over the surrounding ground. Vehicle tyres/tyre valves may only be cleaned from a minimum distance of 30 cm, otherwise the

vehicle tyre/ tyre valve could be damaged by the high-pressure jet. The rst indication of this is a discolouration of the tyre.

Damaged vehicle tyres/tyre valves can be deadly.

WARNING: High pressure jets can be dangerous if subject to misuse. The jet must not be directed at persons, animal, live

electrical equipment or the machine itself.

WARNING! The high pressure jet will cause loose particles to be propelled at high speed, which may cause serious injury.

WARNING: High pressure hoses, ttings and couplings are important for the safety of the machine. Use only hoses, ttings and

couplings recommended by the manufacturer. (it is extremely important to protect these components against damage by avoiding

their improper use and protecting them against bending, knocks and scratches).

9The appliance can be used for washing surfaces outdoors, whenever pressurised water is required to remove dirt.

WARNING: This appliance is equipped with T.S.– Total Stop : these appliances should not be left in standby for more than

5 minutes.

WARNING! DO NOT operate the machine without a water supply. Dry running can seriously damage the unit.

9 Switch the appliance o completely (master switch on (0) OFF) whenever it is left unattended.

9Every machine is tested in its operating conditions, so it is normal for a few drops of water to be left inside it.

9Take care not damage the electric cable. If the supply cord is damaged, it must be replaced by the manufacturer, its service agent

or similarly qualied persons in order to avoid a hazard

8DO NOT move the unit by pulling the hoses or electrical cables. Use the handle.

9 Appliance with uid under pressure. Keep a rm hold on the gun and be prepared to take the kickback pressure. Only use the high

pressure nozzle provided with the appliance.

9Children should be supervised to ensure that they DO NOT play with the appliance.

8DO NOT start the high-pressure cleaner without rst completely unwinding the high-pressure hose.

WARNING: When winding and unwinding the hose take care not to cause the high-pressure cleaner to overturn.

9 Before unwinding or winding the hose, switch the machine o and release the pressure in the hose itself (switching o).

8DO NOT use the washer with ammable or toxic liquids or any other product. Use only recommended detergent. Unapproved

detergents may corrode the machine cover and accessories.

8DO NOT spray ammable liquids risk of explosion.

8DO NOT direct the jet against yourself or others in order to clean clothes or footwear.

WARNING: Water that has owed through backow preventer’s is considered to be non potable.

WARNING! The pressure washer must only be used with clean water. Unltered water or corrosive chemicals must not be used as

these will damage the cleaner.

WARNING: Improper extension cables can be dangerous. If an extension cord is used, it must be suitable for outdoor use, and

the connection must be kept dry and clear of the ground. It is recommended that this be done using a cable reel that holds the plug

at least 60 mm from the ground.

9If an extension cord is used, the plug and socket must be of watertight construction.

9 If, during operation, power failure occurs turn the electricity and water o for safety reasons.

WARNING: During the use of high pressure cleaners, aerosols may form. Inhalation of aerosols can be dangerous to health.

WARNING: Depending on the application, shielded nozzles can be used for high pressure cleaning, which will drastically reduce

the emission of hydrated aerosols. However, not all applications allow the use of such a device. If the armoured nozzles are not

applicable for aerosol protection, a respiratory mask of class FFP 2 or equivalent may be necessary, depending on the cleaning

environment.

