Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

1.1. ELECTRICAL SAFETY

WARNING! It is the user’s responsibility to check the following:

Check all electrical equipment and appliances to ensure that they are safe before using. Inspect power supply leads, plugs and

all electrical connections for wear and damage. Sealey recommend that an RCD (Residual Current Device) is used with all electrical

products. You may obtain an RCD by contacting your local Sealey stockist.

If the product is used in the course of business duties, it must be maintained in a safe condition and routinely PAT (Portable

Appliance Test) tested.

Electrical safety information, it is important that the following information is read and understood.

Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply.

Regularly inspect power supply cables and plugs for wear or damage and check all connections to ensure that they are secure.

Important: Ensure that the voltage rating on the appliance suits the power supply to be used and that the plug is tted with the

correct fuse - see fuse rating in these instructions.

8DO NOT pull or carry the appliance by the power cable.

8DO NOT pull the plug from the socket by the cable.

8DO NOT use worn or damaged cables, plugs or connectors. Ensure that any faulty item is repaired or

is replaced immediately by a qualied electrician.

This product is tted with a BS1363/A 13 Amp 3 pin plug.

If the cable or plug is damaged during use, switch o the electricity supply and remove from use.

Ensure that repairs are carried out by a qualied electrician.

Replace a damaged plug with a BS1363/A 13 Amp 3 pin plug. If in doubt contact a qualied electrician.

