User Manual Modbus TCP Server / Modbus RTU

Master

Document code: MI002260-E

Automation instruments and solutions

0xA8, 0x01, 0x2A, 0x11, 0x22, 0x33, 0x44, 0x55, 0x58. So the IP

is: 192.168.1.42; and the MAC Address: 11-22-33-44-55-58 ).

If the field “Enable Special Command” is checked, it is possible to send a no-Modbus request through the gateway. i.e. a TCP frame

with the first two caracters 0x55 and 0xAA is sent in the Modbus RTU line as is. If you don’t want to send the first two bytes (0x55,

0xAA) in the RTU line it is possible to check the field “Cancel the first two bytes”.

PING EVICE:

If it is necessary to do a Ping on the net, before pressing the “Ping Device” button insert a value in the field on the right and then press the

button. In order to do this, the gateway must be in RUN mode. To use this feature in Vista and 7 you have to open the software with Admin-

istrator right.

OPERATIONAL MO E:

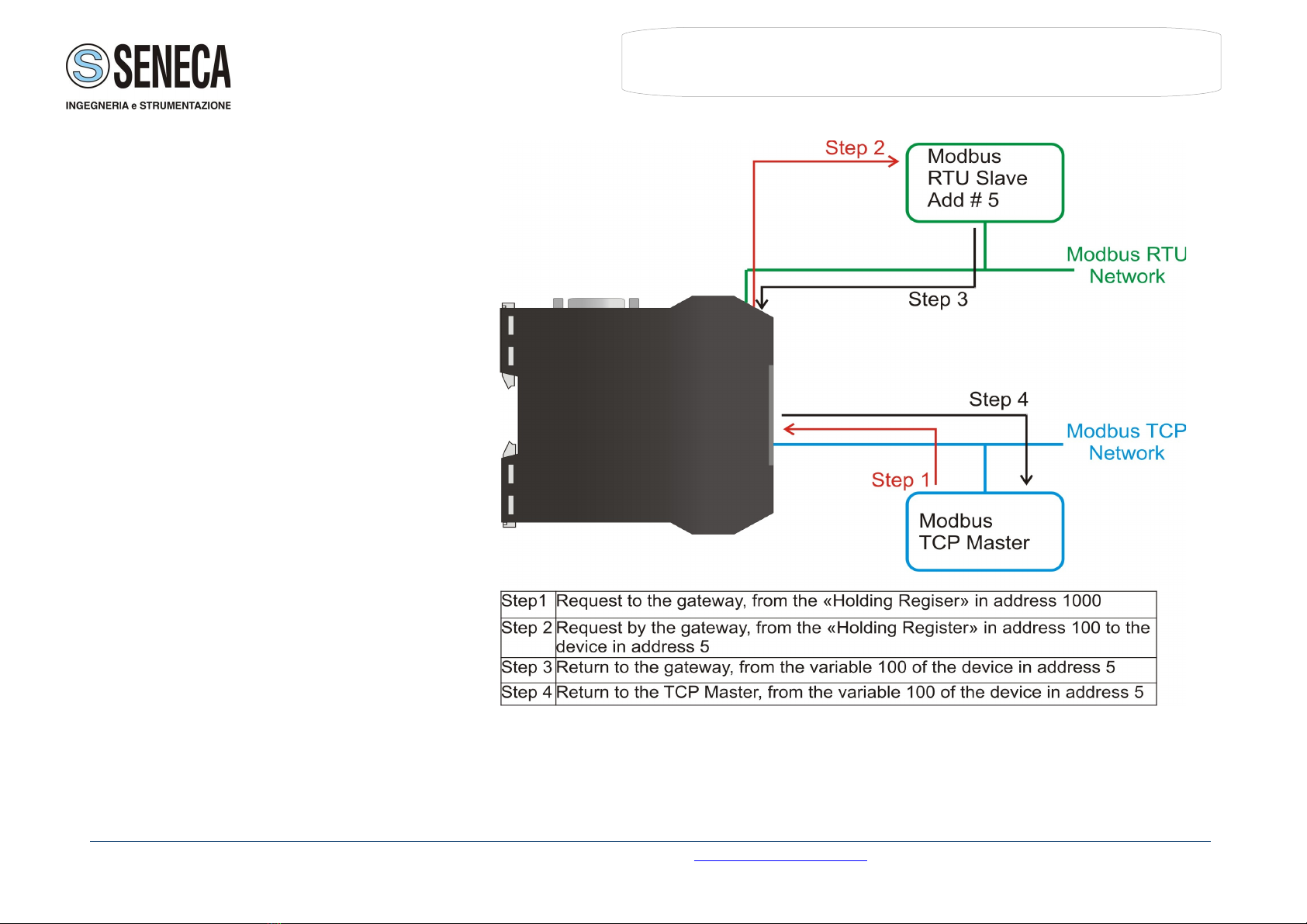

ROUTING:

A few characteristics of the Modbus RTU package have been modified in the standard of the Modbus TCP protocol. Two bytes of the final CRC

were eliminated (no longer necessary for the information to reach its already corrected destination). The first byte of the slave identification

was changed, leaving the one that is called PDU. A frame denominated as MBAP header with dimensions of 7 bytes was added to the head of

the PDU.

It is composed by the following:

Word transaction identifier (recopied from the slave in the response phase);

Word protocol identifier (0=Modbus protocol);

Word length (number of successive bytes);

Byte unit identifier (used for the routing operation).

By using the last byte of the MBAP header, it is possible to carry out the routing from a requested Modbus TCP toward a serial line using the

address from the slave which is specified by the byte unit identifier.

Example:

A requested Modbus TCP made in the device as the address 192.168.0.200 for the holding register address $2000, which is MBAP unit

identifier has the value of 2. It will be followed by the request on the serial for the device with the address 2 at the word $2000.

After the request is made, the RTU will respond. The master TCP will be given the same response which will be reconstructed according to

the specifications of the Modbus TCP.

If the RTU slave responds with an exception, that exception code will be transmitted again to the TCP master. If the RTU slave does not

respond in the estimated time defined by the Timeout parameter, an exception response will be given: error code $0B.

Seneca Srl – IT - 35133 – Z.I. Camin – Padova INFO http //www.seneca.it/ Phone +39.049.87.05.(359) /(408)