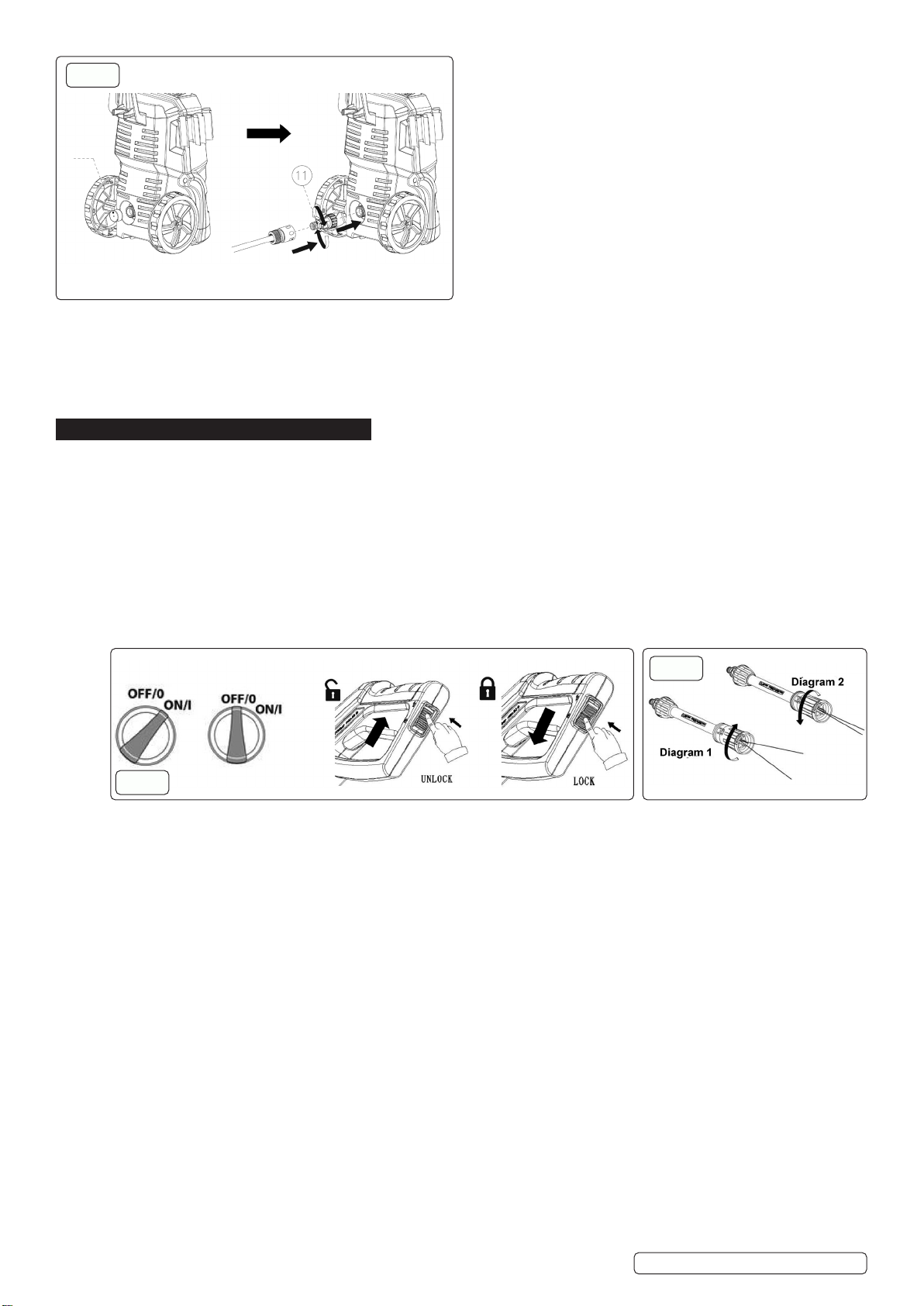

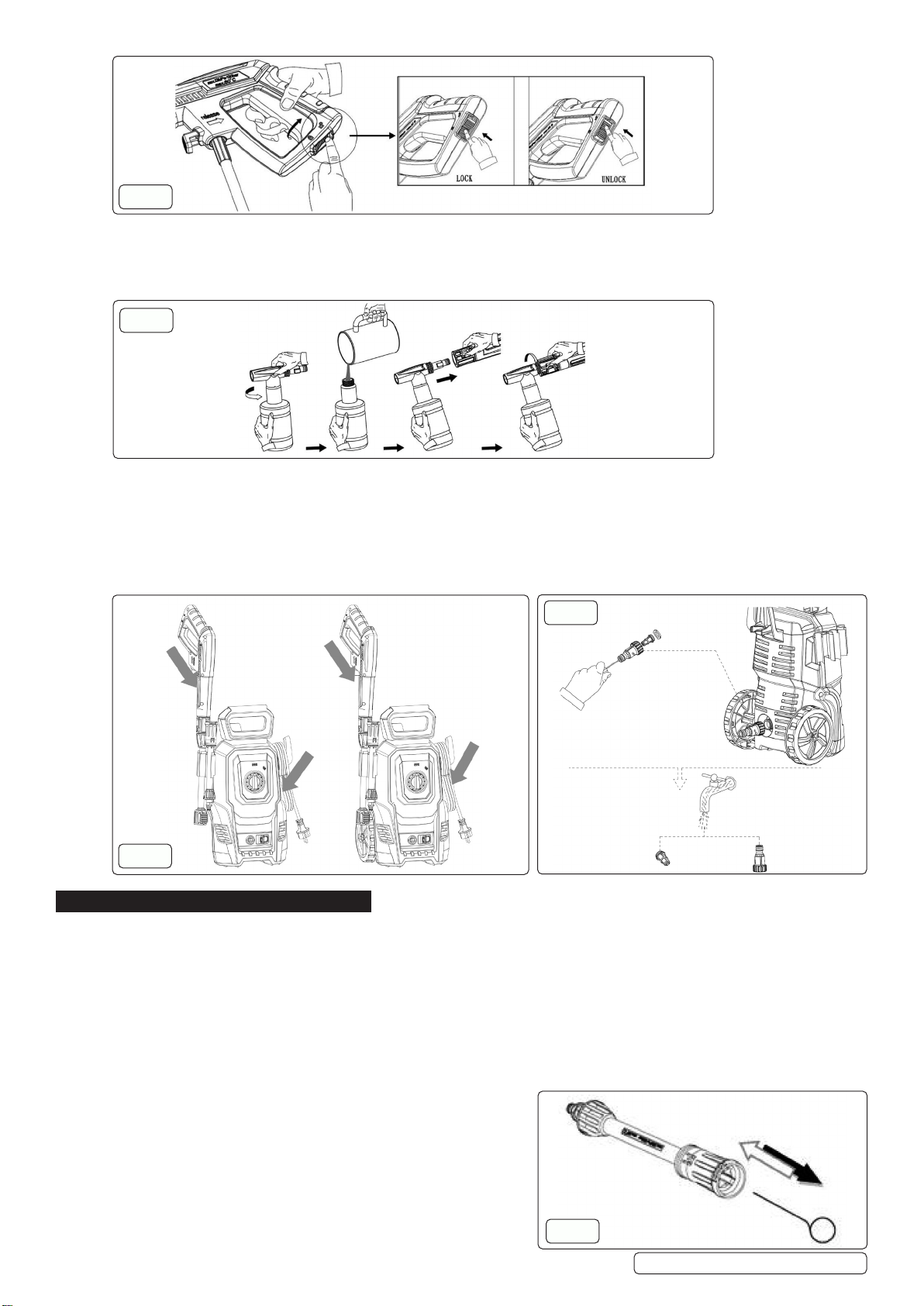

WARNING: the gun is tted with a safety catch.

9 Whenever use of the machine is interrupted it is important to operate the safety catch to prevent accidental activation of the jet.

9Safety features: gun equipped with safety locking device, appliance equipped with (Class I) overload cut out, pump equipped with

by-pass valve or shutdown device.

9The safety button on the gun is not there to lock the lever during operation, but to prevent its accidental operation.

9Ensure the nozzle is aimed correctly at the work surface before switching on the machine.

9 Before activating the trigger, grip the gun rmly to counteract the recoil from the high pressure water jet.

WARNING! Avoid sudden bursts of water as these will cause water pressure to drop and put extreme pressure on hoses and

connectors.

WARNING: The appliance is equipped with a motor protection device: in case of device intervention, wait some minutes or, in

alternative, disconnect and re-connect the product to the electric system. In case this problem repeats again or if the product does

not start again, take the product to the nearest After Sales Service Point

WARNING: The machine must be always kept on horizontal bases, in a safe and stable way.

WARNING! Use washer on a at, levelled surface, in an upright position. Failure to do so will invalidate your warranty.

8NEVER lay the washer down during use.

8DO NOT adjust any internal control valves, as they have been factory set.

8DO NOT connect other appliances to the machine inlet or outlet.

8DO NOT use hoses and ttings other than those designed for use with this machine.

8DO NOT touch plug with wet hands. To avoid the risk of electrocution keep all connections dry and o the ground.

8DO NOT use washer if you are tired or under the inuence of alcohol, drugs or intoxicating medication.

8DO NOT allow children or untrained persons to operate the washer.