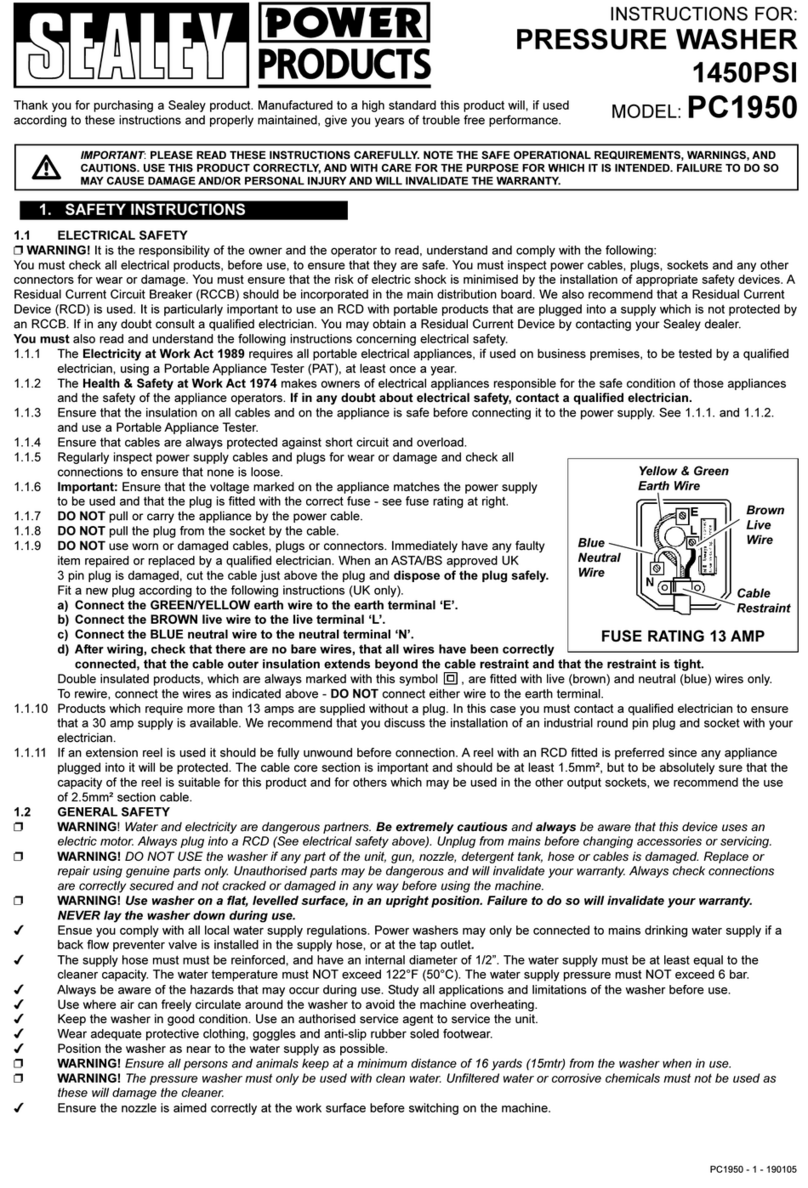

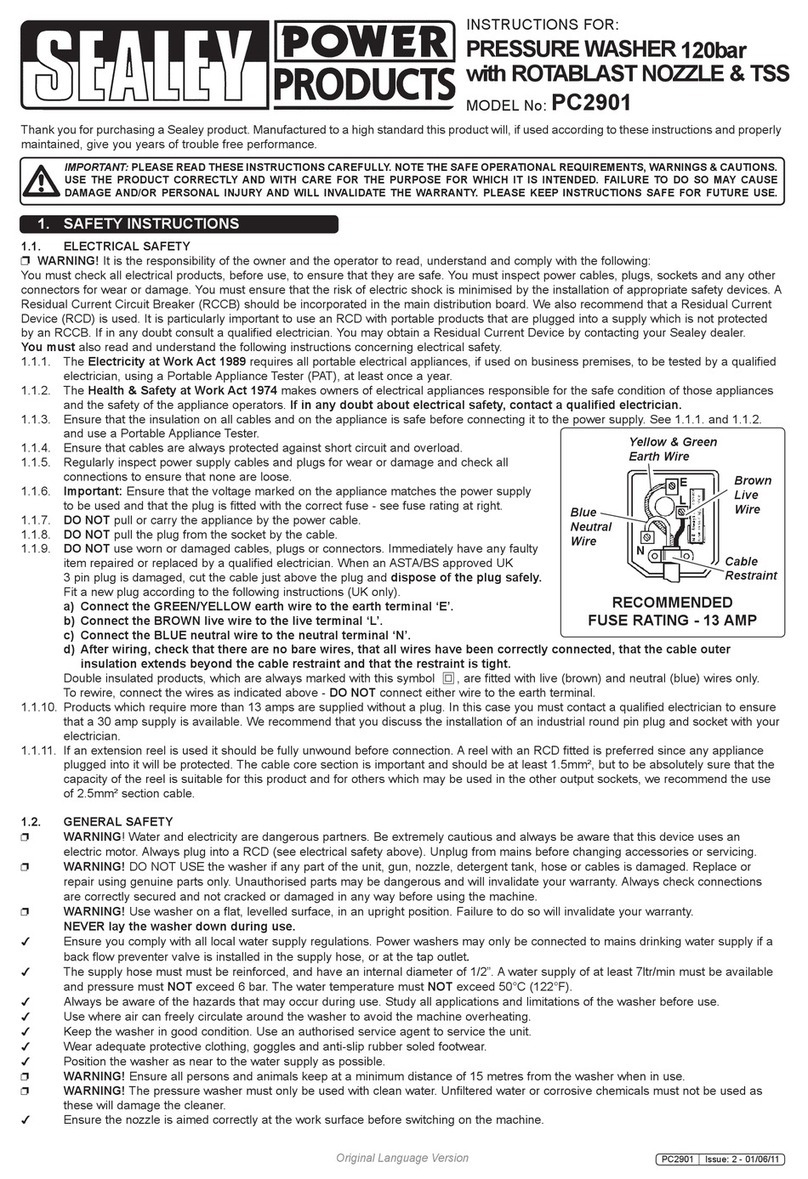

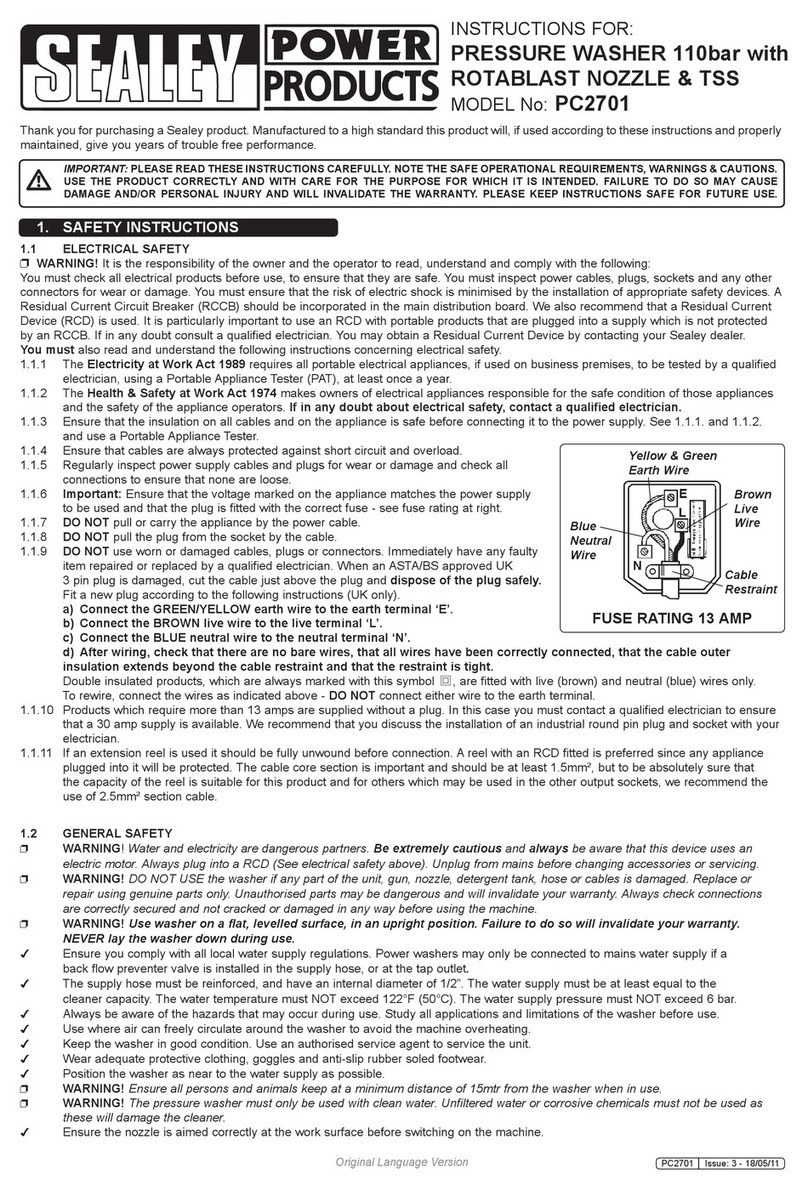

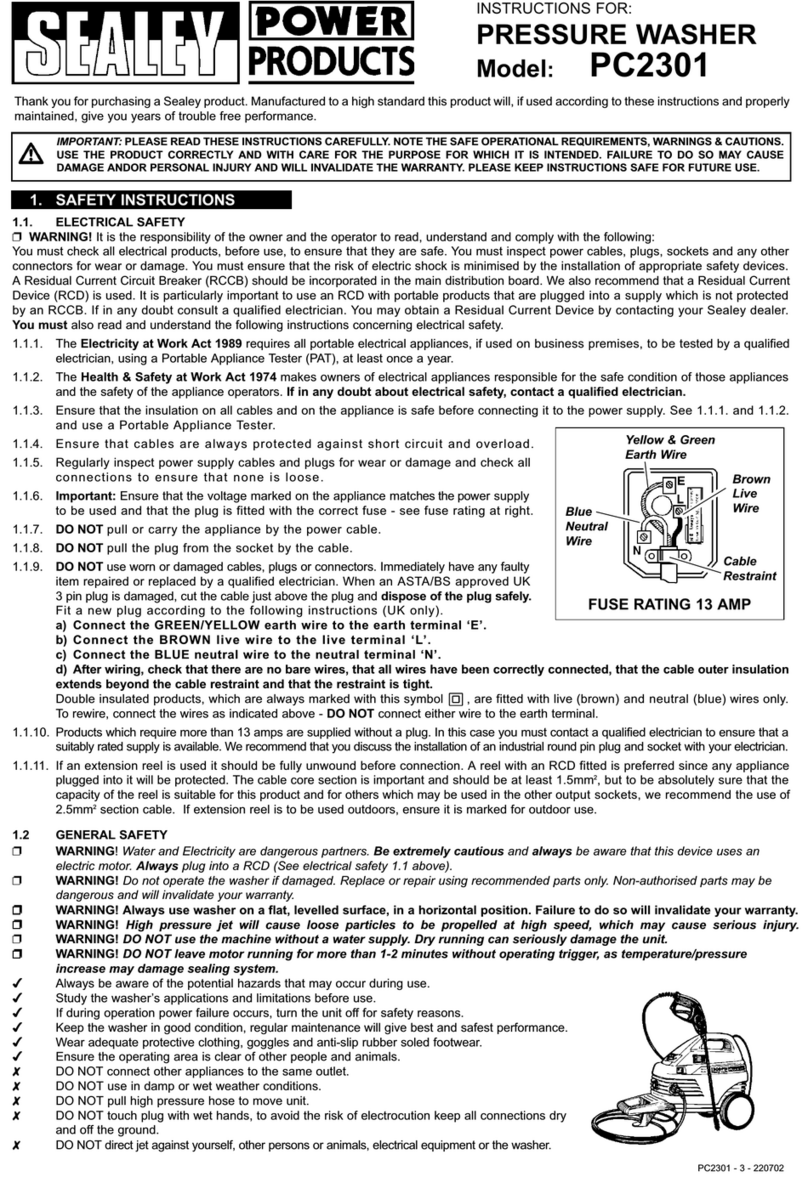

