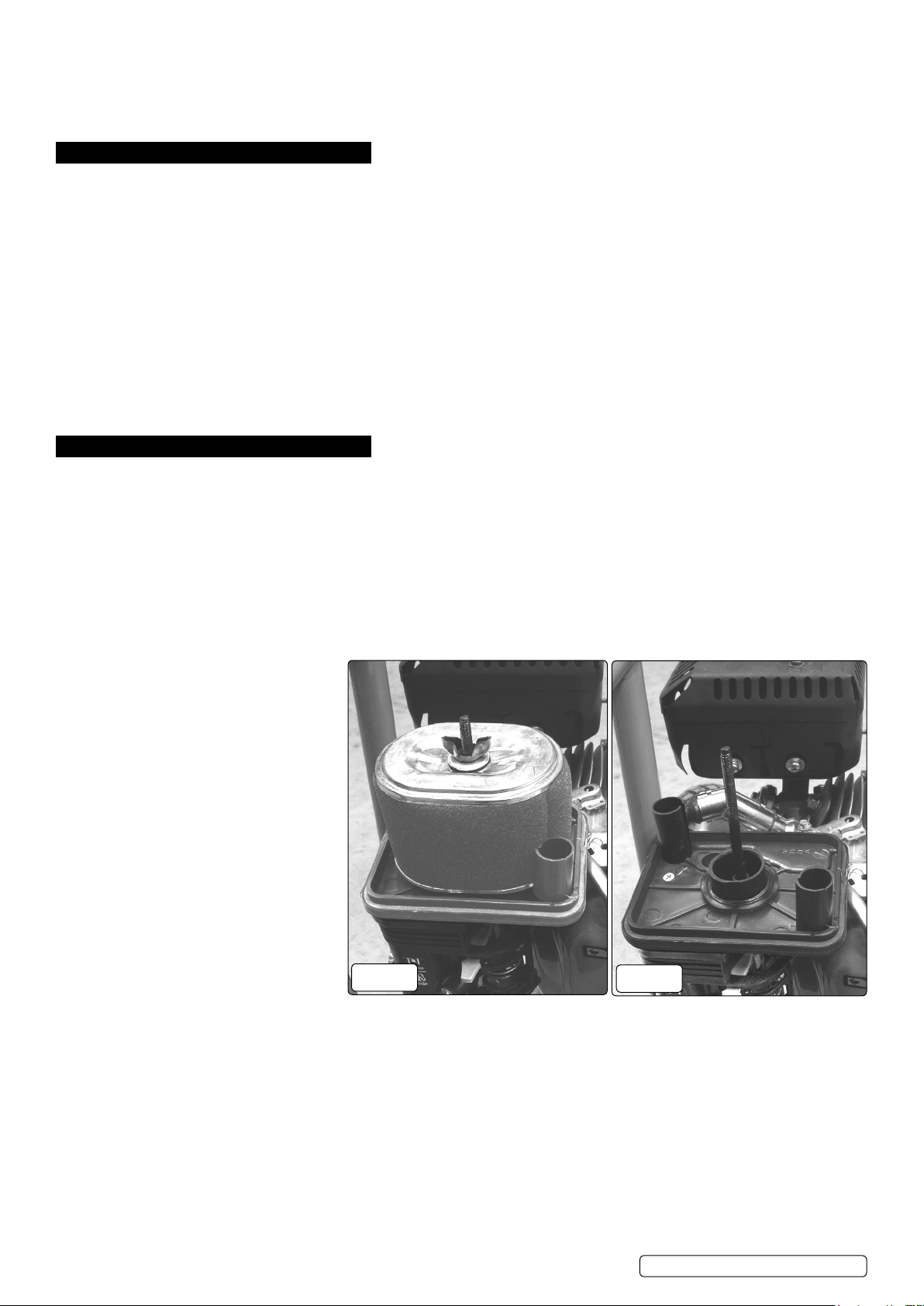

5.2.6. Take hold of the recoil starter handle (see g.9) and pull it slowly until you feel

resistance, then let it return slowly.

5.2.7. Now pull the starting handle hard and fast all the way out. Use two hands if

necessary.

5.2.8. If the engine doesn’t start repeat the process from 5.2.2.

5.2.9. Once started adjust throttle lever to the required setting and return the choke to the

open position when the engine is warm.

