999 WARNING! The high pressure jet will cause loose particles to be propelled at high speed, which may cause serious injury.

999 WARNING! DO NOT operate the machine without a water supply. Dry running can seriously damage the unit.

999 WARNING! DO NOT leave the washer switched on for more than 15 minutes without operating the trigger.

9899 DO NOT obstruct ventilation grilles during operation.

9899 DO NOT use the washer with flammable or toxic liquids or any other product. Use only recommended detergent. Unapproved

detergents may corrode the machine cover and accessories.

9899 DO NOT jam the trigger in the operating position.

9899 DO NOT adjust any internal control valves, as they have been factory set.

9899 DO NOT connect other appliances to the machine inlet or outlet.

9899 DO NOT use hoses and fittings other than those designed for use with this machine.

8DO NOT move the unit by pulling the hoses or electrical cables. Use the handle and transport by means of the wheels.

8DO NOT touch plug with wet hands. To avoid the risk of electrocution keep all connections dry and off the ground.

8DO NOT direct jet against yourself, other persons, animals, electrical equipment or the machine itself.

8DO NOT use washer if you are tired or under the influence of alcohol, drugs or intoxicating medication.

8DO NOT allow children or untrained persons to operate the washer.

999 WARNING! Discharge residual pressure before disconnecting the washer hose. Pressure left in unit may cause injury.

9After use, disconnect washer from electrical mains and water supply and store in a safe, dry, childproof area.

9999 Protect from freezing conditions during winter.

NOTE: Pressure washer shall not be used by children. Children should be supervised to ensure that they do not play with the machine.

The machine can be used by people with reduced physical, sensory or mental capabilities or lack of experience and knowledge if they

have been given supervision or instruction concerning the use of the machine in a safe way and understand the hazards involved.

