Page | 4

CONTENTS

Parts And Accessories.................................................................................................5

Standard Accessories (Included)...........................................................................................5

Accessories And Replacement Parts.....................................................................................5

General Description.....................................................................................................6

Specifications...............................................................................................................7

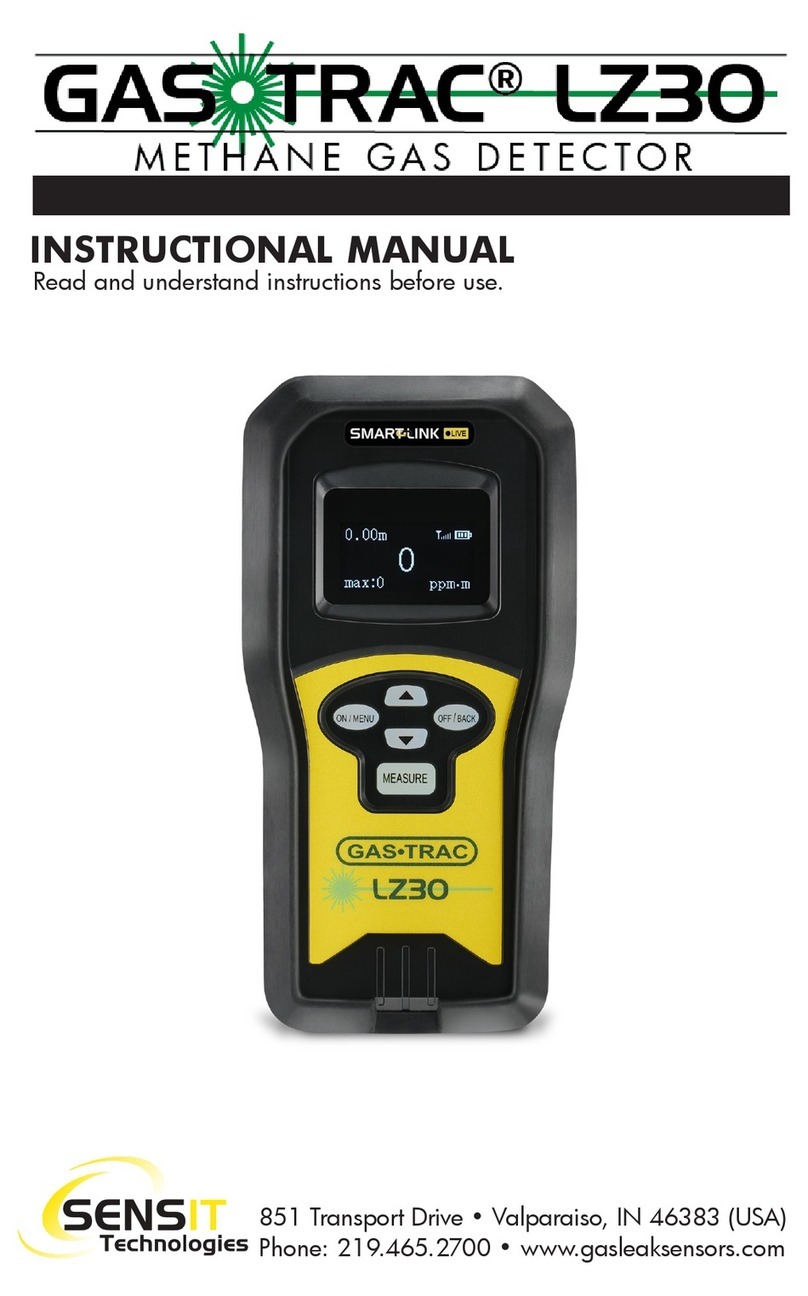

Product Features .........................................................................................................9

Beam Dimensions...............................................................................................................10

Sensor Technology....................................................................................................11

Gas Detection .....................................................................................................................11

Distance Detection..............................................................................................................11

Explanation Of PPM•M ..............................................................................................12

Battery Charging........................................................................................................13

Operation And Use ....................................................................................................14

Operation and Use Tips.............................................................................................16

Investigating Through Windows...........................................................................................16

Shape of the Detection Beam and Line of Sight...................................................................17

Locating Targeting Laser.....................................................................................................19

Wind Conditions and Plume Size.........................................................................................18

Calibration Check (Bump Test)..................................................................................19

Calibration..................................................................................................................21

User Menu.................................................................................................................22

Set Alarm ............................................................................................................................23

Set Red Laser.....................................................................................................................23

Set Green Laser..................................................................................................................24

Reset...................................................................................................................................24

Calibration...........................................................................................................................25

Set Unit...............................................................................................................................25

Maintenance and Care...............................................................................................26

Notes .........................................................................................................................27

Warranty....................................................................................................................28