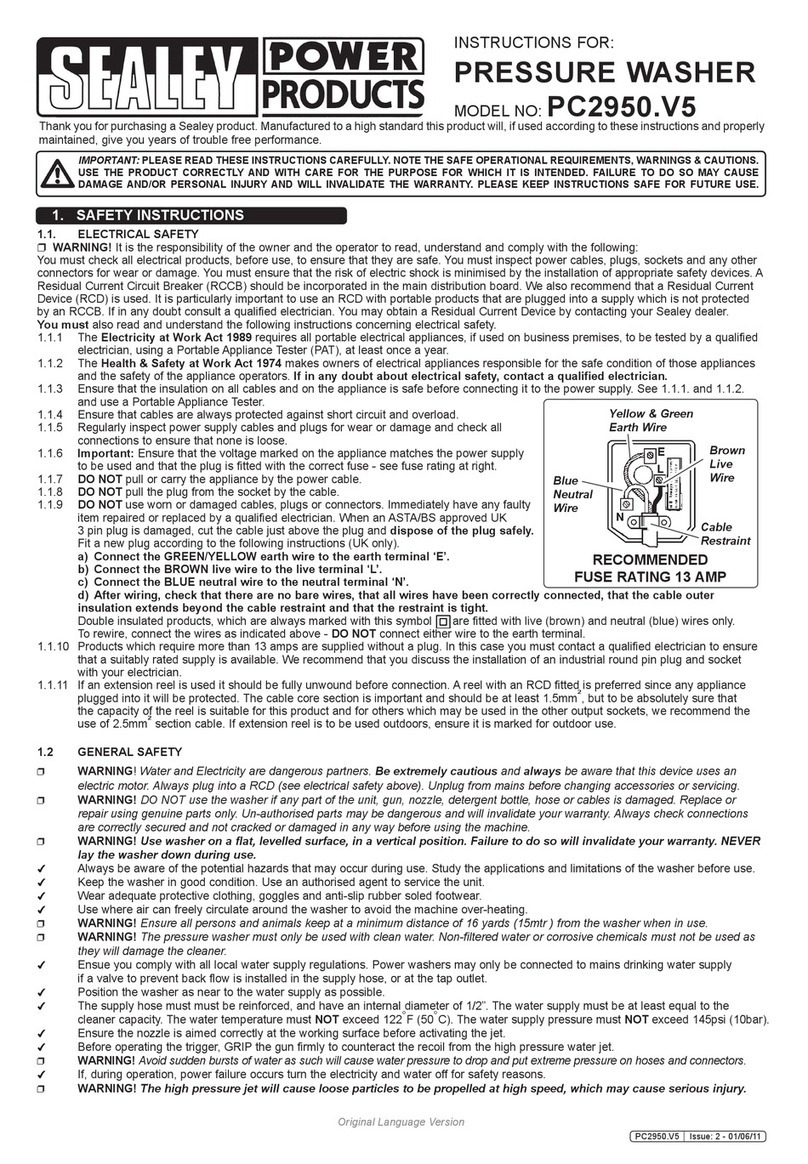

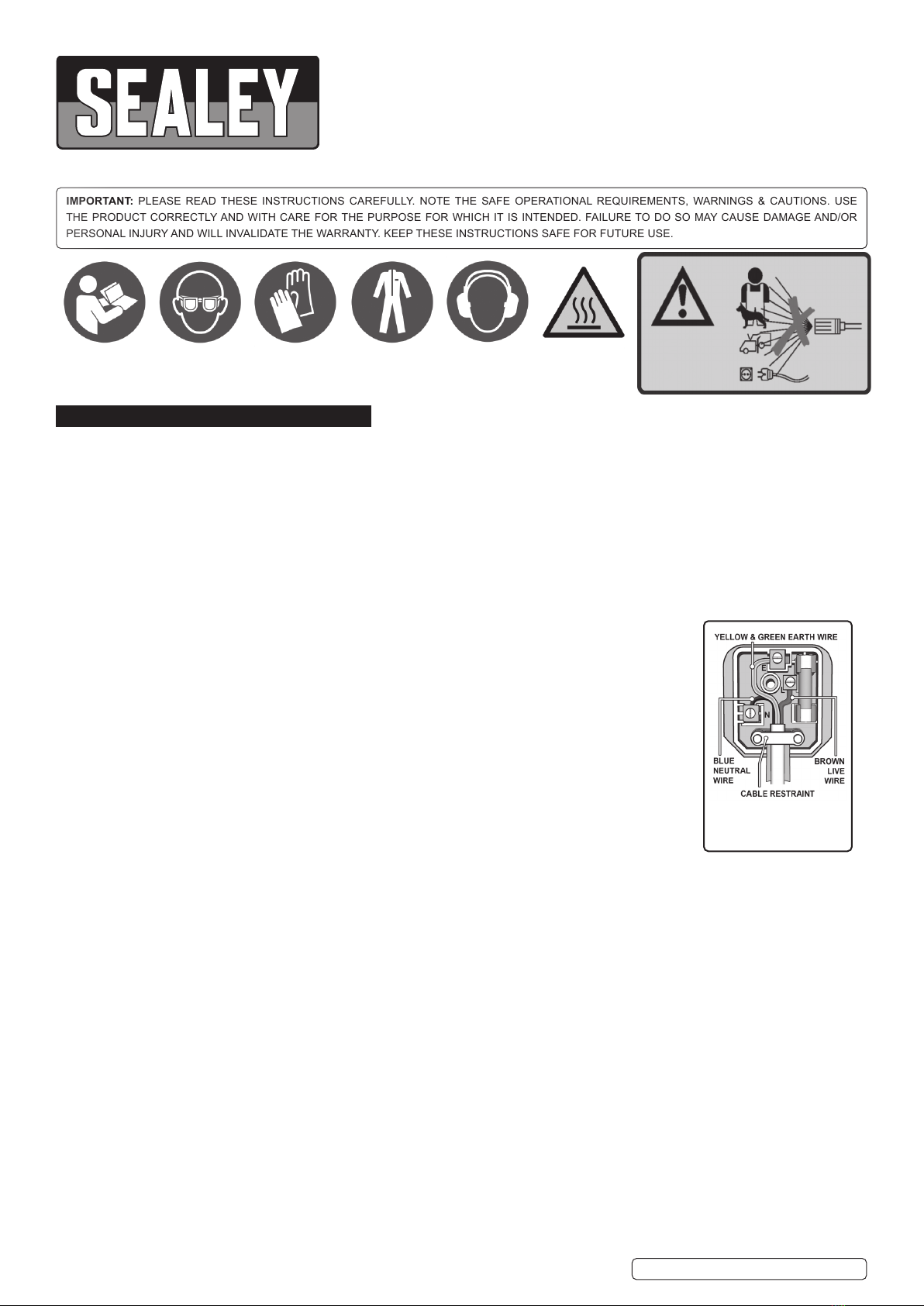

a) Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

b) Connect the BROWN live wire to the live terminal ‘L’.

c) Connect the BLUE neutral wire to the neutral terminal ‘N’.

Ensure that the cable outer sheath extends inside the cable restraint and that the restraint is tight.

Sealey recommend that repairs are carried out by a qualied electrician.