5.3. SHUT DOWN PROCEDURE

5.3.1. When you have nished cleaning, stop the engine by pushing the throttle lever fully

to the right. (See g.9) and turn the engine switch to the OFF position.

5.3.2. Turn off the fuel tap. (See g.9)

5.3.3. In an emergency turn the engine switch to the OFF position.

WARNING! DE-PRESSURIZE After cleaning is completed, turn off the water

supply and pull the trigger to de pressurize the unit. Failure to do so might result

in personal injury due to discharge of high-pressure water.

5.4. CLEANING WITH DETERGENTS

IMPORTANT This pressure washer is intended for use with special pressure washer detergents only. DO NOT use powdered soaps,

this will clog the injection system. Follow the detergent manufacturer’s directions.

IMPORTANT Working with a detergent ensures quick soaking of the dirt, and allows the high-pressure water to penetrate and remove

the dirt more effectively. Always spray detergent on a dry surface, DO NOT pre soak the area. Soaking the surface dilutes the

detergent and reduces its cleaning ability.

WARNING Damage may occur to painted surfaces if chemicals (detergents) are allowed to dry on them. Wash and rinse a small section

at a time. Avoid working on hot surfaces or under direct sunlight.

5.4.1. When using detergent, always use the black detergent nozzle.

5.4.2. When applying detergents, always operate the unit at a low water pressure throttle (fig.9) (set to SLOW position).This provides a

gentle application of the detergent, with the water pressure equivalent to a garden hose. Always test the detergent in a concealed area

before use.