2. i INTRODUCTION

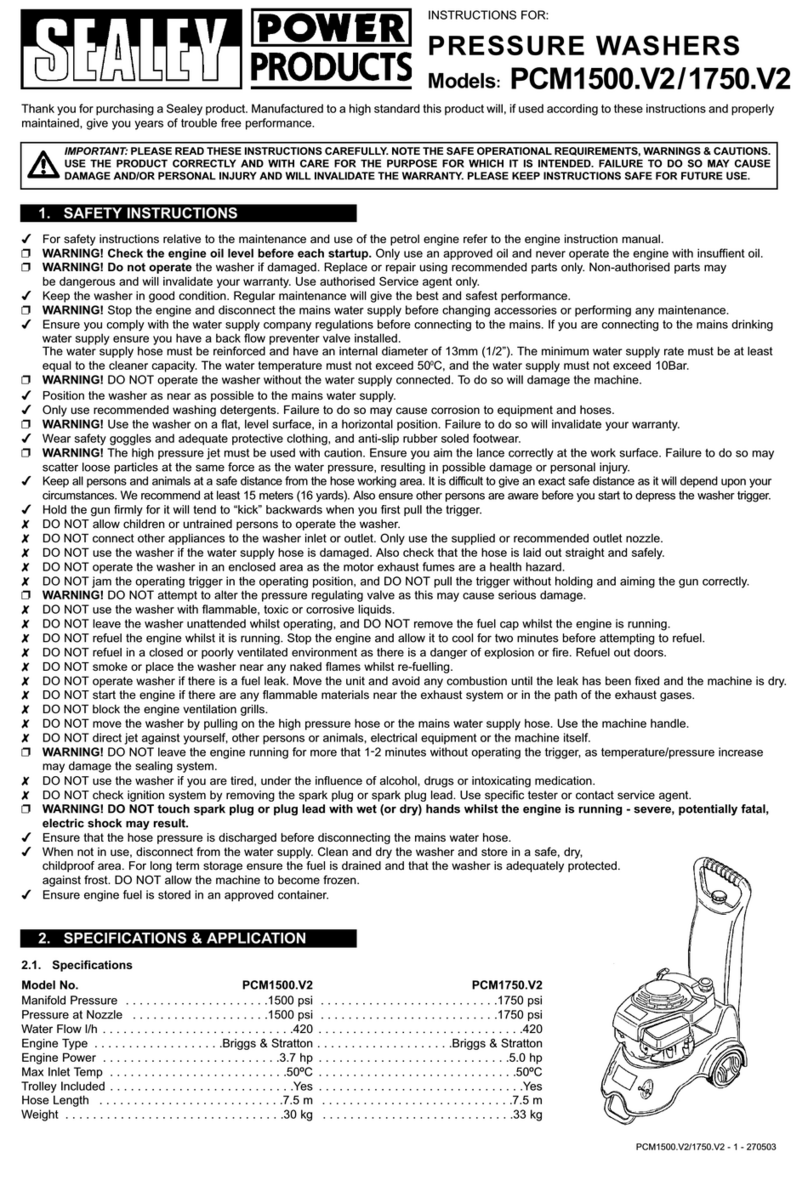

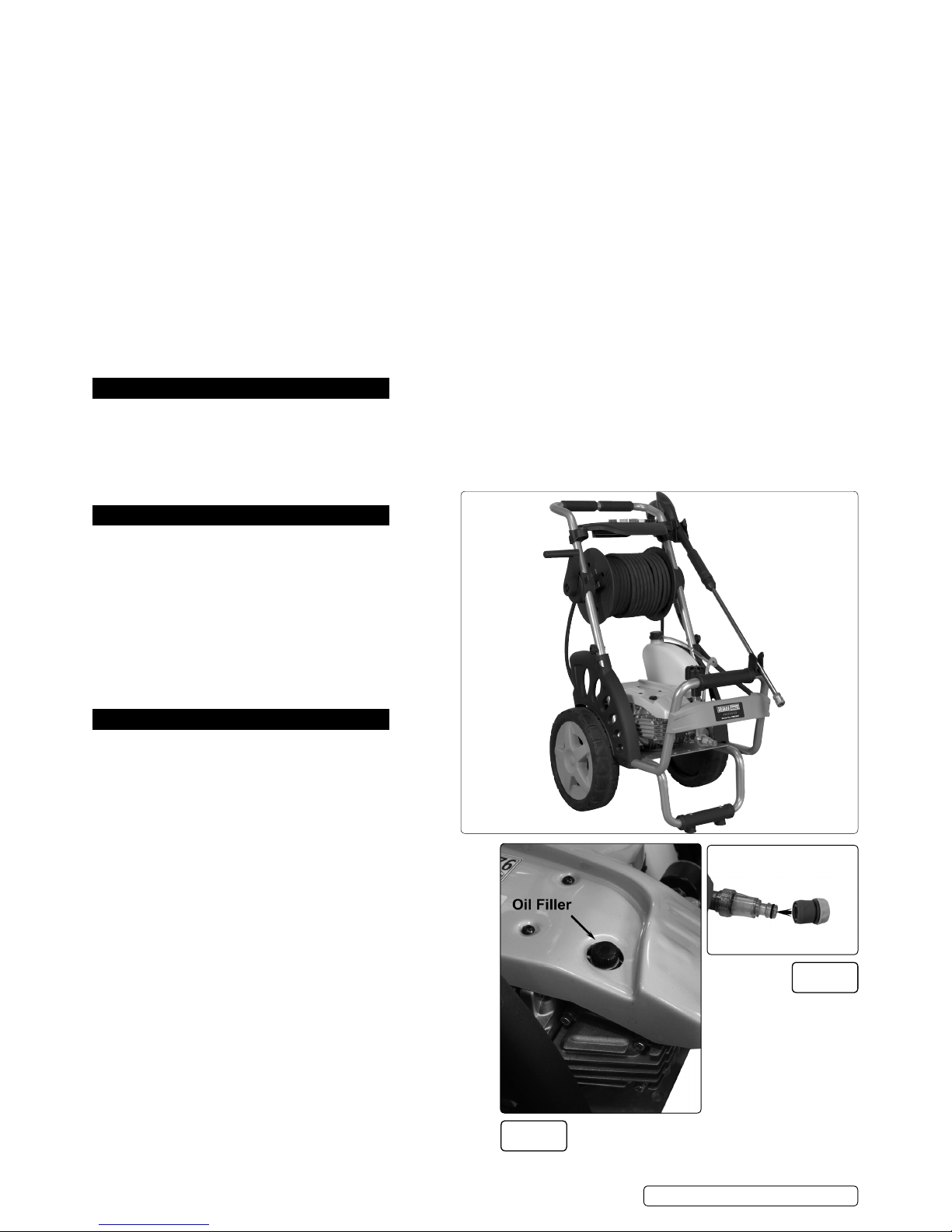

Professional unit, designed and manufactured in Italy. Ideal for a wide variety of applications including commercial and agricultural use. Fitted

with a powerful 2500W induction motor and brass pump head and ttings with ceramic pistons. Capable of pumping up to 8.3 litres of water per

minute with a maximum pressure of 150bar. The PW5000 features Automatic Total Stop System (TSS) technology which switches the motor

on and off when the lance trigger is operated, prolonging motor life. Fitted with 10mtr hose reel, built-in pressure gauge, adjustable pressure

controls and 3ltr detergent tank. Supplied with 5 interchangeable nozzle attachments. Manufactured with a lightweight, durable aluminium frame

and large heavy-duty wheels.

3. SPECIFICATION

Model No:................................................................ PW5000

Maximum Pressure: ..................................... 150bar(2200psi)

Water ow: ................................................................498ltr/hr

Motor power: ...............................................................2500W

Supply:....................................................................230V-13A

Total stop system: ............................................................ Yes

Hose length:..................................................................10mtr

