INSTRUCTIONS FOR:

BOSCH / DELPHI

DIESEL INJECTOR PULLER

MODEL NO: VS2049

WARNING! Ensure Health and Safety, local authority and general

workshop practice regulations are adhered to when using tools.

DO NOT use the kit if any parts are missing or damaged.

DO NOT use this tool for any purpose other than that for which

it is designed.

Switch off vehicle ignition and disconnect the battery before

working under the bonnet.

When work on the vehicle is finished ensure that there are no

tools left under the bonnet.

Maintain the tool components in good and clean condition for

best and safest performance.

Wear approved eye protection. A full range of personal safety

equipment is available from your Sealey dealer.

Wear suitable clothing to avoid snagging. Do not wear jewellery

and tie back long hair.

Keep children and other unauthorised persons away from the

working area.

Ensure there is adequate lighting prior to using this tool.

IMPORTANT: Always refer to the vehicle manufacturer's service

instructions, or proprietary manual, to establish the current

procedures and data.

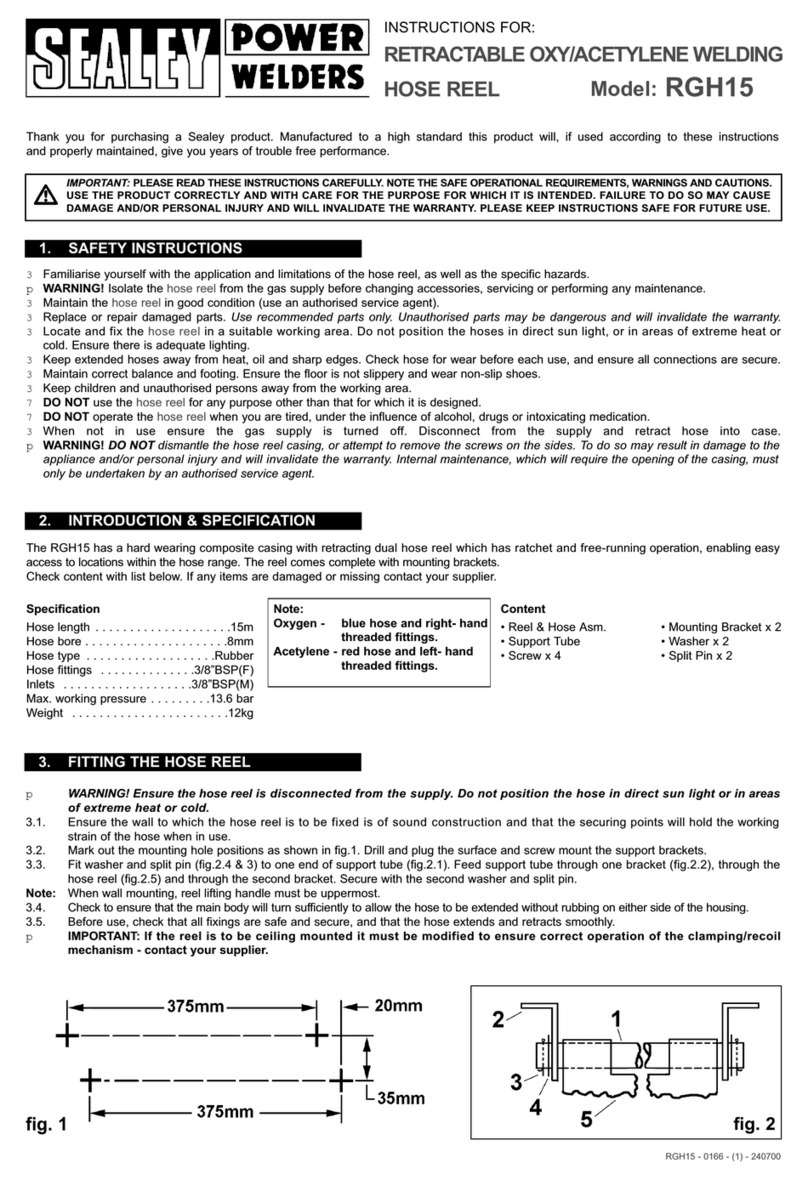

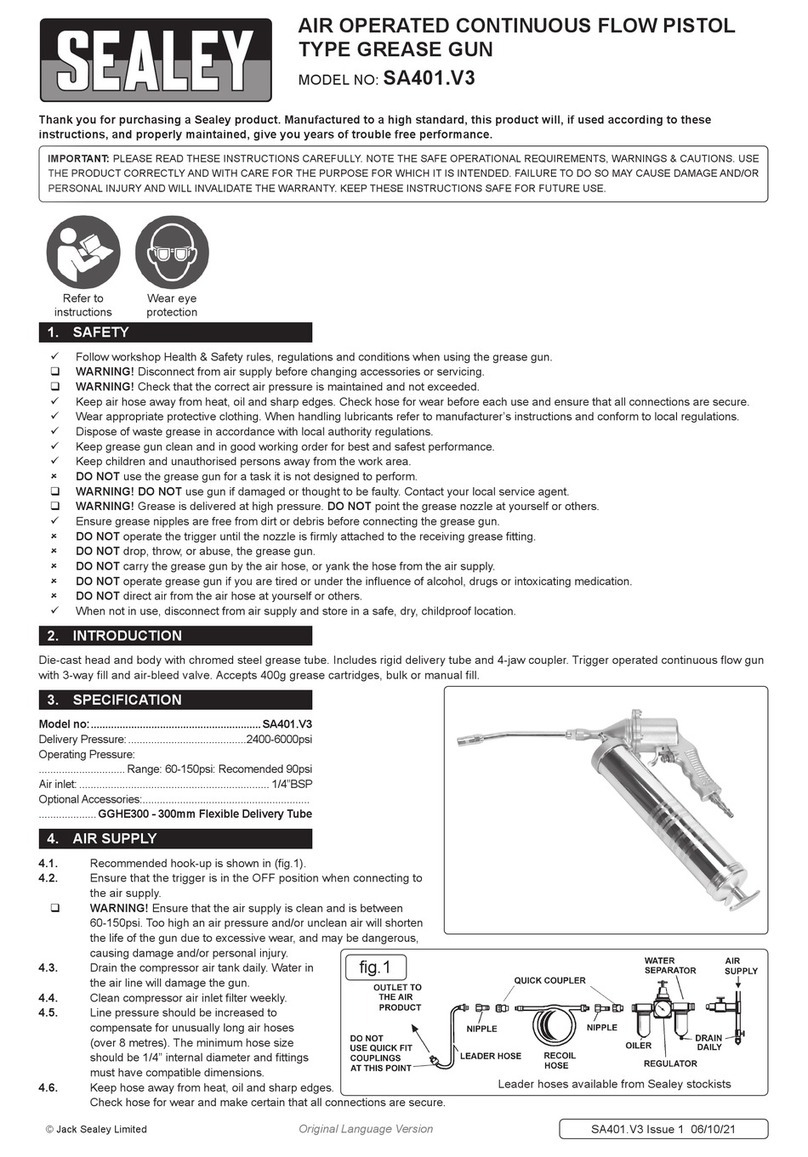

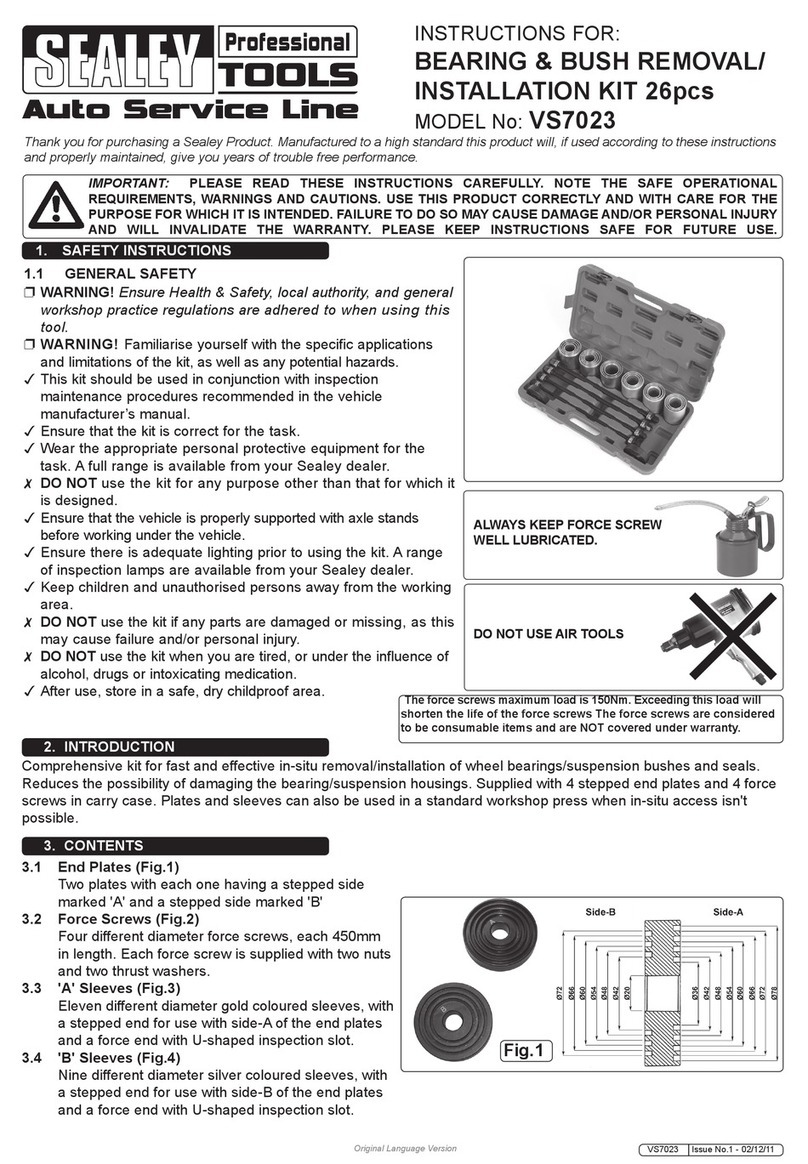

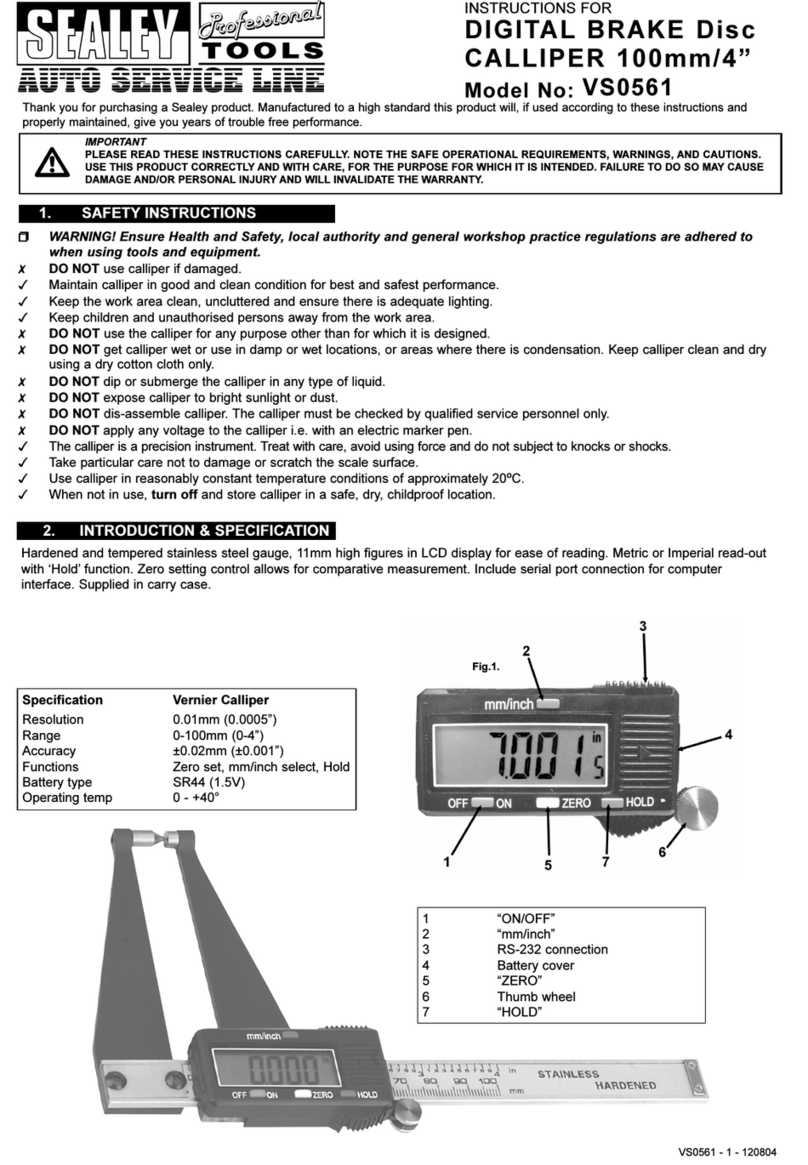

Item Part No: Description

1 VS2049.01 Sliding hammer

2 VS2049.02 Handle (Length 73mm)

3 VS2049.03 Spindle Length 220mm)

4 VS2049.04 Ball type adaptor

VS2049.04-1 Hex nut

VS2049.04-2 Hex nut (male type)