1.2. GENERAL SAFETY

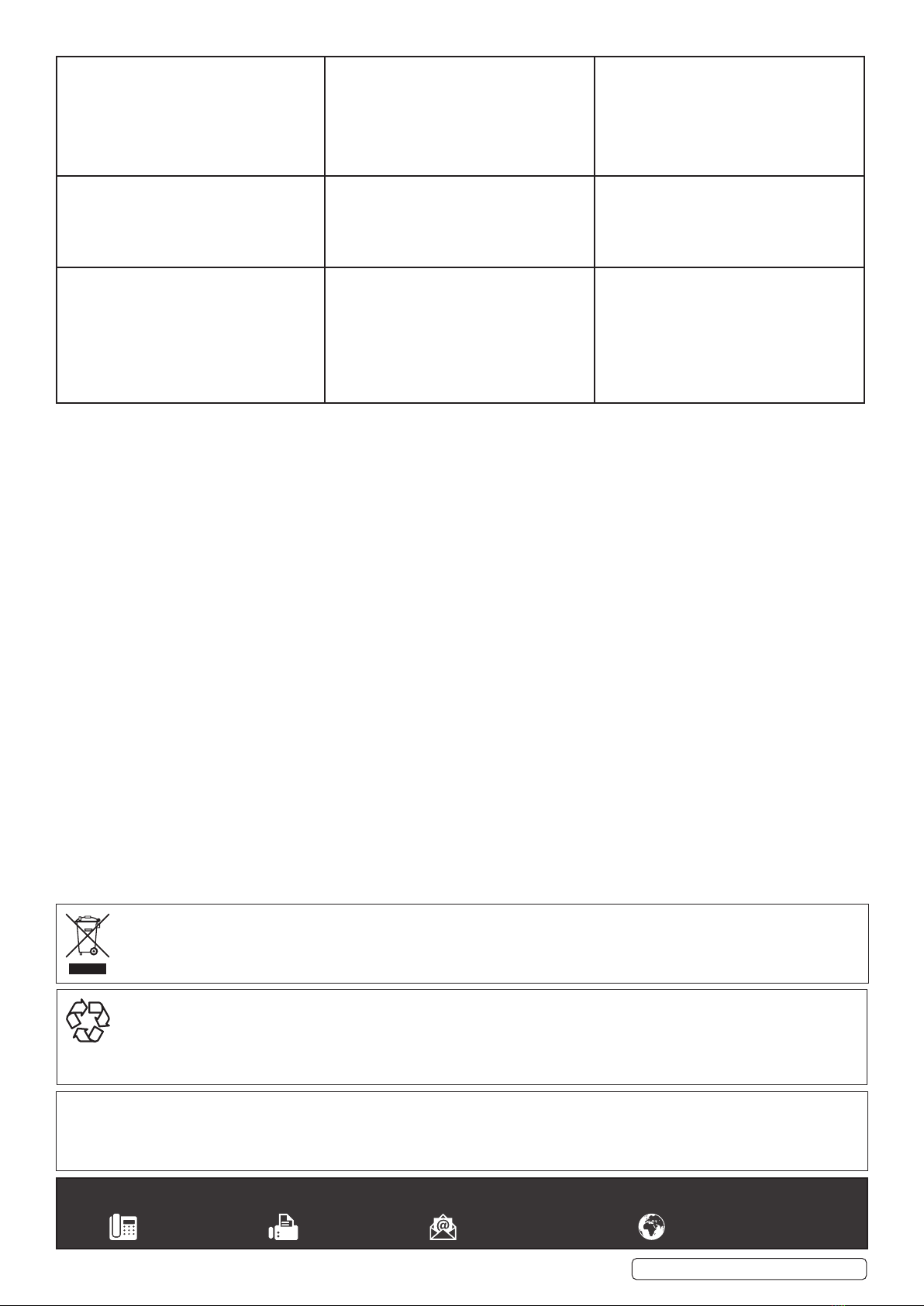

IMPORTANT The machine has to operate with clean water in order to avoid any damage to the machine.

IMPORTANT ALWAYS FLUSH the machine through thoroughly with cold water after hot water use.

IMPORTANT ALWAYS release any stored water after use.

WARNING! This appliance is for outdoor use only. DO NOT use in a closed place where ventilation may be insucient. DO NOT use

indoors unless adequate ventilation is assessed by national labour authorities. Ensure that any exhaust emissions are NOT in the

vicinity of air intakes.

WARNING! always disconnect electrical and water supply on completion of every job.

WARNING! DO NOT use the machine if a supply cord or important parts of the machine are damaged e.g. safety devices, high

pressure hoses, trigger or gun.

WARNING! The machine has been designed to be used with the detergent specied by the manufacturer. The use of other

detergents may put the machine’s safety at risk.

WARNING! Wear appropriate protective clothing: eye, ear, gloves and protective clothing. DO NOT use machine within 15metres

range of people unless they wear protective clothing.

WARNING! Be aware that if the nozzle is directed towards mechanical parts containing lubricant/grease, the grease will dissolve

and spread over the surrounding ground. Vehicle tyres/valves may only be cleaned from a minimum distance of 30cm, other the

vehicle tyre/tyre valve could be damaged by the high pressure jet. The rst indication of this is discolouration of the tyre. Damaged

vehicle tyres/tyre valves can be dangerous.