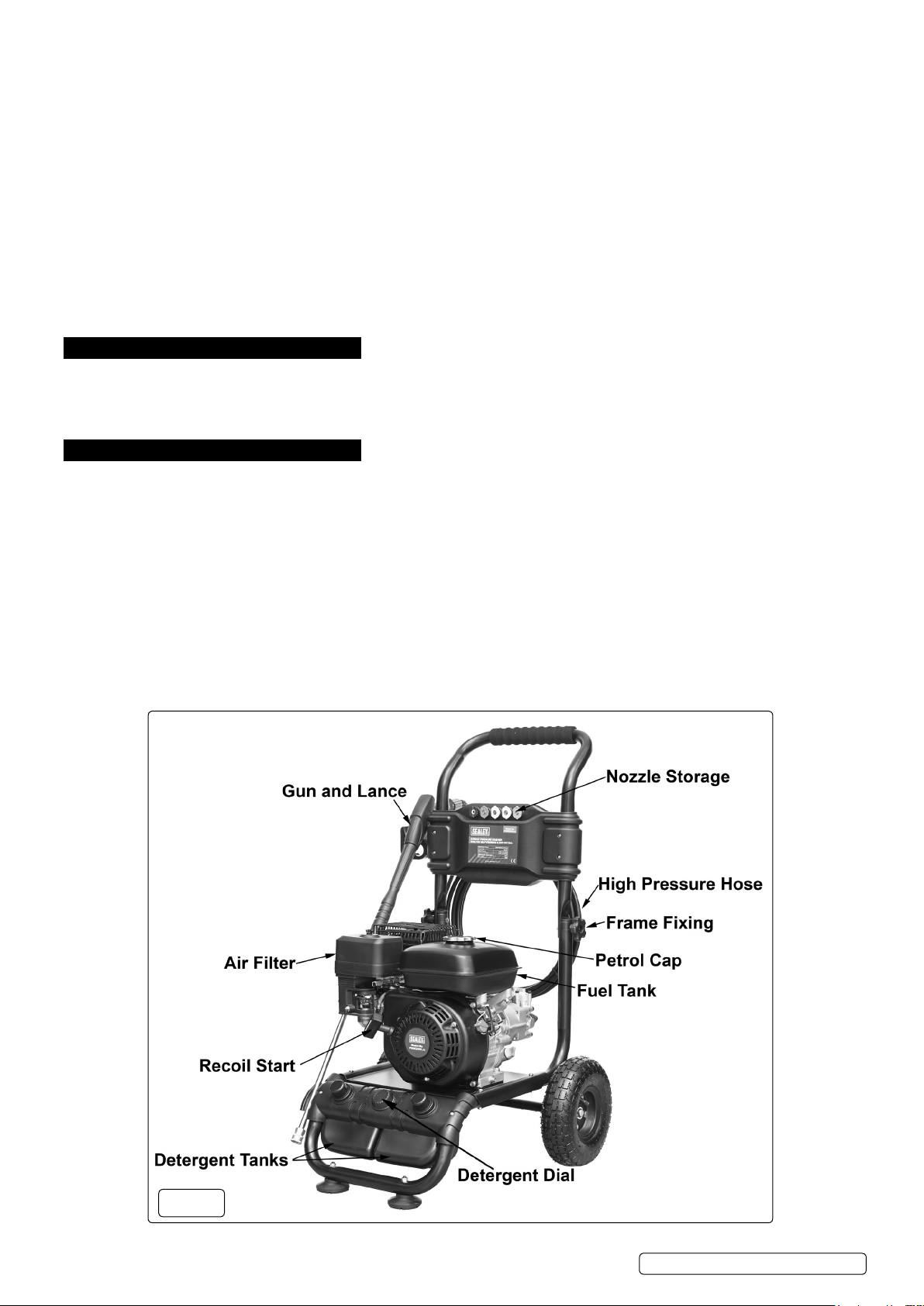

5.4.3. Pour two types of detergents into separate detergent tanks (fig.1). It is recommended to have one detergent tank filled with all-purpose

detergent, and the other filled with a more specific cleaning detergent, depending on the surface to be cleaned.

5.4.4. The liquid detergent will be mixed with water automatically, and discharged through the detergent nozzle at a low pressure.

5.4.5. Use the detergent dial (fig.1) to control the type and amount of detergent used using the scale as reference.

5.4.6. Set the detergent dial to OFF position in order to shut off detergent supply.

5.4.7. Allow detergent to remain on the surface for a short time before rinsing. DO NOT allow detergent to dry on the surface.

5.5. SHUTTING DOWN AND CLEANING UP

5.5.1. Skip step 5.5.2 if you are not using detergent.

5.5.2. After cleaning with detergent, fill the detergent tank with clean water. Spray water at a low pressure for one minute, so that all detergent

is flushed out of the system.