Weight:........................................................................ 33.2kg

Wash nozzles:.. pencil jet, fan jet, 15°, 25°, 40°, low pressure

Noise power: ..................................................................92dB

Noise pressure:.........................................................83.96dB

4. ASSEMBLY

4.1. Attach handle/reel assembly to the machine base by

sliding the handle tubes over tubular stubs protruding

from base and securing by means of M6 x 40 bolts

(x2) and securing knobs.

4.2. Attach winding handle to the reel by 4mm hex bolt.

WARNING! Ensure that the transit plug tted to the

oil ller is replaced by the vented dipstick supplied.

(See g.1)

4.3. Connecting the water supply.

4.3.1. Use a reinforced hose pipe with an internal diameter of 1/2” and

connect to the mains water supply. Before attaching the hose to

the pressure washer flush the hose through with some clean water

to remove any foreign matter from within the hose.

4.3.2. Connect female quick connection hose fitting to the clear inlet filter

on the front of the machine (fig.2).

4.3.3. Push male leader hose connection (fig.3.1.) into the pump outlet

connector (fig.3.2) and secure by tightening the collar (fig.3.3). Push

the nozzle into the gun as shown in fig.4 (1 and 2) and screw the

threaded male lance connector into the gun, again ensuring that

the connection is tight.