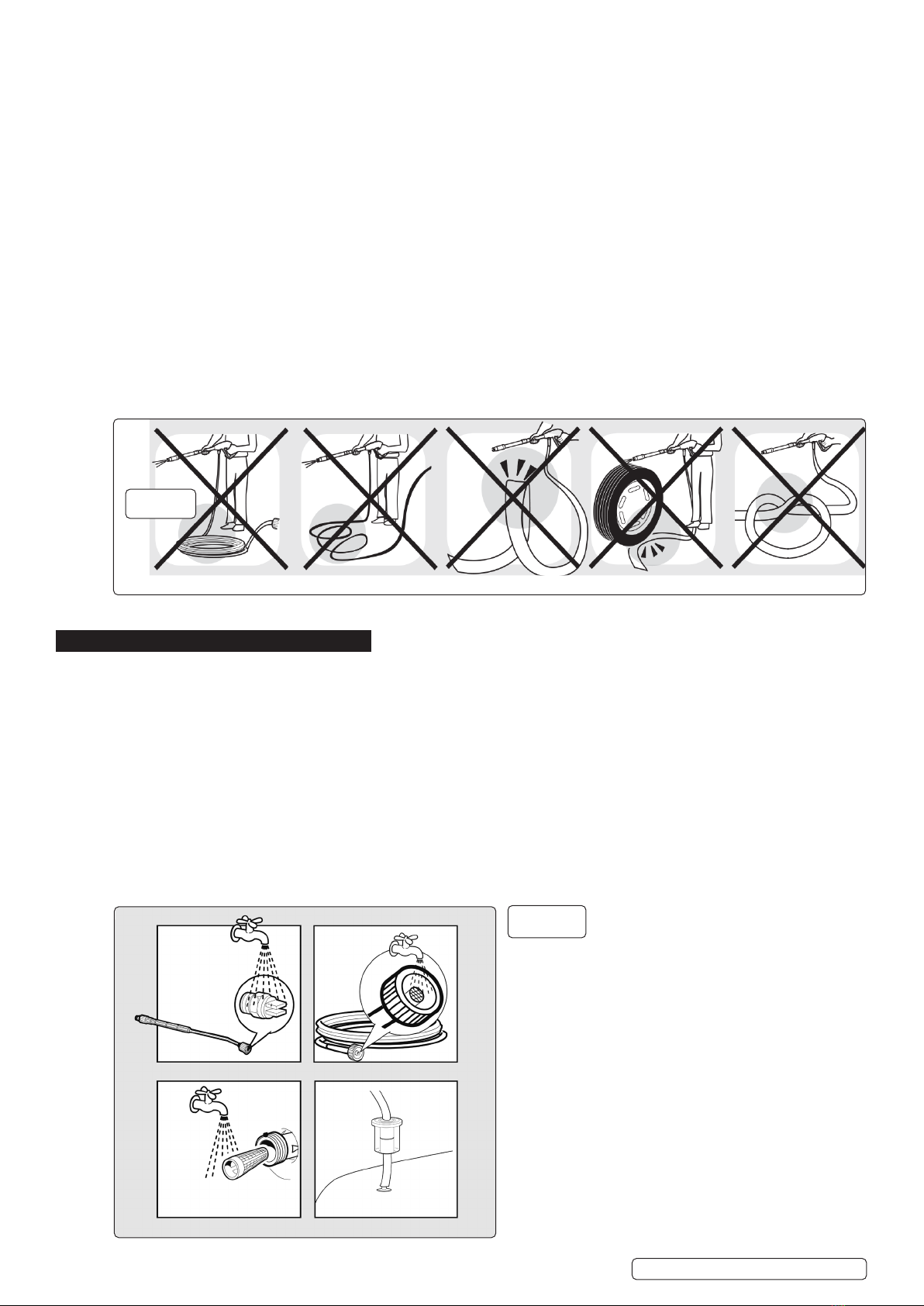

WARNING! High pressure jets can be dangerous if subject to misuse. The jet MUST NOT be directed at persons, animals, live

electrical equipment or the machine itself.

WARNING! High pressure hoses, ttings and couplings are important for the safety of the machine. Use only hoses, ttings and

couplings recommended by Sealey. Protect these components against damage by avoiding their improper use and protecting them

against bending, knocks and scratches.

8DO NOT leave in stand by for more than 5 minutes. Machine is tted with Automatic Stop System.