5.5.3. Stop the engine (→ Section 5.3 Shut Down Procedure).

5.5.4. Turn off the water supply and disconnect the water supply from the water inlet.

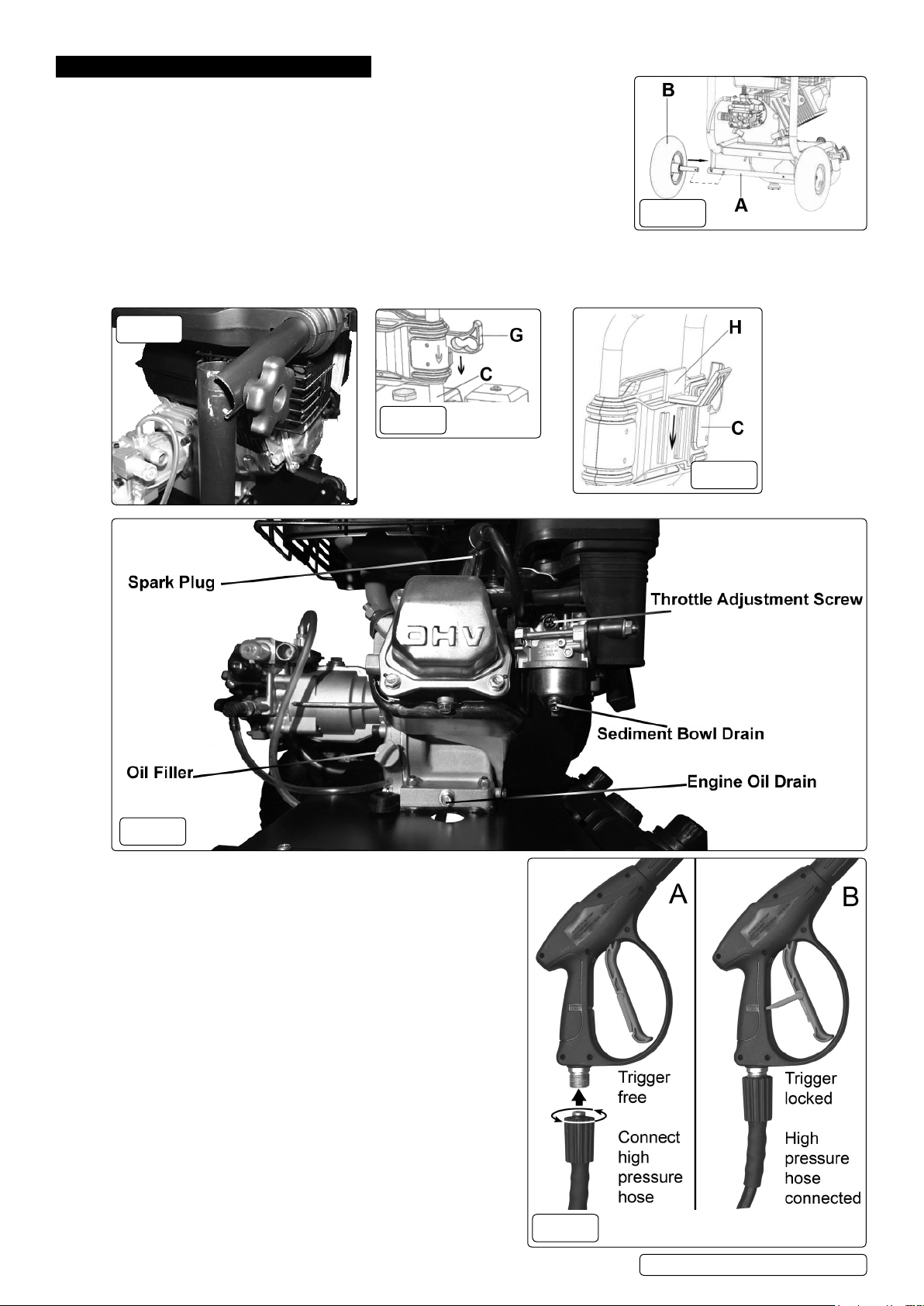

5.5.5. Point spray gun in safe direction, push trigger lock, and squeeze spray gun trigger to relieve retained high water pressure. Engage the

trigger safety lock (fig.7) on the spray gun.

5.5.6. Disconnect the garden hose from the pump.

5.5.7. Disconnect the pressure hose from the pump and pressure gun for storage. For long-term storage instructions, see section 7.8.

5.5.8. Rewind the pressure hose and attach it to the hose hook.

5.5.9. Disconnect the gun and wand, then insert them into the upper gun holder.

5.5.10. Fold the handle and store.

NOTE: After turning off the machine, wait for 20 minutes to prevent plastic parts from being burned by muffler, then fold the handle.

5.6. TRANSIT.

5.6.1. In the upright position the washer stands on four feet and the two wheels are off the ground. The front feet have suckers attached which

help to eliminate creep. The rear feet are out of sight between the wheels. To move the unit tip it backwards on the rear feet until the

wheels make contact with the ground. Keep the unit well tipped back as you move it.

5.7. ADDING/CHECKING OIL

IMPORTANT Oil has been drained for shipping. Failure to fill engine with oil before starting engine

will result in permanent damage and will void engine warranty.

WARNING! Always check the oil level before starting the engine, making sure the pressure

washer is on a level surface.

