12,000BTU/HR PORTABLE AIR CONDITIONER/

DEHUMIDIFIER/AIR COOLER/HEATER WITH

WINDOW SEALING KIT

MODEL NO: SAC12000.V5, SACWK1

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

1.1. ELECTRICAL SAFETY

WARNING! It is the user’s responsibility to check the following:

Check all electrical equipment and appliances to ensure that they are safe before using. Inspect power supply leads, plugs and all

electrical connections for wear and damage. Sealey recommend that an RCD (Residual Current Device) is used with all electrical

products. You may obtain an RCD by contacting your local Sealey stockist.

If the product is used in the course of business duties, it must be maintained in a safe condition and routinely PAT (Portable Appliance

Test) tested.

Electrical safety information: it is important that the following information is read and understood.

1.1.1. Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply.

1.1.2. Regularly inspect power supply cables and plugs for wear or damage and check all connections to ensure that they are secure.

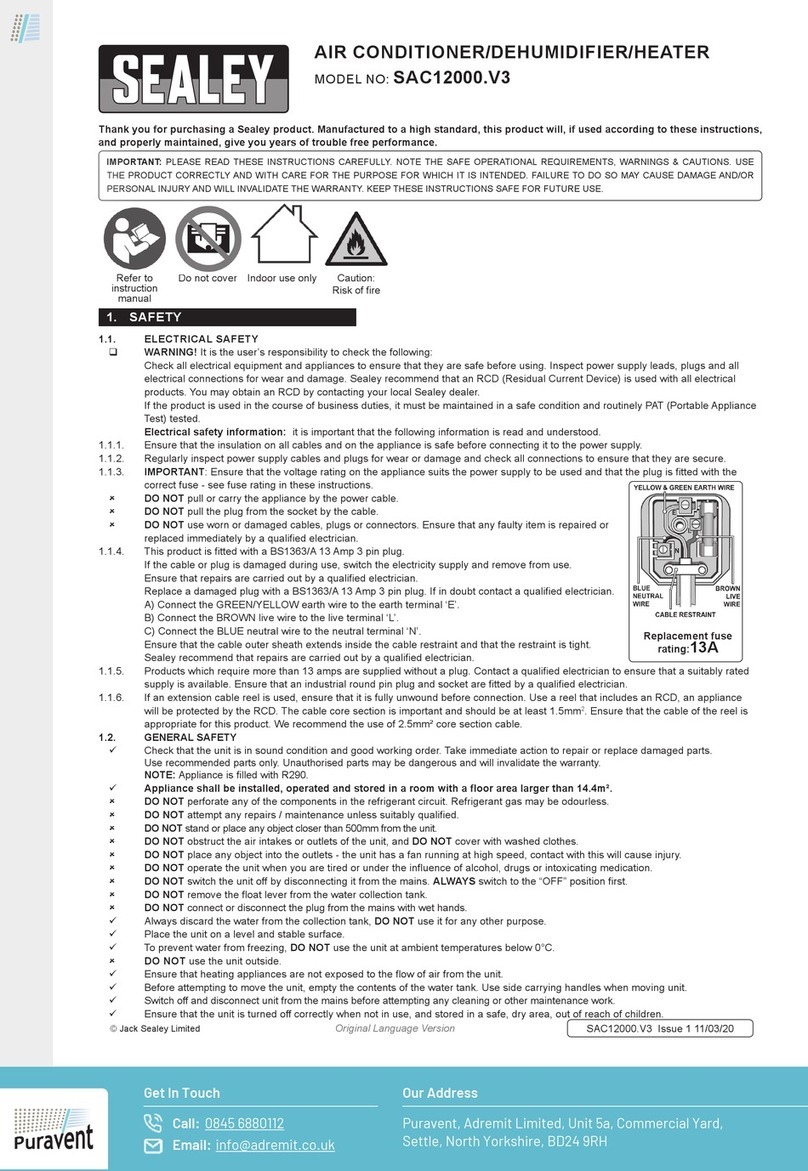

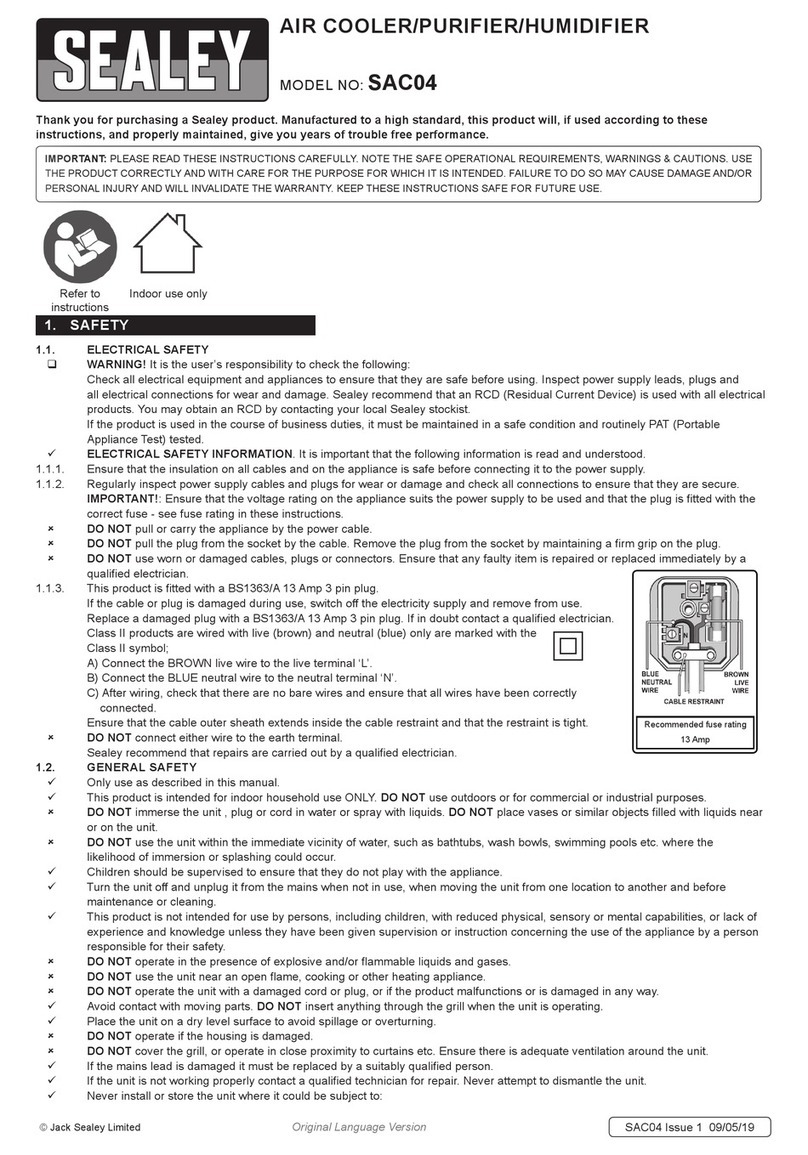

1.1.3. IMPORTANT: Ensure that the voltage rating on the appliance suits the power supply to be used and that the plug is tted with the

correct fuse - see fuse rating in these instructions.

8DO NOT pull or carry the appliance by the power cable.

8DO NOT pull the plug from the socket by the cable.

8DO NOT use worn or damaged cables, plugs or connectors. Ensure that any faulty item is repaired or

replaced immediately by a qualied electrician.

1.1.4. This product is tted with a BS1363/A 3 pin plug.

If the cable or plug is damaged during use, switch the electricity supply and remove from use.

Ensure that repairs are carried out by a qualied electrician.

Replace a damaged plug with a BS1363/A 3 pin plug. If in doubt contact a qualied electrician.