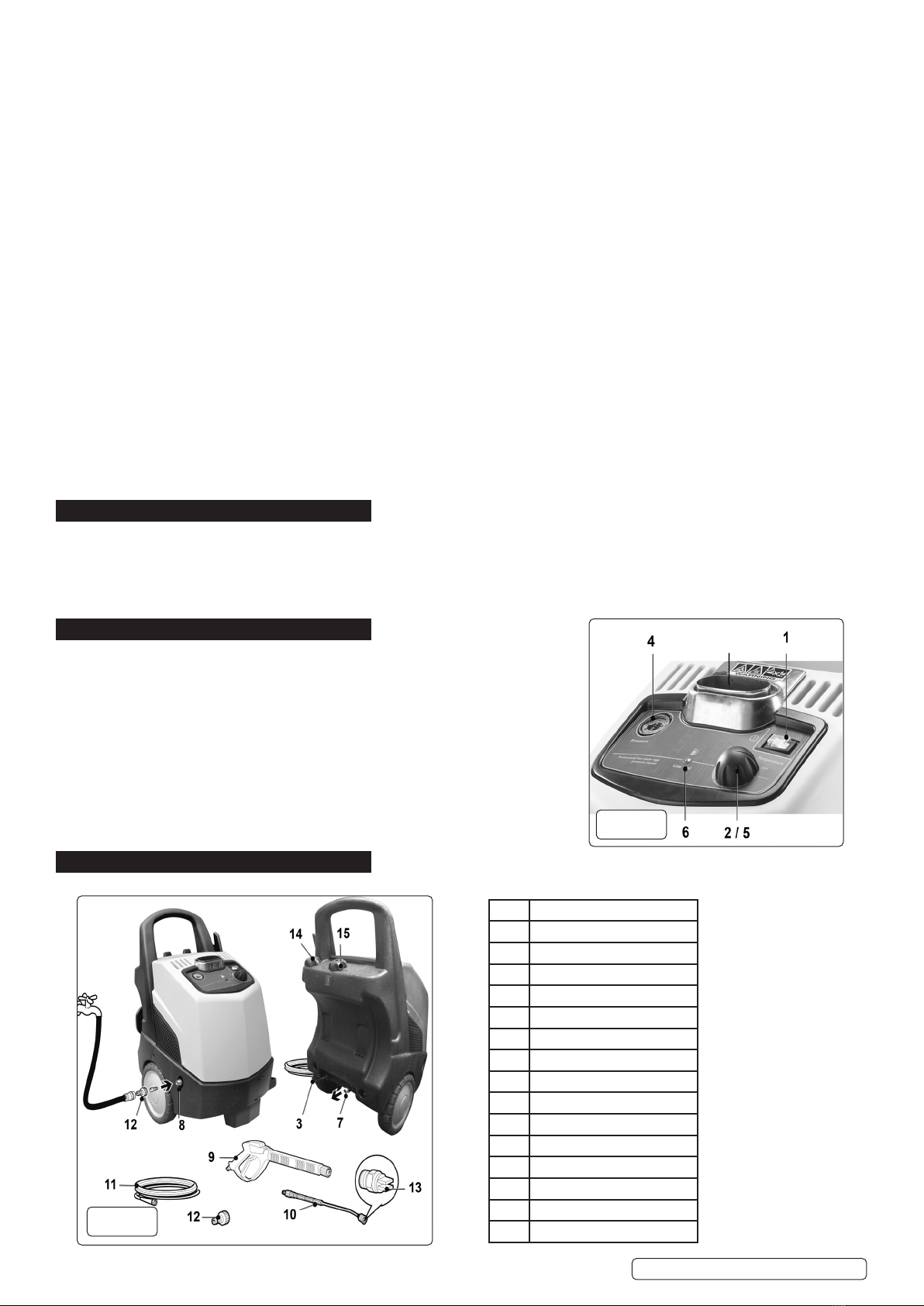

9 Switch Master switch (g.1.1) to O whenever it is left unattended.

PW2500HW Issue:1 12/01/21

Original Language Version

© Jack Sealey Limited

Refer to

instructions

Wear eye

protection

Wear protective

gloves

Wear ear

protection

Warning!

Hot surface

Wear protective

clothing

170BAR HOT WATER PRESSURE WASHER

230V

MODEL NO: PW2500HW

Warning! Jet must not be directed at

people, animals, live electrical

equipment or the machine itself.

Recommended fuse rating

13 Amp