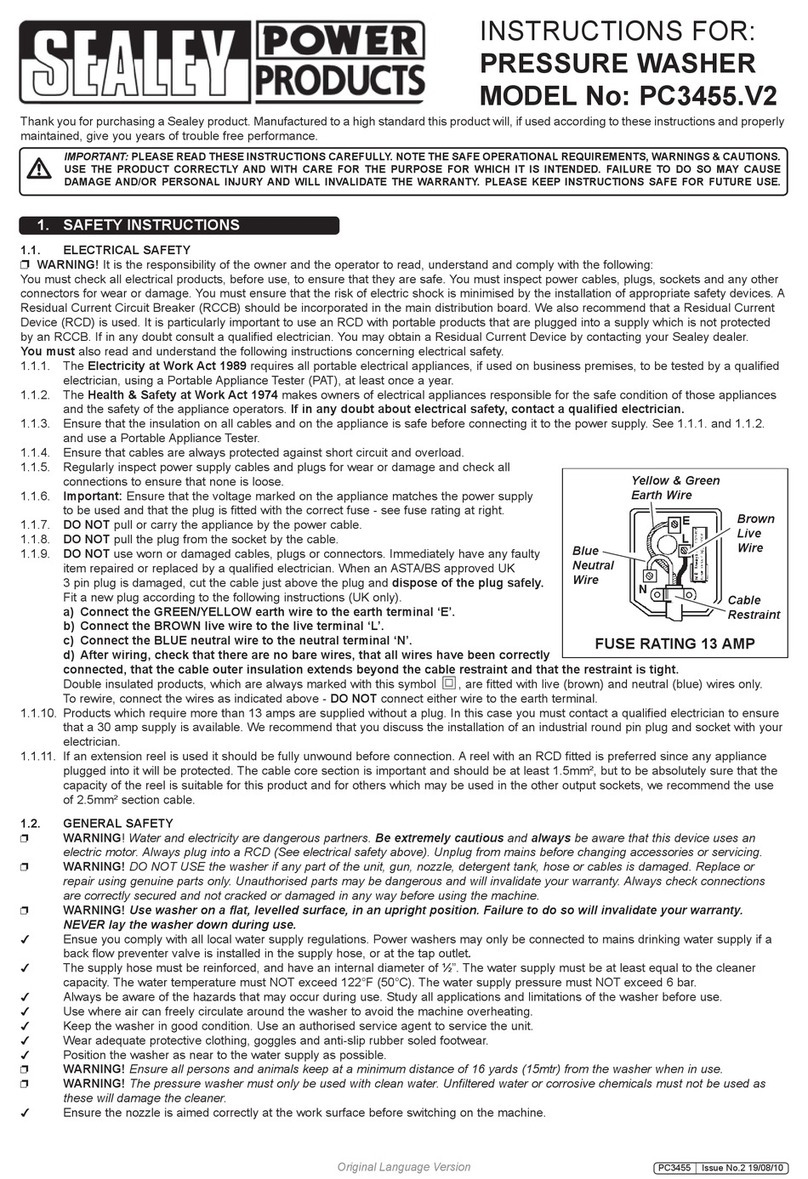

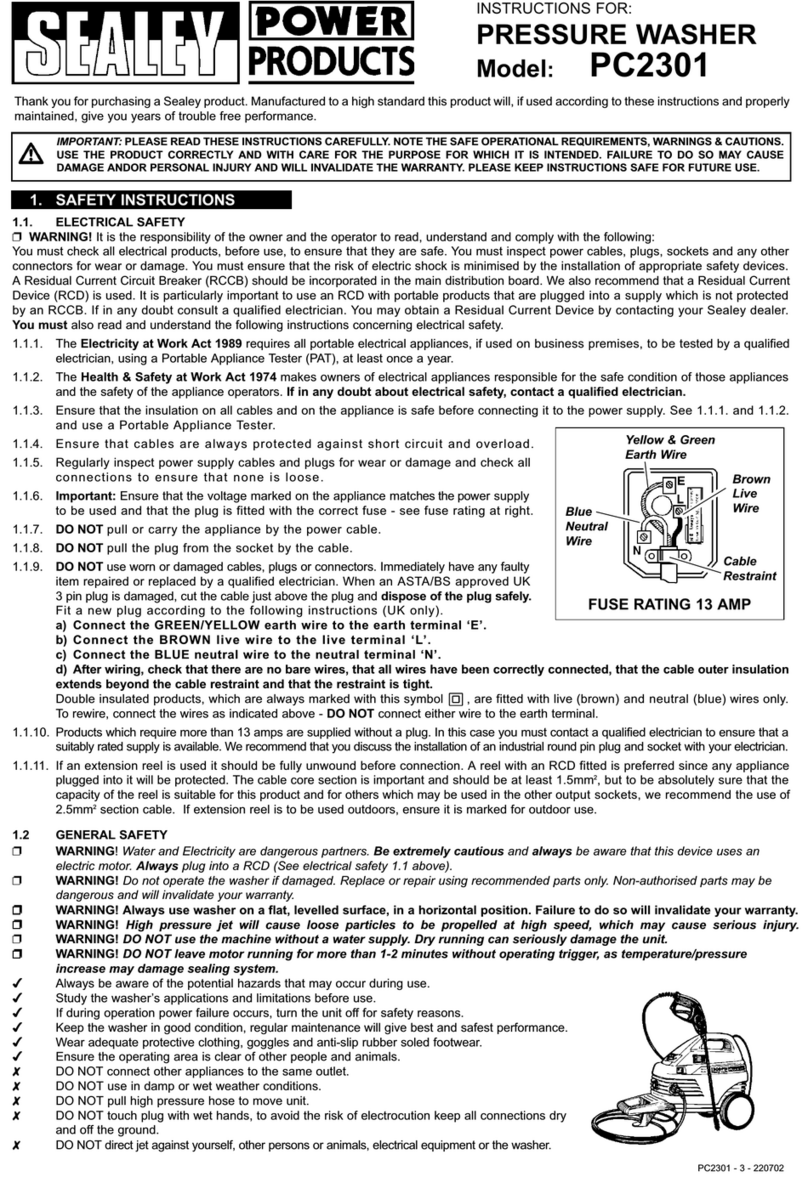

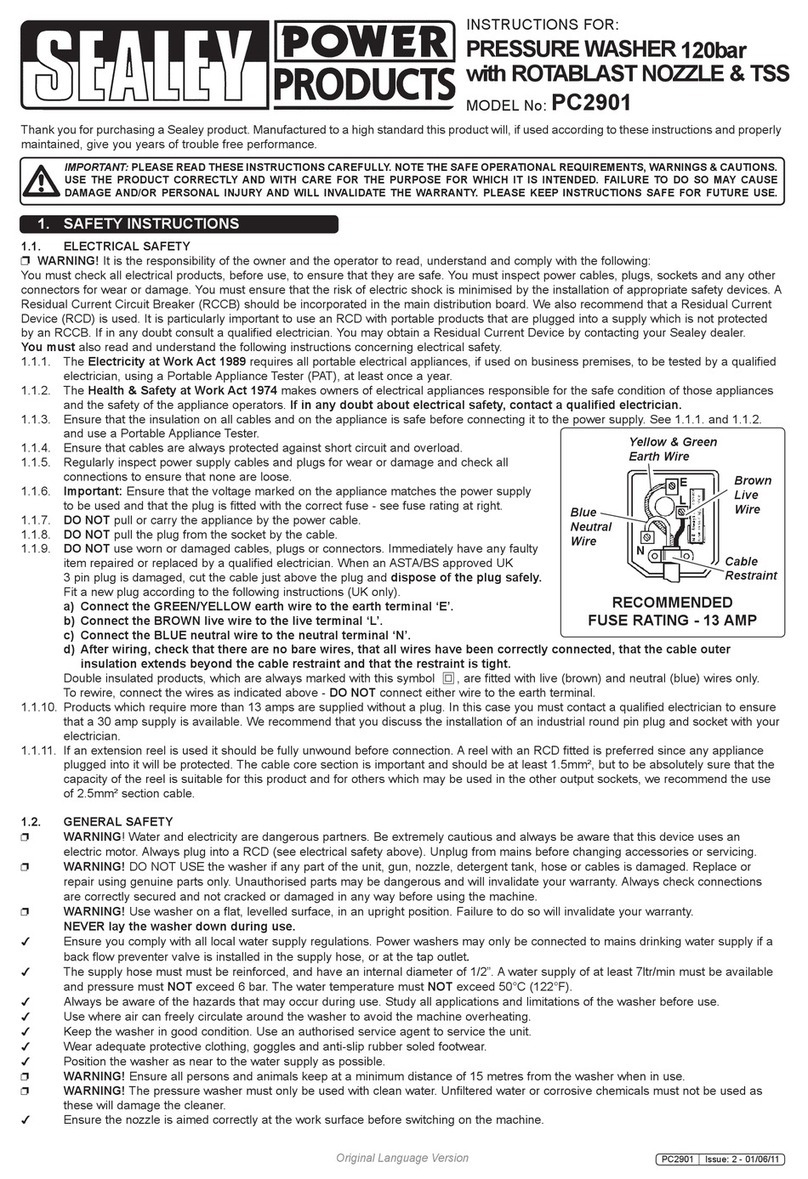

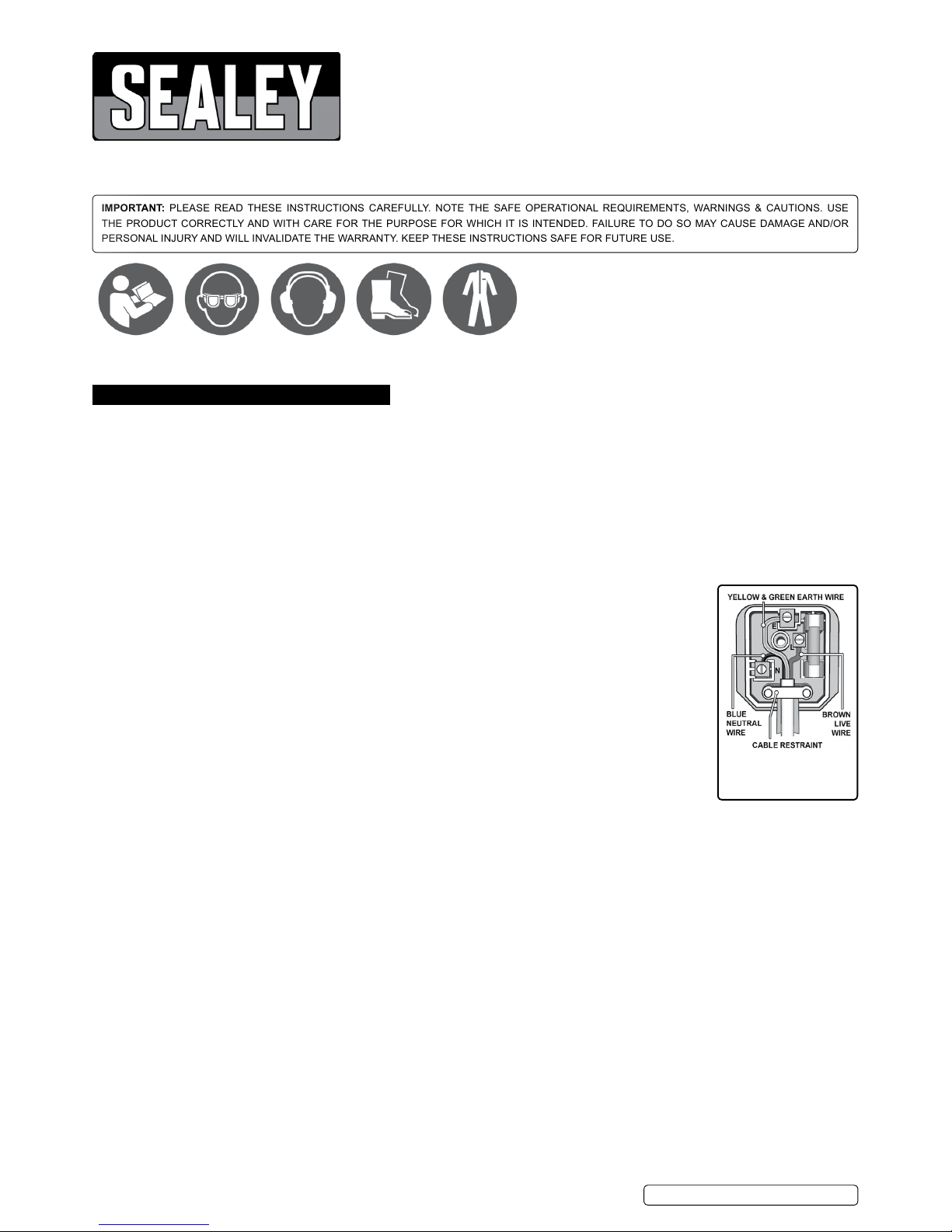

4.4. Connecting to mains electrical supply.

999 WARNING! Ensure the On/Off switch (fig.5) is in the ‘Off’ position.

Using an RCD plugged into a 13A mains socket, DO NOT turn the

power on. DO NOT touch the plug with wet hands

Fig.1

Fig.2

PW5000 | Issue:2(L) 11/04/17

Original Language Version

© Jack Sealey Limited