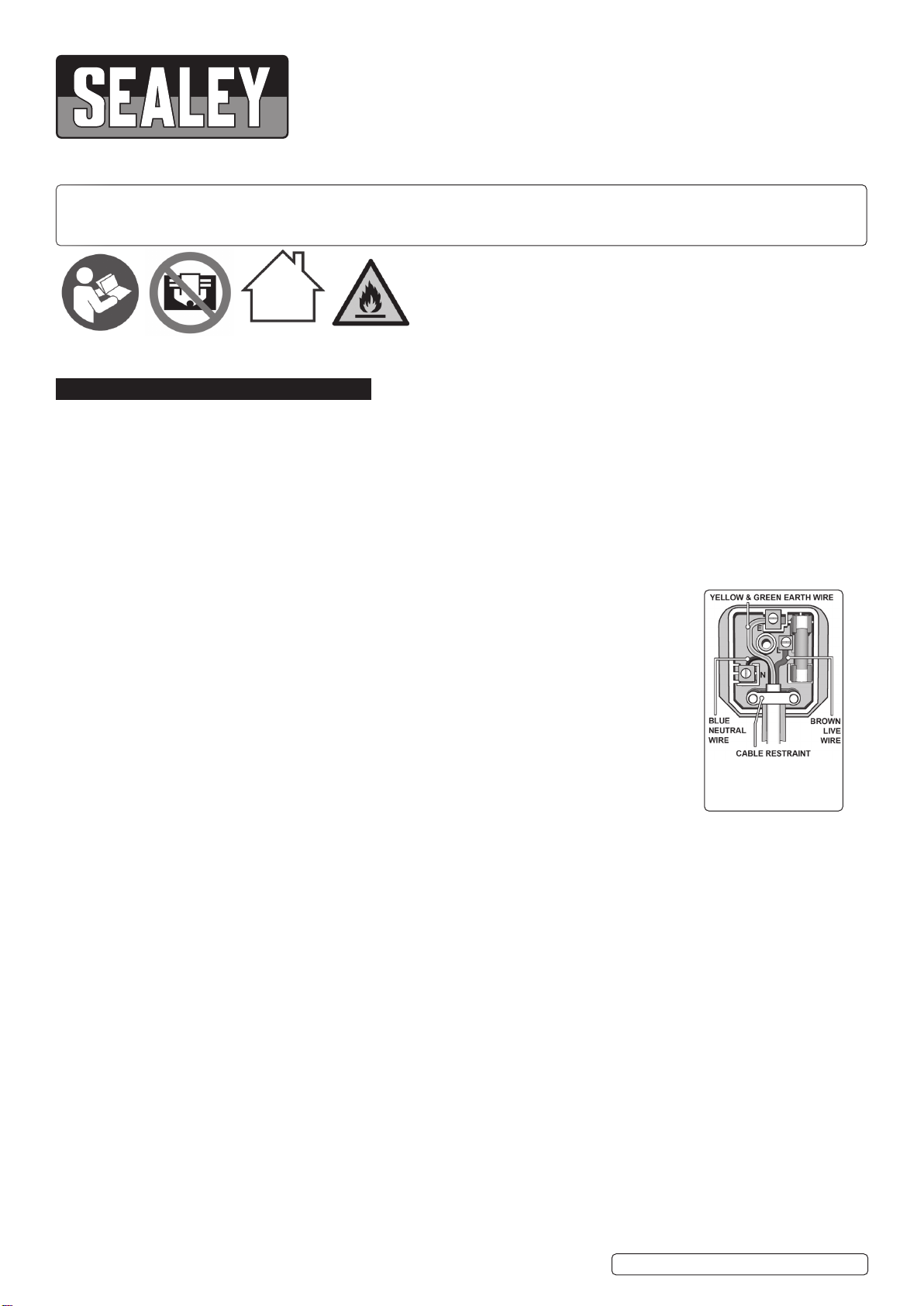

A) Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

B) Connect the BROWN live wire to the live terminal ‘L’.

C) Connect the BLUE neutral wire to the neutral terminal ‘N’.

Ensure that the cable outer sheath extends inside the cable restraint and that the restraint is tight.

Sealey recommend that repairs are carried out by a qualied electrician.

1.1.5. Products which require more than 13 amps are supplied without a plug. Contact a qualied electrician to ensure that a suitably rated

supply is available. Ensure that an industrial round pin plug and socket are tted by a qualied electrician.

1.1.6. If an extension cable reel is used, ensure that it is fully unwound before connection. Use a reel that includes an RCD, an appliance

will be protected by the RCD. The cable core section is important and should be at least 1.5mm2. Ensure that the cable of the reel is

appropriate for this product. We recommend the use of 2.5mm² core section cable.

1.2. GENERAL SAFETY

9Check that the unit is in sound condition and good working order. Take immediate action to repair or replace damaged parts.

Use recommended parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

NOTE: Appliance is filled with R290.

9Appliance shall be installed, operated and stored in a room with a floor area larger than 12m².

8DO NOT perforate any of the components in the refrigerant circuit. Refrigerant gas may be odourless.

8DO NOT attempt any repairs / maintenance unless suitably qualied.

8DO NOT stand or place any object closer than 500mm from the unit.

8DO NOT obstruct the air intakes or outlets of the unit, and DO NOT cover with washed clothes.

8DO NOT place any object into the outlets - the unit has a fan running at high speed, contact with this will cause injury.

8DO NOT operate the unit when you are tired or under the influence of alcohol, drugs or intoxicating medication.

8DO NOT switch the unit off by disconnecting it from the mains. ALWAYS switch to the “OFF” position first.

8DO NOT remove the float lever from the water collection tank.

8DO NOT connect or disconnect the plug from the mains with wet hands.

9Always discard the water from the collection tank, DO NOT use it for any other purpose.

9Place the unit on a level and stable surface.

9To prevent water from freezing, DO NOT use the unit at ambient temperatures below 0°C.

8DO NOT use the unit outside.

9 Ensure that heating appliances are not exposed to the ow of air from the unit.

9 Before attempting to move the unit, empty the contents of the water tank. Use side carrying handles when moving unit.

9 Switch o and disconnect unit from the mains before attempting any cleaning or other maintenance work.

9 Ensure that the unit is turned o correctly when not in use, and stored in a safe, dry area, out of reach of children.

Replacement fuse

rating:13A

Refer to

instruction

manual

SAC12000.V5, SACWK1 Issue 1 09/01/23

Original Language Version

© Jack Sealey Limited

Do not cover Caution:

Risk of re

Indoor use only