5 VS2049.05 Adaptor (M17, Injector internal thread)

6 VS2049.06 Adaptor (M27,Injector external thread)

7 VS2049.07 Hex key M10 + M19

8 VS2049.08 M29 Socket with cut out (1/2" drive)

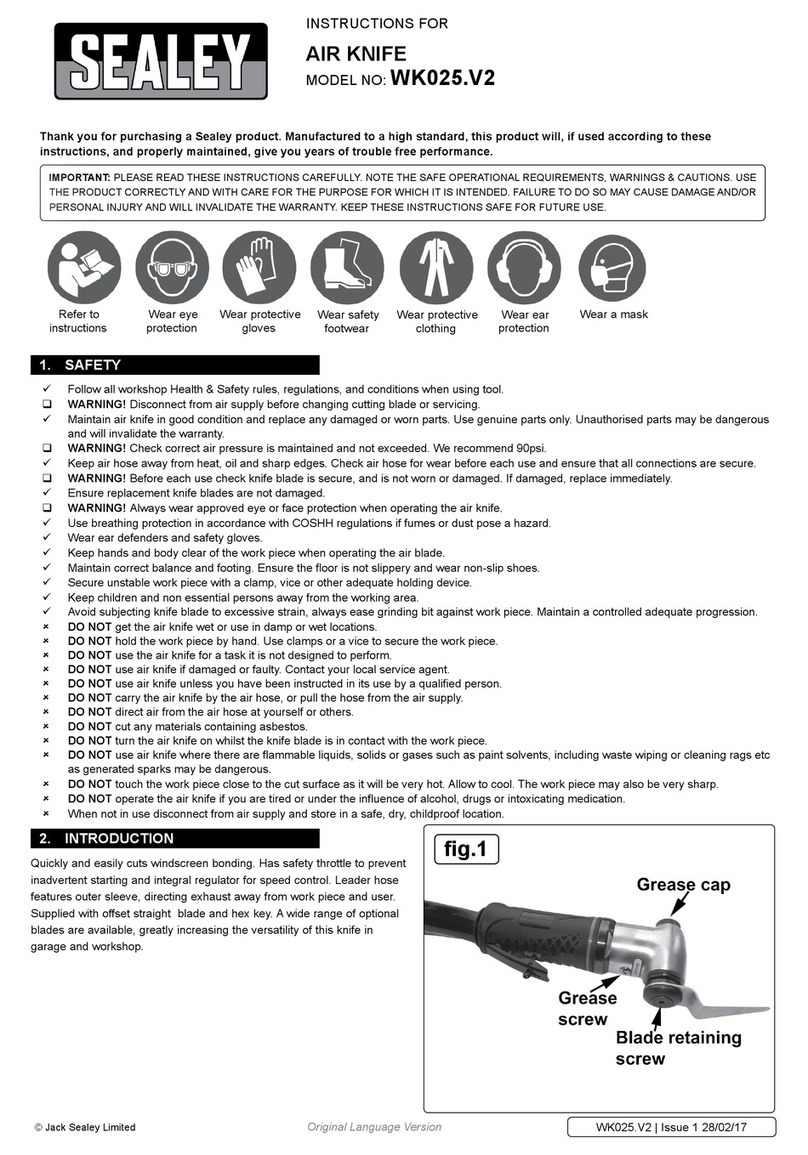

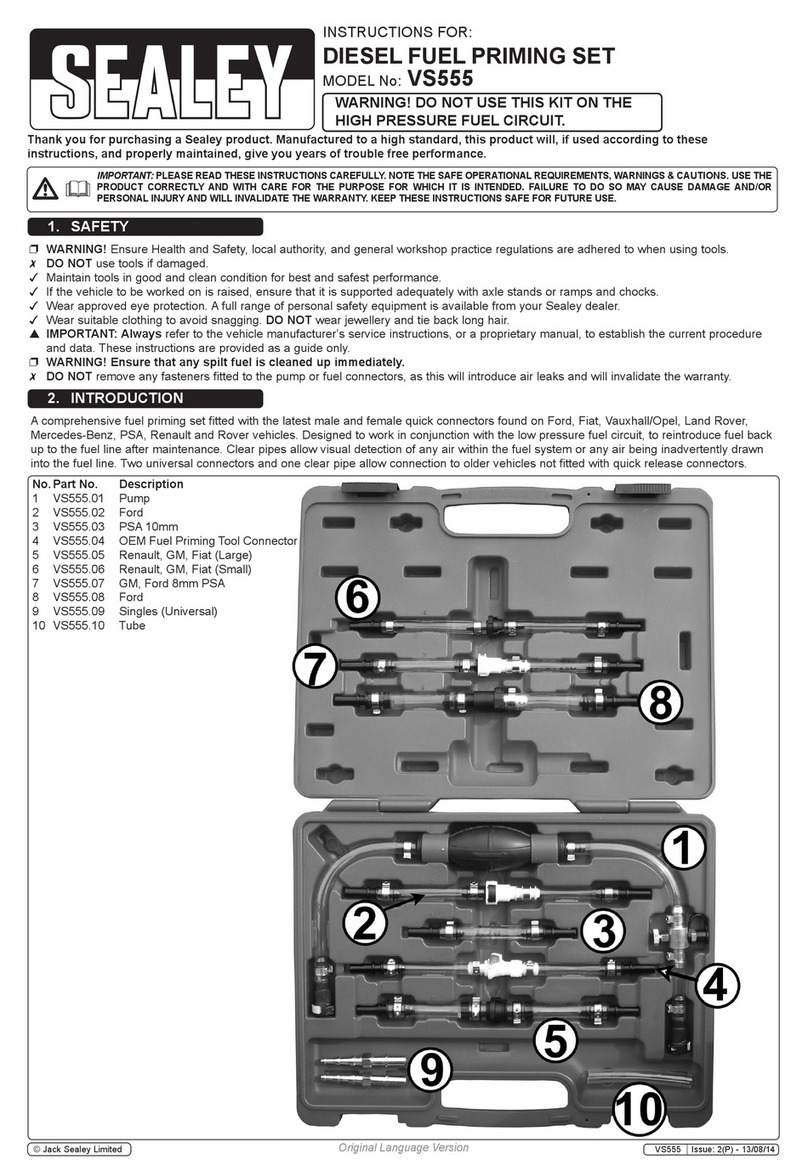

Suitable for the removal of stubborn Bosch/Delphi diesel injectors. Set

includes two adaptors for different removal methods. The first screws

onto the injector cap and the second locates internally inside the injector

allowing for extra force to be used. Features a flexible joint allowing the

slide hammer to be used in restricted areas. Supplied with instructions

in carry-case.

Contents: 1.8kg Slide Hammer, Flexible Joint, 2 x Adaptors, Security

Hex Key 10mm, Injector Cap Socket.

Adaptor Thread Sizes:

Ø17mm Male x 1mm Pitch, Ø28mm Female x 1mm Pitch.