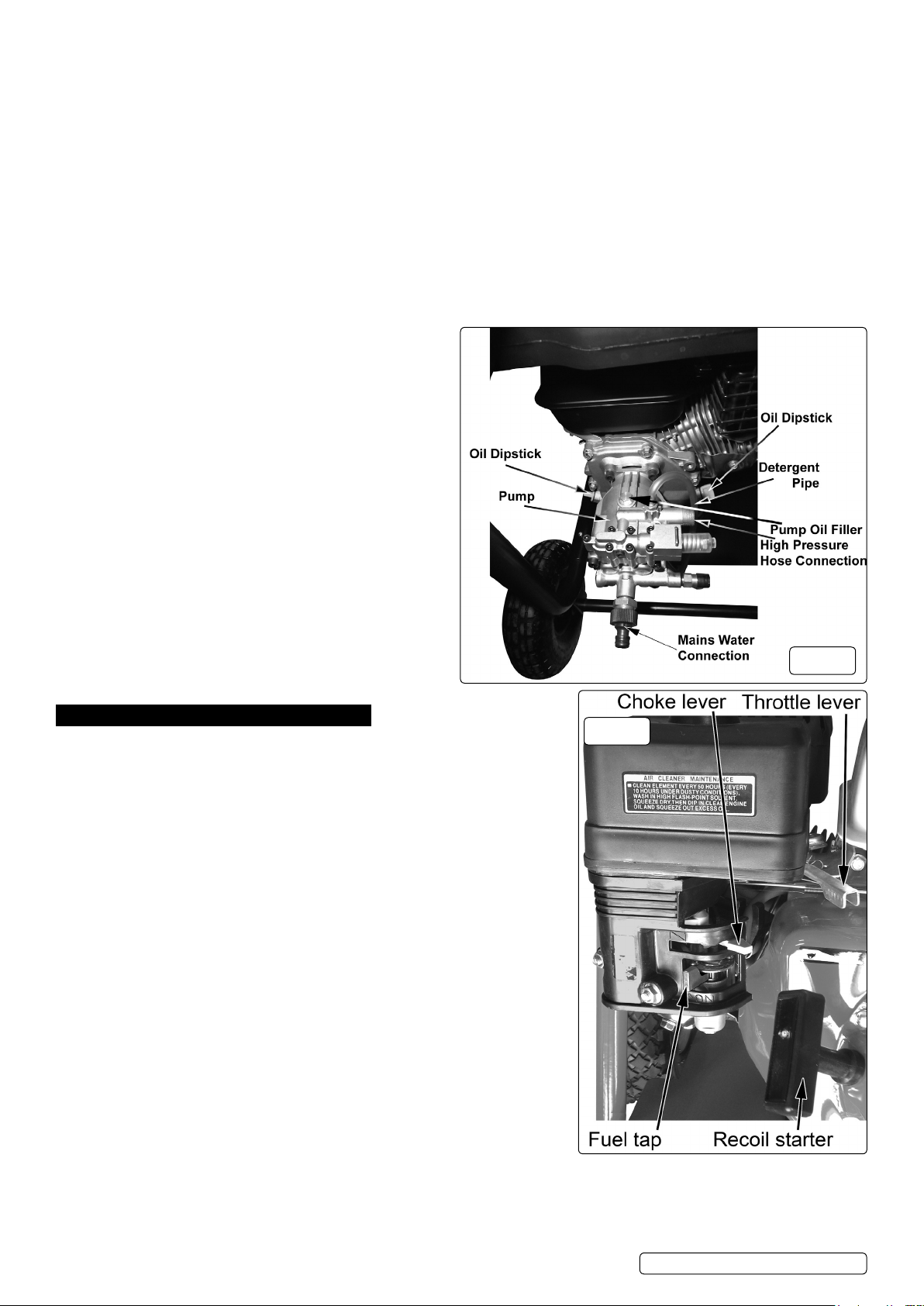

5.7.1. Remove oil tank dipstick (fig.8) and wipe it with a clean cloth.

5.7.2. Replace and retighten the dipstick.

5.7.3. Remove the dipstick again and check the oil level. It should be at the top of the full indicator on

the dipstick.

5.7.4. If low, add oil slowly into the oil tank. DO NOT overfill. After adding oil, wait one minute and then

recheck the oil level.

5.7.5. Replace and retighten the dipstick.

NOTE: When adding oil, use oil funnel.

5.7.6. Check the pump oil level by removing the pump filler cap (fig.8). The pump should be topped

up with 10w-30oil (the oil capacity of the pump is 0.5ltr).

5.8. ADDING FUEL

9Fill the fuel tank outdoors or in well-ventilated areas.

9Make sure there is enough fuel in the fuel tank before operating the pressure washer.

9 Use only clean, fresh, unleaded fuel. Use a minimum of 87octane/87 AKI (91 RON).

9 Keep fuel away from sparks, open ames, pilot lights, heat, and other ignition sources.

9 Check fuel hoses, tank, caps, and ttings frequently for cracks or leaks. Replace if necessary.

9 If fuel spills, wait until it evaporates before starting engine.

8DO NOT use old petrol, and DO NOT mix oil with petrol.

g.10

g.11

Original Language Version

© Jack Sealey Limited PWM2500.V2 Issue 1 29/11/19