20 G6 380V User manual

SEA

SEA SURF Series User manual

SEA

SEA TAURUS Instruction manual

SEA

SEA LEPUS BOX 120V/24V User manual

SEA

SEA SURF User manual

Popular Gate Opener manuals by other brands

HYDOM

HYDOM 3LC33 250A3A Series installation manual

Novoferm tormatic

Novoferm tormatic Novomatic 200 Installation, operating and maintenance instructions

PPA

PPA DZ BRUTALLE 3.0T JetFlex Technical manual

GFA

GFA ELEKTROMAT SE 22.24-30,00 installation instructions

Chamberlain

Chamberlain ELITE Series Wiring diagrams

Roger Technology

Roger Technology M30 Series INSTRUCTIONS AND RECOMMENDATIONS FOR THE INSTALLER

Beninca

Beninca VN.S40V manual

D.A.C.E

D.A.C.E DURASWING Installation and owner's manual

Nice

Nice mindy A400 Instructions and warnings for the fitter

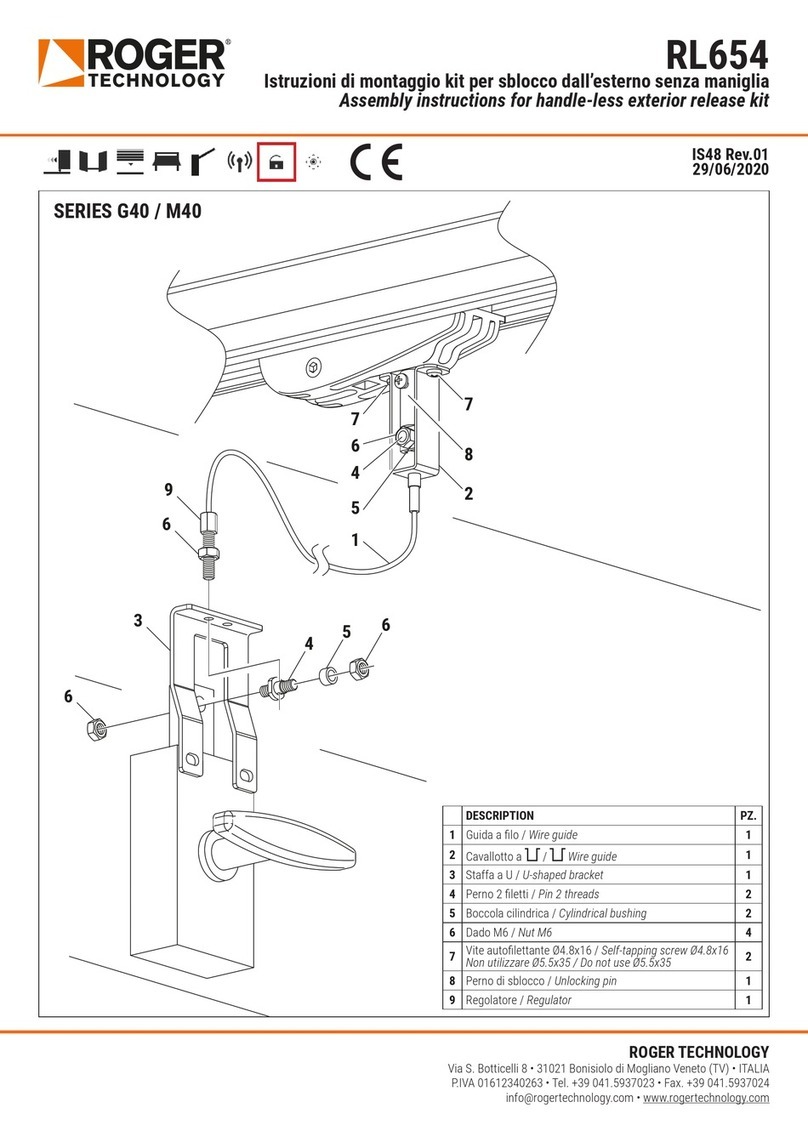

Roger Technology

Roger Technology RL654 Assembly instructions

FAAC

FAAC 400 instruction manual

Chamberlain

Chamberlain LiftMaster Professional BG770 owner's manual