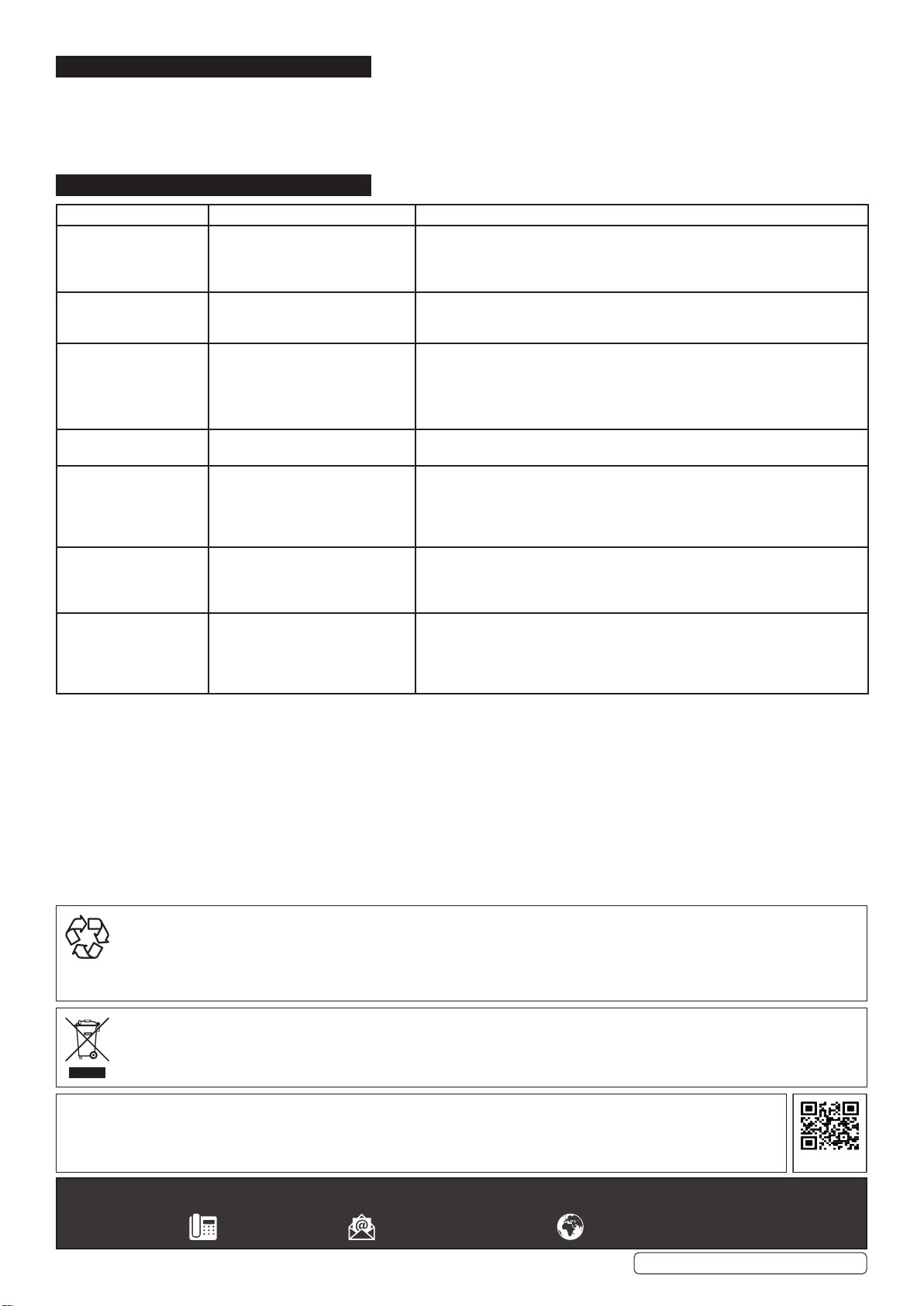

WARNING! Discharge residual pressure before disconnecting the washer hose. Pressure left in unit may cause injury.

9After use, disconnect washer from electrical mains and water supply and store in a safe, dry, childproof area.

9Protect from freezing conditions during winter.

9Always use the appliance at the lowest pressure setting when cleaning in the vicinity of wheels and tyres.

NOTE: This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities or

lack of experience and knowledge, unless they have been given supervision or instruction concerning the use of the appliance by

a person responsible for their safety. Children should be supervised to ensure that they DO NOT play with the appliance.

Original Language Version

© Jack Sealey Limited PW1610 Issue 1 17/11/2022