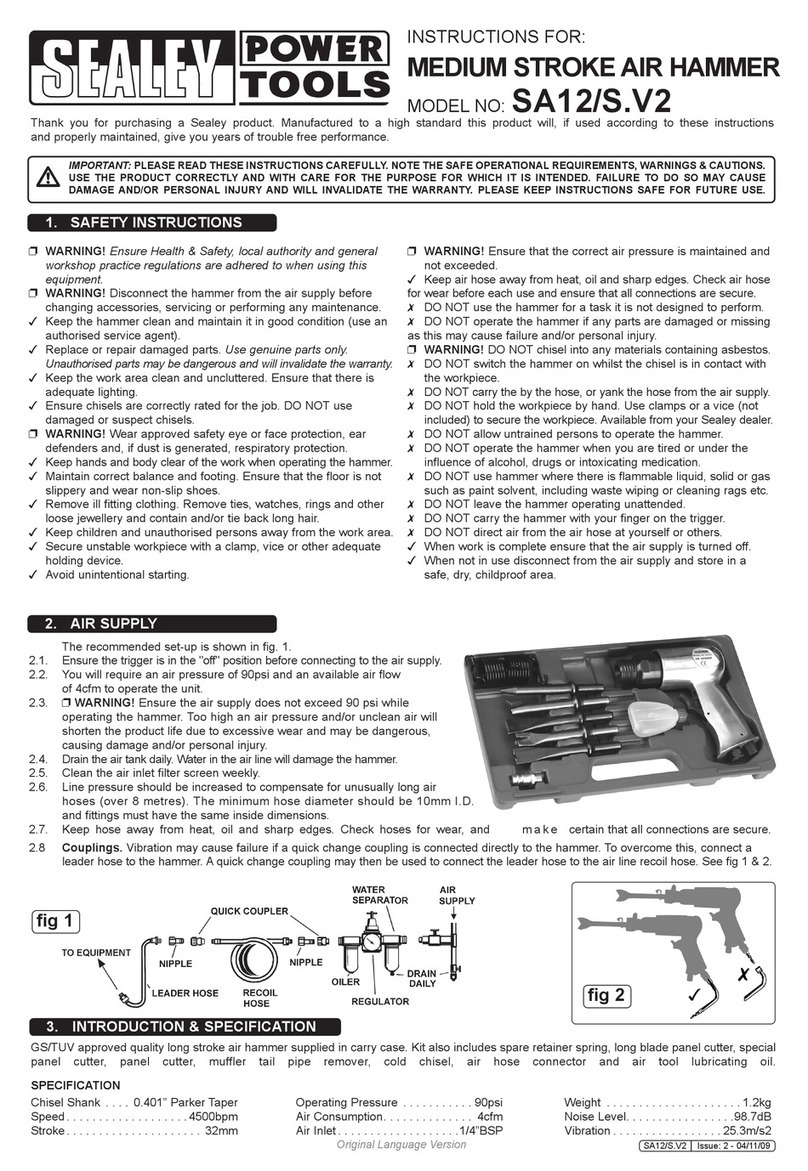

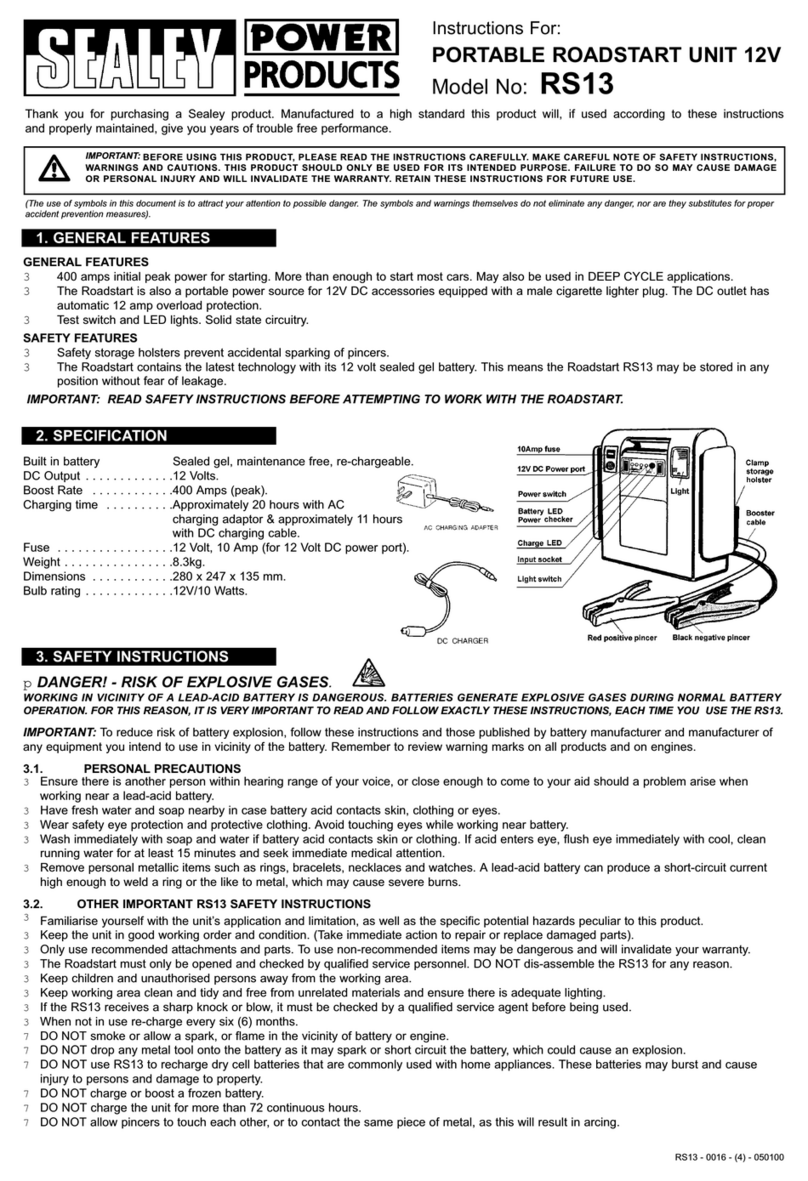

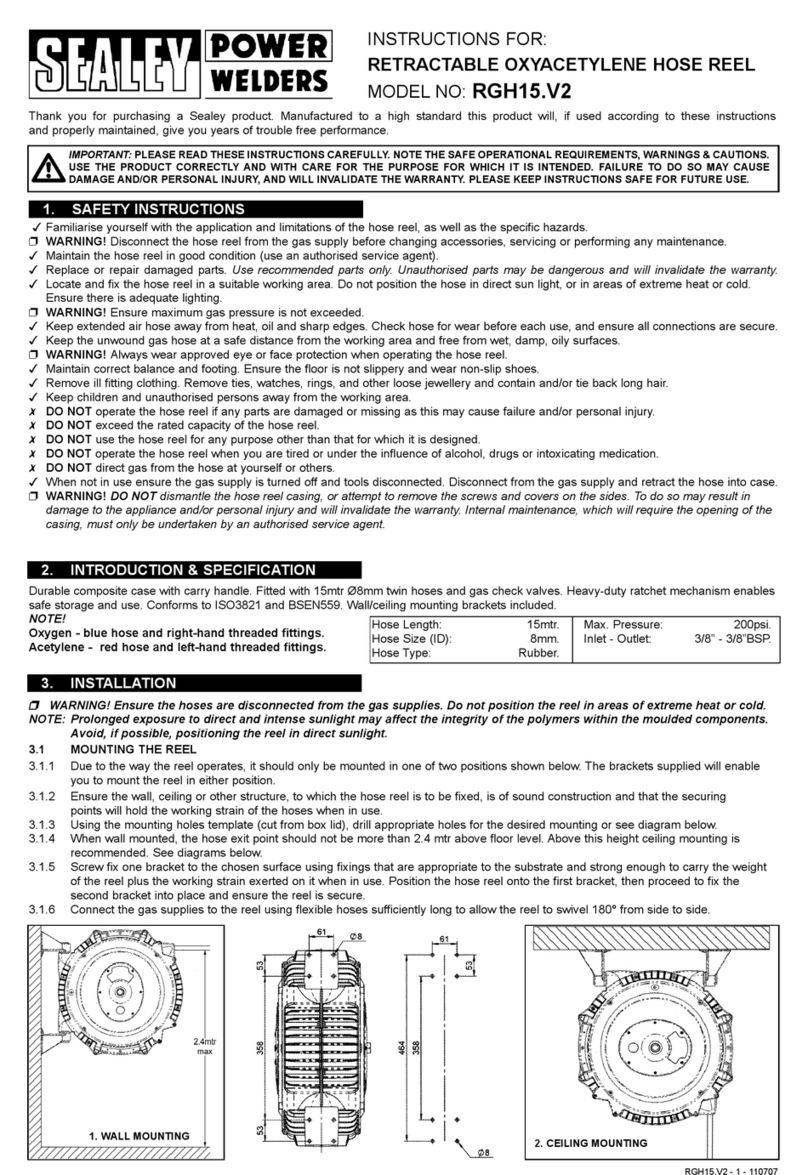

5.1. Referring to the individual components in fig.1 assemble the

Injector Puller as shown above in fig.2.

5.2. Use adaptor 6 when the injector is being extracted using the

external thread revealed when the injector cap has been

removed.

5.3. Use adaptor 7 when the injector is being extracted using the

internal thread revealed when the inner sleeve has been

removed from the injector.

fig.2

fig.1

1. SAFETY

2. INTRODUCTION

4. CONTENTS

5. ASSEMBLY

3. SPECIFICATION

VS2049 Issue: 2(L) - 20/03/15

Original Language Version

© Jack Sealey Limited

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE PRODUCT

CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL

INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.